Patents

Literature

45results about How to "Guaranteed intact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

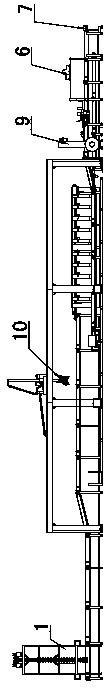

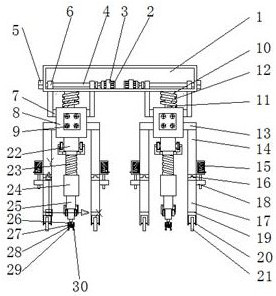

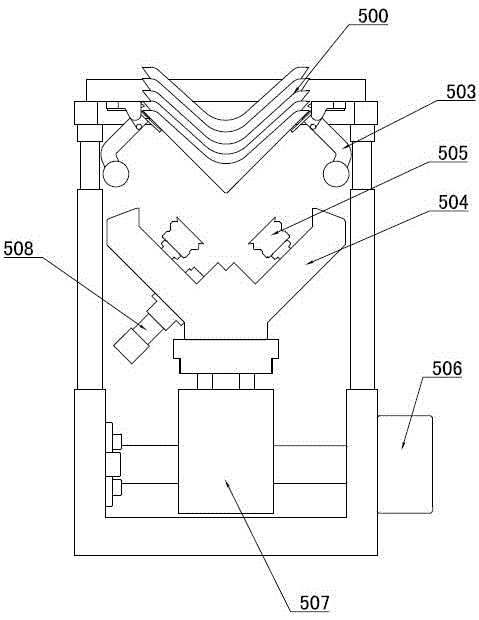

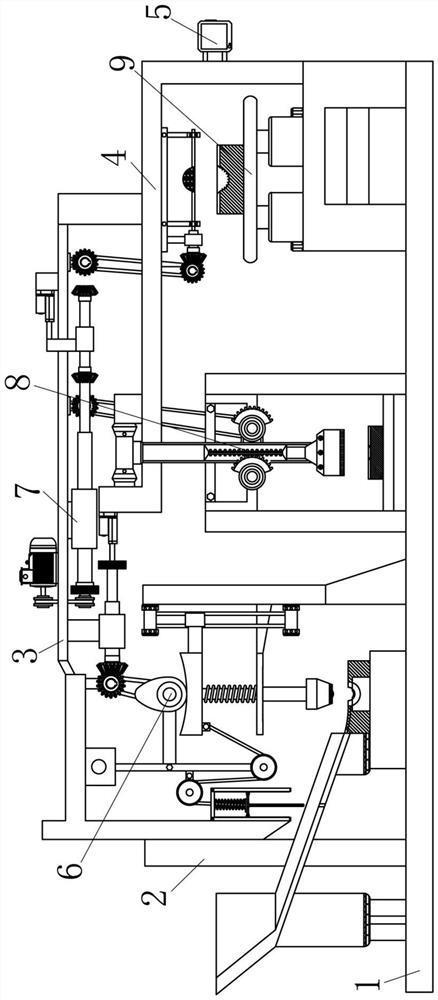

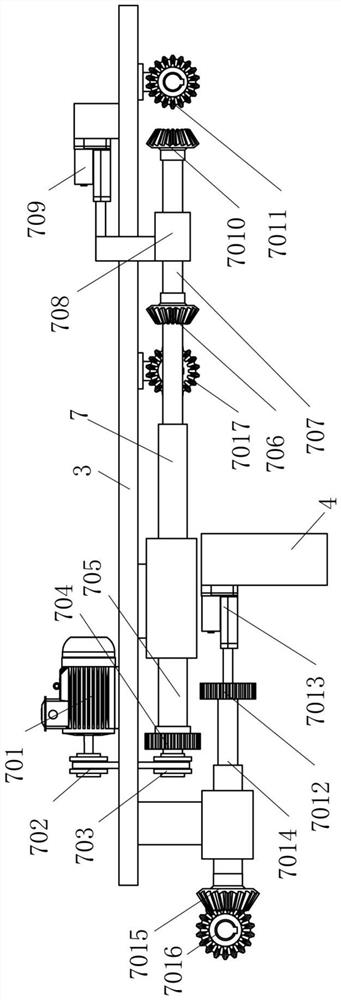

Automatic packaging assembly line and packaging process

ActiveCN104192380ASuitable for quantitative production needsIncrease productivityPackaging machinesProcess engineeringAssembly line

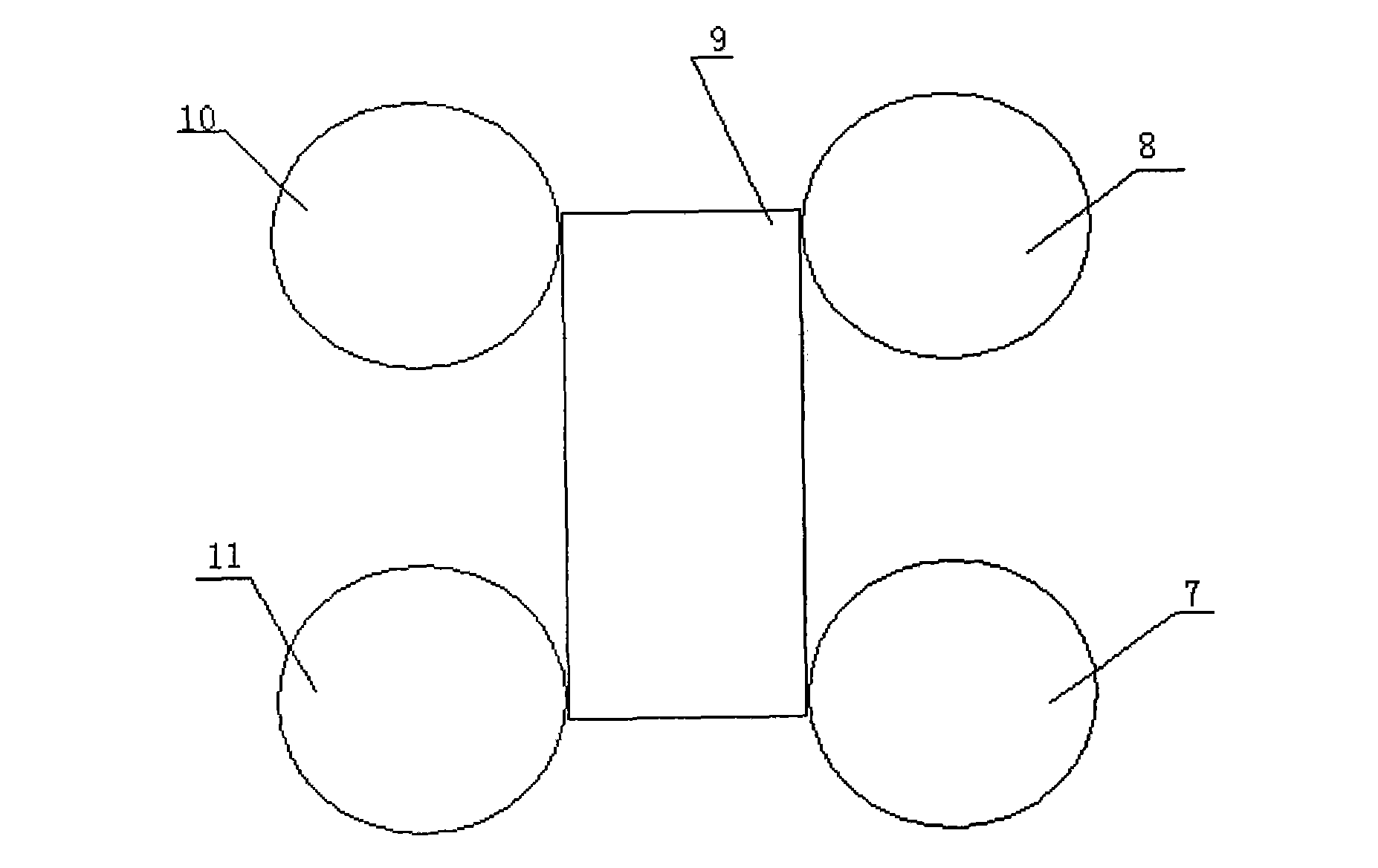

The invention provides an automatic packaging assembly line and a packaging process and belongs to the field of equipment and the process for sorting and packaging square products like ceramic tiles. The automatic packaging assembly line comprises a tile storage machine (1) connected with a finished ceramic tile assembly line. The automatic packaging assembly line is characterized in that the outlet end of the tile storage machine (1) is sequentially provided with a color difference detection device (2), a flatness detector (3), a tile sorting and stacking machine (4), an angle wrapping machine (5), a box filling machine (6), a code spraying and marking machine (7), a box stacking machine (8), a band tying machine (9) and an automatic grabbing machine (10). The packaging process of the automatic packaging assembly line comprises the working procedures of selecting, classifying, color separating, sorting, box filling, band tying, marking, pallet stacking and the like. Seamless joint of the automatic packaging assembly line and a beginning finished product conveyor line is achieved, full-automatic assembly line operation of the working procedures for the finished ceramic tiles can be achieved, the labor cost is greatly reduced, and the work efficiency is improved.

Owner:蔡群龙

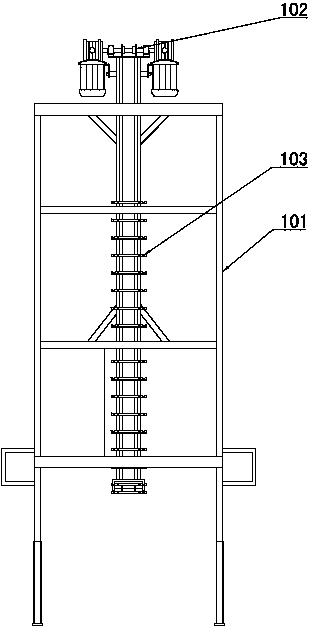

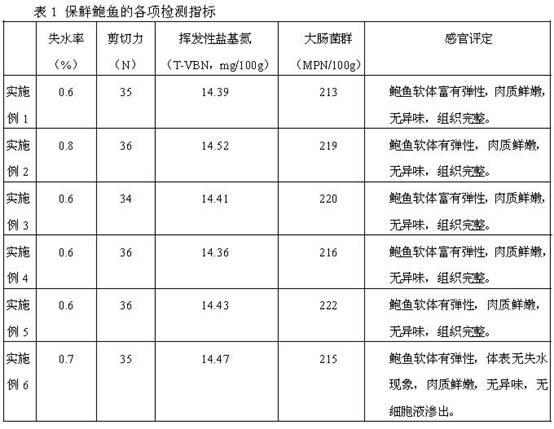

Freshness preservation method of abalone

ActiveCN102150698ANo adverse effect on food safetyFood safety impactMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsBiotechnologyEscherichia coli

The invention discloses a freshness preservation method of the abalone. The method comprises the following steps of: sequentially performing the sterilizing treatment by ozone, the monomer ice temperature treatment and the ice glaze plating treatment on the cleaned abalone. After the freshness preservation abalone prepared by the method is refrigerated, the population number of the volatile salt basic nitrogen and the escherichia coli are lower than the national standard, and the dehydration ratio is less than 1.0%; and a abalone soft body is high in elasticity, free of peculiar smell, and intact in tissue. After the invention is used, the freshness and the tenderness of the abalone are effectively preserved.

Owner:福州日兴水产食品有限公司

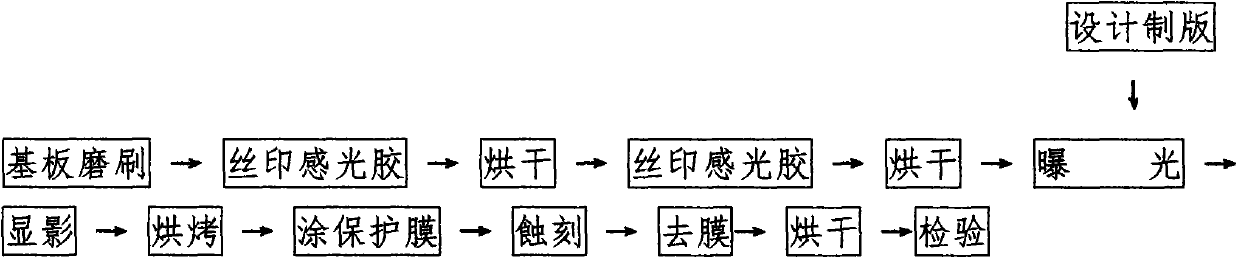

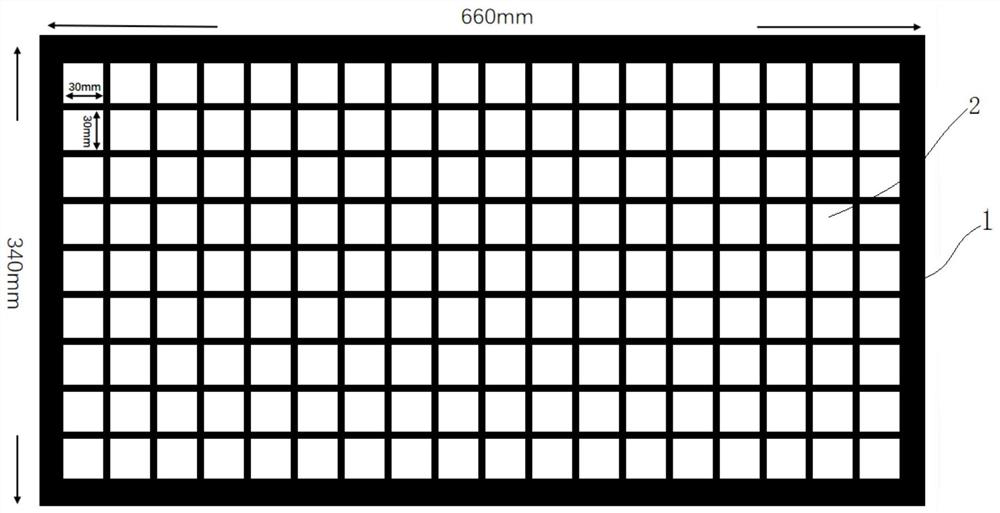

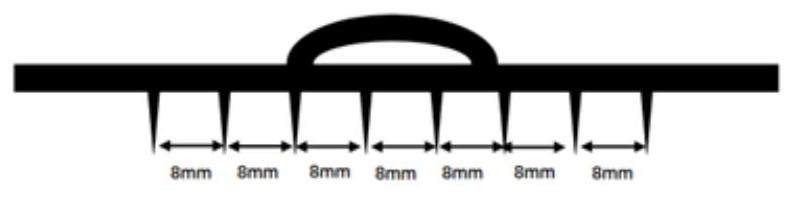

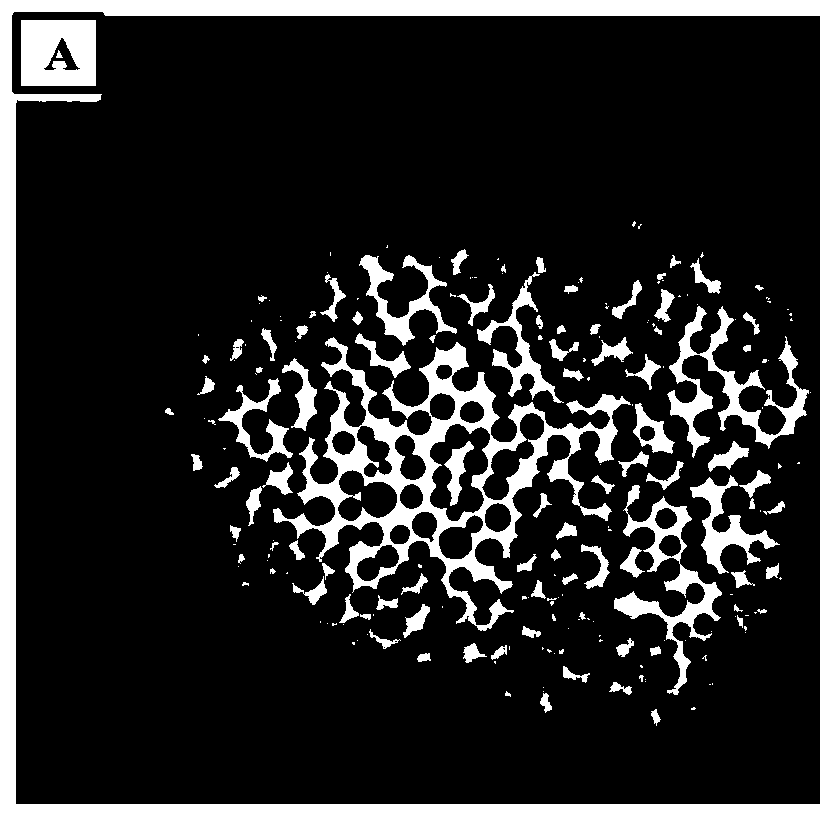

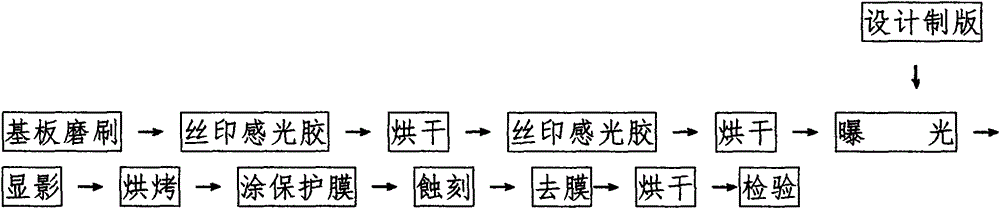

Production technology for stainless steel dot matrix friction plate

The invention discloses a production technology for a stainless steel dot matrix friction plate and belongs to the technical field of optical chemical etching. The production technology comprises the following working procedures of: designing a plate, wherein the diameter of each round dot on the plate is 0.198mm; performing polish-brush treatment on a stainless steel base plate in a large area manner; performing silk-screening on the surface of the base plate for the second time, and drying photo-sensitive resist; exposing a film substrate coated on a photo-sensitive resist membrane layer of the base plate, wherein a light supplementation plate is arranged between a light source of an exposure machine and a base plate to be photo-sensed; developing, fixing and drying the film substrate; baking and firming a membrane at high temperature; dangling the base plate to be etched upside down in the air, etching the base plate through a lower sprayer of an etching machine, wherein etching liquid adopts liquid ferric trichloride with 46 percent of ferrous ions Fe<3+>; removing the membrane from the etched plate, and flushing and drying the membrane. Furthermore, after the step of firming the membrane and before the step of etching the base plate, a protection membrane layer is coated on the back of the base plate, so that the back of the plate is intact. The large-area stainless steel dot matrix friction plate obtained by using the production technology disclosed by the invention is high array-round-dot uniformity consistency, single-surface etching resistance, small light intensity error, high etching speed and god benefits.

Owner:嵊州市迪凯电子有限公司

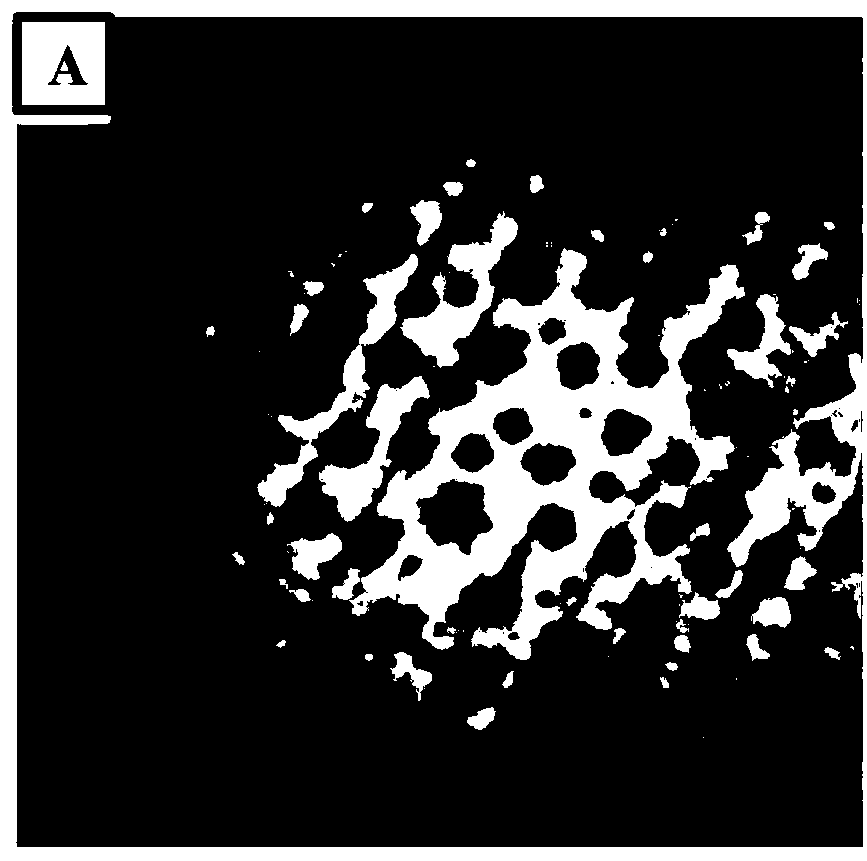

Honeycomb-simulated concrete block and die bar for production thereof

InactiveCN104552577ANo pollution in the processMeet the requirements of self-insulation and sound insulationConstruction materialMouldsHoneycombEngineering

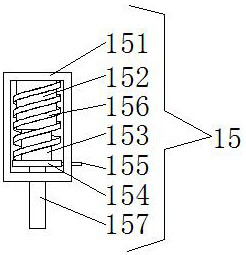

The invention relates a honeycomb-simulated concrete block and a die bar for production of the honeycomb-simulated concrete block, and aims at solving the problems of complex heat preservation construction of wall body of the existing building and high cost. The honeycomb-simulated concrete block is characterized in that a honeycomb-shaped cavity being 9 to 300mm in diameter and 0.5 to 100mm in wall thickness is formed in the block; one end of each honeycomb-shaped cavity is opened and while the other end of each honeycomb-shaped cavity is closed; the closed end is 0.5 to 30mm in layer thickness; the cavities covers 50 to 75% of the size of the block and the volume weight of the cavities is 550 to 800kg. A die bar for producing the honeycomb-simulated concrete block is characterized in that a cavity is formed in a die bar column; a breathing hole is formed in the die bar column; a grid sleeve sleeves the die bar column; a sponge sleeve sleeves the grid sleeve; a rubber sleeve sleeves the sponge sleeve; a closed bar bag is formed between the rubber sleeve and the die bar column. The block meets the requirement on self-heat-preservation and noise insulation of a wall body can be met; the construction links are decreased; the diameter and length of the bar bag can be changed; the die bars can form dies of different specifications; therefore, the honeycomb-shaped concrete block of different specifications can be manufactured.

