Honeycomb-simulated concrete block and die bar for production thereof

A technology for concrete blocks and honeycombs, which is applied to molds, building materials, ceramic molding cores, etc., can solve the problems of cumbersome wall insulation construction and high cost, and achieve the effects of light weight, low cost, and reduced construction links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

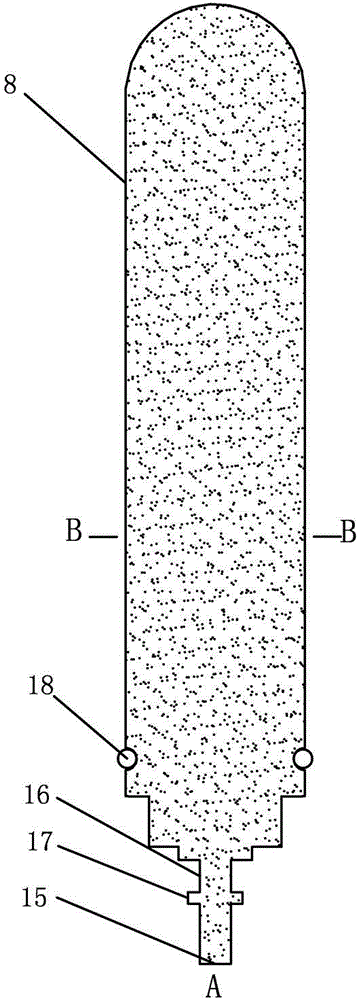

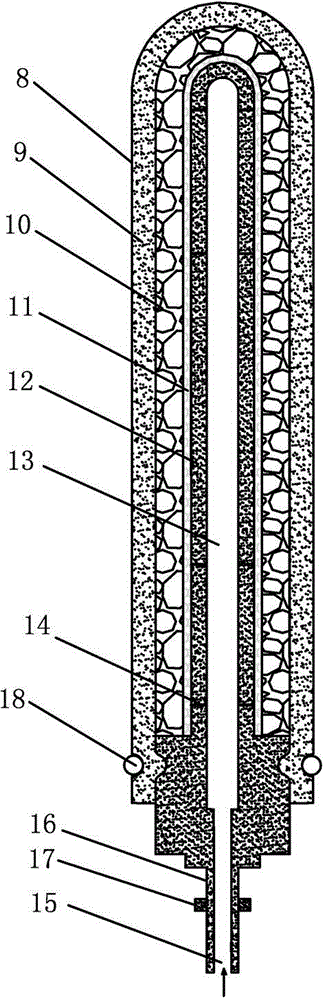

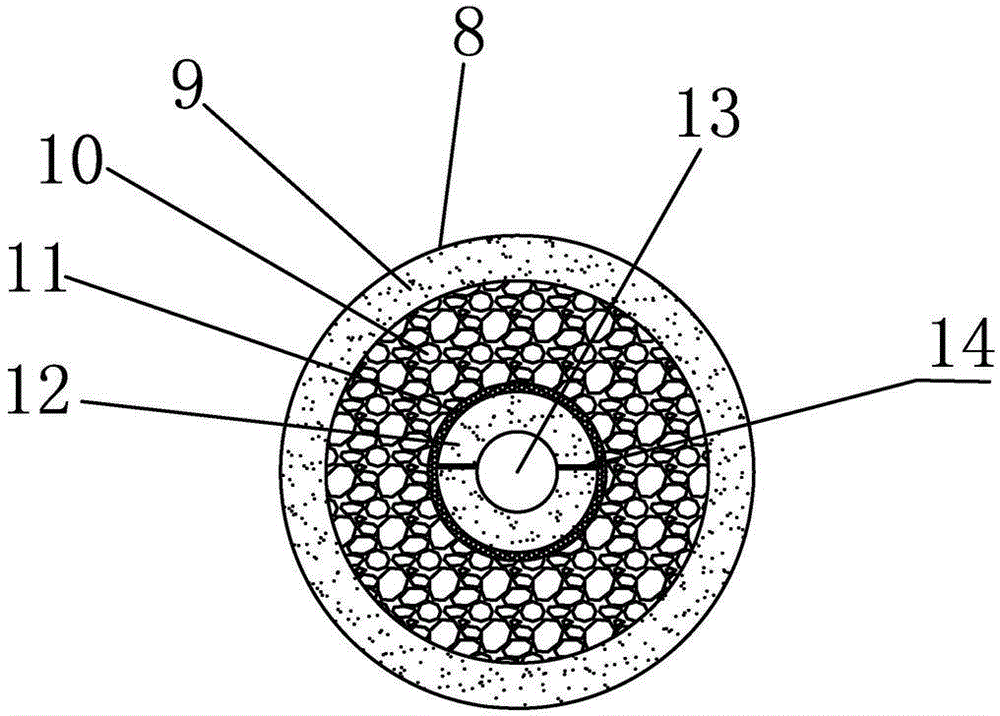

[0021] Depend on Figure 1 to Figure 11 Given, a honeycomb-like concrete block, the outer surface 2 of the block is smooth, there are multiple honeycomb cavities inside the block, the diameter of a single cavity is 9-300mm, and the wall thickness of the cavity is 0.5-100mm. One end is open and the other end is closed, the thickness of the closed end layer is 0.5mm-30mm, the cavity volume accounts for 50%-75% of the block volume, and the bulk density is 550kg-800kg.

[0022] A mold rod 8 for producing honeycomb-like concrete blocks, including a mold rod column, a cavity 13 is provided in the mold rod column 12, one end of the mold rod column 12 is open, and the other end is a spherical structure, and the cylinder body of the mold rod column 12 There is a vent hole 14 connected with the hollow cavity of the mold rod colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com