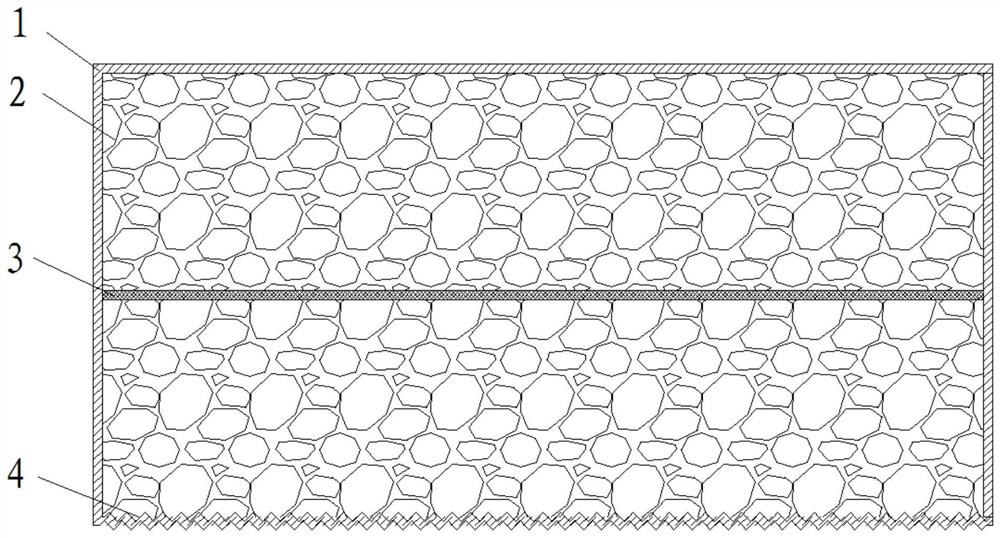

A kind of preparation method of resin-reinforced calcium silicate formwork without demolition

A formwork-free and resin-reinforced technology, which is applied in the field of building materials, can solve the problems of heavy weight and difficult construction, and achieve the effects of light weight, convenient single-person operation, and increased convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] Step 1, 315kg cement, 170kg lime, 440kg quartz sand, 50kg wollastonite, 1850kg wood pulp fiber slurry and 2175kg water are stirred to obtain slurry; the mass content of wood pulp fiber in the wood pulp fiber slurry is 4 %;

[0033] Step 2, transfer the slurry obtained in step 1 to the felt through the mesh wheel, and then use a Roots vacuum pump and a water circulation pump to carry out vacuum dehydration treatment to obtain the slurry after the vacuum dehydration treatment; in the slurry after the vacuum dehydration treatment The mass percent of water is 42%;

[0034] Step 3, extruding the slurry obtained in step 2 after the vacuum dehydration treatment with a forming cylinder and a breast roll to obtain a wet billet; the mass percentage of water in the wet billet is 30%, and the thickness of the wet billet is 2mm ;

[0035] Step 4. Carry out single-sided roughening and double-sided roughening of the wet billets...

Embodiment 2

[0062] This embodiment includes the following steps:

[0063] Step 1, 360kg cement, 160kg lime, 420kg quartz sand, 40kg wollastonite, 1300kg wood pulp fiber slurry and 2720kg water are stirred to obtain slurry; the mass content of wood pulp fiber in the wood pulp fiber slurry is 4 %;

[0064] Step 2, transfer the slurry obtained in step 1 to the felt through the mesh wheel, and then use a Roots vacuum pump and a water circulation pump to carry out vacuum dehydration treatment to obtain the slurry after the vacuum dehydration treatment; in the slurry after the vacuum dehydration treatment The mass percentage of water is 46%;

[0065] Step 3, extruding the slurry obtained in step 2 after vacuum dehydration treatment with a forming cylinder and a breast roll to obtain a wet billet; the mass percentage of water in the wet billet is 32%, and the thickness of the wet billet is 1.5% mm;

[0066] Step 4. Carry out single-sided roughening and double-sided roughening of the wet bille...

Embodiment 3

[0072] This embodiment includes the following steps:

[0073] Step 1, 260kg cement, 210kg lime, 470kg quartz sand, 30kg wollastonite, 1800kg wood pulp fiber slurry and 2230kg water are stirred to obtain slurry; the mass content of wood pulp fiber in the wood pulp fiber slurry is 4 %;

[0074] Step 2, transfer the slurry obtained in step 1 to the felt through the mesh wheel, and then use a Roots vacuum pump and a water circulation pump to carry out vacuum dehydration treatment to obtain the slurry after the vacuum dehydration treatment; in the slurry after the vacuum dehydration treatment The mass percent of water is 44%;

[0075] Step 3, extruding the slurry obtained in step 2 after vacuum dehydration with a forming cylinder and a breast roll to obtain a wet billet; the mass percentage of water in the wet billet is 31%, and the thickness of the wet billet is 2.5% mm;

[0076]Step 4. Carry out single-sided roughening and double-sided roughening of the wet billets obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com