Owner:胡启富

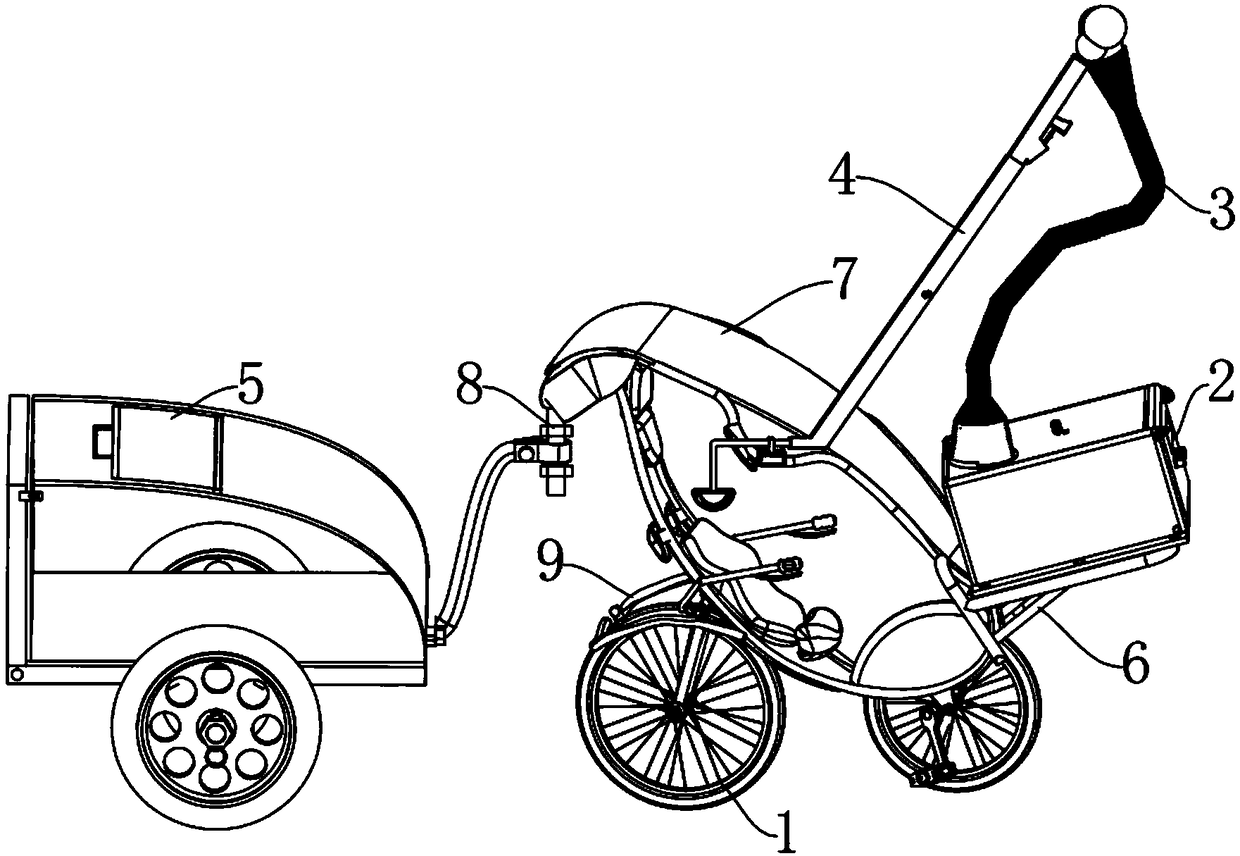

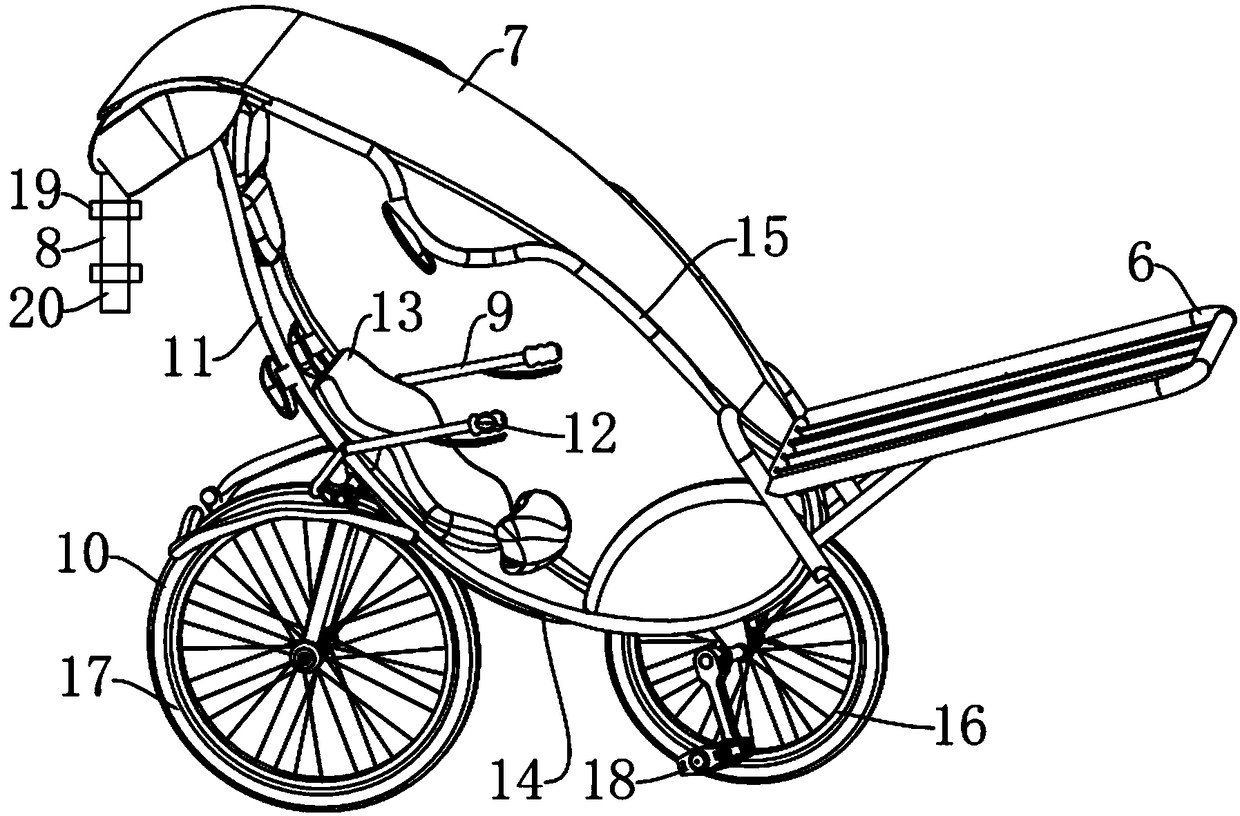

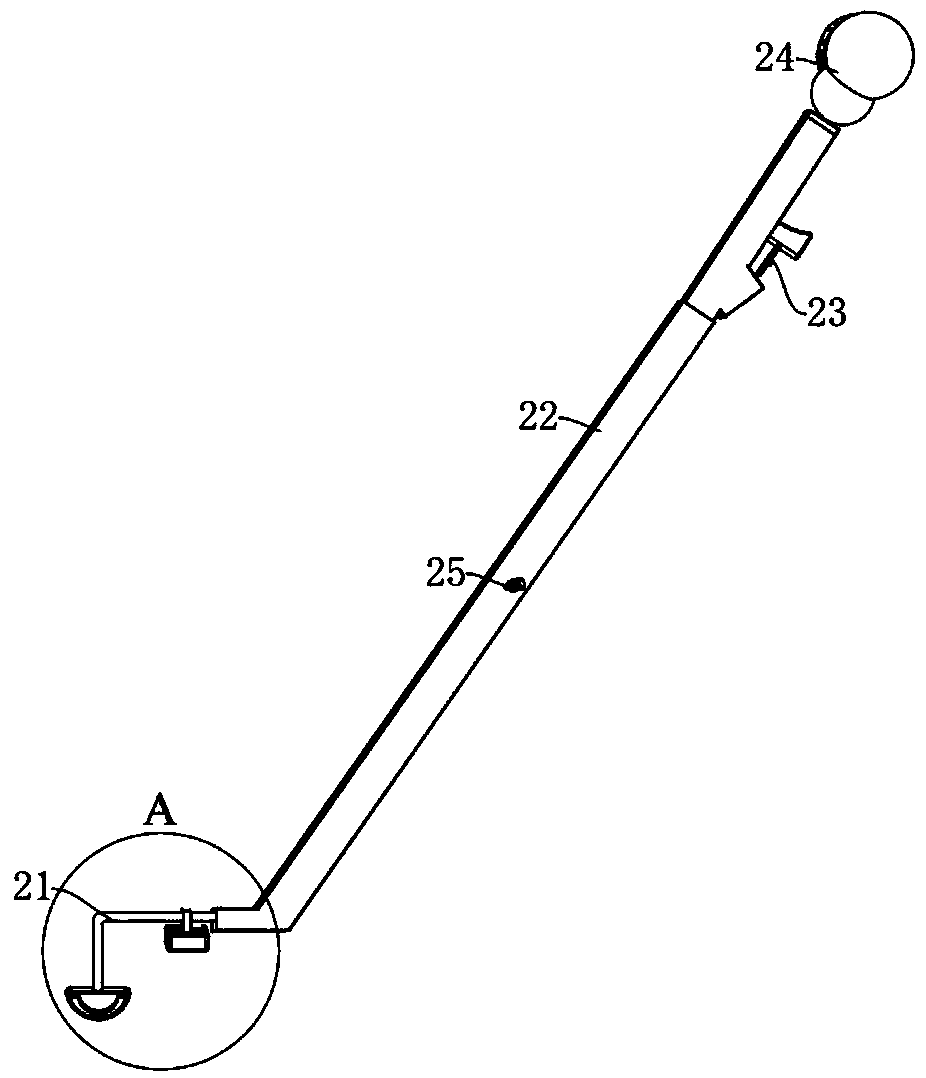

Leaning type safe light and convenient vehicle for people to pick and husk Chinese chestnuts

InactiveCN109479512AReasonable structural designSimple and fast operationHuskingHullingEngineeringCervical diseases

The invention discloses a leaning type safe light and convenient vehicle for people to pick and husk Chinese chestnuts. The leaning type safe light and convenient vehicle for people to pick and husk the Chinese chestnuts comprises a leaning type movable mechanism, a husking mechanism, a flexible telescopic gliding module, a wrapping type telescopic grabbing and picking mechanism and a detachable loading vehicle, wherein the husking mechanism is arranged on the leaning type movable mechanism; the wrapping type telescopic grabbing and picking mechanism is arranged on the leaning type movable mechanism; one end of the flexible telescopic gliding module is arranged on the wrapping type telescopic grabbing and picking mechanism; the other end of the flexible telescopic gliding module is arranged on the husking mechanism; and the detachable loading vehicle is detachably arranged at the rear end of the leaning type movable mechanism. The invention belongs to the field of farm tools, particularly, by the leaning type safe light and convenient vehicle for people to pick and husk the Chinese chestnut, the practicality is high, people pick the Chinese chestnuts comfortably, the working efficiency is improved, the labor intensity is reduced, the problems that people who pick the Chinese chestnuts easily suffer from cervical diseases when looking up to observe the Chinese chestnuts, and theChinese chestnuts are difficult to pick due to over-high Chinese chestnut trees are solved, and husks of the Chinese chestnuts are automatically and nondestructively removed.

