Adjustable frame rear hanging and filling belt and use method thereof

An adjustable and adjustable technology, applied in the direction of conveyor objects, conveyors, transportation and packaging, etc., can solve problems such as difficulty in adapting to high-efficiency mining and filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

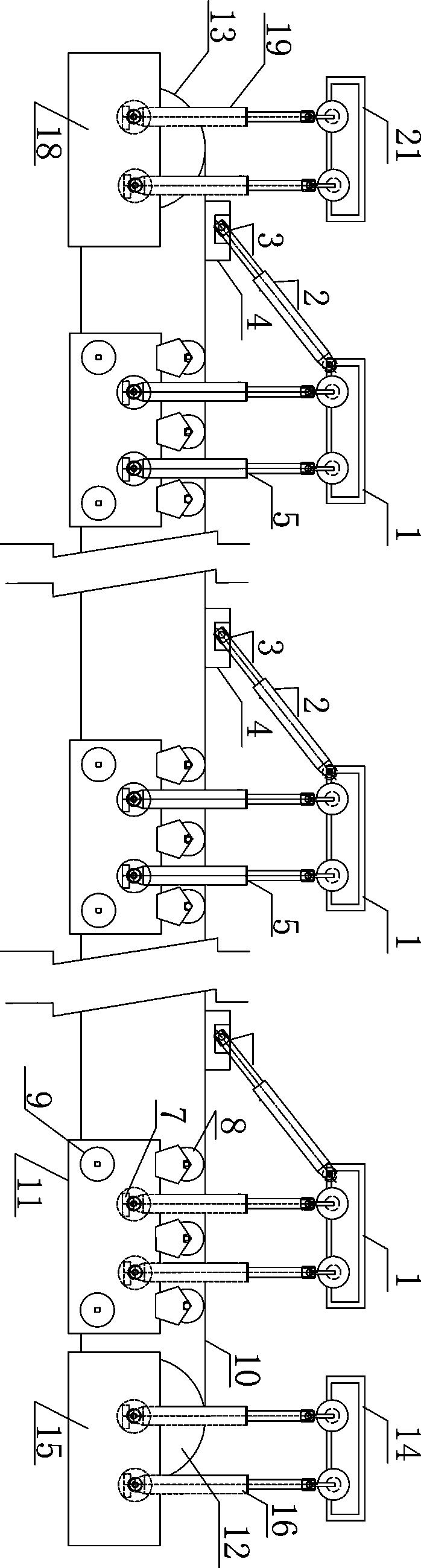

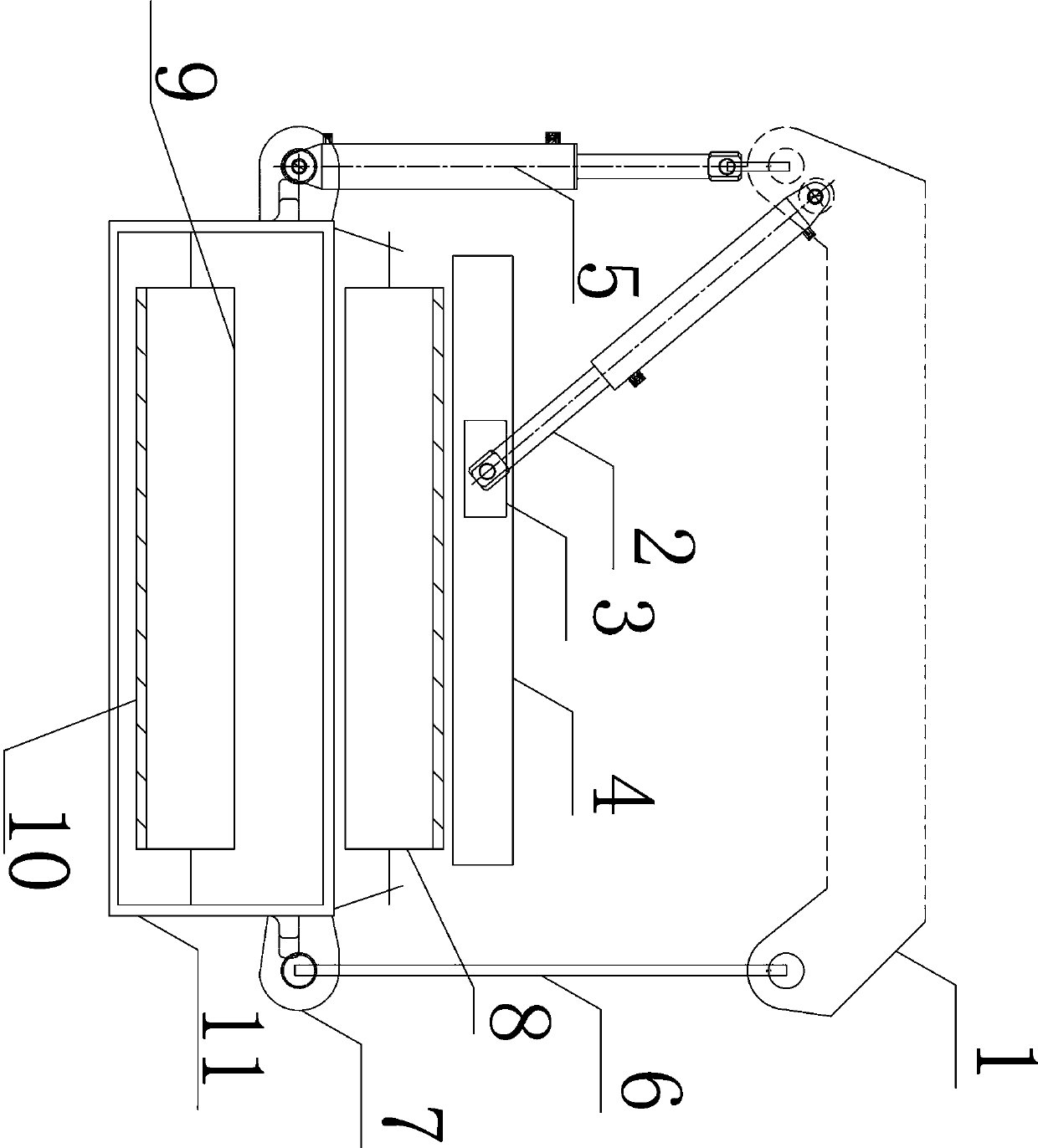

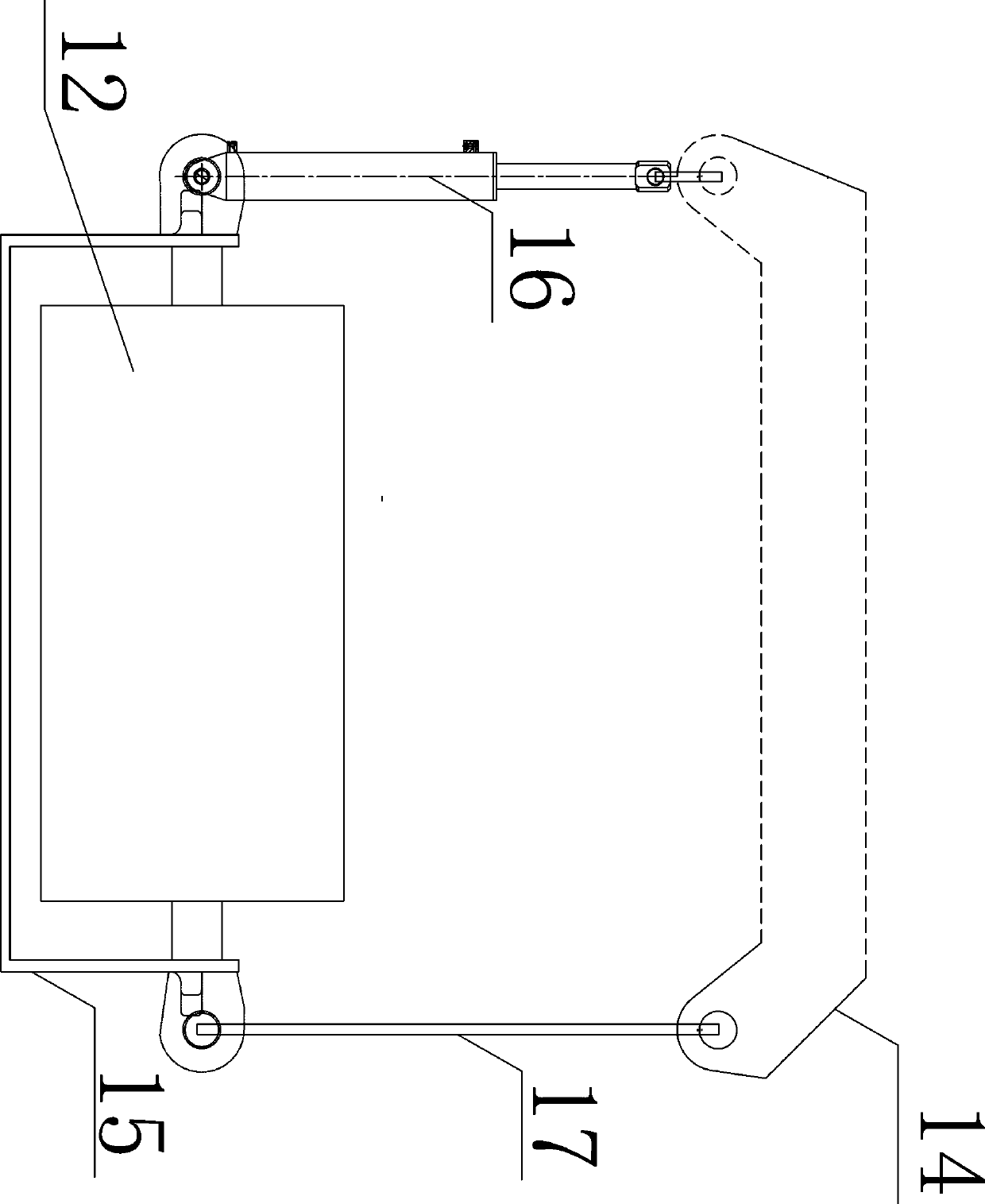

[0030] like Figure 1-5As shown, the adjustable rack hangs the filling belt, including the conveyor belt 10; the belt support front section, the belt support middle section and the belt support tail section for supporting the conveyor belt 10, the belt support front section, the belt support middle section and the belt support The tail sections are all hung below the rear top beam of the support, and are connected in turn to jointly support the conveyor belt 10. The front section of the belt support is an angle-adjustable belt support front section, and the middle section of the belt support is an angle-adjustable belt support middle section. The support tail section is an angle-adjustable belt support tail section. By setting the belt support front section as an angle-adjustable belt support front section, the belt support middle section is set as an angle-adjustable belt support middle section, and the belt support tail section is set as an angle-adjustable belt support secti...

Embodiment 2

[0033] The present invention also provides a method for using an adjustable back-hanging filling belt. The conveyor belt 10 is driven by the electric drum 12 of the machine head, and the front section of the belt support is set as an angle-adjustable belt support front section. The middle section of the support is set as an angle-adjustable belt support middle section, and the tail section of the belt support is set as an angle-adjustable belt support tail section, so as to realize the raising and lowering of one side of the conveyor belt 10 and enable the rear filling of the conveyor belt 10 The gangue is naturally unloaded and dumped to the old empty side as a whole, and the conveyor belt 10 is hung under the rear roof beam of the bracket. When the rack is moved, the belt and the bracket move synchronously. When the bracket is stressed, the bracket and the belt do not interact with each other. Influence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com