Air intake filter device for automobile engine

A technology of automobile engine and filter device, which is applied in the direction of engine components, machine/engine, fuel air filter, etc. It can solve the problems of reducing filter efficiency, filter dirty blockage, filter element disassembly, cleaning, and installation inconvenience, etc., to achieve The effect of reducing the cost of use and increasing the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

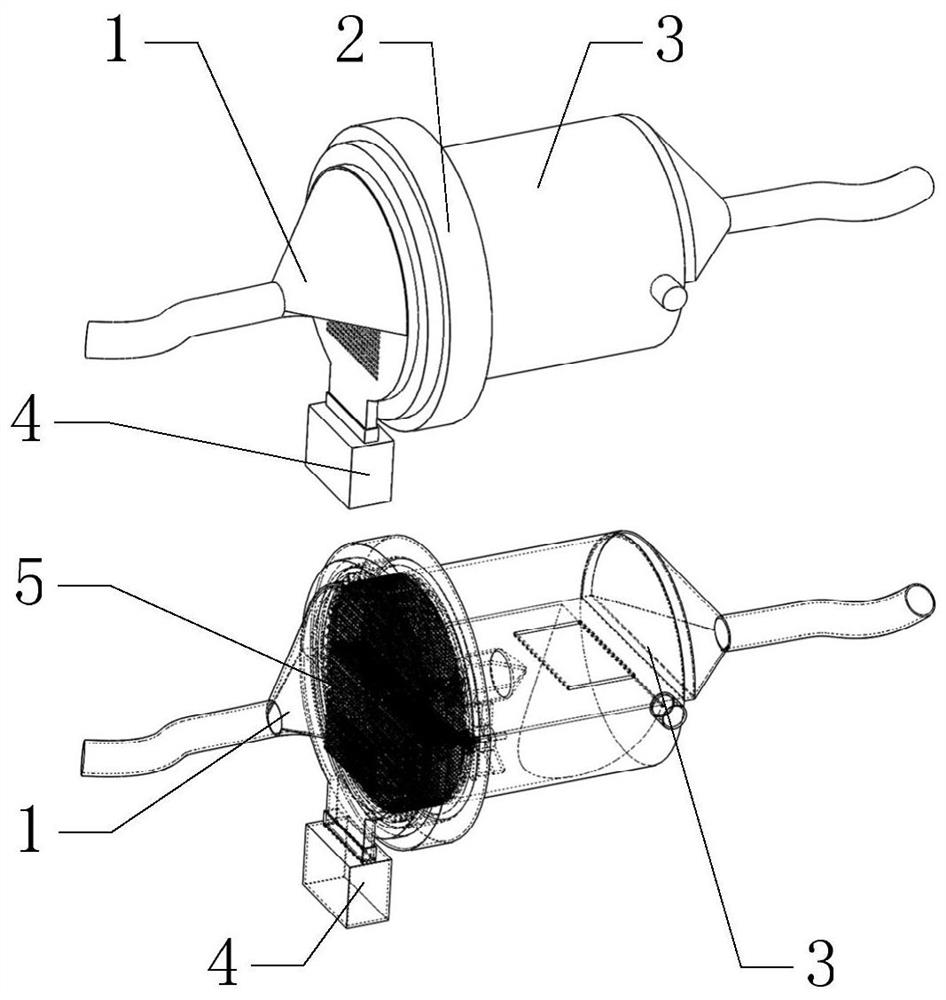

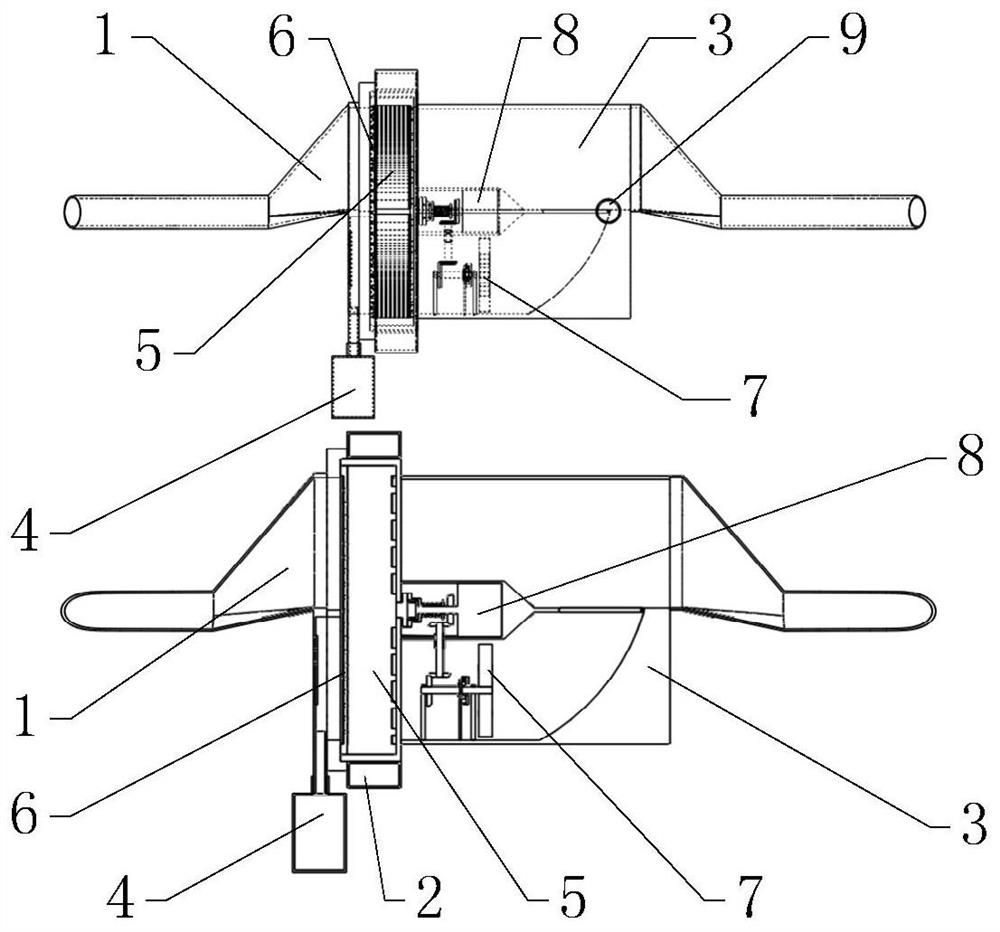

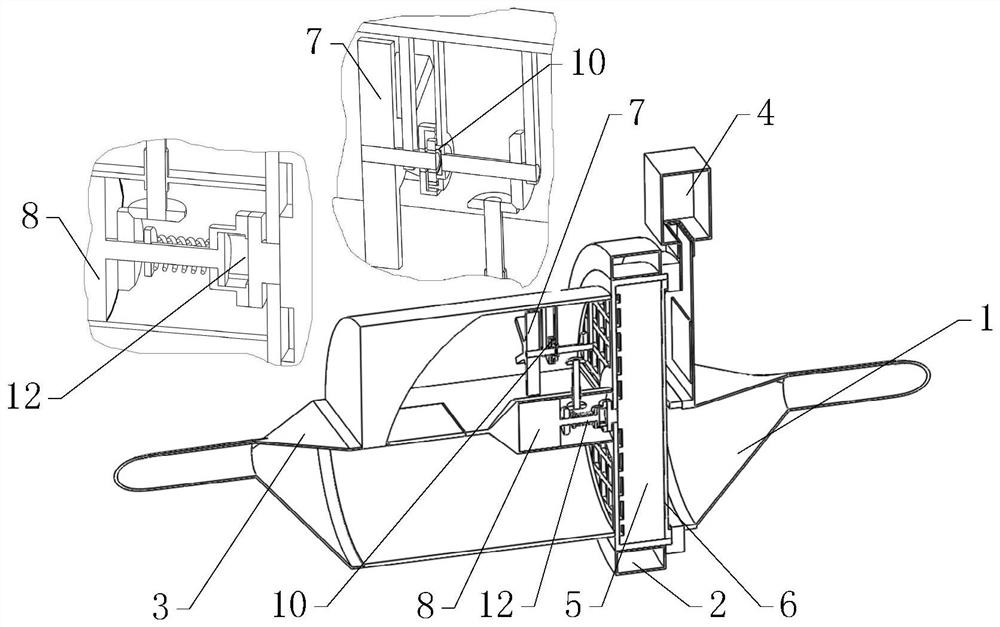

[0050] Such as figure 1 , 2 As shown, it includes an air inlet 1, an air outlet 3, a filter structure 5, a drive motor 8, an installation shell 18, an adjustment motor 9, and a swing plate 33, among which as Figure 5 , 6 As shown, the filter structure 5 is installed in the installation shell 18 by dismounting; Figure 6 As shown, the filter structure 5 is composed of a circular mounting frame 22 and four groups of quarter-circle filter elements 23, and the mounting frame 22 is divided into four quarter-circle areas of the same size by two isolation plates horizontally and vertically. Four groups of quarter circle filter cores 23 are respectively nested and installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com