Synchronous hinge module

一种枢轴、转轴的技术,应用在同动枢轴模块领域,能够解决限位结构卷入异物、限位结构损伤、无法顺利转向等问题,达到确保稳定性、阻挡异物卷入、减少损伤的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

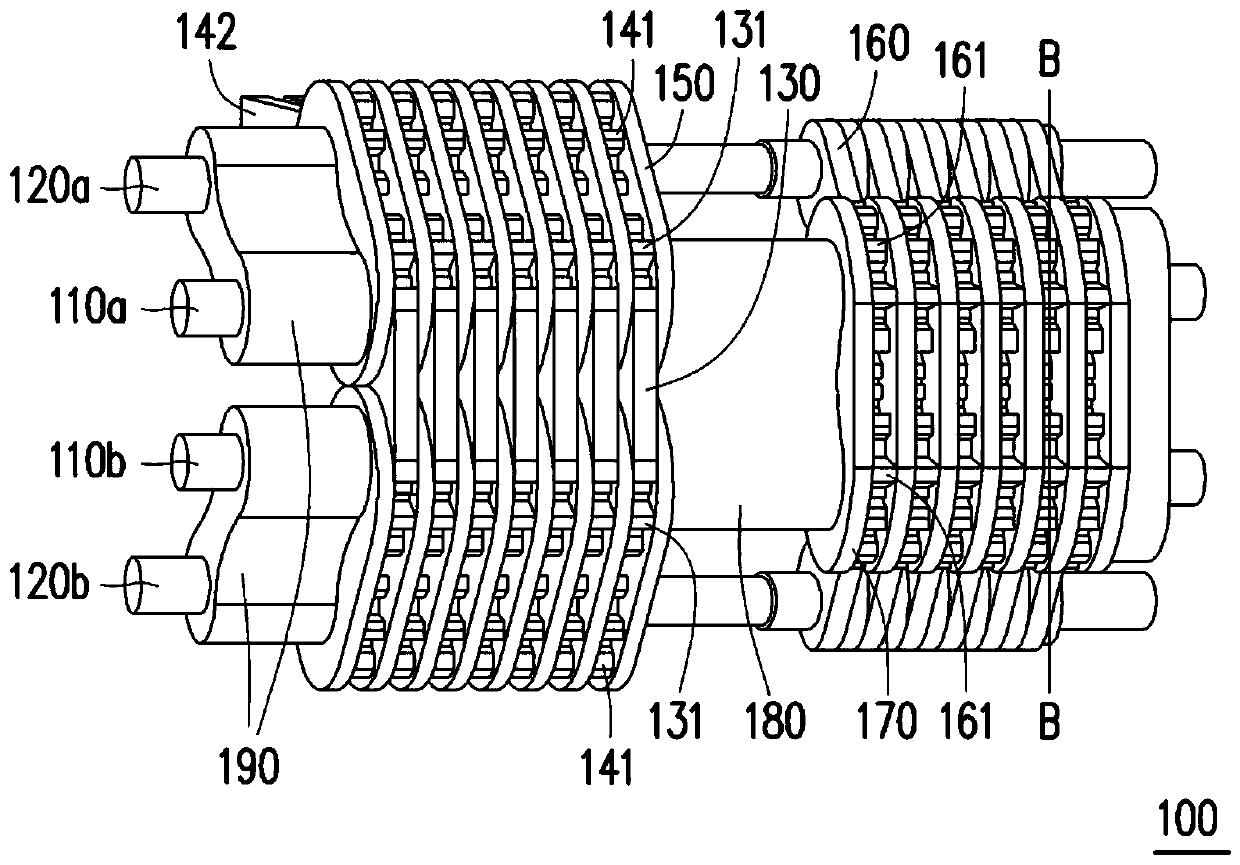

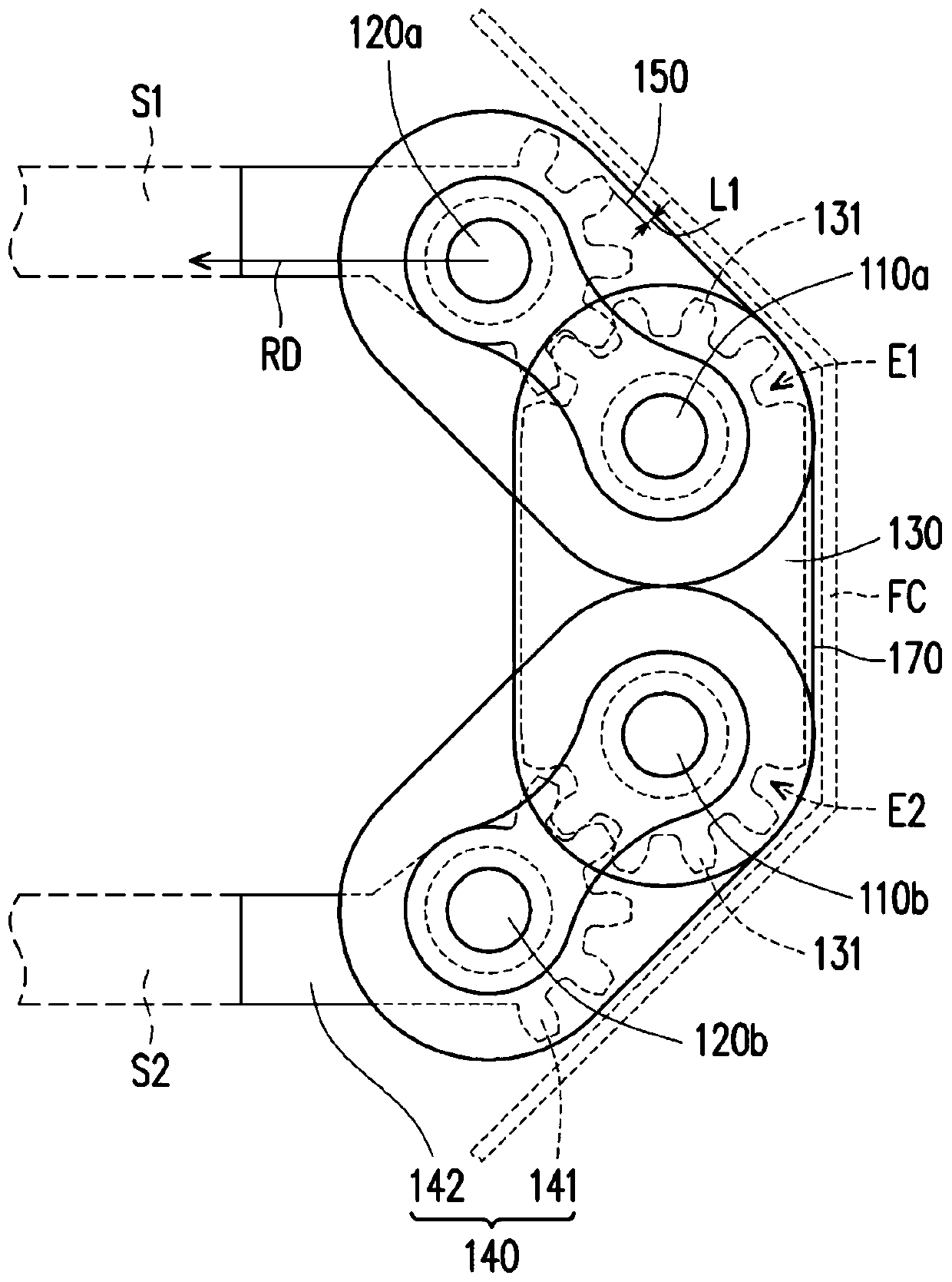

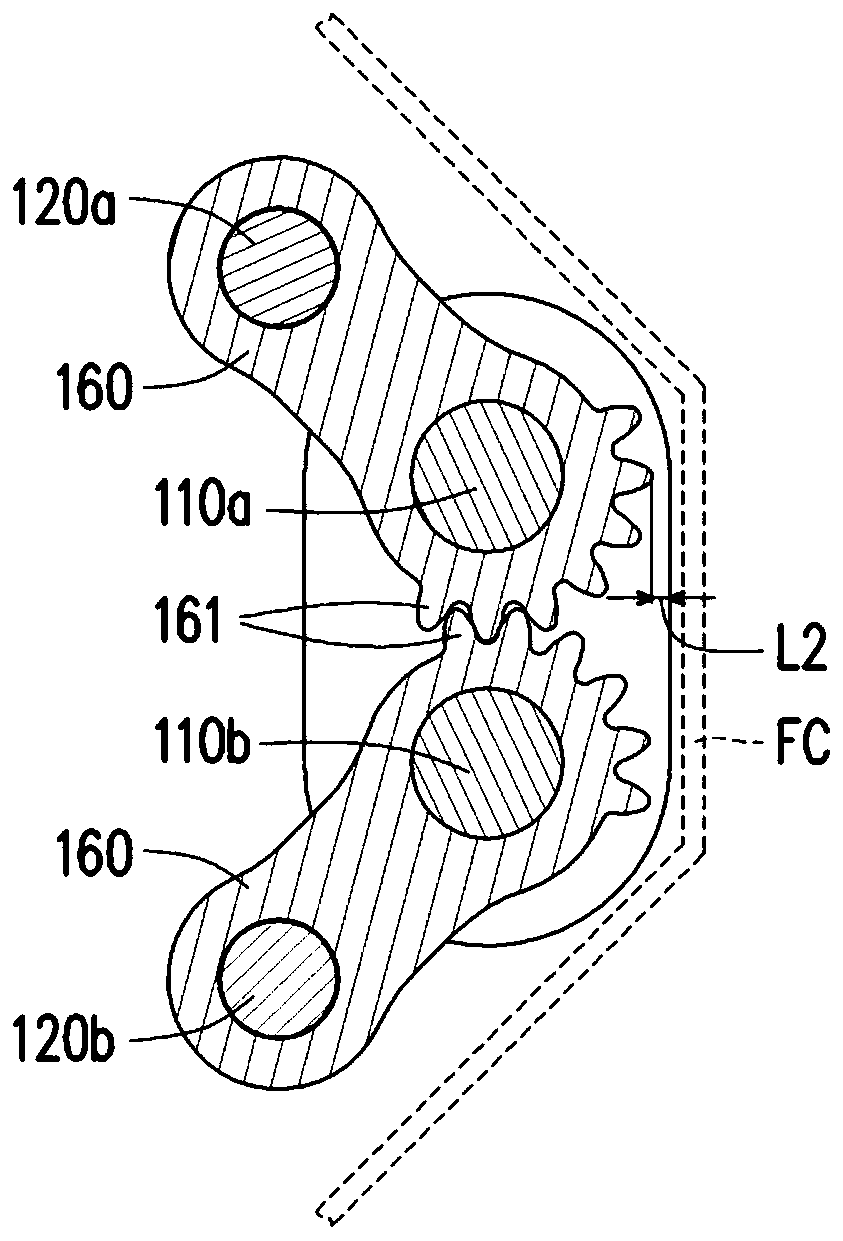

[0046] Figure 1A It is a three-dimensional schematic diagram of a co-moving pivot module according to an embodiment of the present invention. Figure 1B yes Figure 1A A perspective view of the side view structure of the co-moving pivot module of . Figure 1C yes Figure 1A A partial structural perspective view of the B-B section of the co-moving pivot module of .

[0047] Please refer to Figure 1A and Figure 1B , the co-moving pivot module 100 of this embodiment is suitable for carrying two bodies S1 and S2 of an electronic device, so as to facilitate synchronous opening or synchronous closing. Wherein, the electronic device is, for example, a notebook computer, and the two bodies S1 and S2 are, for example, the system end and the display end of the notebook computer, and are connected to each other through the co-moving pivot module 100 .

[0048] The co-moving pivot module 100 of this embodiment includes a first rotating shaft 110a, a second rotating shaft 110b, a thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com