Chuck used for optical fiber joints

An optical fiber splicer and collet technology, which is applied to the coupling of optical waveguides and other directions, can solve the problems of non-stop function, difficult miniaturization, large overall structure and other problems, and achieves easy insertion, good clamping and fixing, and good guidance. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

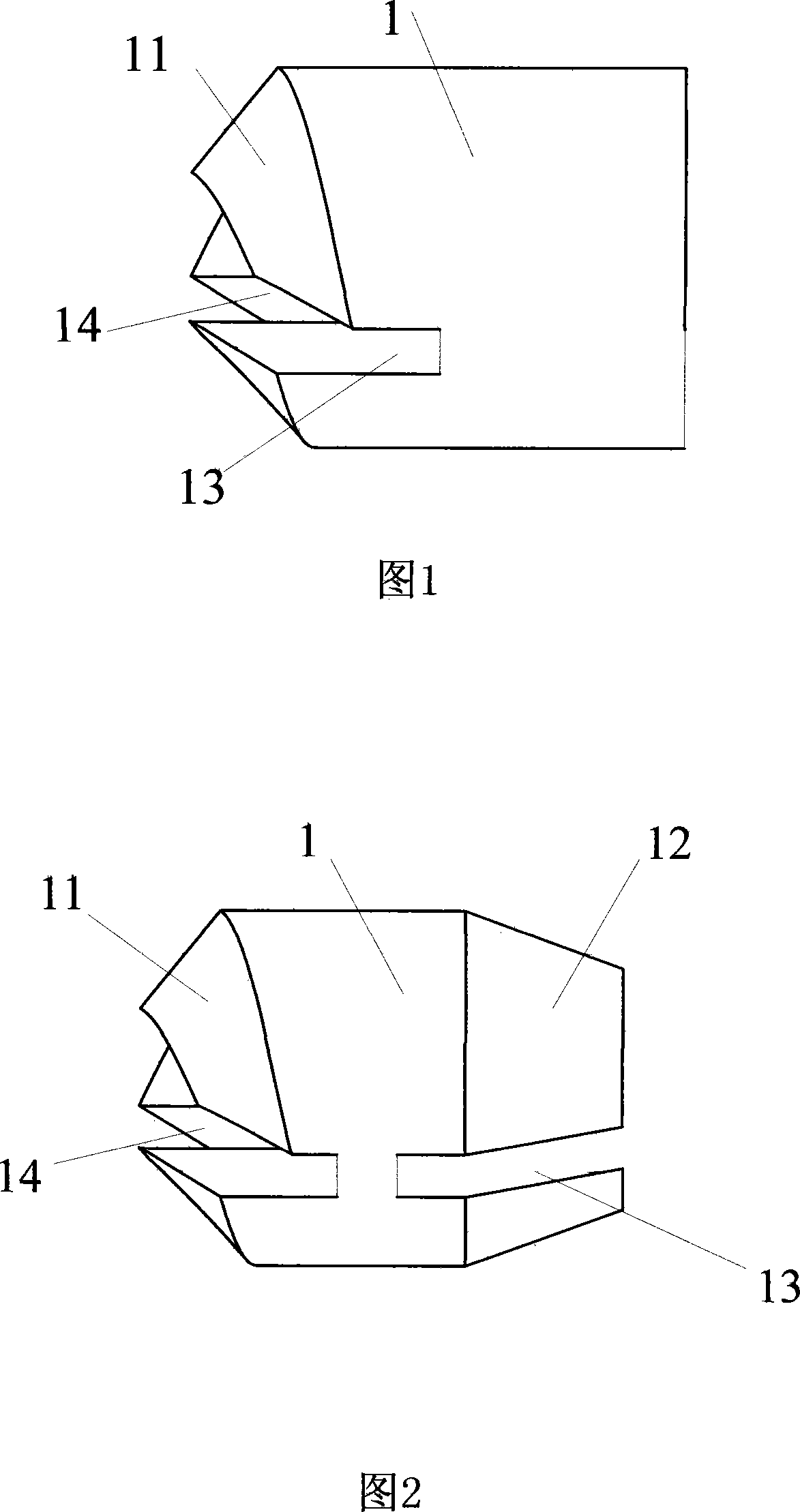

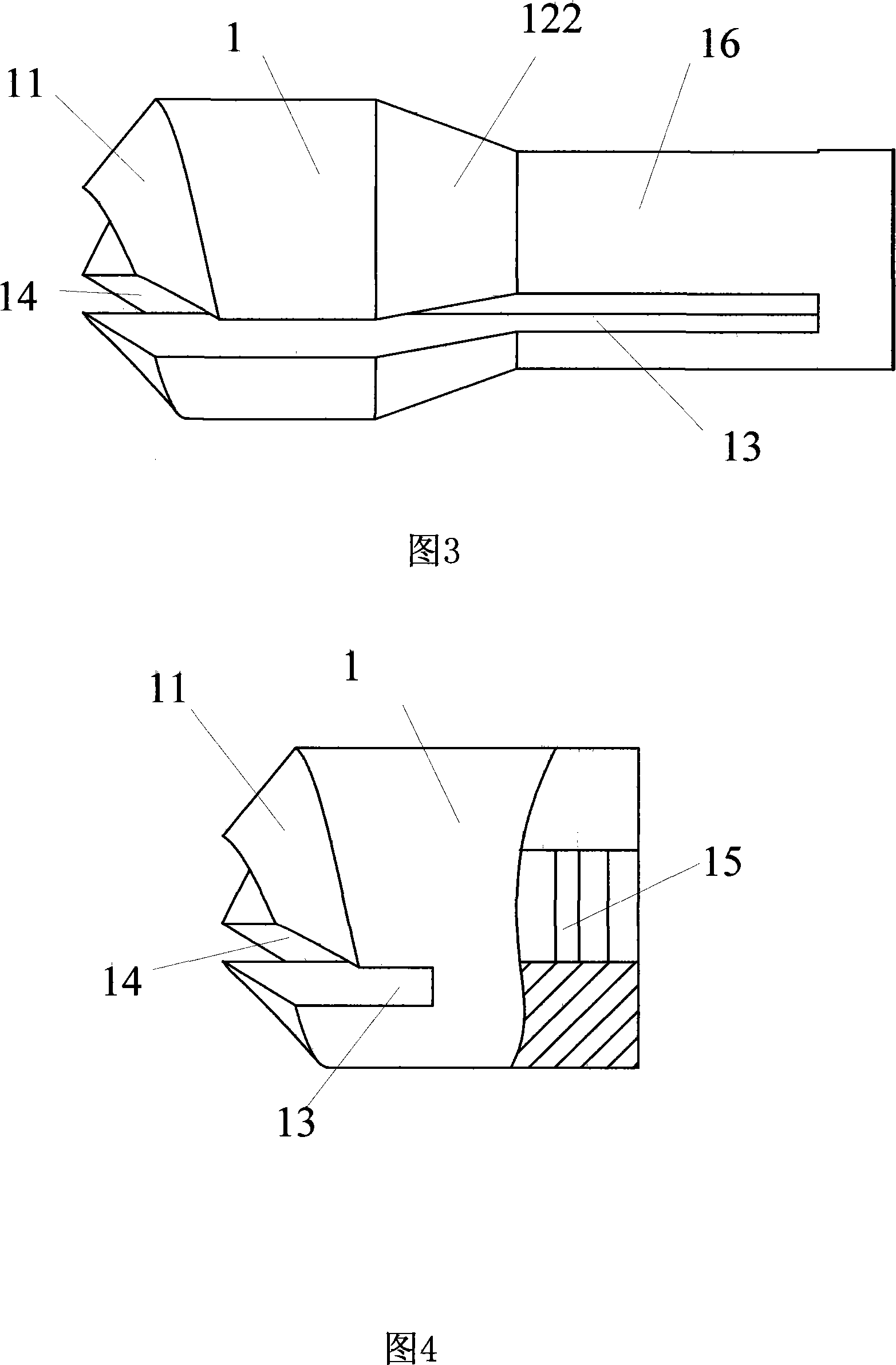

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] As shown in Figure 1, it includes a cylindrical body 1, the body 1 can also be made into a rectangular or other polygonal cylinder, and at the front end of the body 1 are at least two helical surface locking heads 11 formed by dividing the locking groove 13, the The helicoid locking head can also be an equiconic helicoid, that is, a helical surface processed on a conical body, and the taper of multiple locking heads 11 is the same. The number of locking heads can be 2, 3 or 4 according to actual conditions or needs. In the center of the body 1 is an optical fiber hole 14, which is an optical fiber through hole.

[0024] As an improvement of the present invention, as shown in Figure 2, the rear end of the body 1 is also processed into a cone 12, and a locking groove 13 is also provided on the cone 12, and the conical surface 12 is squeezed during installation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com