Carbon fiber flexible continuous sucker rod operation equipment

A technology for operating equipment and sucker rods, which is applied to drilling equipment, drill pipes, earthwork drilling and production, etc., can solve problems such as inappropriateness, and achieve the effect of complete and non-destructive surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with example:

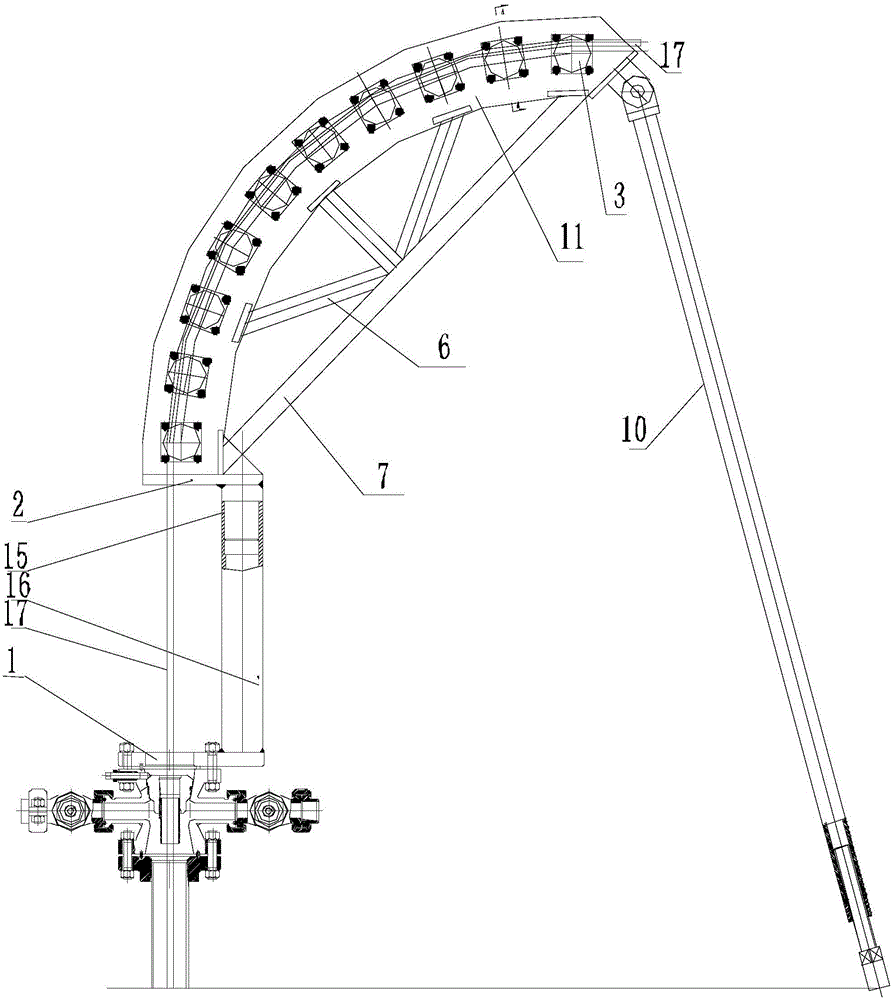

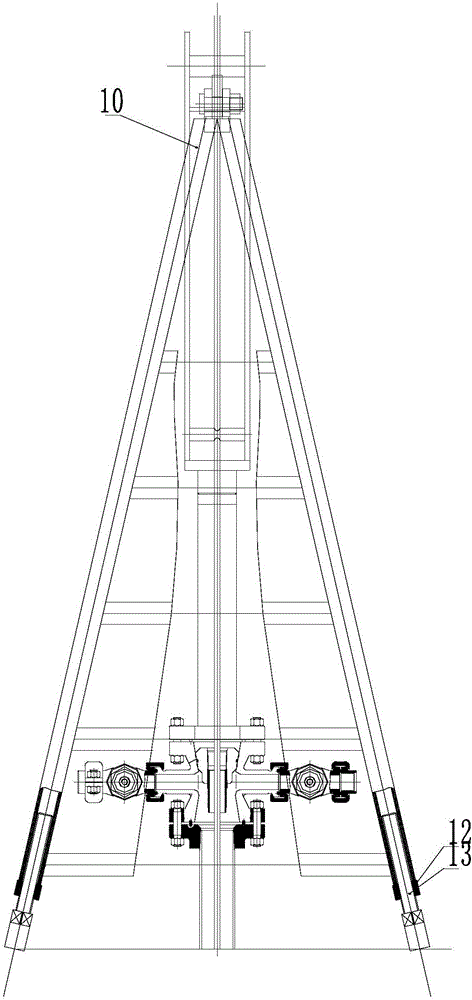

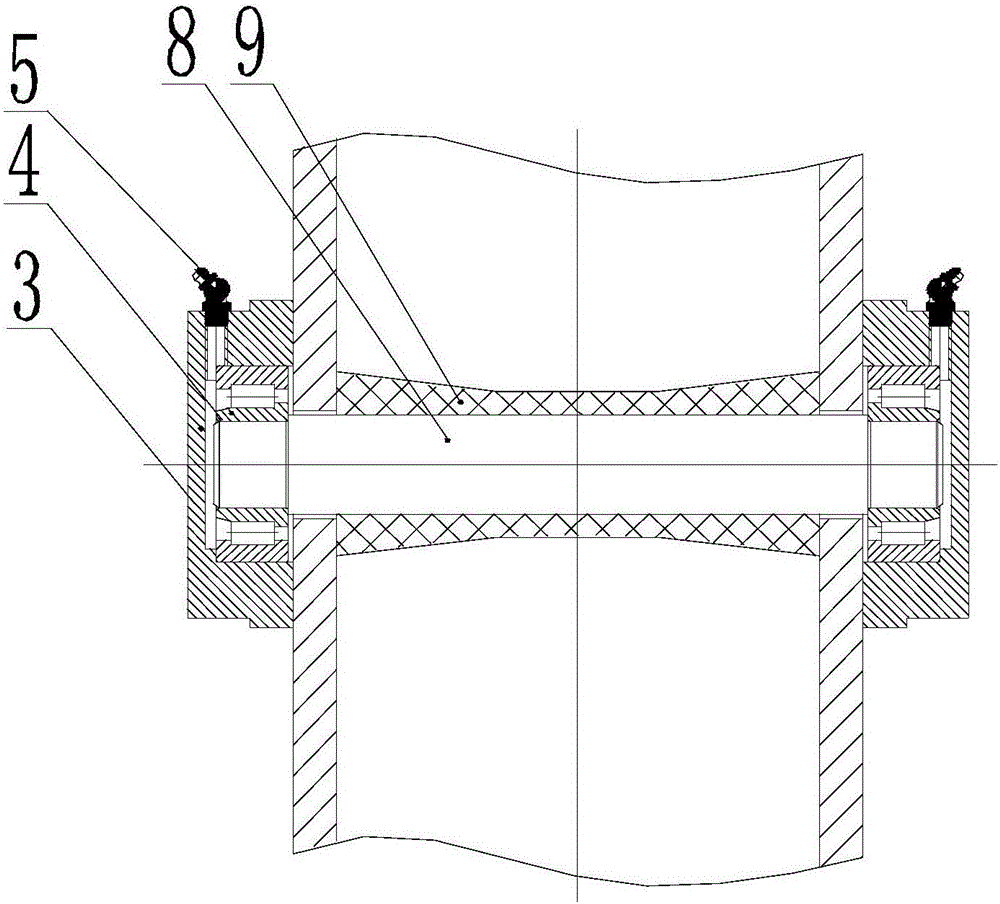

[0015] The carbon fiber continuous flexible sucker rod operation equipment of this application includes two arc-shaped plates 11, which are arranged in parallel, and the setting of the two arc-shaped plates 11 determines the trajectory of the carbon fiber sucker rod 17 running on it It is an arc-shaped track, which ensures the smooth transition of the carbon fiber sucker rod 17 from the horizontal direction to the vertical direction. The bottom plate 7 is fixed between the two ends of the arc-shaped plate 11, and the support plate 6 is fixed between the bottom plate 7 and the arc-shaped plate 11. , the bottom plate 7 and the support plate 6 play the role of fixing and supporting the two arc-shaped plates 11, and the rotating shaft 8 is evenly spaced between the two arc-shaped plates 11, and the outer wall of the rotating shaft 8 is covered with a rubber sleeve 9, and the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com