Loading device applied to drilling machines

A drilling rig and telescopic device technology, which is applied in the field of loading devices for drilling rigs, can solve problems such as high center of gravity, casualties, and vehicle overturning accidents, and achieve the effects of avoiding vehicle overturning accidents, high safety, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

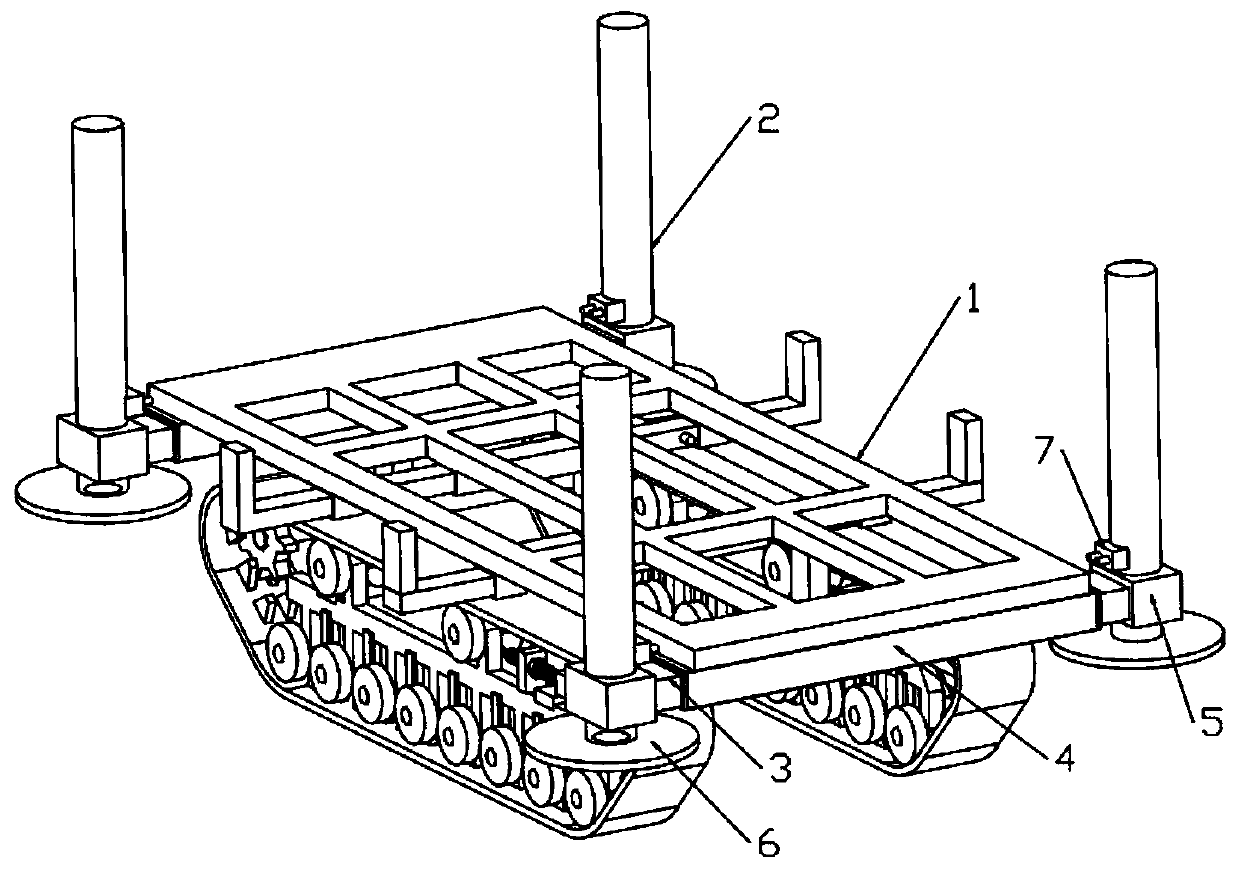

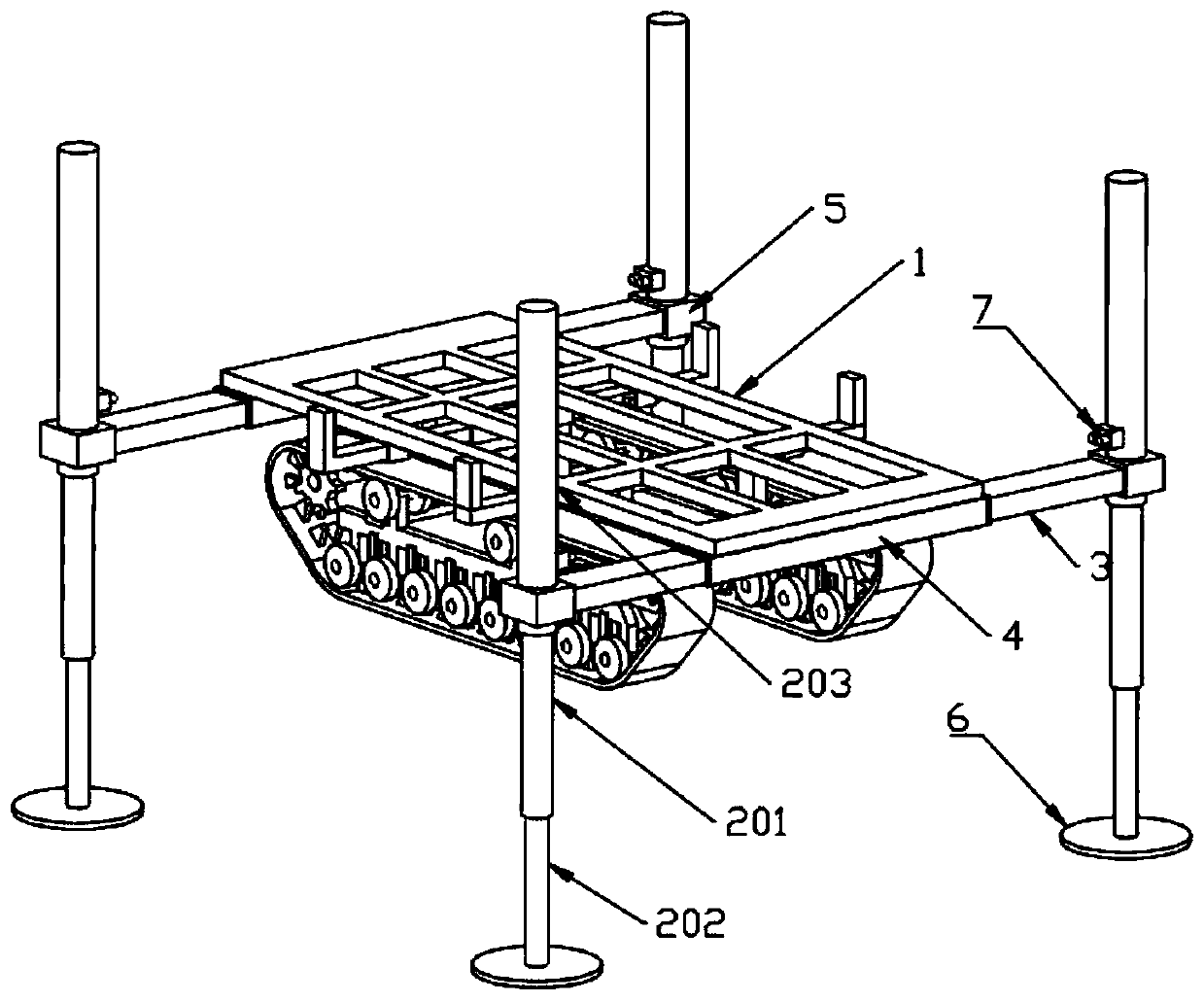

[0013] combined with figure 1 - attached figure 2 , a loading device for a drilling rig, comprising a chassis 1, a telescopic device 2, and a support arm 3 arranged below the drilling rig platform, the front and rear ends of the chassis 1 are fixedly provided with a chute 4, and one end of the support arm 3 is automatically The notch of the chute 4 extends into the inside of the chute 4, and the connecting block 5 provided at one end of the support arm 3 away from the chute is fixedly connected with the telescopic device 2, and the telescopic device 2 is provided with a telescopic rod inside, and the telescopic rod A spacer 6 is provided at the end.

[0014] As a preferred implementation of this embodiment, the telescopic device is composed of a first telescopic rod 201 , a second telescopic rod 202 and a hydraulic cylinder 203 which are sequentially socketed.

[0015] As a preferred implementation of this embodiment, the middle part of the connecting block 5 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com