Owner:江苏普瑞德智能科技有限公司

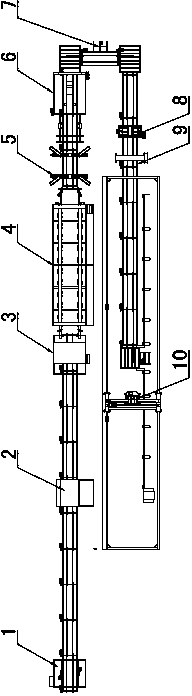

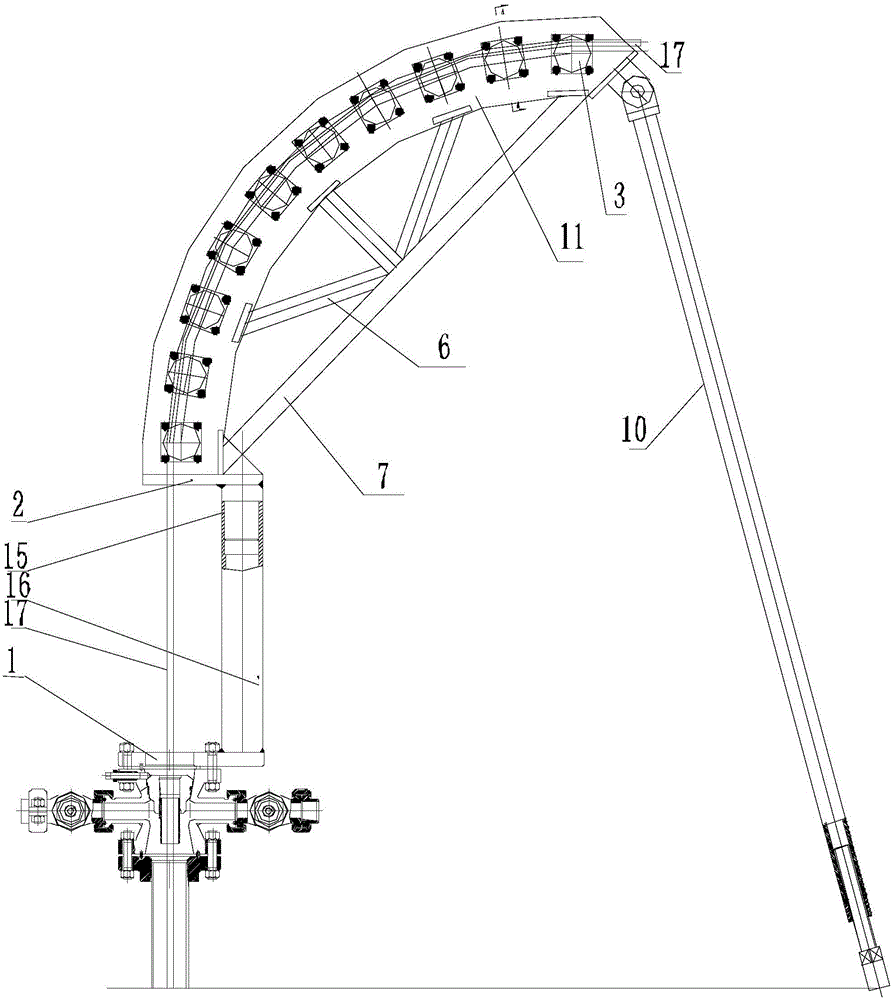

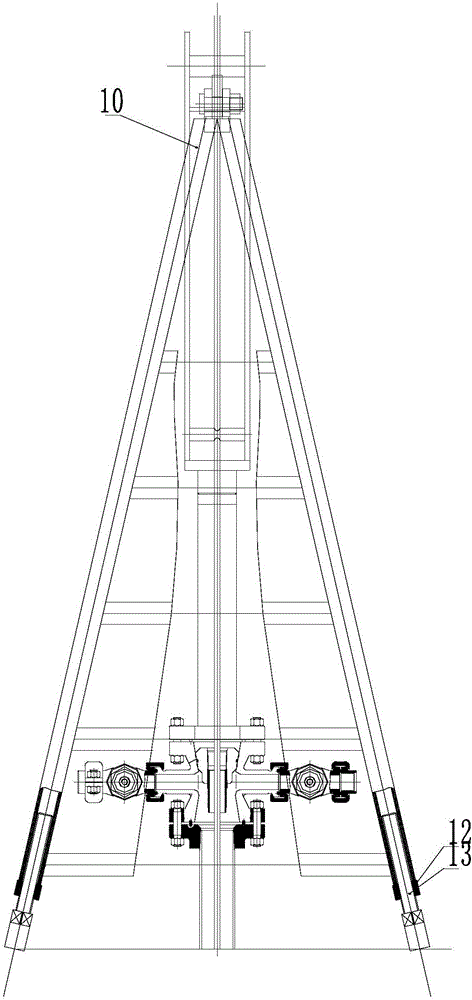

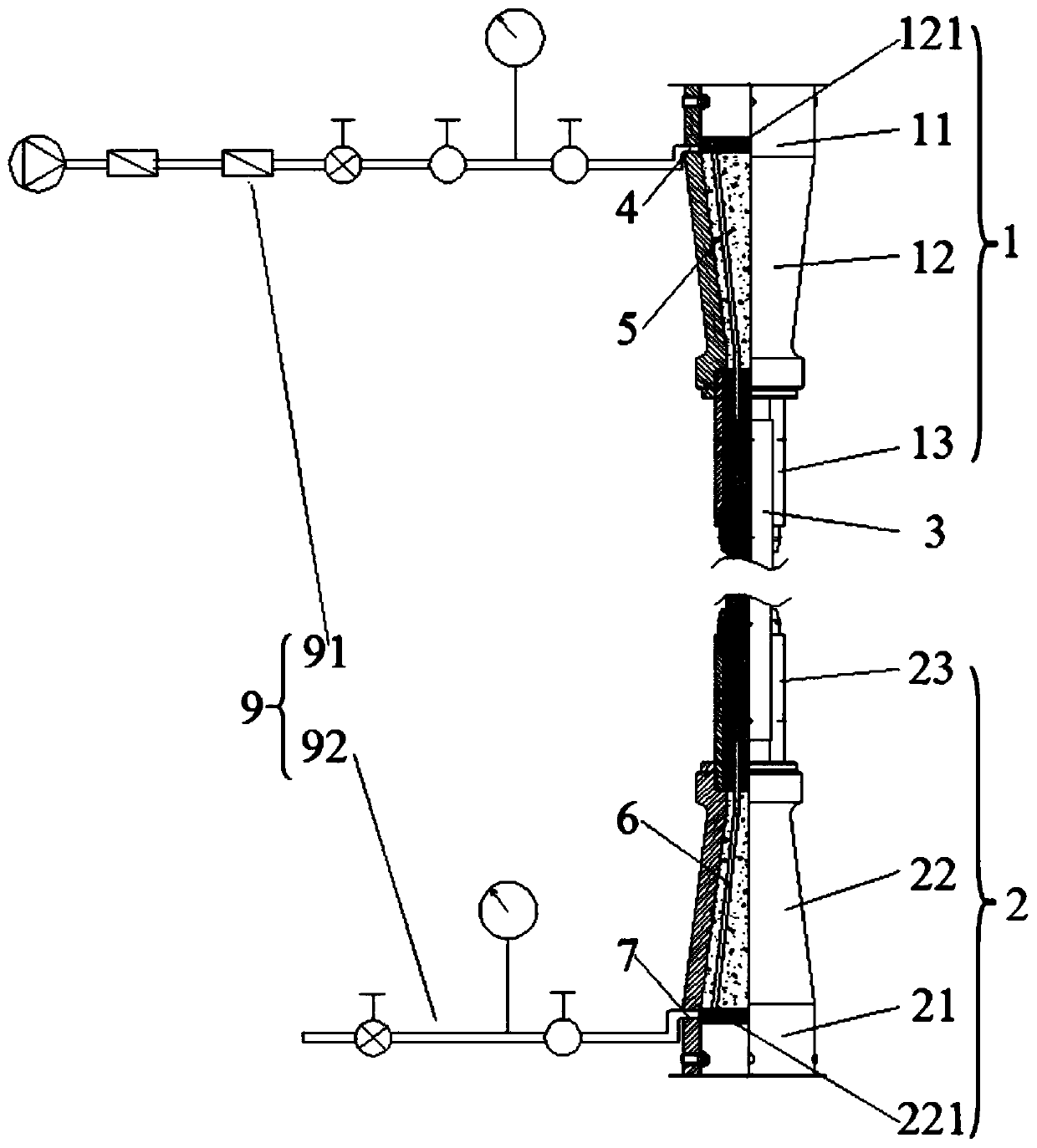

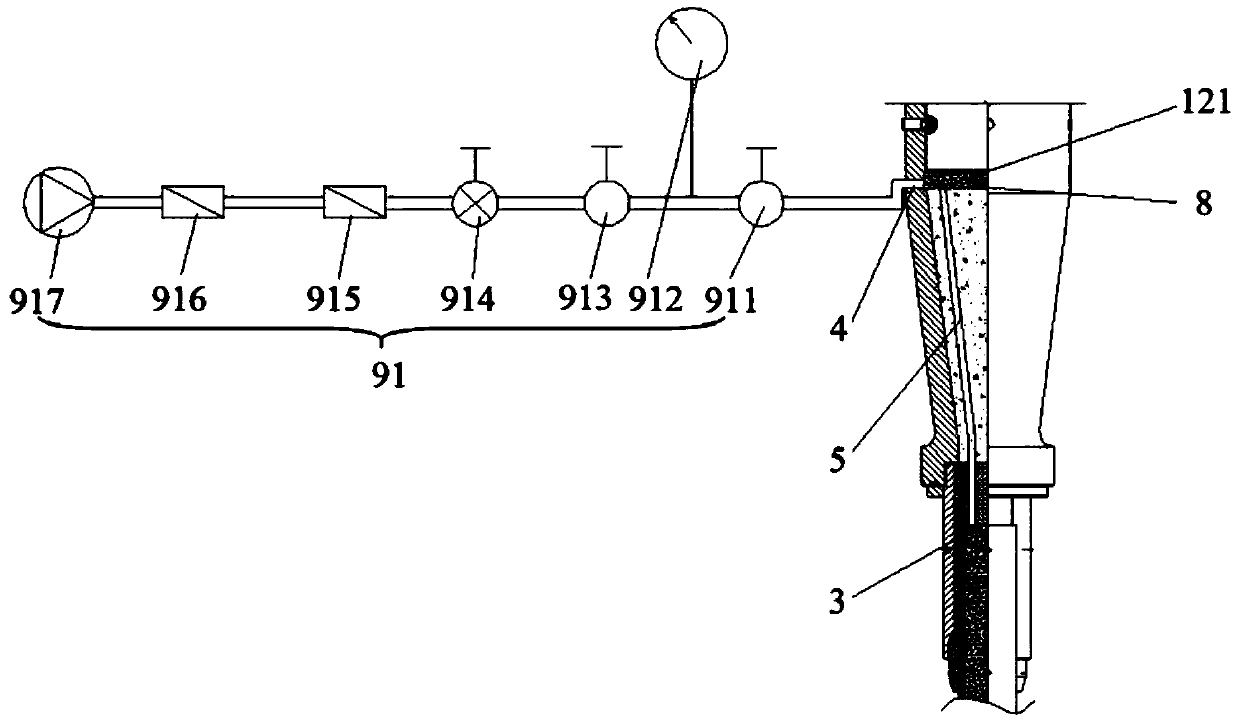

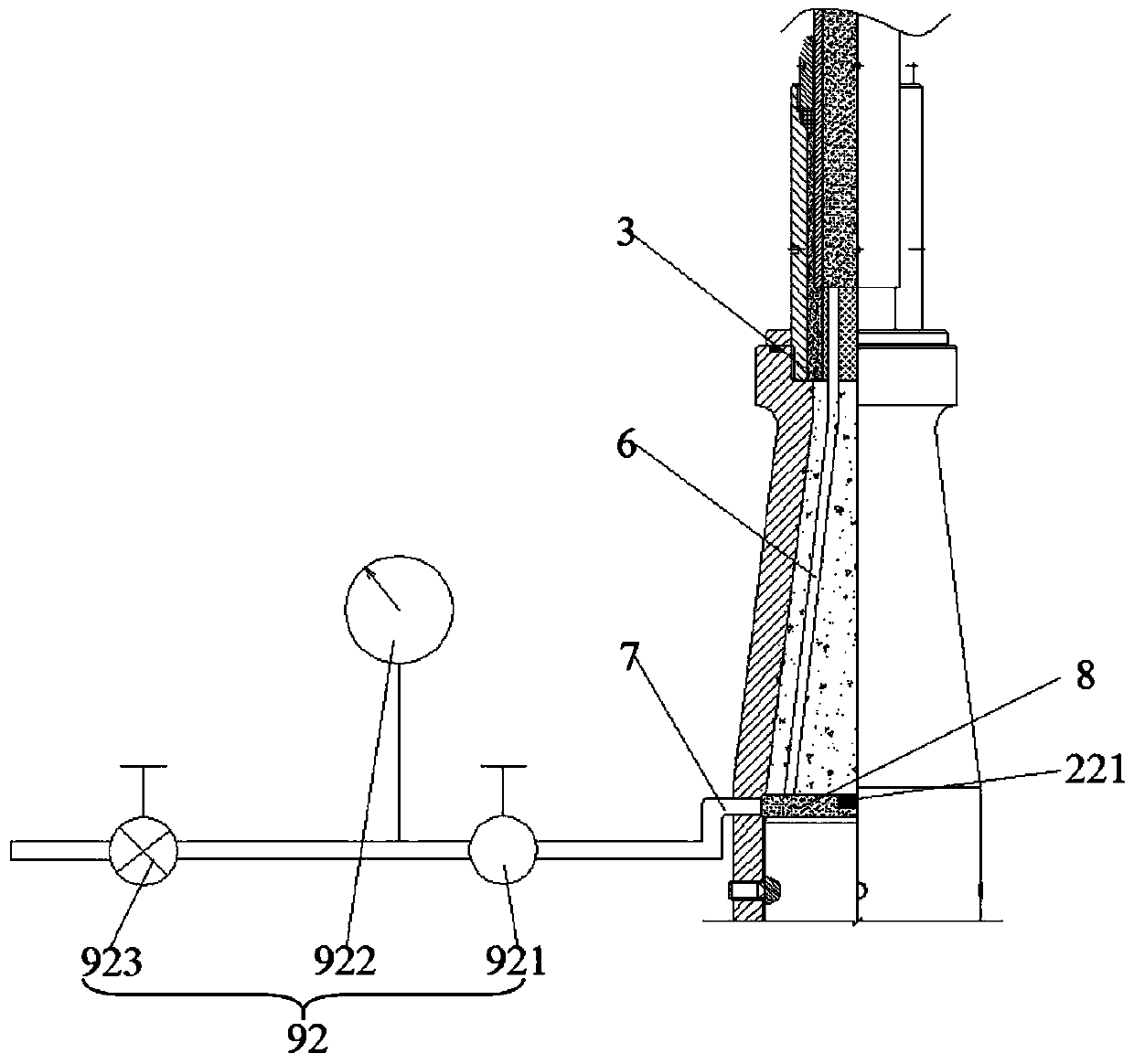

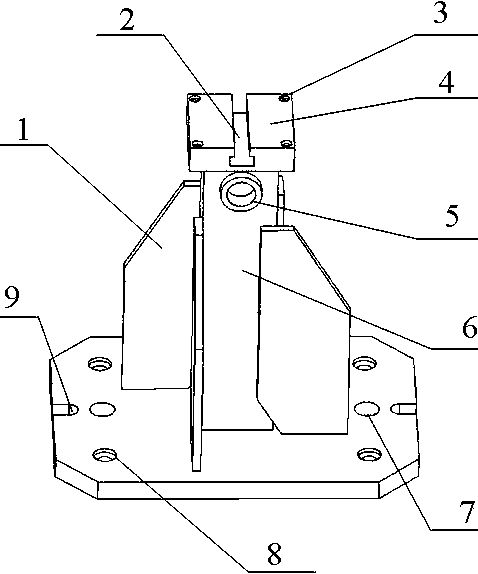

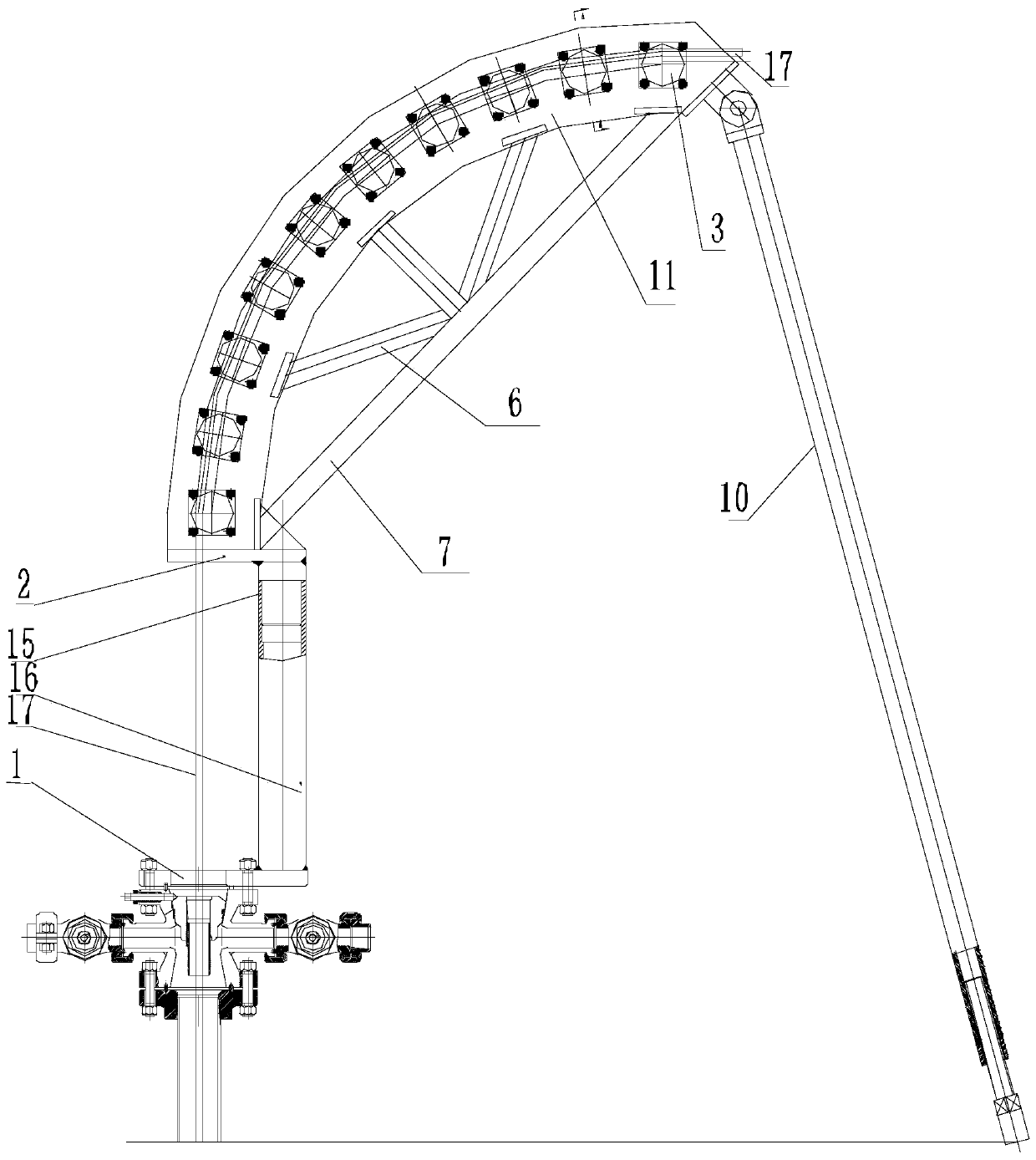

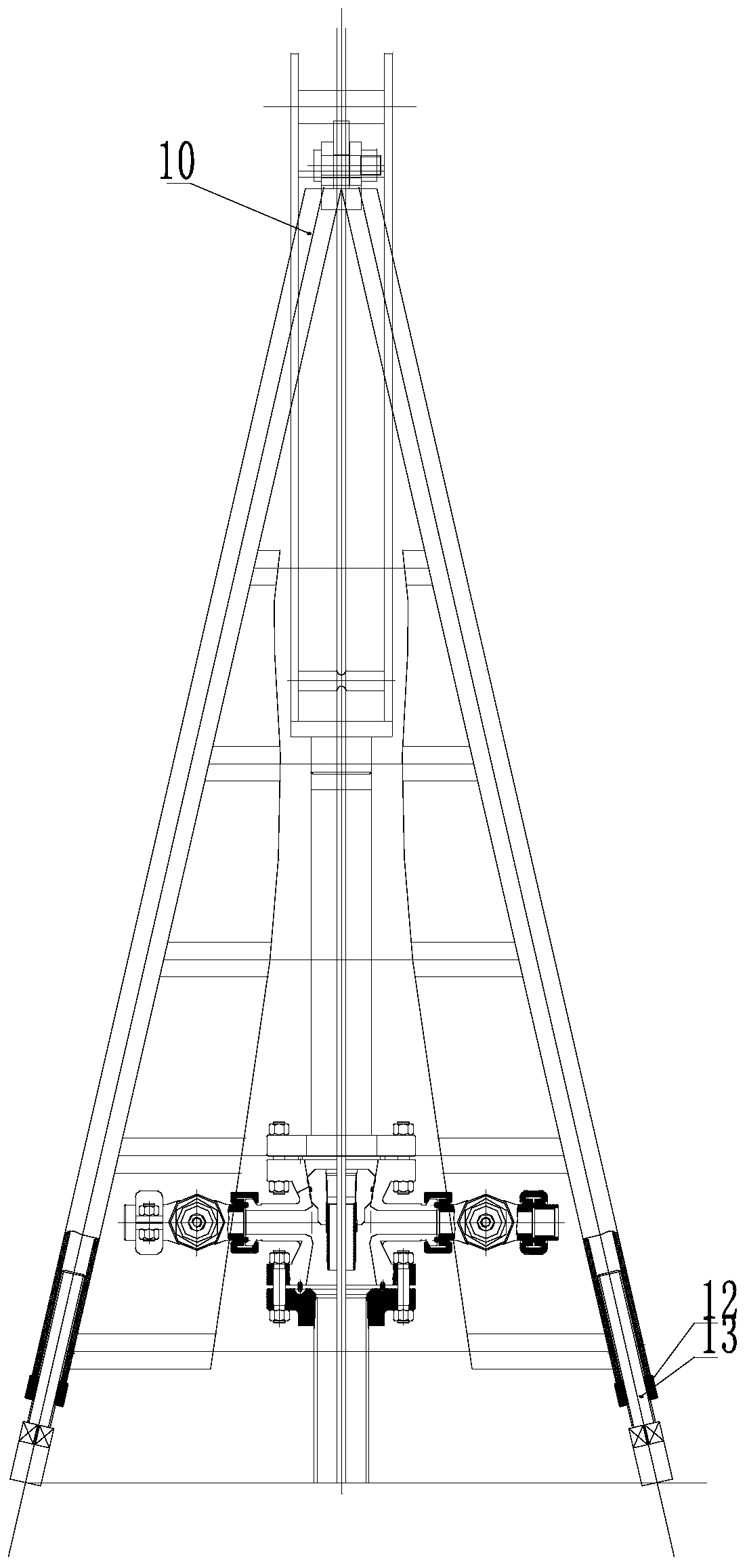

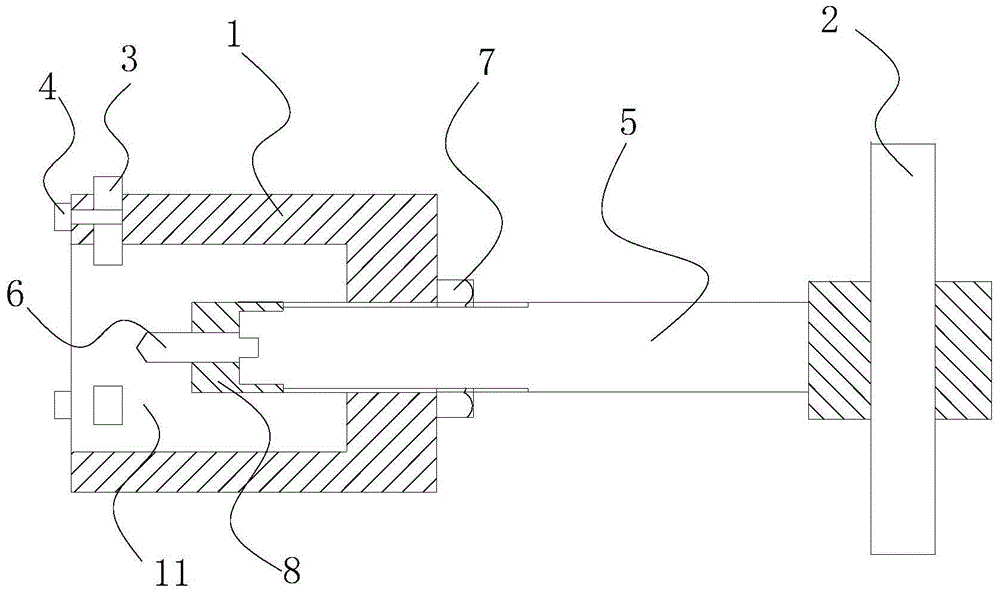

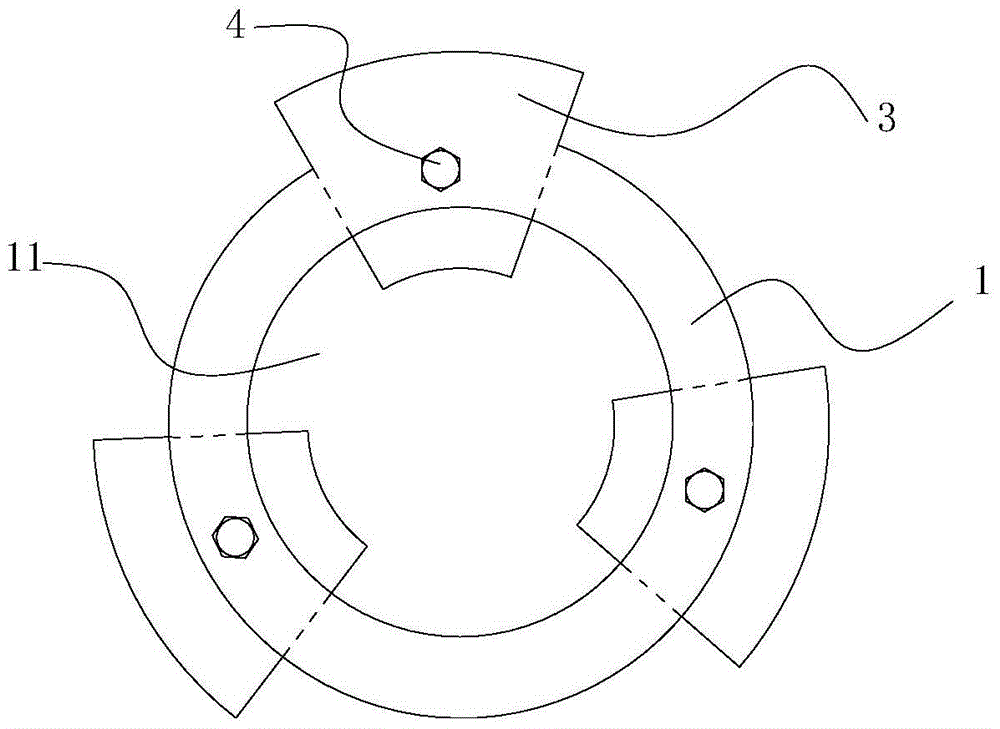

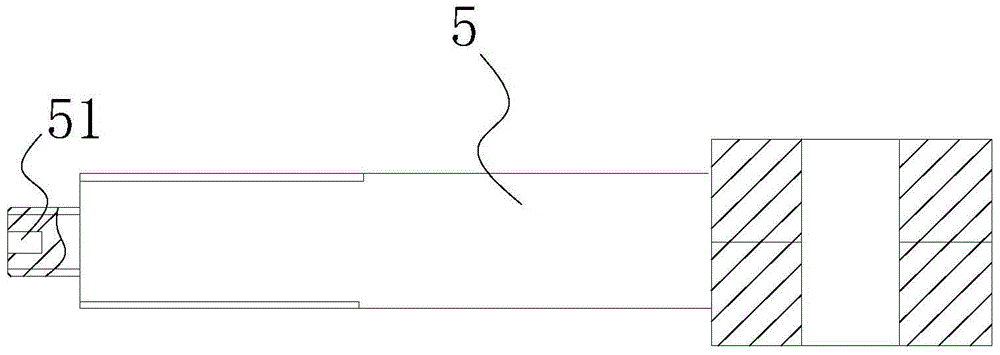

Carbon fiber flexible continuous sucker rod operation equipment

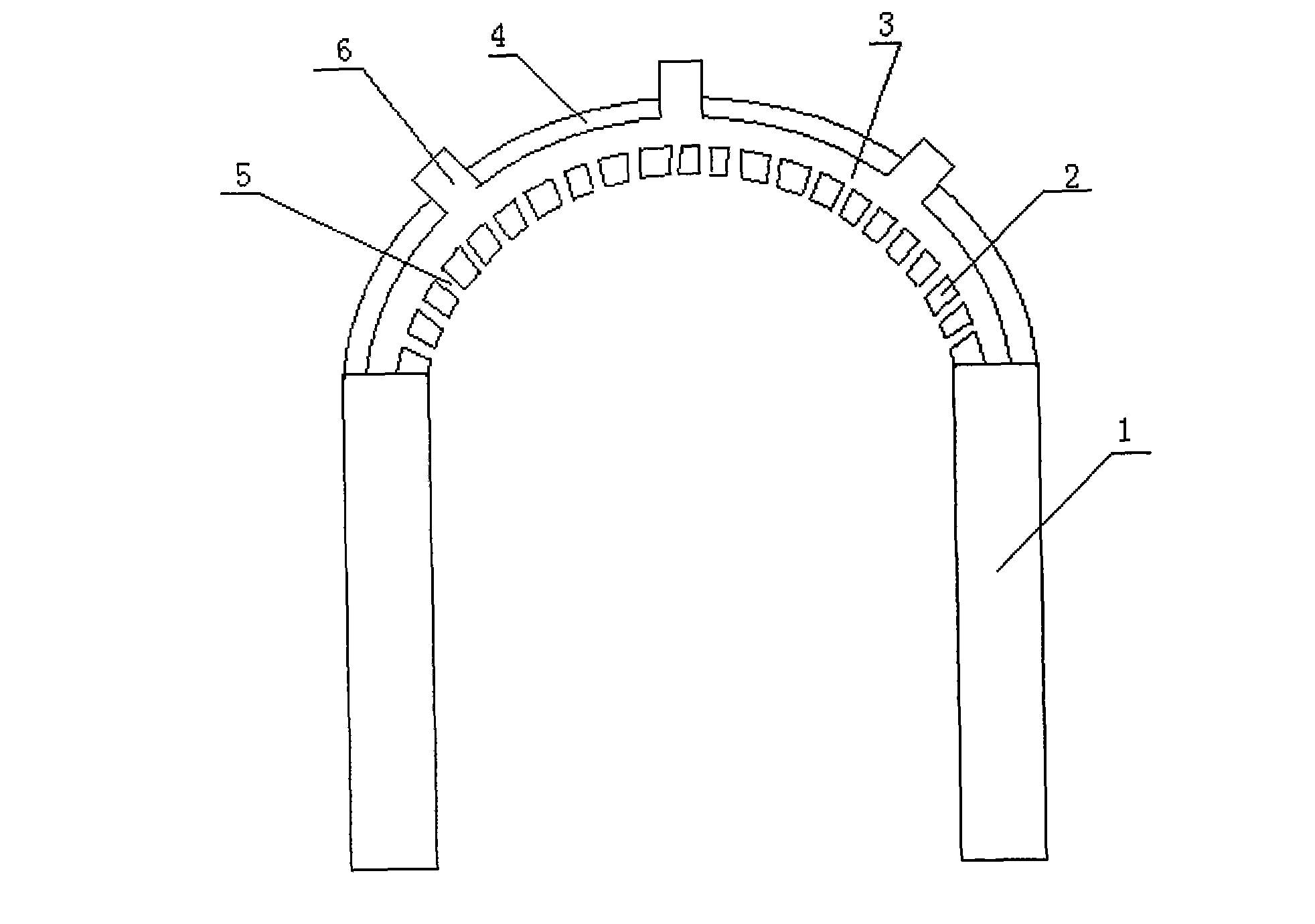

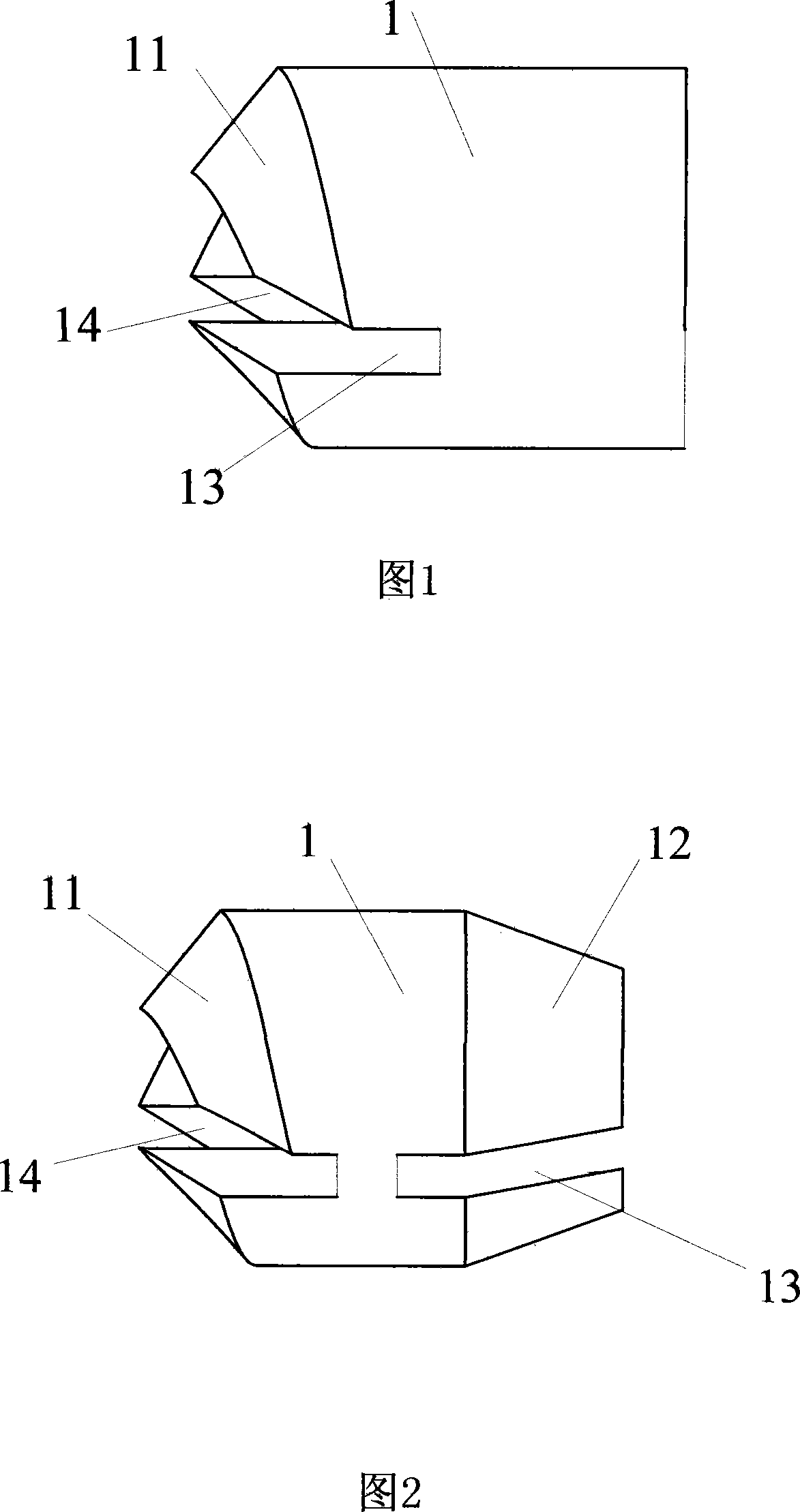

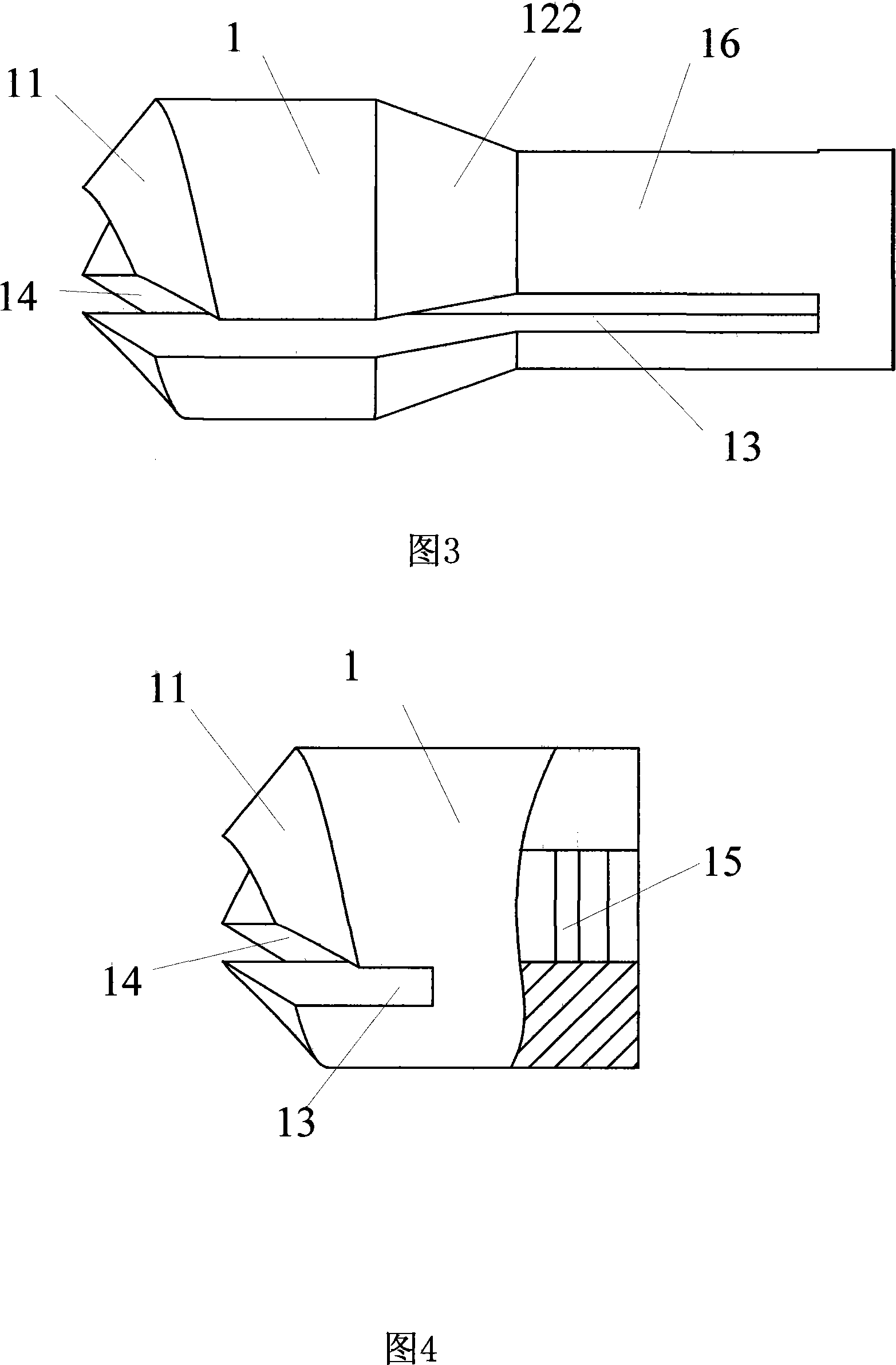

ActiveCN106285504AGuaranteed intactNo plastic deformationDrilling rodsDrilling casingsFiberStress concentration

The invention provides carbon fiber flexible continuous sucker rod operation equipment which comprises two arc-shaped plates arranged in parallel. A bottom plate is fixed between the two ends of each arc-shaped plate, supporting plates are fixed between each bottom plate and the corresponding arc-shaped plate, and rotating shafts are evenly arranged between the two arc-shaped plates at intervals. The outer walls of the rotating shafts are sleeved with rubber sleeves with the arc-shaped surfaces. A support is hinged to one ends of the two arc-shaped plates, and adjusting screws are connected to the lower ends of two supporting rods of the support correspondingly. The other ends of the two arc-shaped plates are fixedly connected with an operation frame which is inserted into a rotating base, and the rotating base is mounted on the well mouth. By means of the operation equipment, it can be guaranteed that a carbon fiber flexible continuous sucker rod can be smoothly taken off, stress concentration caused by mechanical abrasion on the carbon fiber flexible continuous sucker rod operation equipment is avoided, and the service life of the equipment is prolonged; and by the adoption of the equipment, the carbon fiber flexible continuous sucker rod is protected against plastic deformation during operation, and normal use of the carbon fiber flexible continuous sucker rod operation equipment is guaranteed.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

