A Coupling Control Method of Afterburner and Free Nozzle of Small Turbojet Engine

A turbojet engine, coupled control technology, applied in engine control, engine function, machine/engine, etc., can solve problems such as causing danger, difficult to achieve optimal working conditions, and inability to guarantee control accuracy, to improve coupling, improve The effect of controlling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

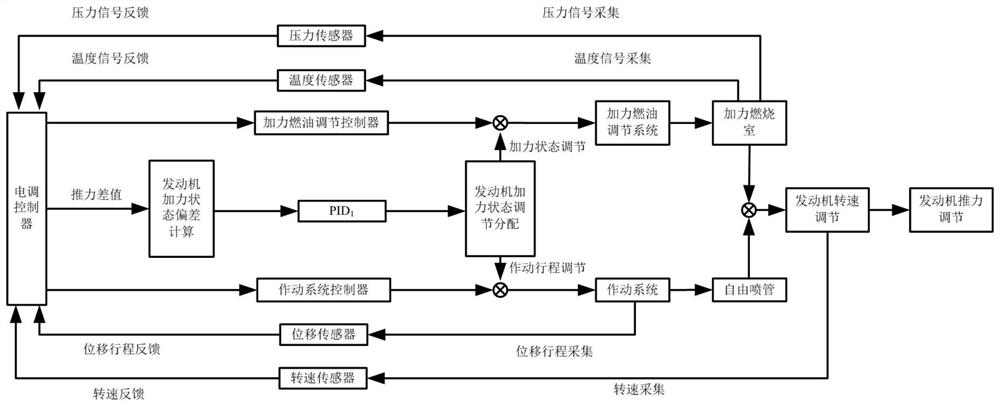

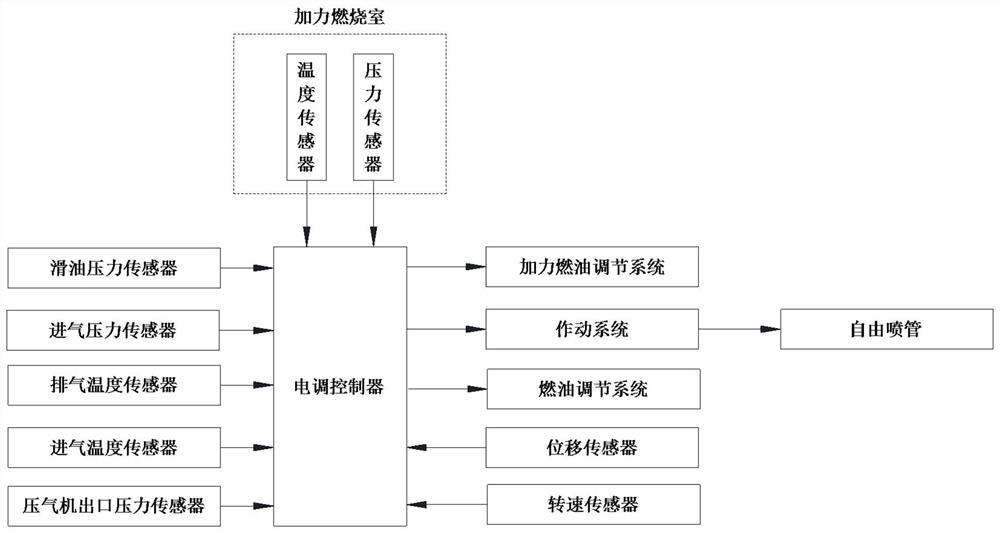

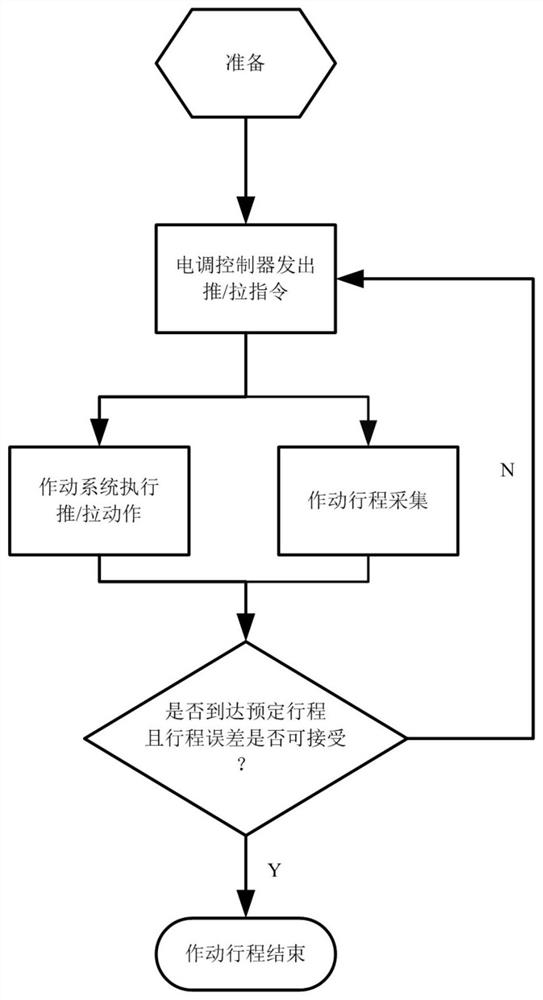

[0024] see Figure 1~5 , the coupling control method of afterburner and free nozzle of small turbojet engine,

[0025] Step 1: Calculate the thrust output of the engine through the GASTURB simulation software. The actual thrust is measured by the thrust scale, and the difference between the thrust output and the actual thrust is calculated, which is used as the input for the coupling control of the afterburner and the free nozzle.

[0026] Step 2: Obtain the actual temperature parameters of the afterburner, the actual pressure parameters of the afterburner and the actual area parameters of the free nozzle by collecting the working state of the afterburner and the adjustment parameters of the free nozzle area, and compare them with those obtained by GASTURB simulation Afterburner simulation temperature parameters, afterburner simulation pressure parameters, and free nozzle simulation area parameters are calculated by difference, and the deviations of afterburner temperature, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com