A CNC machining tool for six-sided parts

A technology of parts installation and tooling, which is applied in the field of CNC machining tooling for six-sided parts, can solve problems that affect the quality and efficiency of parts processing, have not yet found a solution, and are difficult to control the part processing process, so as to improve processing efficiency and reduce the cost of clamping Difficulty, the effect of reducing a large number of knife marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

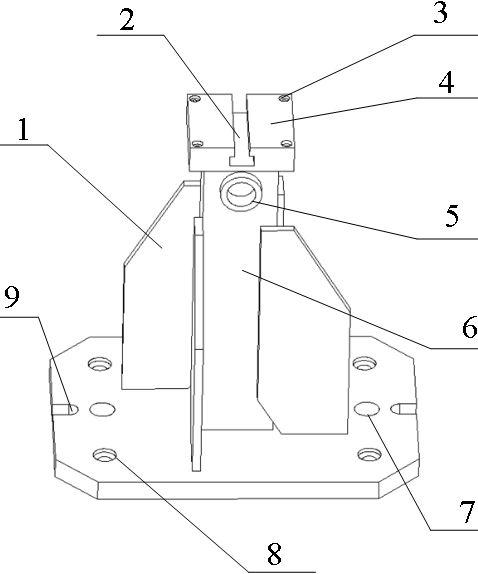

[0044] A kind of tooling for CNC machining of six-sided parts, including a tooling base and a tooling pressing mechanism, the tooling base includes a tooling support frame 6 and a part installation positioning plate 4 arranged on the top of the tooling support frame 6; the part installation positioning plate 4 The top is provided with a transverse T-shaped slot 2, and the bottom of the tooling pressing mechanism is installed in the T-shaped slot 2; the tooling support frame 6 is provided with a knife inspection block placement hole 5 for installing a knife inspection block.

[0045] During the use of the present invention, the numerical control machining of the six-sided part 21 is realized through the following steps:

[0046] Step 1: Place the six-sided part 21 on the part installation positioning plate 4, and fix the six-sided part 21 on the tooling;

[0047] Step 2: Install the knife inspection block in the hole 5 of the knife inspection block;

[0048] Step 3: Carry out ...

Embodiment 2

[0059] This embodiment is further optimized on the basis of Embodiment 1. The part mounting positioning plate 4 is provided with mounting screw holes 3, and the screws pass through the mounting screw holes 3 from the bottom of the mounting positioning plate reversely to connect the six-sided parts 21.

[0060] During the use of the present invention, through the setting of the mounting screw holes 3, four clamping holes can be prepared on the side with more blank margins of the six-sided machined parts before the installation of the six-sided parts 21, and the clamping holes Internal tapping thread, the diameter of the pressing hole is the same as that of the mounting screw hole 3; place the side with the pressing hole on the positioning plate of the tooling, and use screws to tighten the screws from the bottom of the mounting screw hole 3 upwards, and the tooling and the blank fixed.

[0061] In the present invention, through the setting of the mounting screw hole 3, by tight...

Embodiment 3

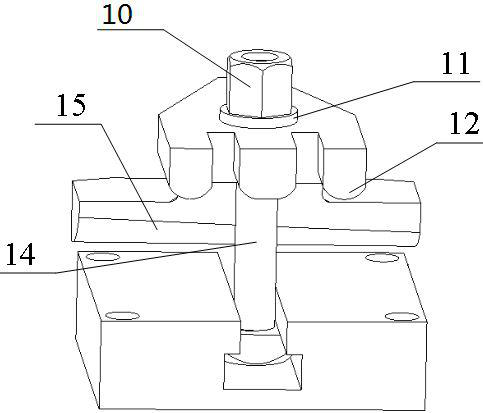

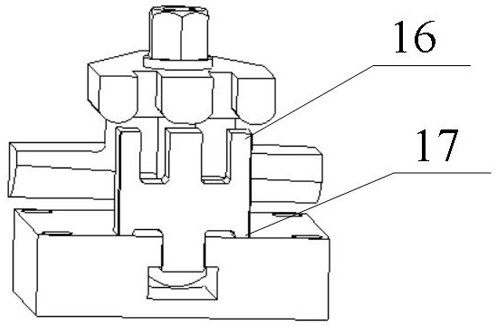

[0064] This embodiment is further optimized on the basis of Embodiment 2. The tooling pressing mechanism includes a nut 10, an adjustable screw 14, a screw washer 11, and a pressing plate. The adjustable screw 14 is installed in the T-shaped groove 2, and A pressure plate is installed on the adjustable screw 14 , the top of the adjustable screw 14 passes through the pressure plate and is connected with the nut 10 , and a screw washer 11 is arranged between the pressure plate and the nut 10 .

[0065] During the use of the present invention, when performing the second clamping, the adjustable screw rod 14 is first installed in the T-shaped groove 2, and the bottom of the adjustable screw rod 14 is determined to be in the T-shaped groove 2 according to the position of the six-sided part 21. Then clamp the processed surface of the six-sided part 21, put the six-sided part 21 on the part mounting plate, pass the pressure plate and the screw washer 11 into the adjustable screw rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com