A kind of bentonite quality evaluation method

A technology of quality evaluation and bentonite, which is applied in the direction of measuring devices, material analysis using radiation diffraction, instruments, etc., can solve the problems of not evaluating the core indicators of bentonite, and achieve the effect of simple and reliable evaluation method and strong applicability in industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

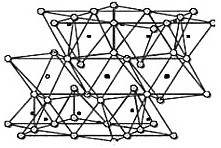

Image

Examples

Embodiment 1

[0073] Embodiment 1, choose the natural bentonite of a certain city in Liaoning, according to the K determined by the test method of GB / T20973-2007 Appendix A cation exchange capacity and exchangeable cation content + 、Na + , Ca 2+ , Mg 2+ cation calculations.

[0074] Before sodium treatment

[0075] + =9.37mmol / 100g

[0076] + =31.13mmol / 100g

[0077] CEC (折合Na+总量) = + +2× +2× =71.63 mmol / 100g.

[0078] After sodium treatment

[0079] + =35.39mmol / 100g

[0080] + =19.82mmol / 100g

[0081] CEC (折合Na+总量) = + +2× +2× =75.03 mmol / 100g.

[0082] According to the characteristics of montmorillonite, the CEC in the middle of the montmorillonite sheet is usually in the range of 60-120mmol / 100G, which is equivalent to Na before and after sodium treatment. + The total deviation is 4.53%, and the natural bentonite quality grade of embodiment 1 is relatively poor.

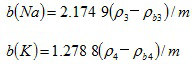

[0083] The interlayer distance d was measured by X-ray diffraction method (001)...

Embodiment 2

[0084] Embodiment 2, choose the natural bentonite of a certain city in Jilin, according to the K determined by the test method of GB / T20973-2007 Appendix A cation exchange capacity and exchangeable cation content + 、Na + , Ca 2+ , Mg 2+ The cation calculation:

[0085] Before sodium treatment

[0086] + =13.29mmol / 100g

[0087] + =39.52mmol / 100g

[0088] CEC (折合Na+总量) = + +2× +2× =92.33 mmol / 100g.

[0089] After sodium treatment

[0090] + =76.21mmol / 100g

[0091] + =8.56mmol / 100g

[0092] CEC (折合Na+总量) = + +2× +2× =93.33 mmol / 100g.

[0093] According to the characteristics of montmorillonite, the CEC in the middle of the montmorillonite sheet is usually in the range of 60-120mmol / 100G, which is equivalent to Na before and after sodium treatment. + The total deviation is 1.07%, and the natural bentonite quality grade of embodiment 2 is medium.

[0094] The interlayer distance d was measured by X-ray diffraction method (001) is 1.3...

Embodiment 3

[0095] Embodiment 3, choose the natural bentonite of a city in Inner Mongolia, the K measured according to the test method of GB / T20973-2007 appendix A cation exchange capacity and exchangeable cation content + 、Na + , Ca 2+ , Mg 2+ cation calculations.

[0096] Before sodium treatment

[0097] + =22.35mmol / 100g

[0098] + =55.16mmol / 100g

[0099] CEC (折合Na+总量) = + +2× +2× =132.67 mmol / 100g.

[0100] After sodium treatment

[0101] + =76.53mmol / 100g

[0102] + =24.96mmol / 100g

[0103] CEC (折合Na+总量) = + +2× +2× =126.45mmol / 100g.

[0104] According to the characteristics of montmorillonite, the CEC in the middle of the montmorillonite sheet is usually in the range of 60-120mmol / 100G, which is equivalent to Na before and after sodium treatment. + The total deviation is 4.91%, and the bentonite quality grade of embodiment 3 is higher.

[0105] The interlayer distance d was measured by X-ray diffraction method (001) is 1.29 nm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com