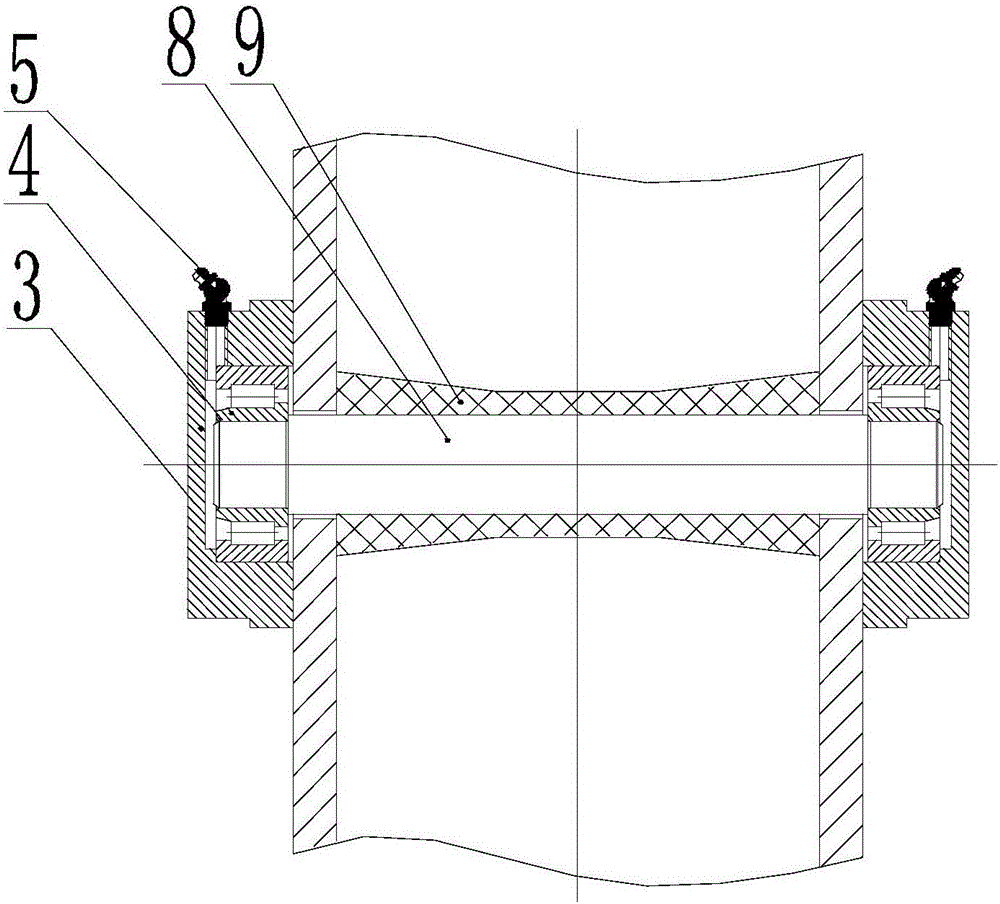

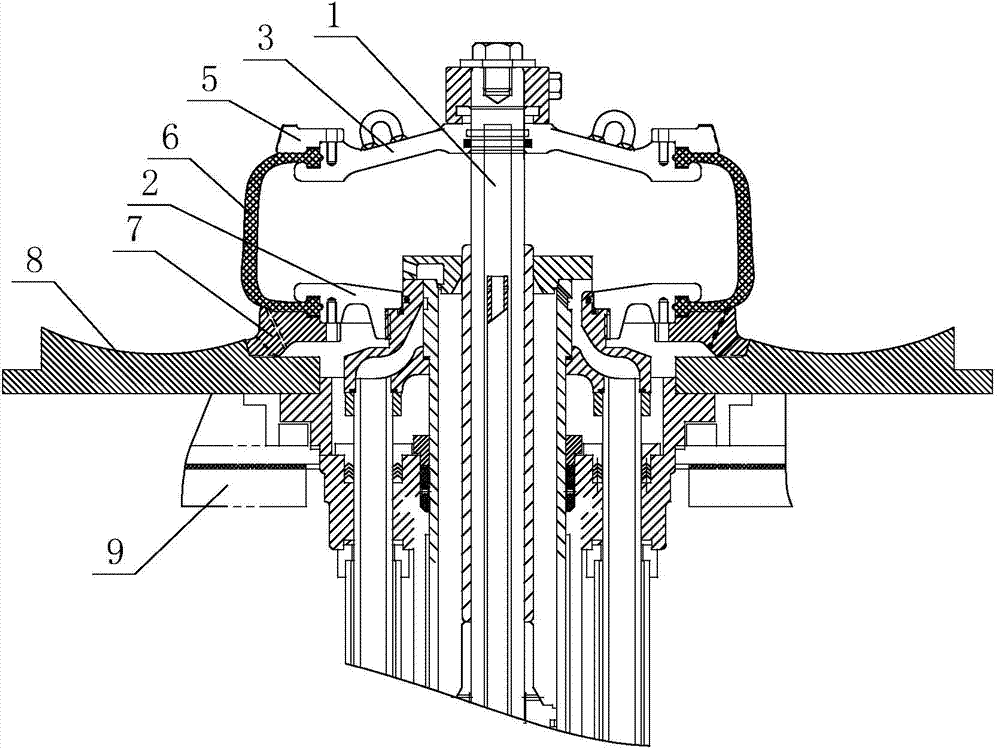

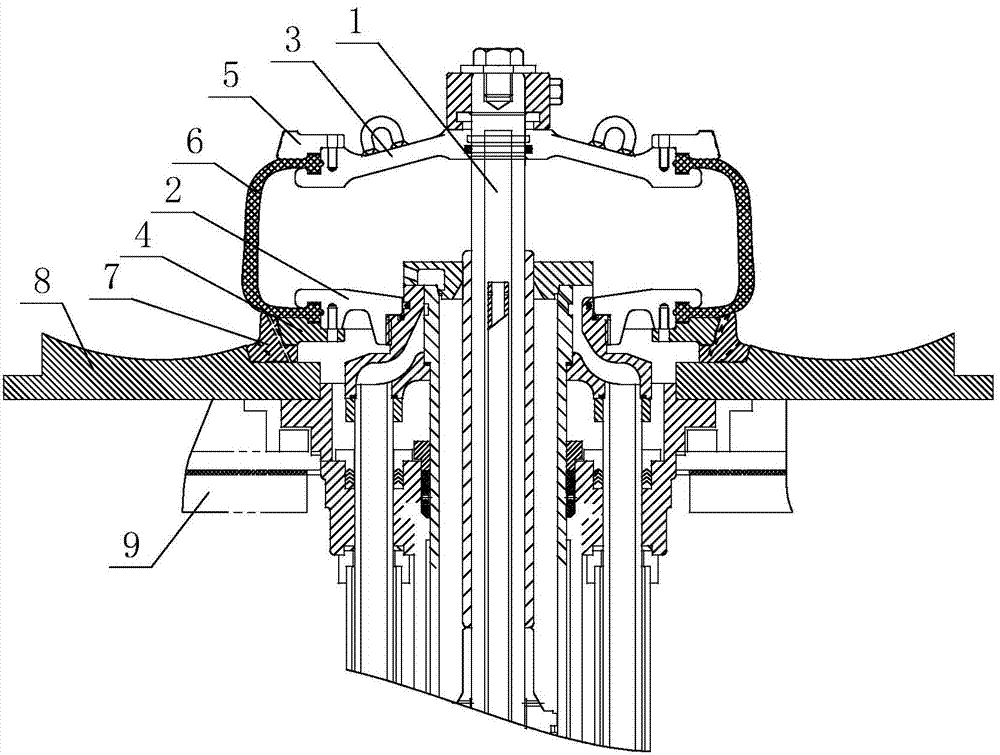

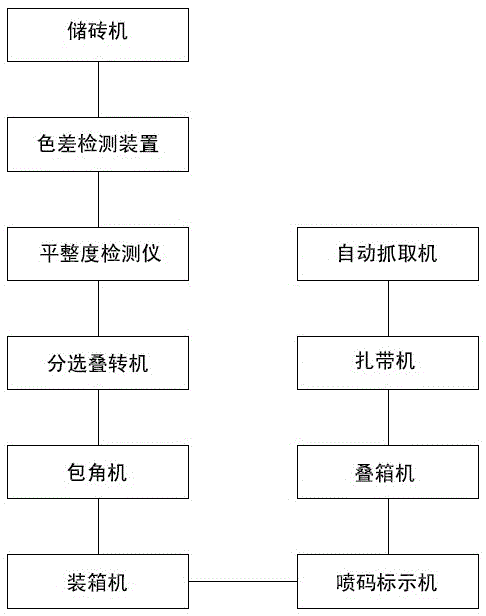

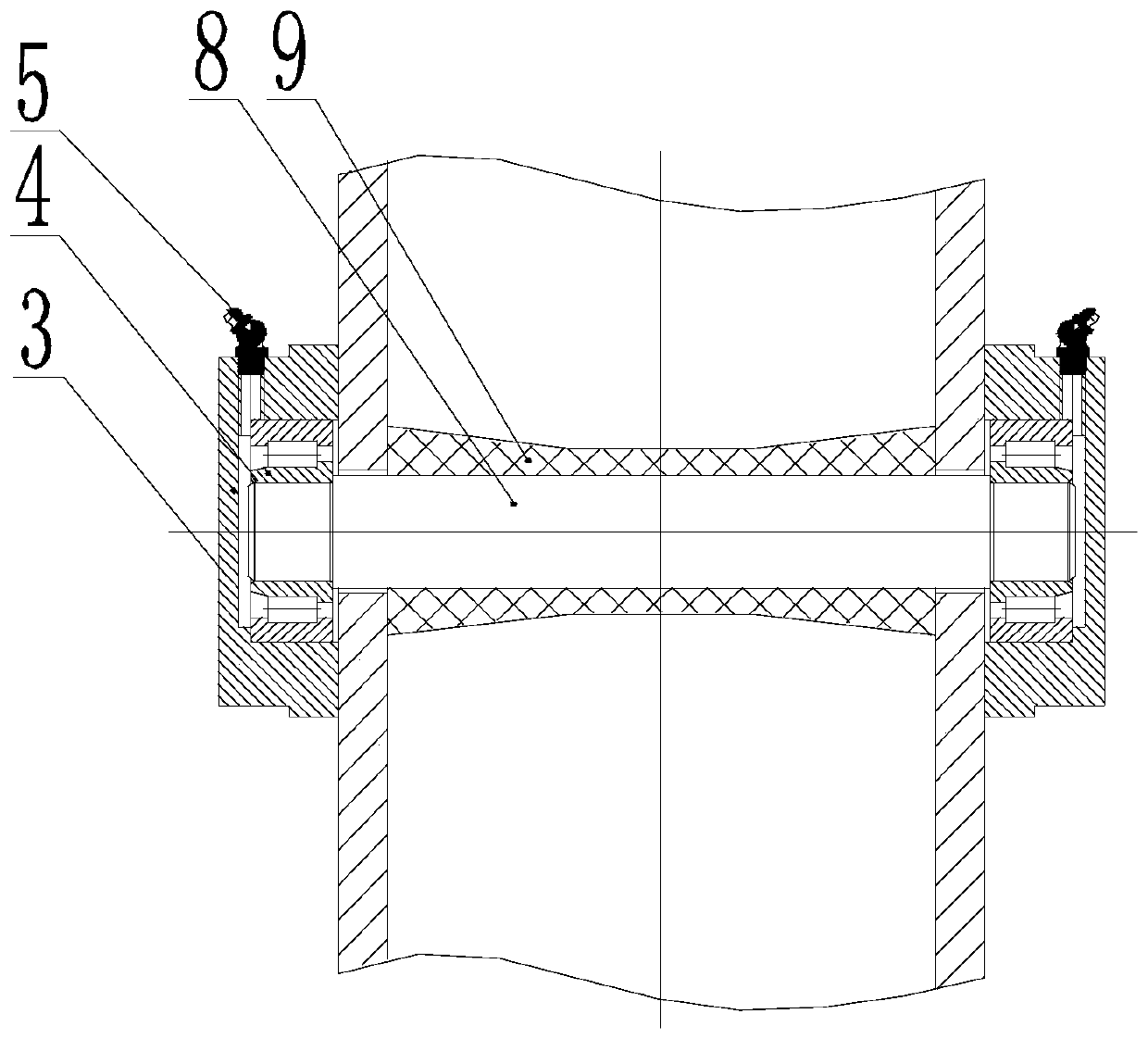

Adjustable mold for tyre molding vulcanizing machine

The invention provides an adjustable mold for a tyre molding vulcanizing machine. The adjustable mold comprises a lower chuck and an upper chuck, which are connected with a vulcanizing machine central mechanism; the lower chuck and the upper chuck are fixedly connected with a transition disc and an upper steel ring by bolts respectively; the lower chuck and the transition disc are used for clamping a clamping edge part of the bottom of a capsule; the clamping edge part at the top of the capsule is clamped by the upper chuck and the upper steel ring; a lower steel ring is arranged on the outer side of the transition disc; the edge of the bottom of the transition disc is matched with and in butt joint with the lower steel ring; and the lower steel ring is fixedly mounted on a lower side plate. The lower chuck is connected with the lower steel ring by the transition disc; the lower steel ring is directly and fixedly mounted on the lower side plate; the transition disc and the lower chuck are hoisted along with the vulcanizing machine central mechanism; firstly, the transition disc does not need to be detached when tyres with the same size and different specifications are vulcanized, and only the lower steel ring and the lower side plate need to be replaced; the operation is simple, the time and labor are saved and the utilization rate of workpieces is high; and secondly, the matched part of the lower steel ring and the lower side plate is intact and lossless, and the vulcanized tyres do not have the defects of rubber edges or bulges so that the quality of the tyres is guaranteed.

