Weather-resistant type heat transfer printing light-emitting sign

A technology of luminous marking and thermal transfer printing, which is applied to illuminated markings, instruments, display devices, etc., can solve the problems of pattern layer thickness and low transparency, achieve high transmittance, improve luminous brightness, and excellent transparency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

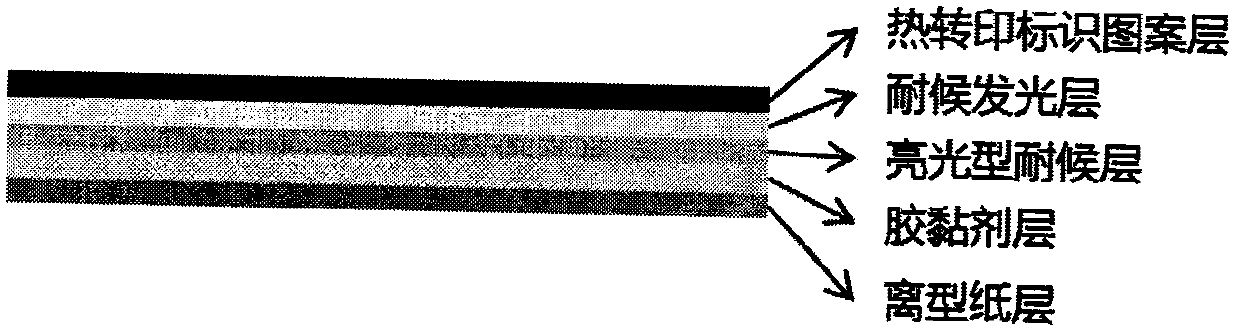

[0020] A weather-resistant heat-transfer luminescent sign, comprising a heat-transfer mark pattern layer, a weather-resistant luminous layer, a bright weather-resistant layer, an adhesive layer, and a release paper layer; one side of the bright weather-resistant layer is sequentially arranged from the inside to the outside It is a weather-resistant luminous layer and a thermal transfer logo pattern layer, and the other side is an adhesive layer and a release paper layer from the inside to the outside.

[0021] The thermal transfer logo pattern layer is printed with a thermal transfer ribbon using a thermal transfer method, and can be printed immediately according to actual needs. If it is necessary to print a red "No Smoking", a red ribbon is used to print it through thermal transfer printing. Method, the corresponding position of the printing head is heated, and the red "no smoking" that needs to be printed is printed on the formed tape (including the weather-resistant lumines...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com