Production technology for stainless steel dot matrix friction plate

A production process, stainless steel technology, applied in the field of photochemical etching, can solve the problems of not reaching the uniformity of the full board array dots, the uneven distribution of the whole board dots, the high failure rate of semi-finished products, etc., and achieve the spray pressure setting Reasonable, good uniformity, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

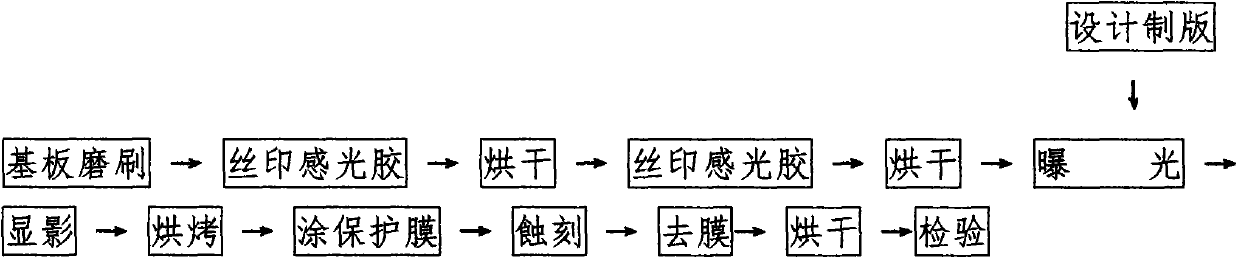

[0036] Please refer to shown in Figure 1, the production process of the present invention is as follows:

[0037] 1. Design and plate making: design dot matrix graphics through the computer CAD system, combine with photoplotter (resolution 16000DPI), draw the film negative with dot matrix graphics, and obtain the round dots on the film negative with a diameter of 0.198mm. The spacing is 0.5mm, and the arrangement angle of the dots is 15°.

[0038] In order to achieve the dot diameter and height required by the post-etching process, the side etching coefficient must be added when designing the plate. Among them, the data of the dot diameter of the plate making is 0.198mm is obtained after many times and repeated tests.

[0039] The film negative adopts the MYLAR type film produced by DuPont Company of the United States.

[0040] 2. Base material selection: The base material is a 304-type stainless steel plate with a thickness range of 0.40-0.48mm. In this embodiment, a substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com