Owner:山东力创模具股份有限公司

Self-recovery anti-collision column

InactiveCN109518633AGuaranteed intactPrompt safe boundaryTraffic signalsRoad signsElastomerEnergy absorption

The invention discloses a self-recovery anti-collision column. The self-recovery anti-collision column comprises an anti-collision column body, an energy absorption base and a buried flange; wherein the buried flange is laid in the foundation, the energy absorption base is disassembly fixed on the buried flange, and the bottom of the anti-collision column body and the energy absorption base are detachably connected and fixed; when the anti-collision column body is hit, under the action of an elastomer hidden in the energy absorption base, the anti-collision column body can be tilted slightly within the preset angle range, the impact energy is gradually absorbed accordingly, and the buffering function is achieved; and after the impact, the anti-collision column can be recovered to the upright state automatically under the elastic action of the elastomer, and the fact that the anti-collision column body can be intact is ensured when the anti-collision column body is hit. The self-recovery anti-collision column adopts the split design, the cost of repair and maintenance installation is reduced, meanwhile, a reflective sticker on the anti-collision column body of the self-recovery anti-collision column can effectively prompt the safe boundary of driver driving at night, and the safety of gas station personnel and property is protected.

Owner:杨新

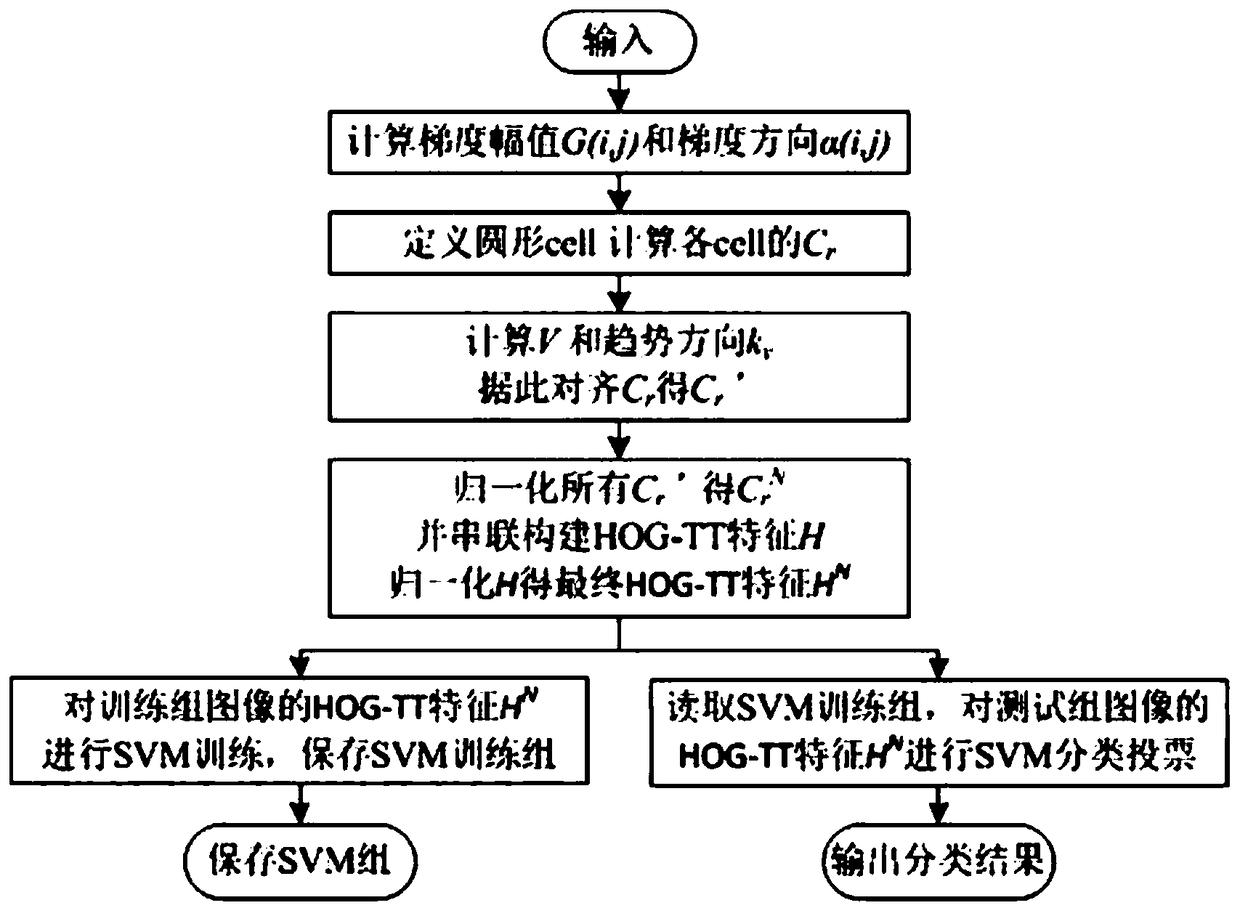

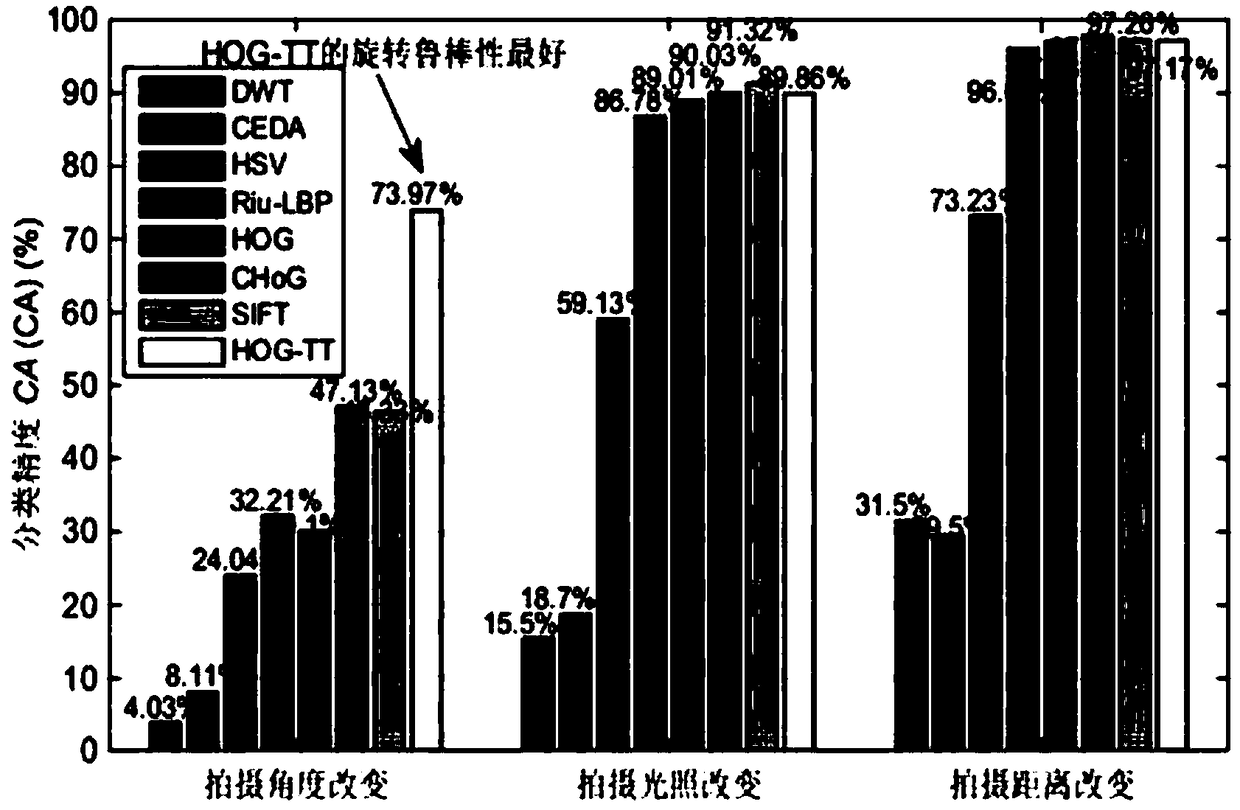

Improved gradient histogram feature extraction algorithm based on texture trend and its application method

InactiveCN109508723AEliminate the effects ofGuaranteed intactCharacter and pattern recognitionGradient directionScale invariance

The invention discloses an improved gradient histogram feature extraction algorithm based on texture trend and an application method thereof. Comprises the following five modules: (1) a gradient calculation module for extracting pixel point gradient amplitude and gradient direction; (2) a statistical module defining circular statistical units and performing directional gradient histogram statistics on each unit; 3) alignment module that extracts that texture trend, calculating the trend direction, and align the alignment module of the eigenvector of the unit according to the trend direction; (4) a construction model that connects unit eigenvector to construct HOG-TT feature; (5) a clasisification training module Using the trained SVM model group to analyze the input HOG-TT feature classification or HOG using training data-TT feature training SVM. The invention adds excellent rotation invariance on the premise of keeping HOG characteristic illumination and scale invariance, and reducesthe dimension of the characteristic according to the characteristic of the tire pattern image, and reduces the computational complexity.

Owner:XIAN UNIV OF POSTS & TELECOMM

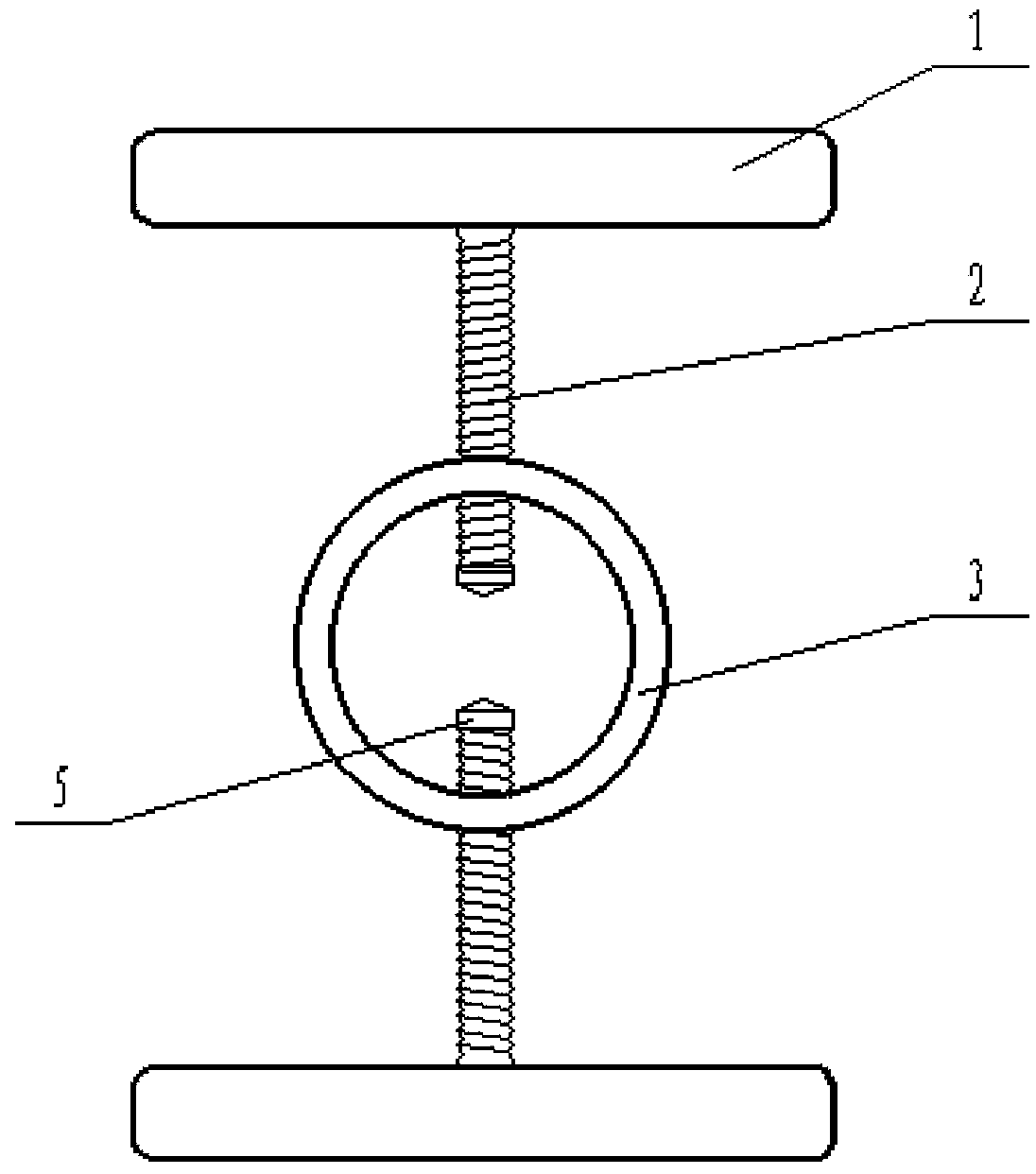

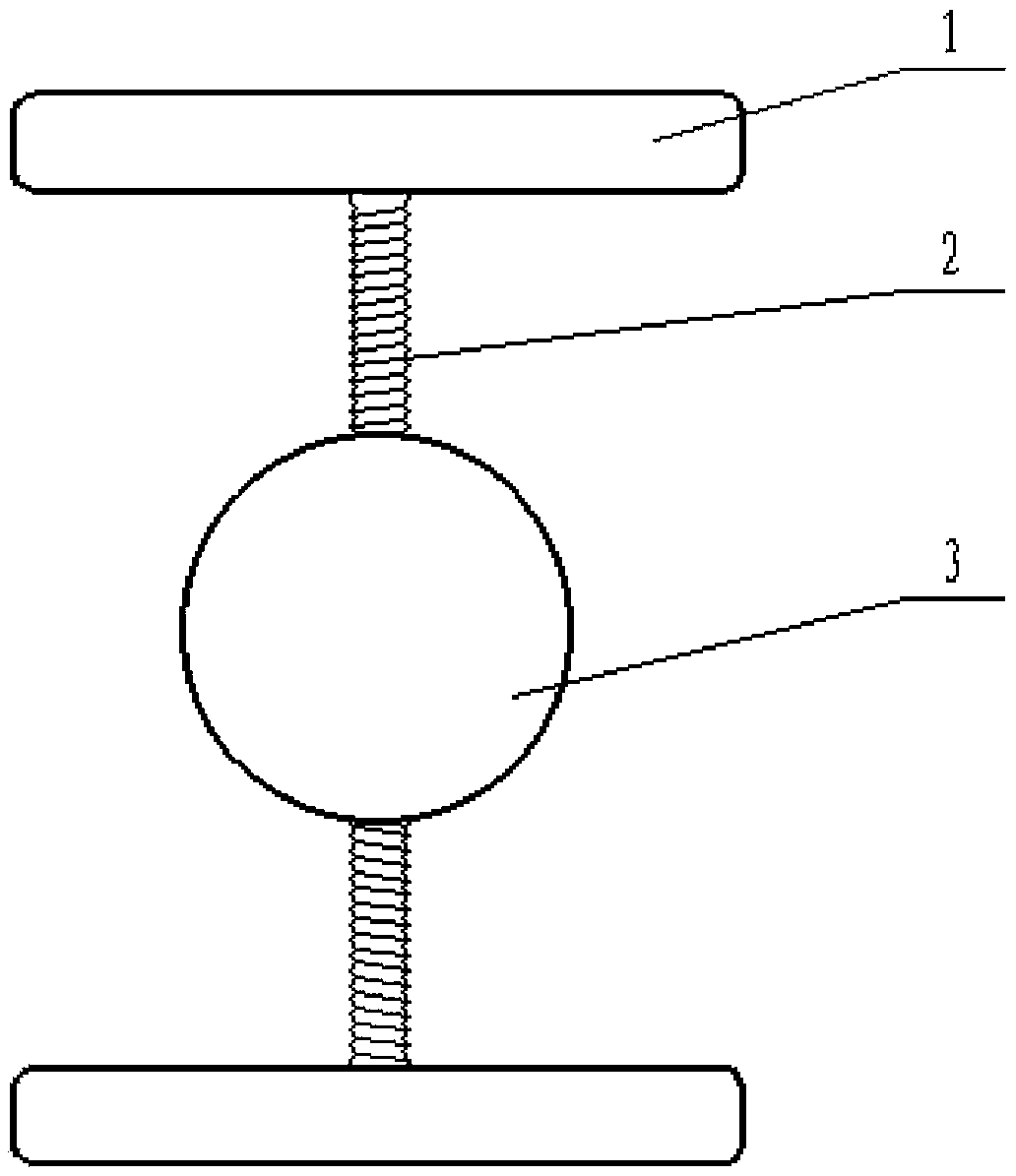

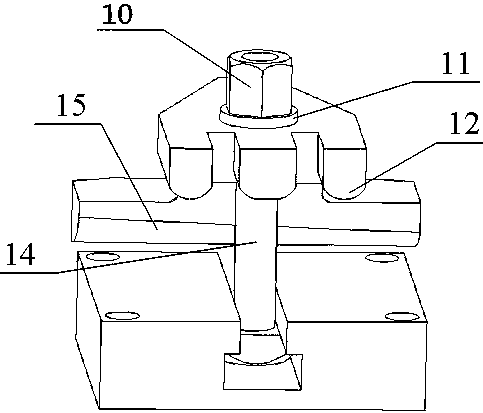

Nut shell breaking device

InactiveCN103989422AStrong shell breaking abilityGood effectKitchen equipmentEngineeringBreaking capacity

The invention discloses a nut shell breaking device which comprises a nut containing tank (3). Symmetrical threaded holes (4) are formed in the nut containing tank (3), a threaded rod (2) penetrates through the threaded holes (4) and stretches into the nut containing tank (3), one end of the threaded rod (2) is connected with a rotary knob handle (1), and the end, stretching into the nut containing tank (3), of the threaded rod (2) is connected with a shell breaking head (5). The nut shell breaking device has the advantages of being simple in structure, high in shell breaking capacity, safe and the like, integral and hygienic nuts can be obtained through the nut shell breaking device, and the nut shell breaking device is convenient to use.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

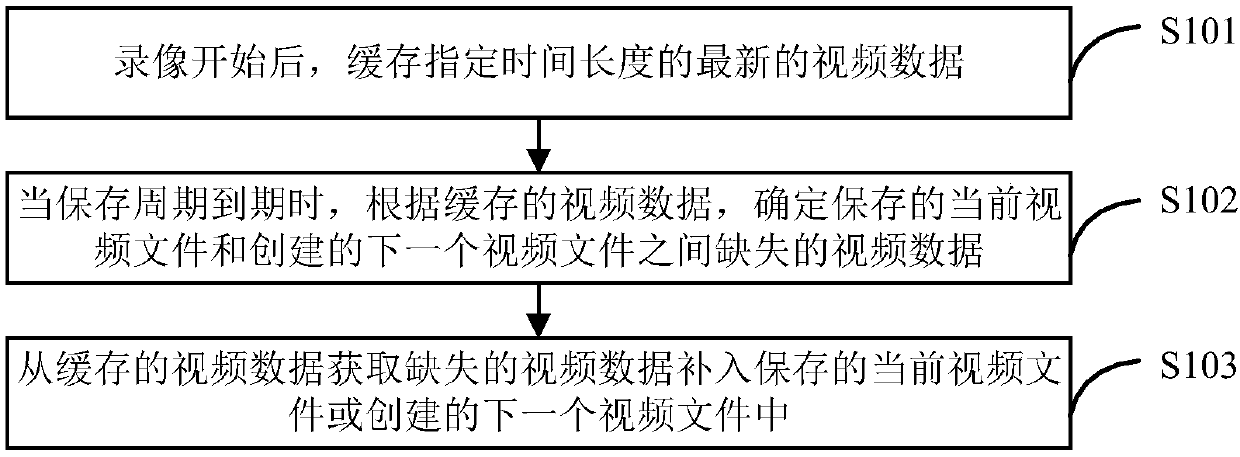

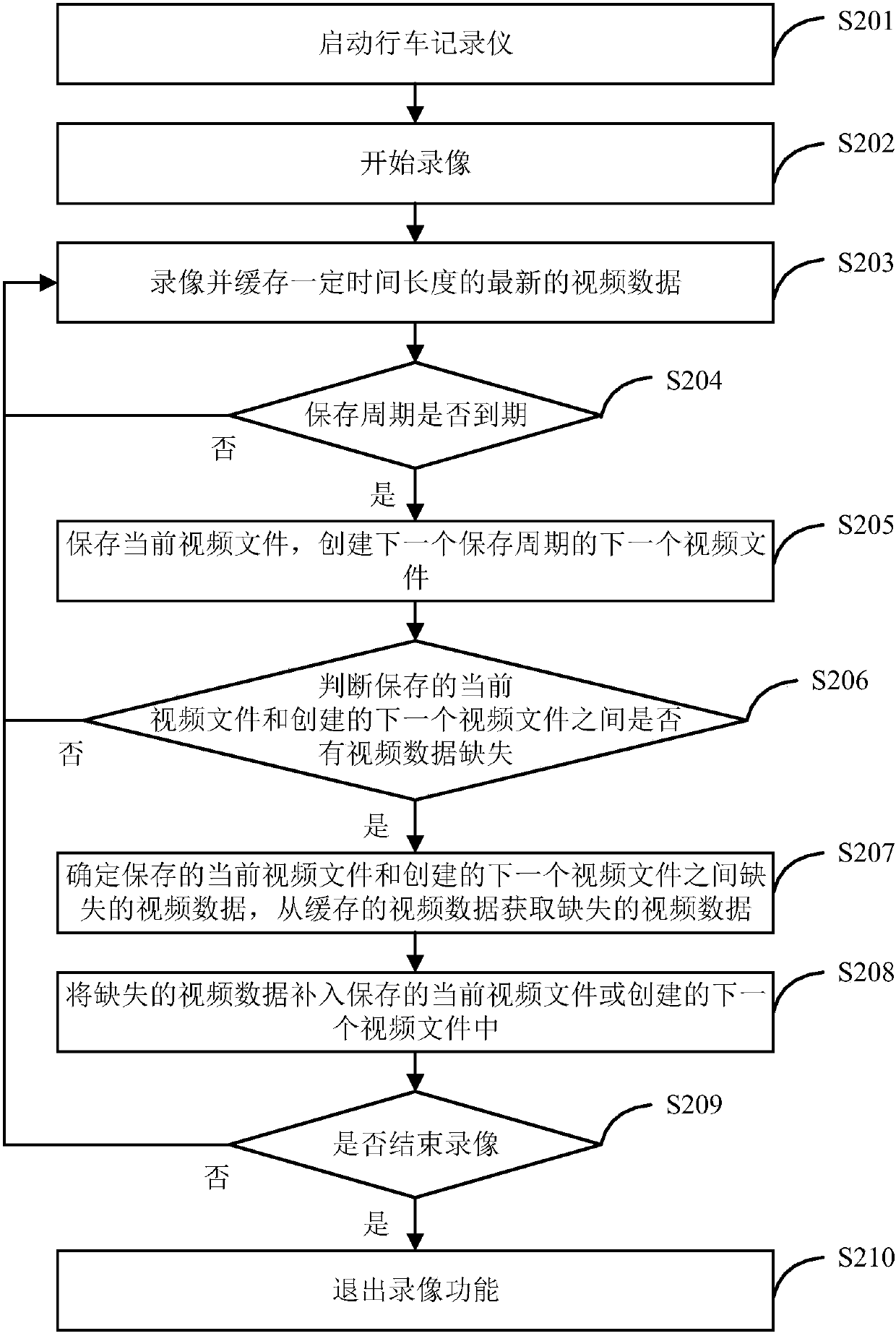

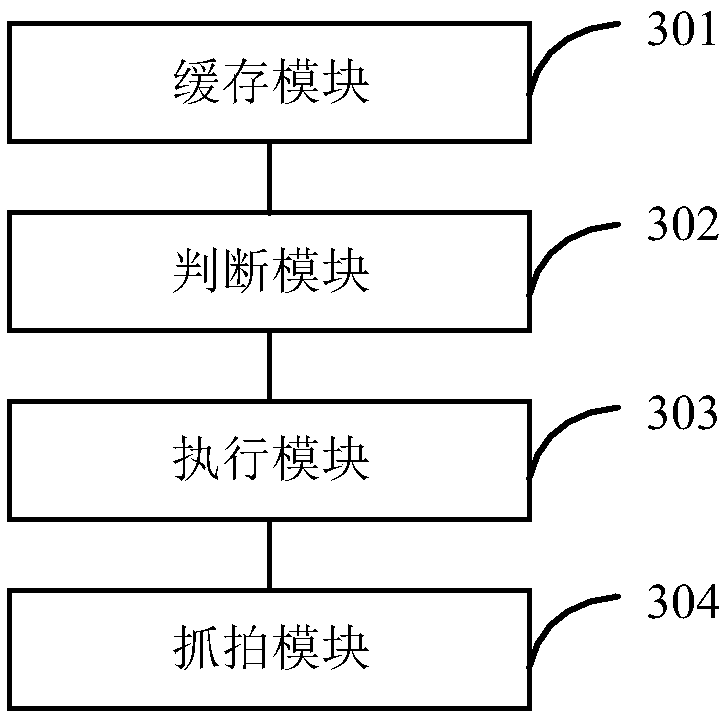

Video recording method, device and equipment

ActiveCN110324549AGuaranteed intactAvoid missingTelevision system detailsRegistering/indicating working of vehiclesElectricityComputer graphics (images)

The invention discloses a video recording method, device and equipment. The method comprises the following steps: after video recording is started, caching latest video data of a specified time length; when the storage period expires, determining missing video data between the stored current video file and the created next video file according to the cached video data; and acquiring missing videodata from the cached video data, and supplementing the missing video data into the stored current video file or the created next video file. According to the invention, the completeness of video recording in the driving process can be ensured, the lack of video recording is avoided, the equipment power consumption is not increased, and the effect of saving more electricity for equipment is achieved.

