Method for improving performance of CsPbBr3 perovskite QLED through polymer compounding

A polymer, perovskite technology, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, nanotechnology for materials and surface science, etc., can solve the problem of incompatibility with industrial production, affecting device efficiency, and poor repeatability and other problems, to achieve the effect of improving color rendering quality and device stability life, balancing transmission, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

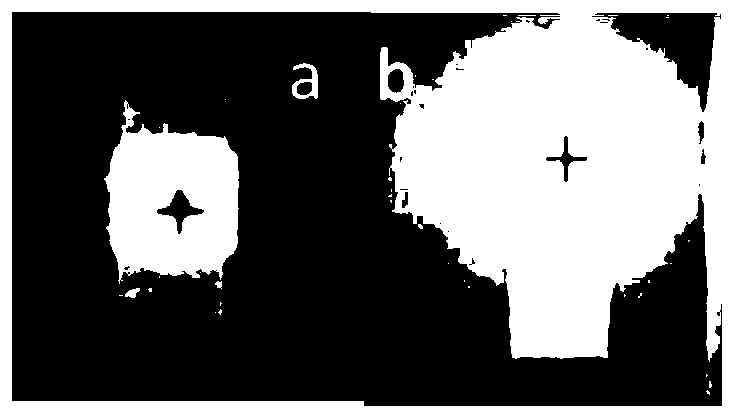

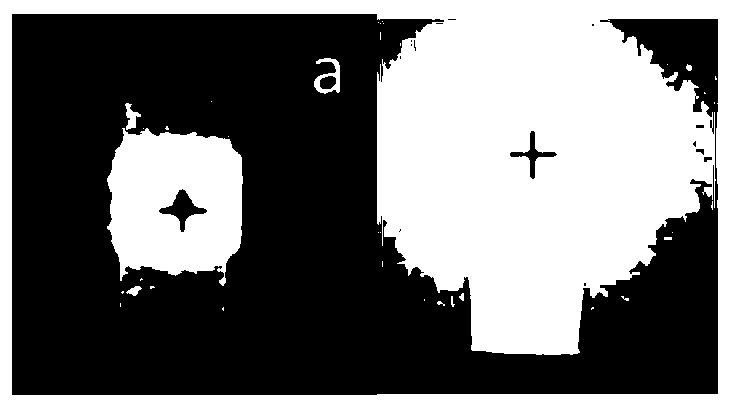

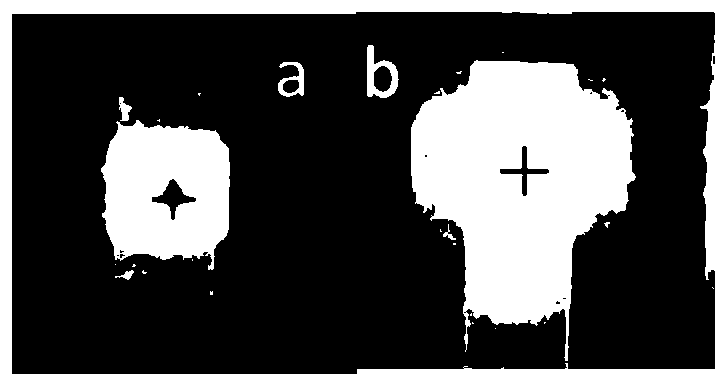

Image

Examples

Embodiment 1

[0028] (1) Ultrasonic dissolve 1mmol PbBr in 25ml toluene 2 , 2mmol TOAB, obtain the Pb precursor;

[0029] (2) Dissolve 20mg of PTAA in 5ml of toluene;

[0030] (3) Add 4ml PTAA toluene solution in the above-mentioned Pb precursor;

[0031] (4) Dissolve 0.3mmol CsCO in 4ml octanoic acid 3 , to obtain the Cs precursor;

[0032] (5) ultrasonically dissolve 0.3mmol DDAB in 10mL toluene solution;

[0033] (6) Inject the Cs precursor into the blend of the lead precursor and the polymer with a syringe, stir for 8 minutes, add 3 mL of DDAB toluene solution, and stir for 2 minutes to obtain PTAA-CsPbBr 3 Quantum dot stock solution;

[0034] (7) Add 40mL of ethyl acetate to the above-mentioned quantum dot stock solution, centrifuge to take the precipitate, disperse the precipitate with 8mL of n-hexane, and obtain PTAA-CsPbBr 3 quantum dots;

[0035] (8) PEDOT:PSS, PTAA and PTAA-7-CsPbBr 3 Quantum dots were spin-coated on ITO glass, and then TPBi, LiF and Al electrodes were the...

Embodiment 2

[0037] Using the same process as in Example 1, the difference is that the PTAA in step 2) of Example 1 is replaced by PVK, and other conditions remain the same.

Embodiment 3

[0039] Using the same process as in Example 1, the difference is that the PTAA in step 2) of Example 1 is replaced by Poly-TPD, and other conditions remain the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap