Cellulose treatment device for biodegradation

A processing device and biodegradation technology, applied in food processing, application, food science and other directions, can solve the problems of pulp cellulose waste extraction rate, anthocyanin waste, anthocyanin overflow and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

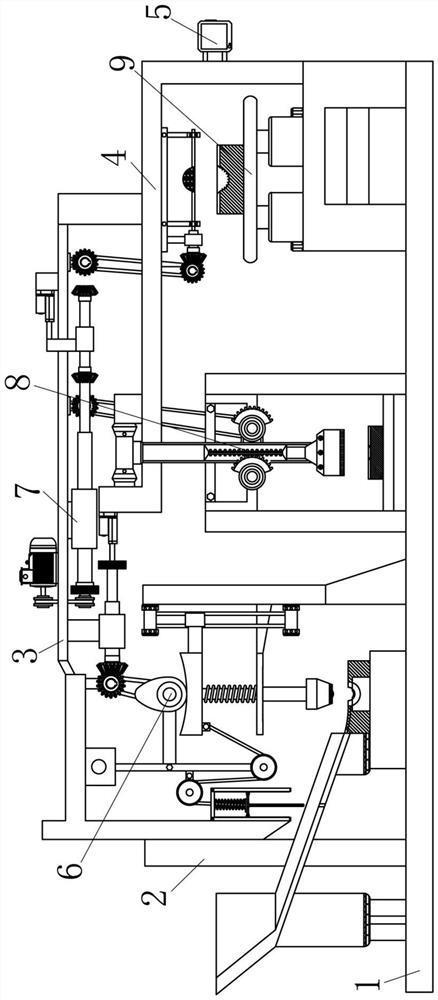

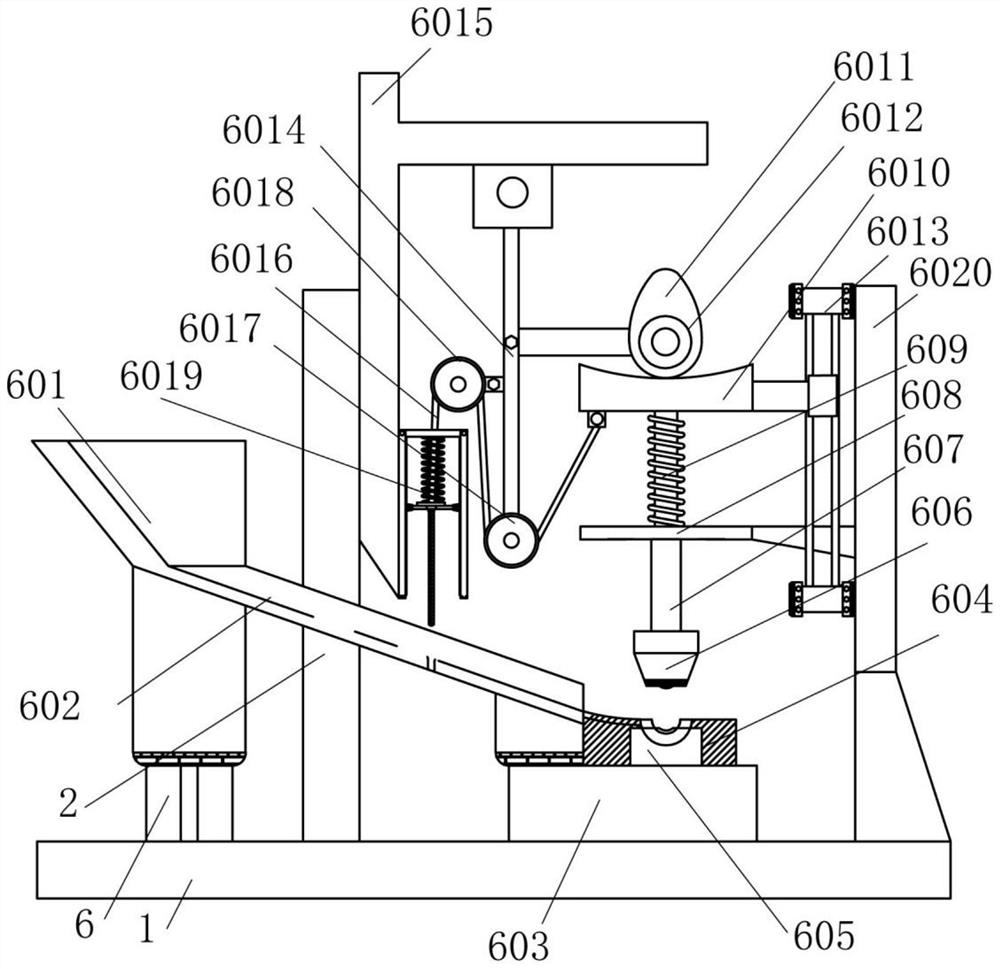

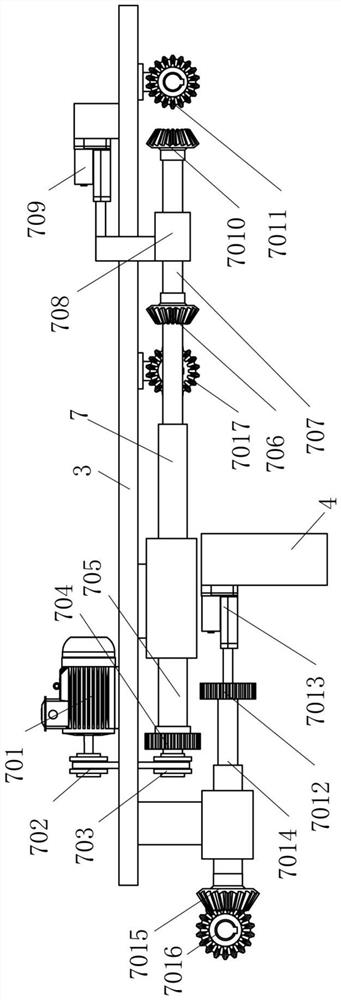

[0030] A cellulose processing device for biodegradation, such as Figure 1-8 As shown in the figure, it includes a connecting machine base plate 1, a left side frame plate 2, a top connection plate 3, a right frame plate 4, a real-time control screen 5, a fruit head and fruit tail separation mechanism 6, a power system control mechanism 7, and the middle part of the fruit body. Mechanism 8 and pulp and peel separation mechanism 9; the top left side of the bottom plate 1 of the connecting machine is welded with the left side elevated plate 2; the top left middle part of the bottom plate 1 of the connecting machine is connected with the separation mechanism 6 for the head and the tail, and the head and tail are separated. The middle part of the left end of the mechanism 6 is connected with the left side elevation plate 2; the middle part of the top end of the bottom plate 1 of the connection machine is connected with the middle parting mechanism 8 of the fruit body; The upper ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com