Owner:SHENYANG MXNAVI CO LTD

Artificial geochemical landscape museum

InactiveCN101634193AGuaranteed intactSolve ventilation and exhaust problemsMuseumsEngineeringTropics

The invention relates to an artificial geochemical landscape museum, belonging to the building field. A hall is respectively communicated with a tropical landscape hall, a temperate landscape hall, a cold zone polar landscape hall and a sea landscape hall; walls of the tropical landscape hall, the temperate landscape hall, the cold zone polar landscape hall and the sea landscape hall are cylindrical structures; the upper ends of the walls of the tropical landscape hall, the temperate landscape hall, the cold zone polar landscape hall and the sea landscape hall are semicircular roofs, the roofs are composed of semicircular top covers and semicircular ceilings, hollow layers are arranged between the top covers and the ceilings, minitype vent holes are evenly distributed on the ceilings, the top covers are provided with air vents communicated with the hollow layers, and the semicircular ceilings are in stable transition with the inner sides of the walls by a circular arc no matter the direction is longitudinal or transverse. The artificial geochemical landscape museum is applicable to actually displaying tropical landscape, temperate landscape, cold zone polar landscape and sea landscape, and has good ventilation.

Owner:刘敬昌

Efficient artificial seed extraction method of litchi cross bred fruits

InactiveCN106961879AGuaranteed intactVitality is not affectedSeed and root treatmentFruit stoningComparative testEconomic benefits

The invention provides an efficient artificial seed extraction method of litchi cross bred fruits. The method comprises the following steps: collecting mature litchi fruits; fixing the fruits, glidingly cutting from the middle of a litchi fruit to the middle of the other side of the litchi fruit through a cutter, so as to form a cut around half of the fruit; thirdly, separating a peel with flesh at the cut at the bottom of the fruit, and taking out a seed. According to the method, a comparative test is performed through cutters, such as a paper cutter or a fruit knife, the effect that the fruit is cut and the seed is taken out through a surgical knife handle with a surgical knife blade is achieved, the effect is best, and the efficiency is the highest. Fruit cutting and fruit peeling are performed separated, and flow process is performed. The seed extraction efficiency of the litchi cross bred fruits is improved. The method has the advantages that the peel and the fresh are separated completely so as to be processed and utilized after seeds of the litchi cross bred fruits are extracted, and economic benefit is obtained while the seed extraction efficiency of the cross bred fruits is improved.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

Chuck used for optical fiber joints

ActiveCN101158736APrevent rotationGuaranteed intactCoupling light guidesEngineeringOptical fiber connector

The invention discloses a collet applied for an optical fiber connector. The collet consists of a body with an optical fiber hole, and one end of the body is separated into at least two lock clamps by a lock groove, the surface of the lock clamp is a helicoid which is the helicoid with equal conicity. The other end of the cylinder body is provided with a rear part, and the center of the rear part is also provided with an optical fiber hole. Compared with the prior art, the collet of the invention is provided with at least two lock clamps in the front of the body, the surfaces of the lock clamps are helicoids, and a trap step is formed among the lock clamps. When the collet of the invention is arranged in the optical fiber connector, the helicoid in the front of the collet and a tapering step helicoid in a sleeve of the optical fiber connector rotate, and the two helicoids are engaged with each other automatically, thus effectively preventing the rotation caused during the connection process of the optical fiber; simultaneously, the optical fiber hole in the collet is has the guiding function, thus ensuring the surface of the optical fiber to be undamaged during the connection process. On the other hand, the invention avoids the manual intervention and is favorable for implementing the micromation of the whole structure.

Owner:JIANGSU UNIKIT OPTICAL TECH

Floating seedling raising method in fine comparison of tobacco gene editing material strains

PendingCN113016547AEasy to traceSeedlings in orderTobacco cultivationCultivating equipmentsBiotechnologyGrowth plant

The invention relates to a floating seedling raising method in fine comparison of tobacco gene editing material strains. Seedling raising holes of a seedling tray are covered with non-woven fabric, and the non-woven fabric can effectively avoid the situation that root systems are damaged due to adhesion of a matrix and the seedling tray (or dispersion of the matrix) during transplanting and seedling pulling, so that the root systems of transplanted tobacco seedlings are kept complete. The non-woven fabric used in the method is a polylactic acid material, can be degraded in soil after being transplanted, is free of harmful degradation product residues after being degraded, and is safe and environmentally friendly. Compared with common field production, the method has the advantages that fine screening of edited materials has higher requirements for uniformity of planting growth vigor, the growth vigor is uniform and neat, errors caused by inconsistent growth and development can be reduced to the greatest extent, and the efficacy of genes is highlighted.

Owner:CHINA TOBACCO YUNNAN IND

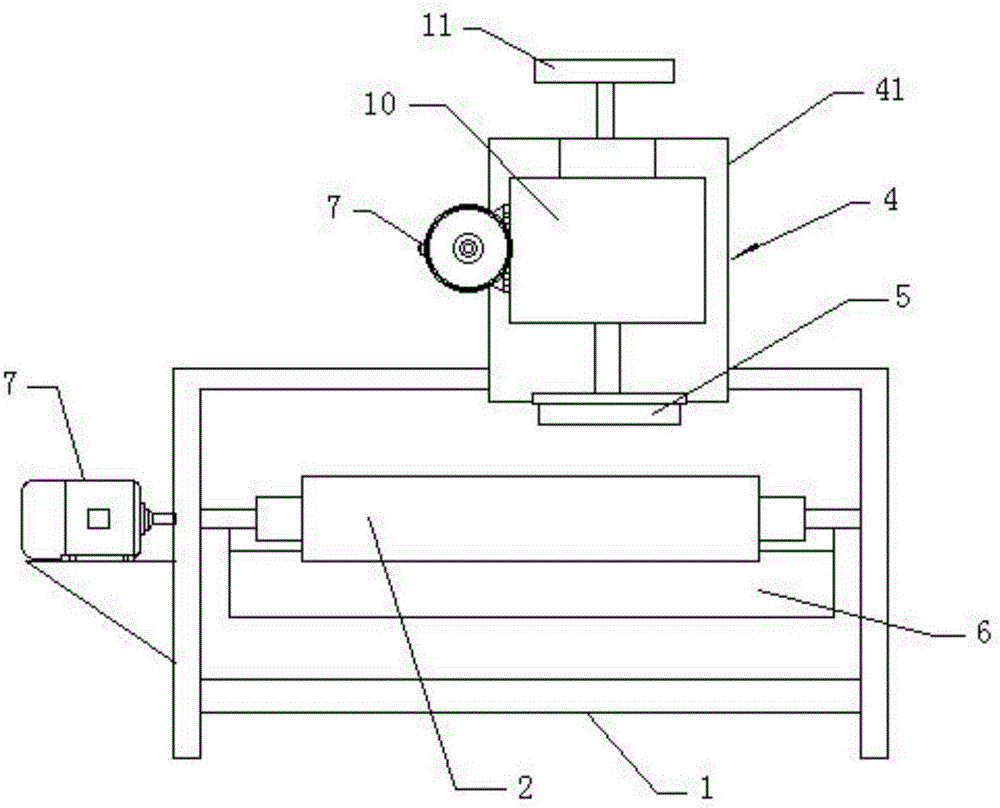

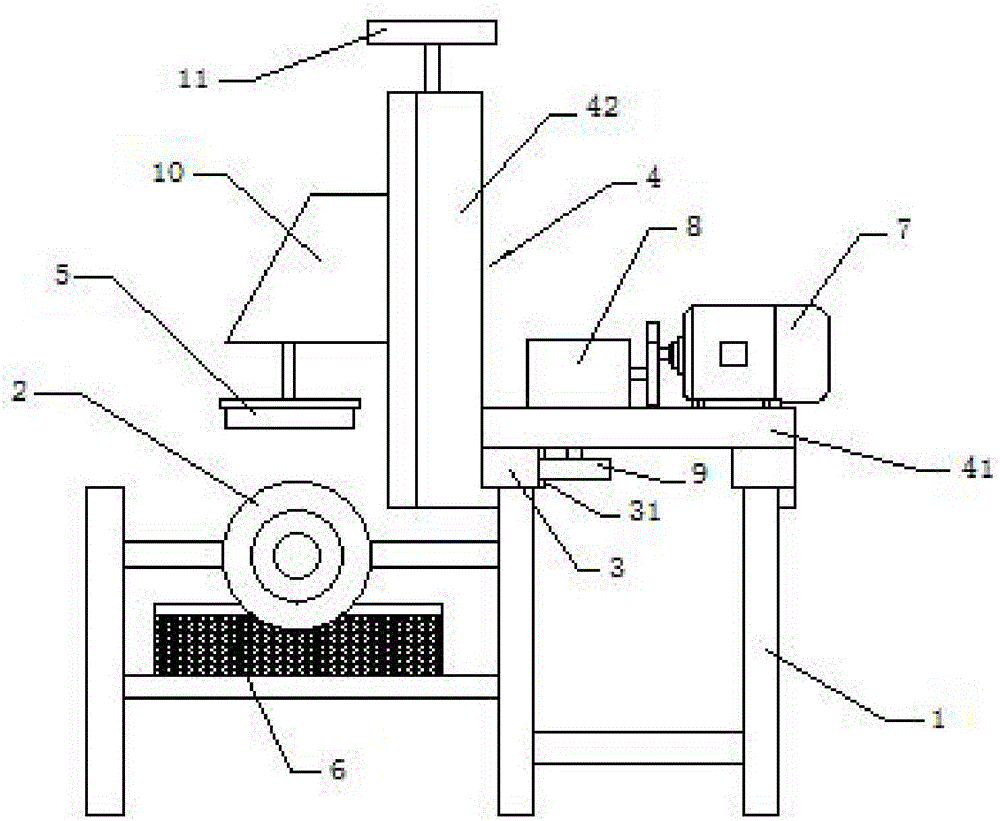

Surface grinding device for nickel mesh core die production

InactiveCN106695531AHeight adjustableGuaranteed intactGrinding carriagesGrinding drivesMotor driveGrinding wheel

The invention discloses a surface grinding device for nickel mesh core die production and relates to the technical field of nickel mesh production. The surface grinding device comprises a rack, the rack is rotatably provided with a core die and slidably provided with a grinding wheel, the sliding direction of the grinding wheel is parallel to the axial direction of the core die, the position of the grinding wheel corresponds to that of the core die, a grinding fluid tank is formed below the core die, and the core die and the grinding wheel are in transmission connection with a motor correspondingly. The motor drives the grinding wheel to rotate to grind the surface of the core die, and in the grinding process, the core die is rotated under the drive of the motor; meanwhile, the grinding wheel moves in the direction parallel to the axial direction of the core die, so that the surface of the whole die core is uniformly ground; the grinding fluid tank is formed below the core die, certain grinding and heat dissipation functions are achieved, and the grinding effect is guaranteed; and it is guaranteed that glue is complete in mesh points, a bridge line and the diameter face are straight, a hand wheel is arranged, the surface grinding device is convenient to use, and grinding quality and efficiency are improved.

