Floating seedling raising method in fine comparison of tobacco gene editing material strains

A technology for gene editing and floating seedlings, applied in tobacco cultivation, botanical equipment and methods, container cultivation, etc., can solve the problems of large differences in the seedling stage of tobacco seedlings, interference of fine screening, damage to seedling root systems, etc., to achieve intelligent Chemical, water-permeable and air-permeable, not easy to rot roots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be described in detail by the following examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations on the technical solutions of the present invention.

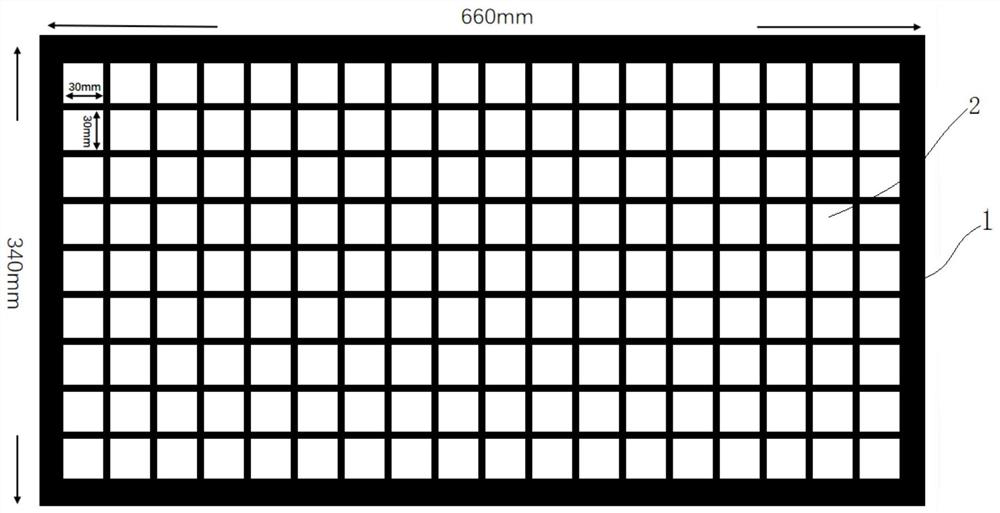

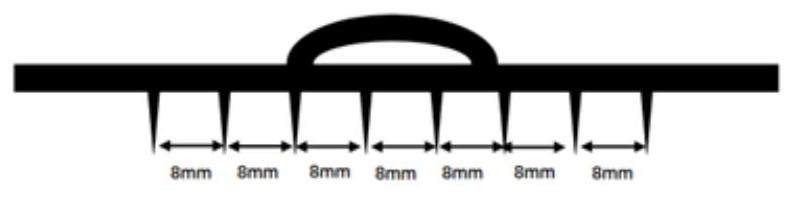

[0040] like Figure 1 to Figure 3 As shown, the present embodiment provides a floating seedling matrix filling scheme and tools used, which mainly include

[0041] Matrix: according to the regulations in YC / T310; Matrix packing principle: uniform, moderate tightness.

[0042] A flat and hygienic site is selected as the loading site, and the substrate is moistened before loading, so that the moisture content of the substrate reaches 30%-40%.

[0043] For standard 162-well seedling trays used in a large number of field plantings, lay a layer of non-woven fabric on the empty floating tray. Then press the non-woven fabric on each hole so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com