Owner:湖北海富镍网科技股份有限公司

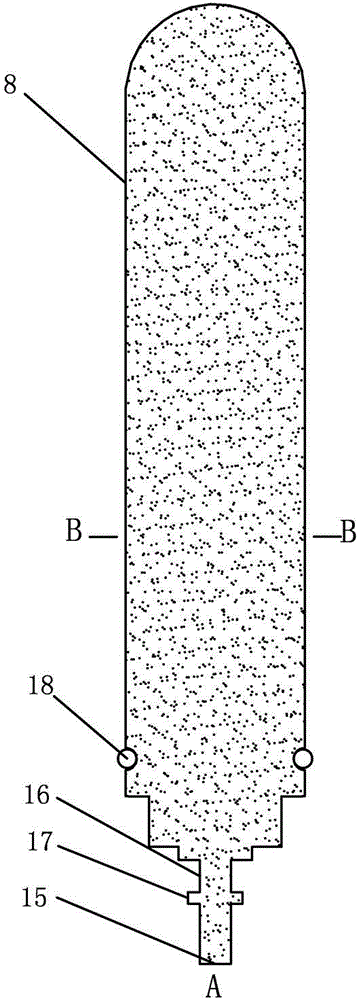

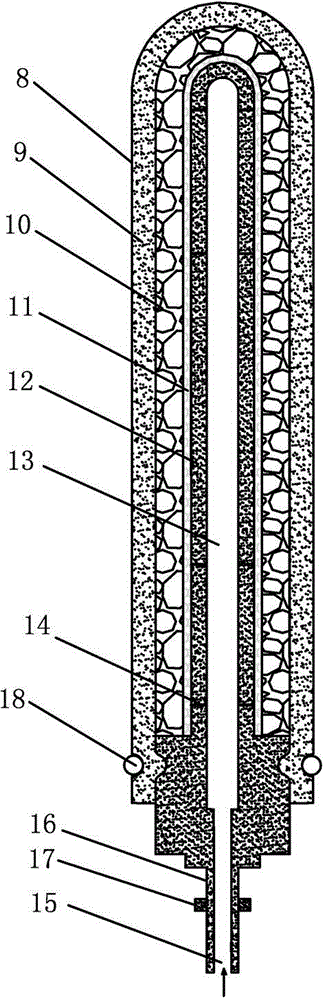

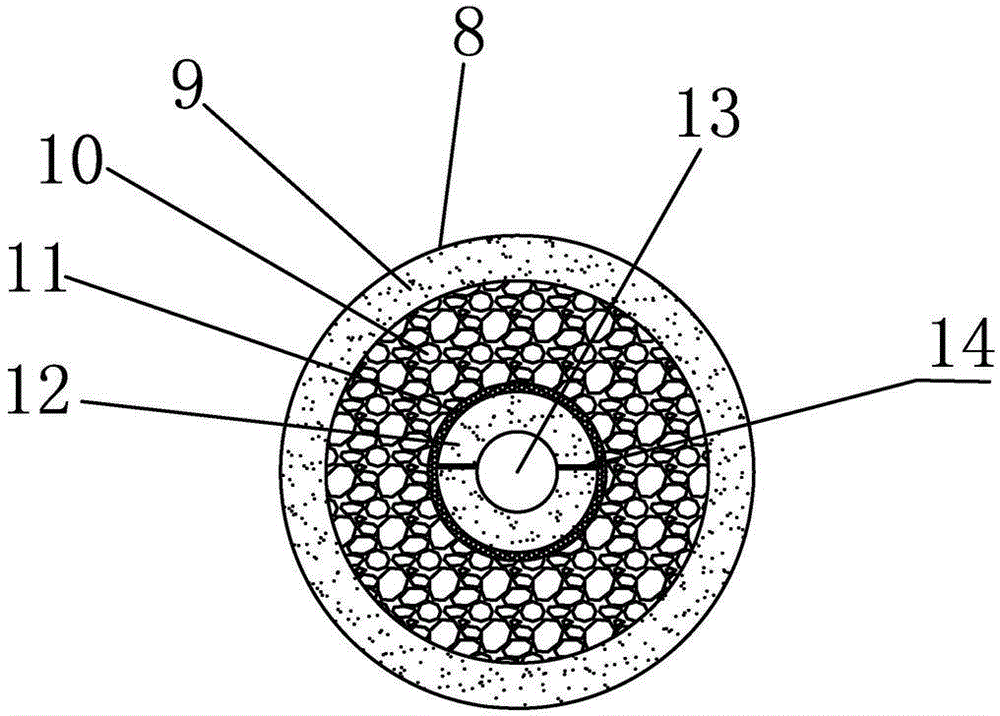

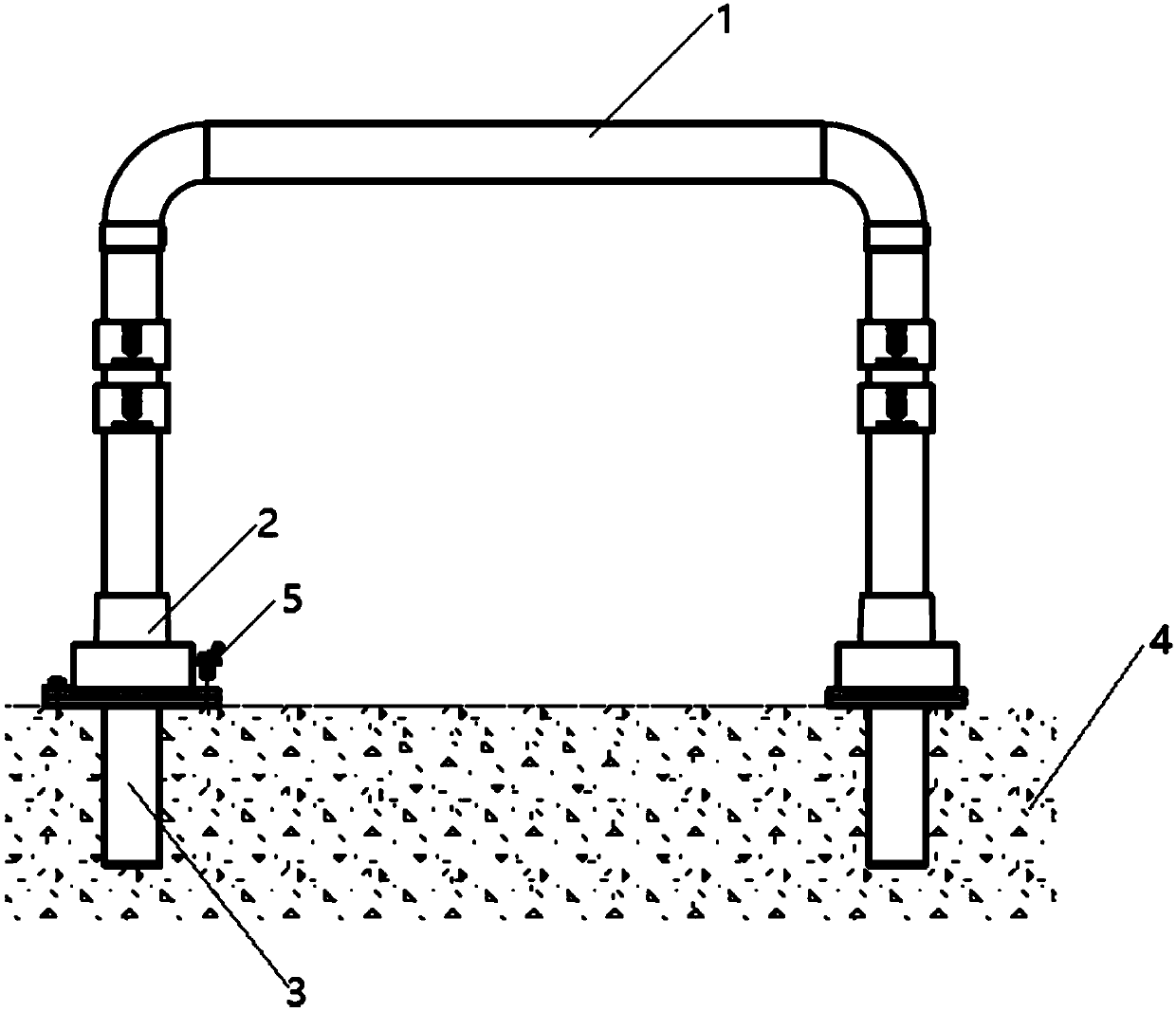

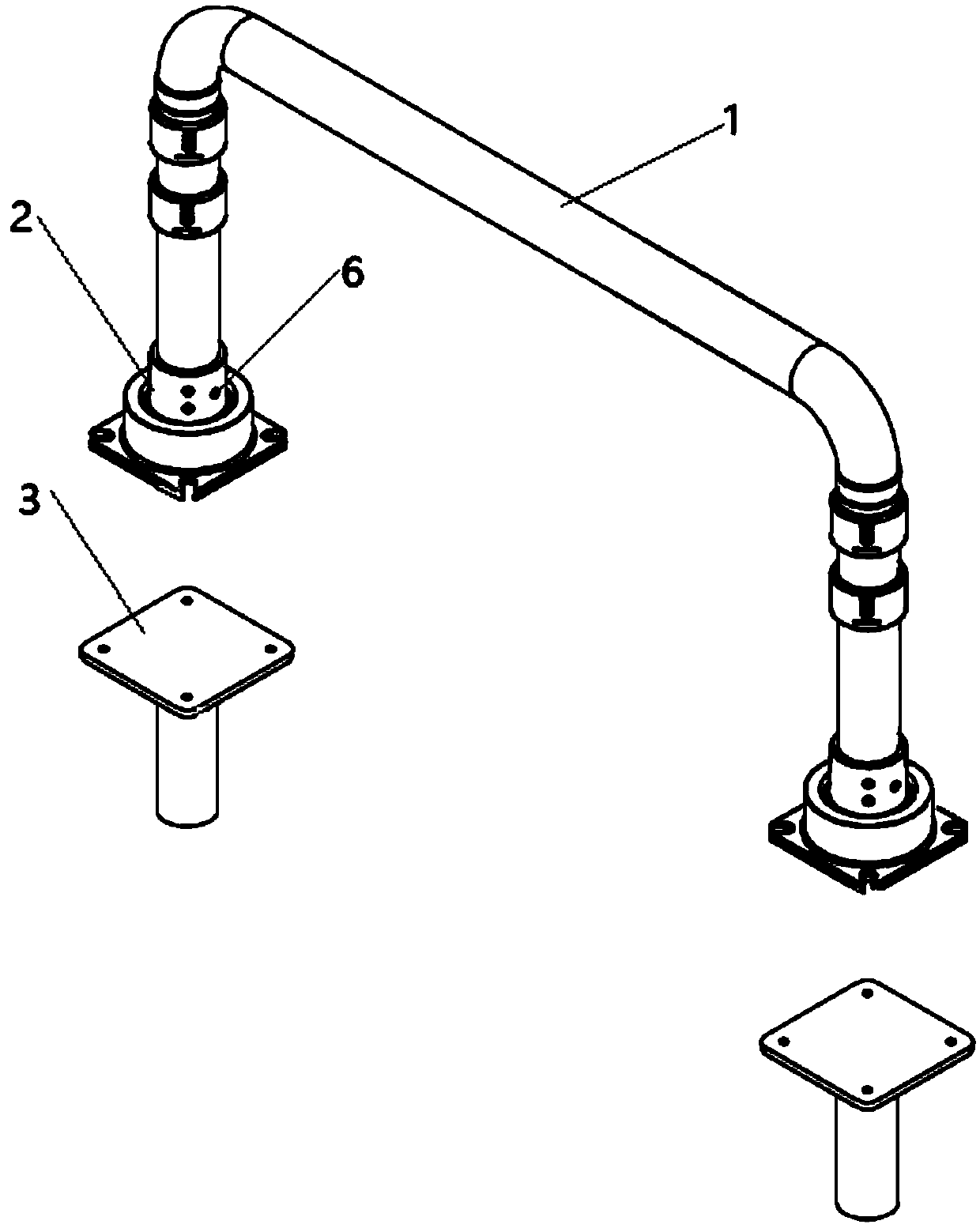

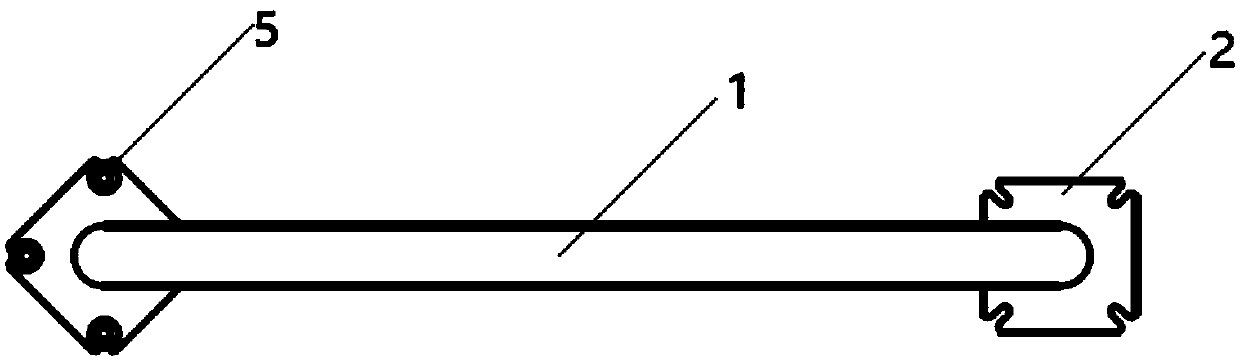

Convenient-to-dehumidify suspension cable protective structure

ActiveCN109653091ANot corrodedExtended service lifeBridge structural detailsBridge materialsEngineeringMechanical engineering

The invention discloses convenient-to-dehumidify suspension cable protective structure, which comprises an upper end anchorage component, a lower end anchorage component and a cable. The upper end anchorage component comprises an upper anchorage cup and an upper end connection barrel; the lower end anchorage component comprises a lower anchorage cup and a lower end connection barrel; the upper anchorage cup is internally provided with an air inlet reserved space; the lower anchorage cup is internally provided with an air outlet reserved space. The convenient-to-dehumidify suspension cable protective structure comprises an air inlet pipe, an air inlet passage, an air outlet passage and an air outlet pipe. The air inlet pipe is inserted into the air inlet reserved space; one end of the air inlet pipe is communicated with the interior of the air inlet reserved space while the other end is communicated to the top end of a PE protective sleeve; the air outlet pipe is inserted into the air outlet reserved space; one end of the air outlet pipe is communicated with the interior of the air outlet reserved space while the other end is communicated to the bottom end of the PE protective sleeve. By feeding of clean and dry air into a suspension cable, an internal durable dry environment of the suspension cable is constantly kept, and parallel steel wires in the suspension cable are protected from corrosion, so that the service life of the cable is prolonged effectively.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

A robotic leg that adapts to multiple terrains

The invention relates to the field of intelligent machine technology, and discloses a mechanical leg capable of adapting to various terrains. The mechanical leg capable of adapting to various terrainscomprises a robot waist, the bottom of the inner cavity of the robot waist is fixedly connected with a driving motor, and the bottom of the inner cavity of the robot waist is fixedly connected with afixed block and the fixed block is located at the top of the driving motor, and one end of the driving motor is fixedly sleeved with a rotating shaft, and the rotating shaft penetrates to the outer side of the robot waist, and one end of the rotating shaft is threaded with a threaded cap, the middle portion of the rotating shaft is sleeved with a moving rod. The mechanical leg capable of adaptingto various terrains has the advantages that the cooperation of the heat dissipating device and the robot thigh facilitates lowers the temperature of the machine surface and ensures the integrity of the machine components, thereby solving the problem that the robot temperature is too high, resulting in internal components damage, the machine explosion and causing casualties, and improving the safety of the robot.

Owner:安徽策达科技有限公司

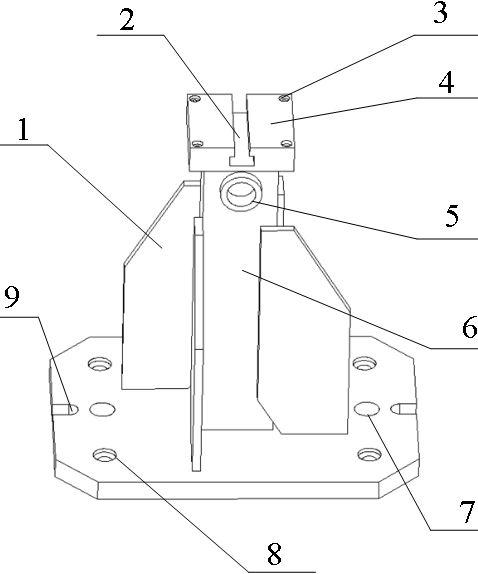

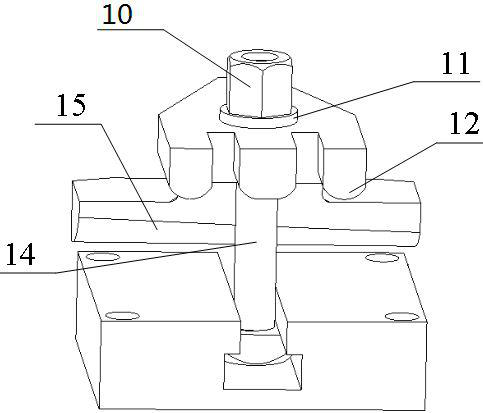

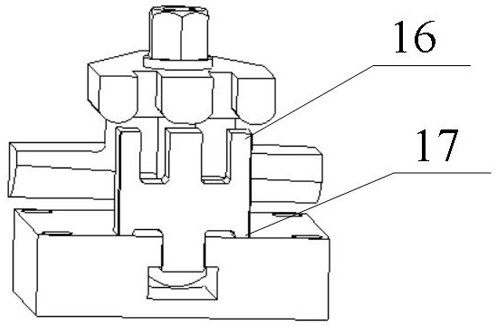

Six-surface part numerical control machining tool

ActiveCN109702514AGuarantee processing qualityImprove pass rateAutomatic control devicesMeasurement/indication equipmentsNumerical controlEngineering

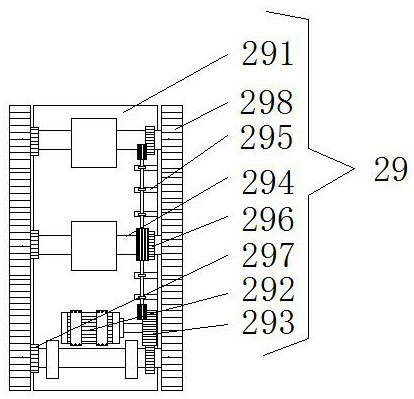

The invention discloses a six-surface part numerical control machining tool. The six-surface part numerical control machining tool comprises a tool base and a tool pressing mechanism; the tool base comprises a tool support frame, and a part mounting positioning plate arranged at the top of the tool support frame; a transverse T-shaped groove is formed in the top of the part mounting positioning plate; the bottom of the tool pressing mechanism is mounted in the T-shaped groove; and the tool support frame is provided with a cutter checking block placing hole for mounting a cutter checking block.Through arrangement of the machining tool, the need of multiple tools for multiple times of clamping in the six-surface part machining is solved, the machining of six-surface parts is realized through twice clamping, errors caused by multiple times of clamping are reduced, the machining quality of the parts is improved, and the machining efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

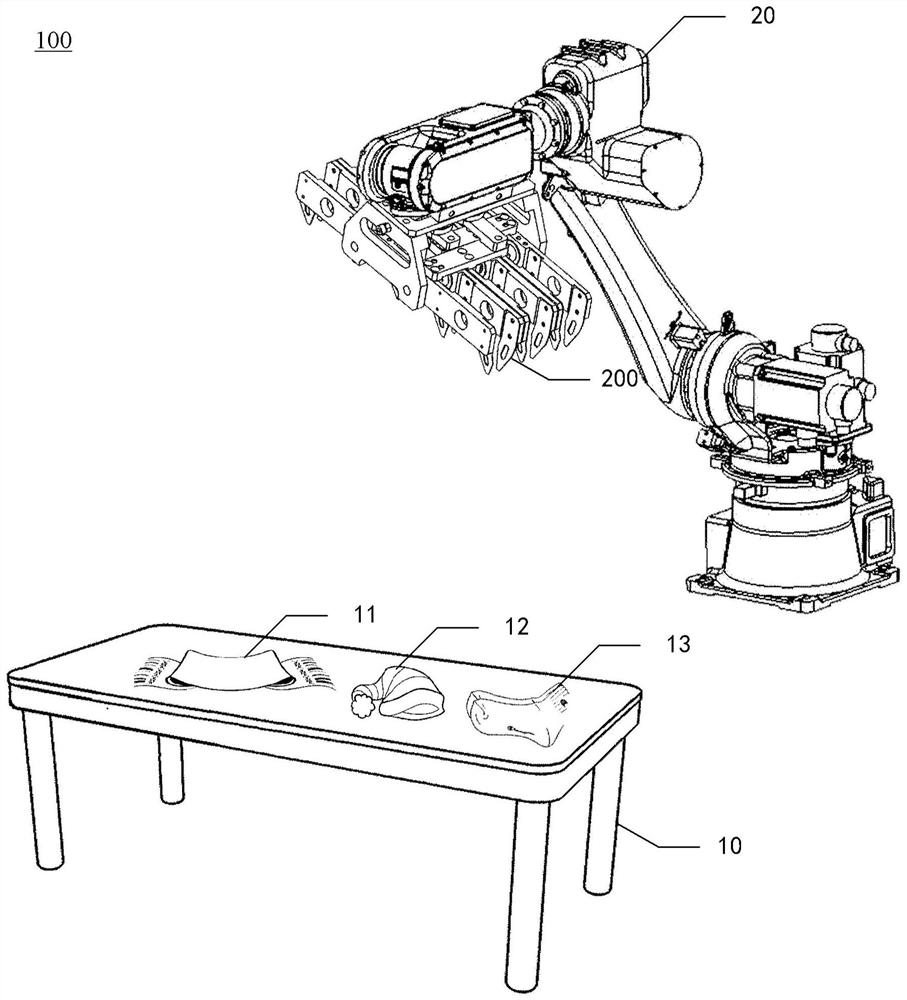

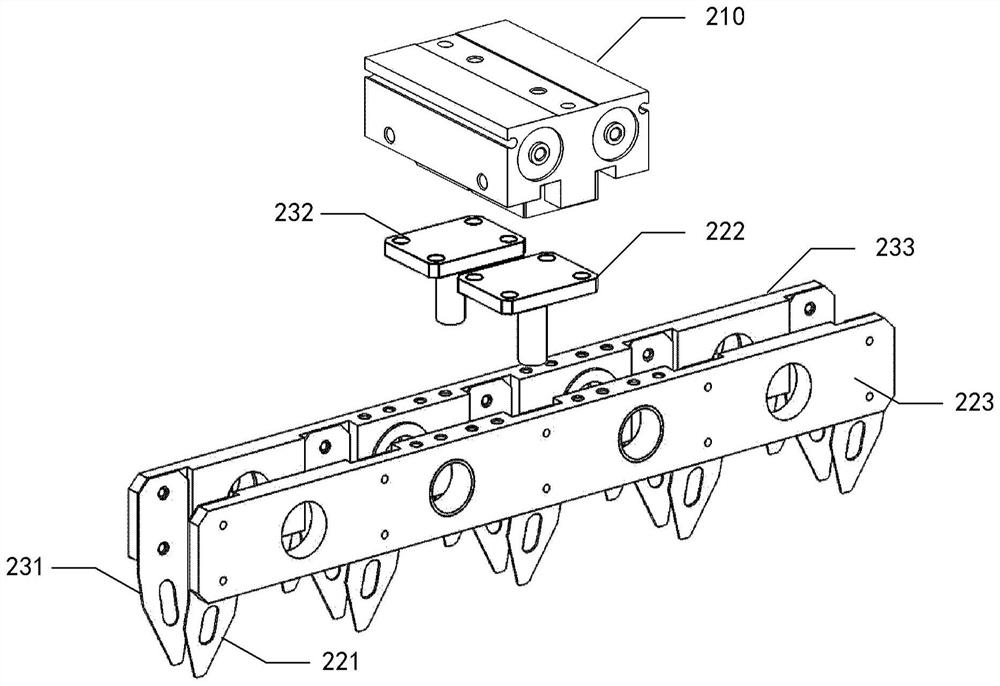

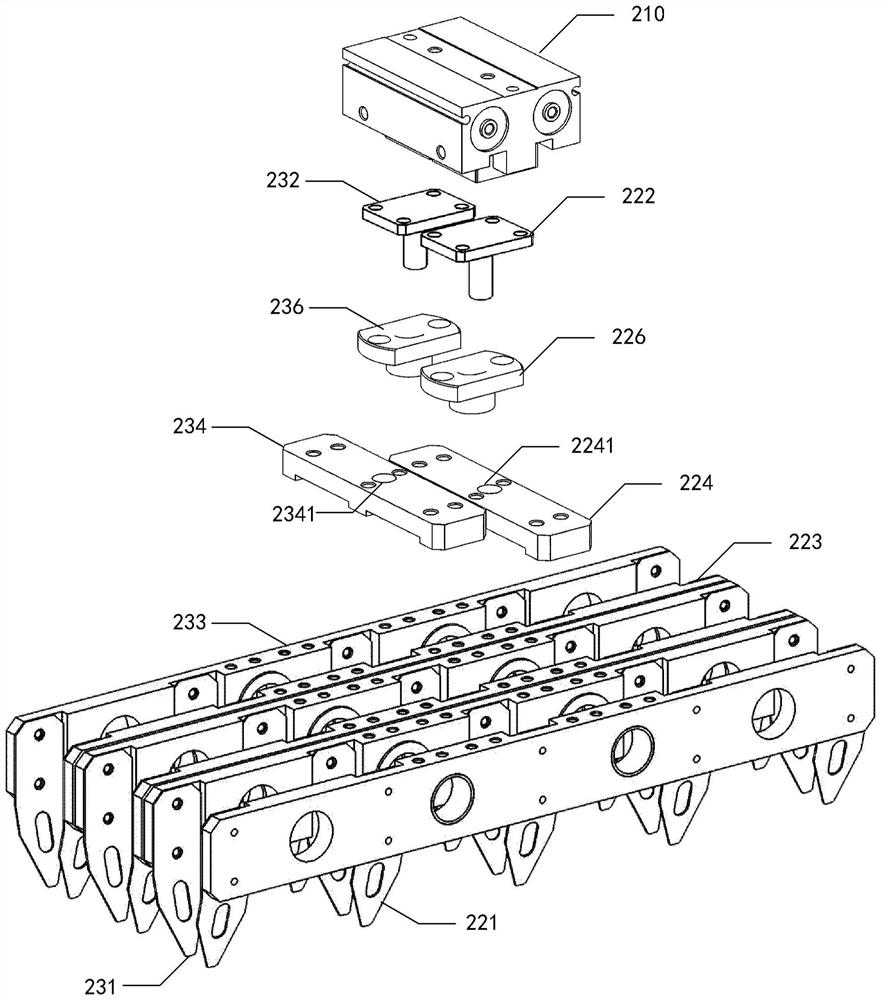

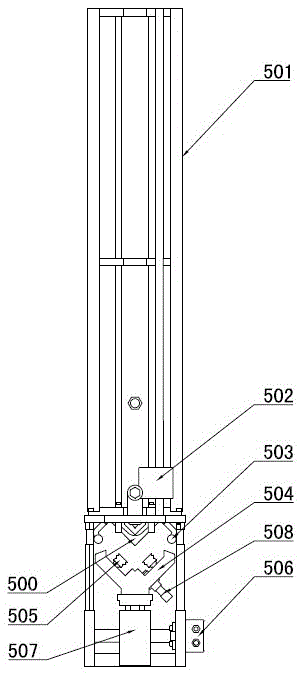

Robot gripper and robot

PendingCN111618887AAvoidance of technical defects that damage the appearance of the grasped objectGuaranteed intactGripping headsMechanical engineeringRoboty

The invention provides a robot gripper and a robot. The robot gripper comprises a drive piece and two clamping mechanisms. The drive piece comprises two output ends capable of moving relatively. One ends of the two clamping mechanisms are connected with the two output ends of the drive piece correspondingly, and the other ends are provided with a sheet first clamping piece and a sheet second clamping piece in an extending manner, wherein the first clamping piece and the second clamping piece are perpendicular to the two output ends. The first clamping piece and the second clamping piece are oppositely arranged. The two clamping mechanisms can move towards or away from each other under driving of the two output ends so that objects can be clamped or thrown through the first clamping piece and the second clamping piece which are oppositely arranged.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

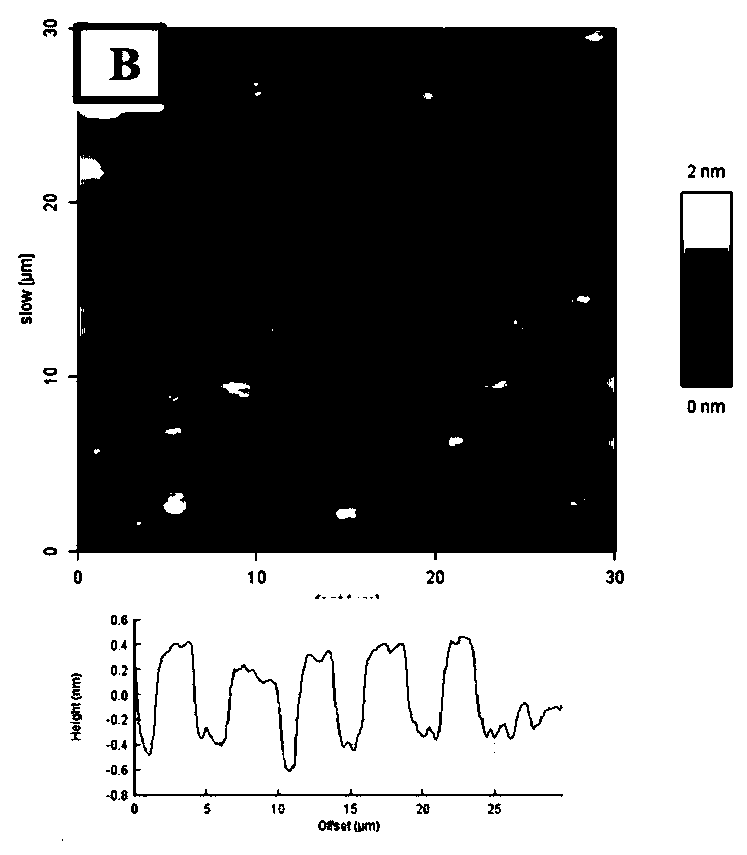

A Fluorescence Detection Method of Amphiphilic Monolayer Molecular Film

ActiveCN106959287BGuaranteed intactThe test result is accurateFluorescence/phosphorescenceFluorescence microscopeCover glass

The invention belongs to the technical field of fluorescence detection and particularly relates to a fluorescence detection method for an amphiphilic single-layer molecular film. A single-layer film transferred to an ultrathin mica sheet is adsorbed to cover glass containing water in surface through film making, film formation employing a vertical film lifting method and fluorescence detection after dripping adsorption, the surface tension of the water and the transparency are skillfully utilized to nondestructively test the molecular film on the ultrathin mica sheet, the damage to the film is avoided, the undamaged film is ensured, further operations such as atomic force microscope observation are facilitated and the accurate detection result is ensured. The mica sheet can be easily separated from the cover glass through tweezers after fluorescence microscope detection is completed and the cleaned cover glass can still be repeatedly used, so that the detection cost is reduced. Furthermore, the detection method is clear in detection result, relatively low in cost, nontoxic, free of pollution and suitable for large-scale popularization and application.

Owner:SHAANXI NORMAL UNIV

A production process of stainless steel lattice friction plate

Owner:嵊州市迪凯电子有限公司

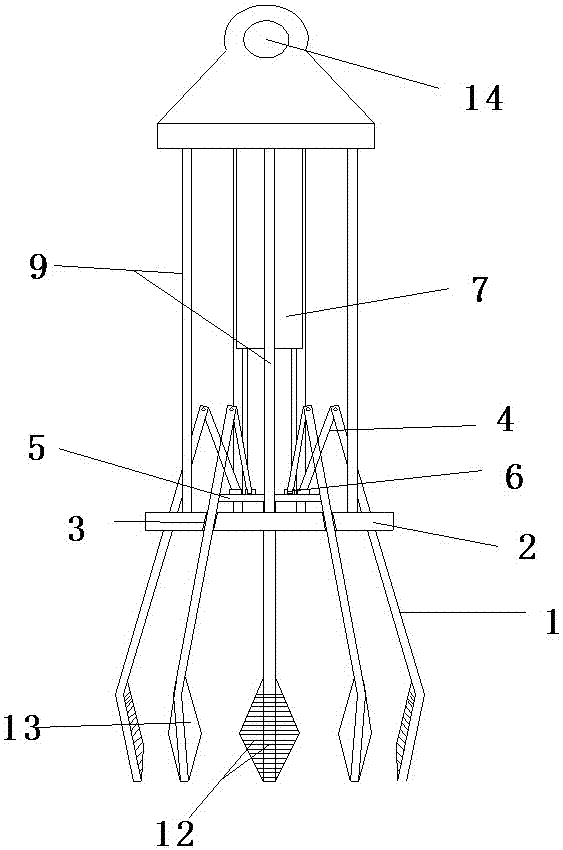

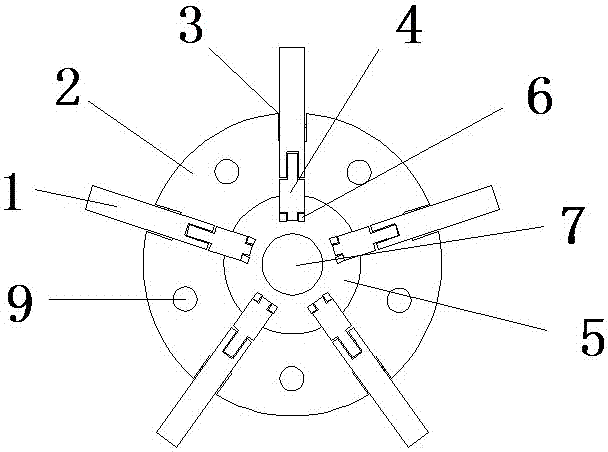

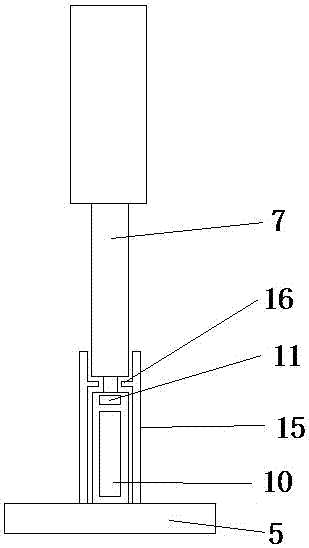

Quick grabbing mechanism of mechanical parts

The invention discloses a fast grabbing mechanism for mechanical parts, which includes a grabbing arm, a fixed circular plate is arranged in the middle of the grabbing arm, the grabbing arm is arranged on the edge of the fixed circular plate, and a position corresponding to the edge of the circular plate and the grabbing arm is arranged Groove, the middle part of the grasping arm is set in the groove and is flexibly connected, the top of the grasping arm is provided with a connecting plate, the bottom of the connecting plate is provided with a movable circular plate, the upper edge of the movable circular plate is provided with a card slot, and one end of the connecting plate is connected to the The top of the grasping arm is flexibly connected, and the other end of the connecting plate is flexibly connected to the card slot. There is a telescopic rod in the middle of the top of the movable circular plate, a base is provided on the top of the telescopic rod, and several fixed round rods are arranged between the base and the fixed circular plate. The rod is arranged between every two adjacent grooves and fixed on the fixed circular plate, and a spring force measuring device is arranged between the telescopic rod and the movable circular plate. The beneficial effect is that the structure is simple, the application range is wide, the grasping force can be adjusted, and the surface of the parts is guaranteed to be complete without damage.

Owner:陈炳林

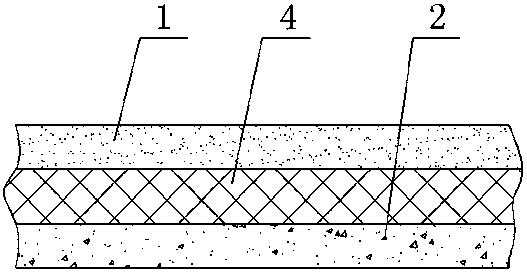

Magnetic mosaic tile

The invention relates to a magnetic mosaic tile, which comprises a mosaic tile body. A magnetic material layer is further fixed at the bottom of the mosaic tile body. Both the mosaic tile body and the magnetic material layer are connected in a frame in a clamped manner. The magnetic material layer is made of optional one of magnets, electric steel, nickel base alloy and rare earth alloy. The magnetic mosaic tile is specially designed for a steel / iron exterior wall, is sucked on the exterior wall via the magnetic material layer, and can be quickly mounted and replaced at any time. In addition, the mosaic tile body is not damaged when the magnetic mosaic tile is detached, the magnetic mosaic tile can be reused, the service life of the magnetic mosaic tile is prolonged, waste to materials is reduced, and cost is saved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

A CNC machining tool for six-sided parts

ActiveCN109702514BGuarantee processing qualityImprove pass rateAutomatic control devicesMeasurement/indication equipmentsNumerical controlMachine tool

The invention discloses a six-surface part numerical control machining tool. The six-surface part numerical control machining tool comprises a tool base and a tool pressing mechanism; the tool base comprises a tool support frame, and a part mounting positioning plate arranged at the top of the tool support frame; a transverse T-shaped groove is formed in the top of the part mounting positioning plate; the bottom of the tool pressing mechanism is mounted in the T-shaped groove; and the tool support frame is provided with a cutter checking block placing hole for mounting a cutter checking block.Through arrangement of the machining tool, the need of multiple tools for multiple times of clamping in the six-surface part machining is solved, the machining of six-surface parts is realized through twice clamping, errors caused by multiple times of clamping are reduced, the machining quality of the parts is improved, and the machining efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Carbon fiber continuous flexible sucker rod operating equipment

ActiveCN106285504BGuaranteed intactNo plastic deformationDrilling rodsDrilling casingsFiberStress concentration

The invention provides carbon fiber flexible continuous sucker rod operation equipment which comprises two arc-shaped plates arranged in parallel. A bottom plate is fixed between the two ends of each arc-shaped plate, supporting plates are fixed between each bottom plate and the corresponding arc-shaped plate, and rotating shafts are evenly arranged between the two arc-shaped plates at intervals. The outer walls of the rotating shafts are sleeved with rubber sleeves with the arc-shaped surfaces. A support is hinged to one ends of the two arc-shaped plates, and adjusting screws are connected to the lower ends of two supporting rods of the support correspondingly. The other ends of the two arc-shaped plates are fixedly connected with an operation frame which is inserted into a rotating base, and the rotating base is mounted on the well mouth. By means of the operation equipment, it can be guaranteed that a carbon fiber flexible continuous sucker rod can be smoothly taken off, stress concentration caused by mechanical abrasion on the carbon fiber flexible continuous sucker rod operation equipment is avoided, and the service life of the equipment is prolonged; and by the adoption of the equipment, the carbon fiber flexible continuous sucker rod is protected against plastic deformation during operation, and normal use of the carbon fiber flexible continuous sucker rod operation equipment is guaranteed.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

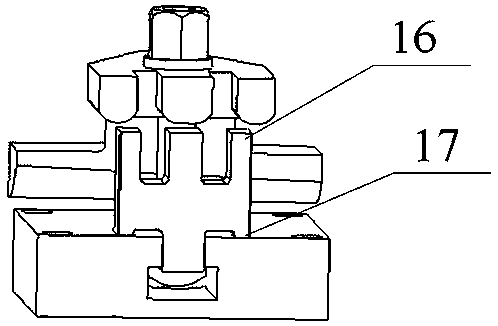

Quick release device for hexagon socket bolts

The invention relates to the technical field of device disassembling and assembling, and provides an inside hexagonal bolt quick disassembling device which comprises a sleeve and a handle. One end of the sleeve serves as a force appliance end, and the other end of the sleeve serves as a fastening end. The handle is installed at the force appliance end of the sleeve. An axial hole is formed in the fastening end of the sleeve. The inside hexagonal bolt quick disassembling device further comprises a fastening structure. The fastening end of the sleeve is provided with an installation through hole and a locating structure used for fixing the fastening structure. The installation through hole extends to the inner wall of the sleeve from the outer wall of the sleeve and is perpendicular to the center line of the sleeve. The fastening structure is disposed in the installation through hole. After an inside hexagonal square hole of a back-nut bolt is broken down, the bolt can be smoothly disassembled without breaking thread connection, the completeness of a connected piece is guaranteed, and disassembling efficiency is improved. The inside hexagonal bolt quick disassembling device is mainly used for disassembling screws or bolts with cylindrical heads.

Owner:PANGANG GRP ENG TECH

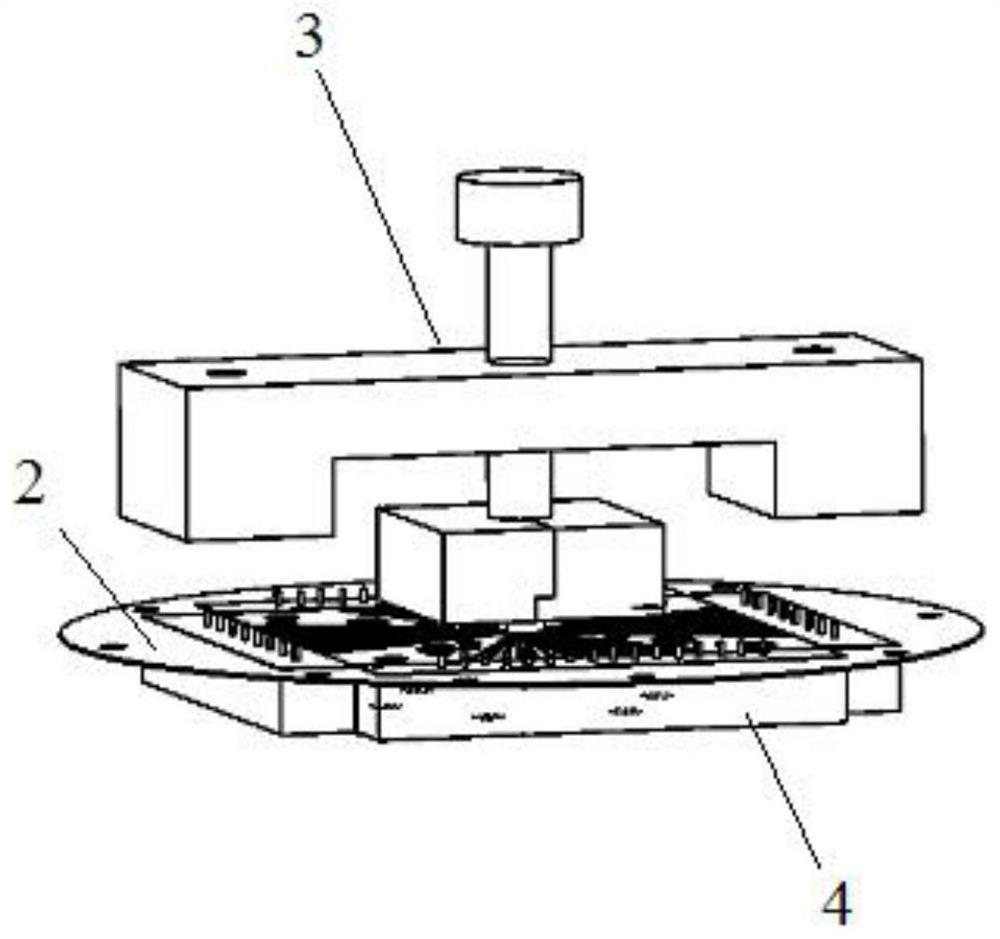

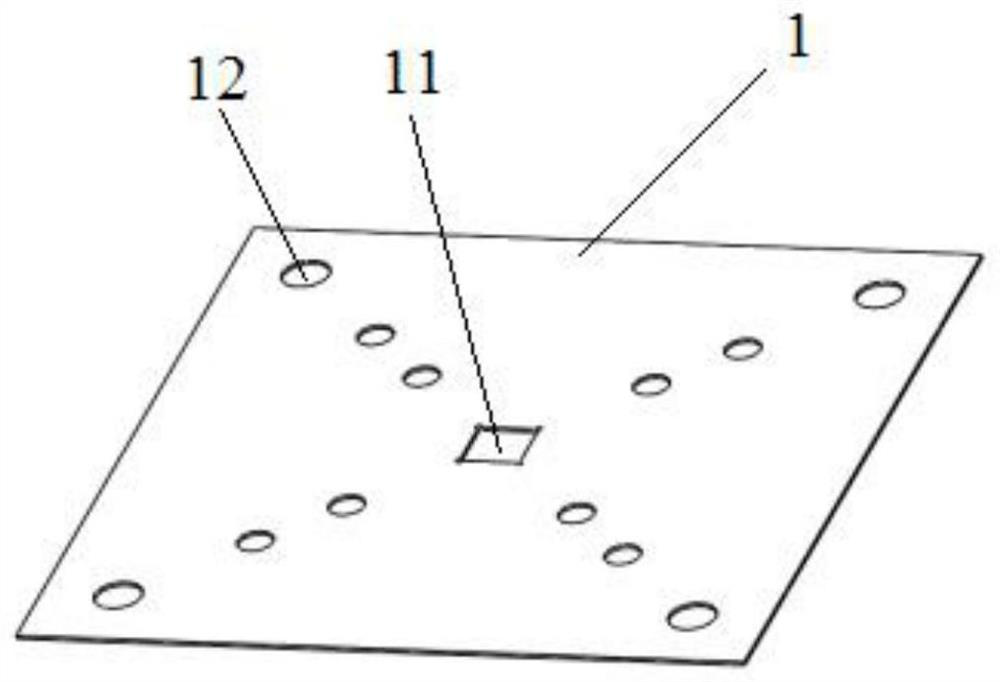

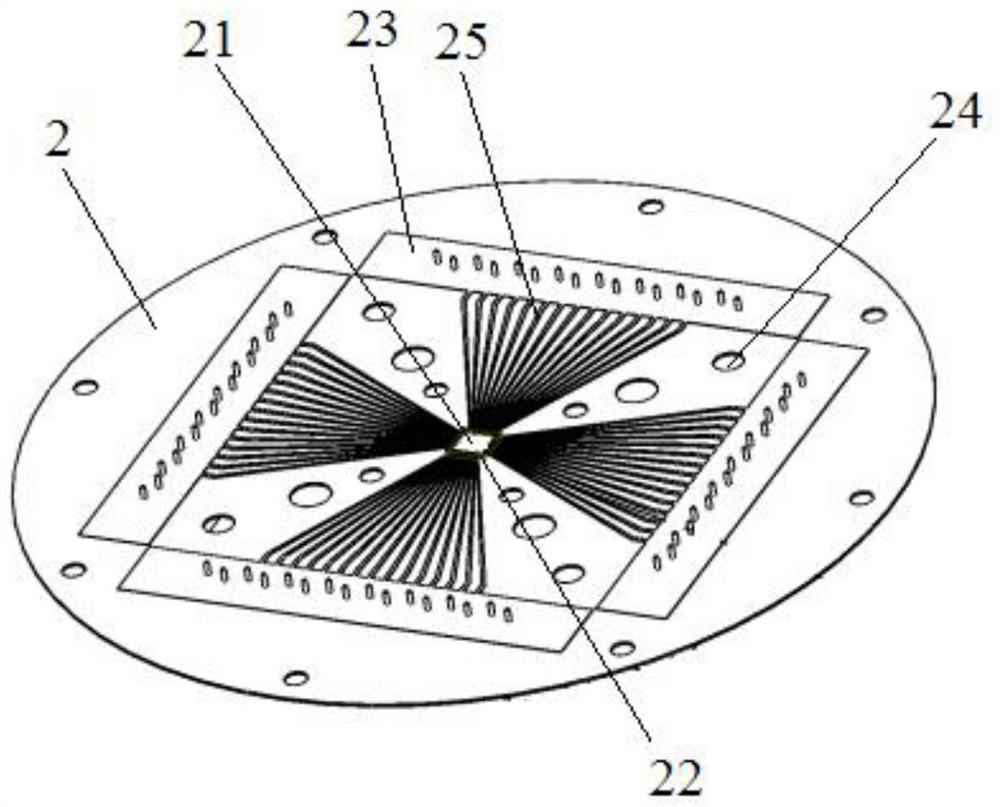

Low-temperature test structure of multi-channel high-frequency chip

PendingCN111693738AGuaranteed intactEasy to assemble and disassembleElectronic circuit testingMeasurement instrument housingElectrical connectionEngineering

The invention relates to a low-temperature test structure of a multi-channel high-frequency chip. The structure comprises a chip positioning printed circuit board, a multi-channel interface circuit board and a pressure applying device. The chip positioning printed circuit board is used for placing a chip to be tested. The multi-channel interface circuit board is provided with a multi-channel metalprobe structure, and the metal probe structure is used for realizing signal input and output of a to-be-tested chip and external equipment. And the pressure applying device is used for applying pressure to enable a pin pad of a chip to be tested on the chip positioning printed circuit board to be in contact with the multiple paths of metal probes on the multi-channel interface circuit board so asto realize electrical connection. According to the invention, completeness and no damage of the chip in the test can be ensured.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

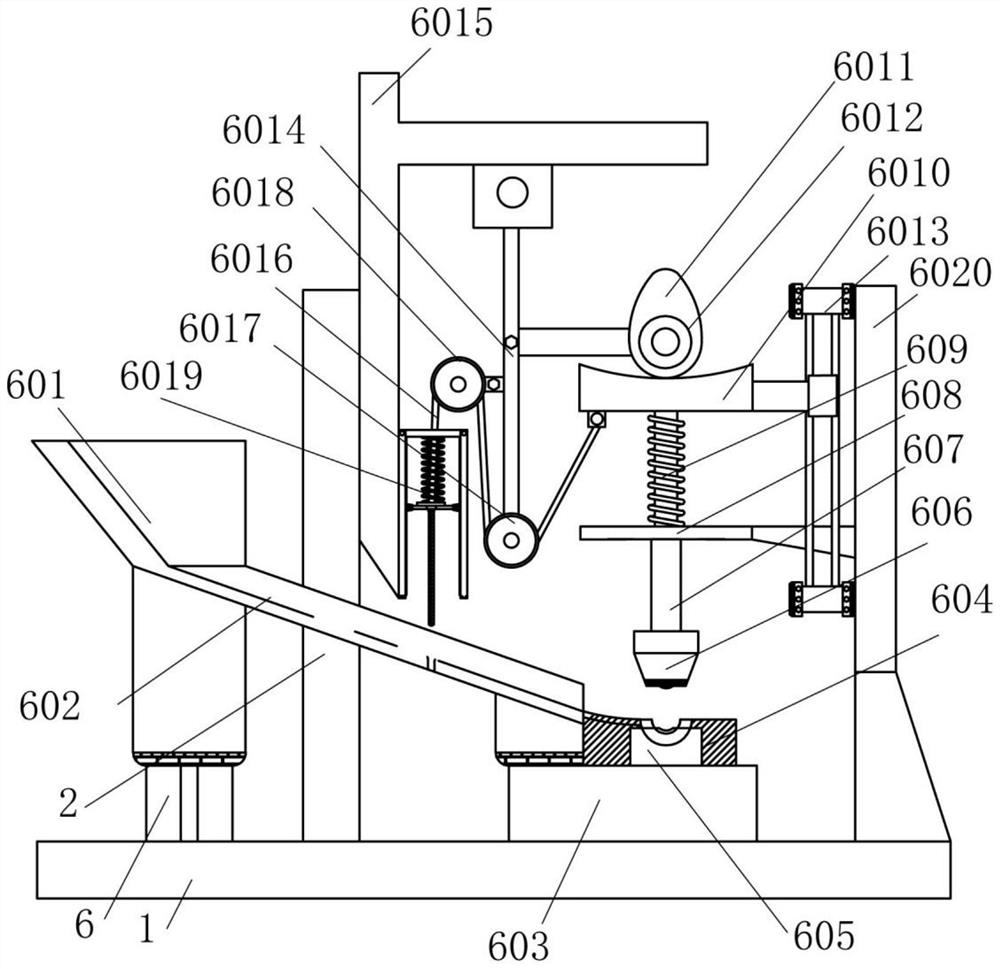

Cellulose treatment device for biodegradation

ActiveCN111513352BIntegrity guaranteedEliminate wastePlastic recyclingVegetable peelingCellulosePulp and paper industry

The invention relates to a biodegradable material, in particular to a cellulose processing device for biodegradation. The technical problem to be solved by the present invention is to provide a cellulose processing device for biodegradation. A cellulose processing device for biodegradation, comprising a connecting machine bottom plate, a fruit head and fruit tail separation mechanism, a power system control mechanism, a fruit body middle dividing mechanism, a pulp and peel separating mechanism, etc.; the top left side of the connecting machine bottom plate and the left side are elevated plate to be welded. The invention realizes efficient cutting and separation of the head and the tail of the fig fruit, completely separates the pericarp from the pulp containing cellulose, the cellulose can be used for the production of biodegradable materials, and at the same time ensures that the pericarp of the fig is kept intact and not damaged, that is, the flowers inside the pericarp are completely preserved. The anthocyanins eliminate the waste of pulp cellulose caused by manual cutting of the peel, and the anthocyanins with antioxidant properties inside the peel can also be utilized.

Owner:嘉禾伍丰(河北)包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com