Arc-shaped linear motor

A linear motor and arc technology, applied in the field of motors, can solve the problems of motor processing, transportation difficulties, and high manufacturing costs, and achieve the effects of reducing processing and transportation difficulties, increasing output per unit volume, and high-precision operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

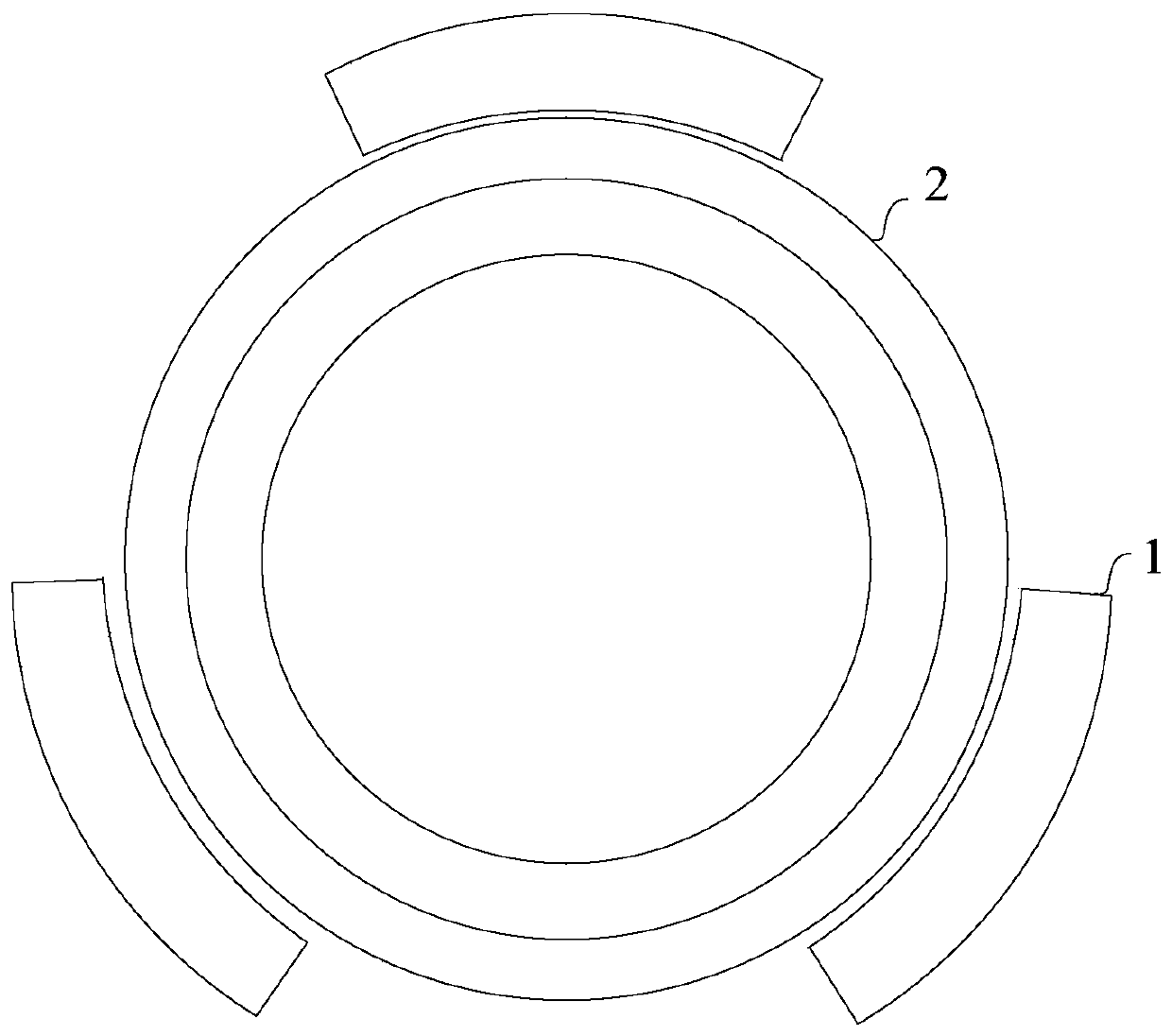

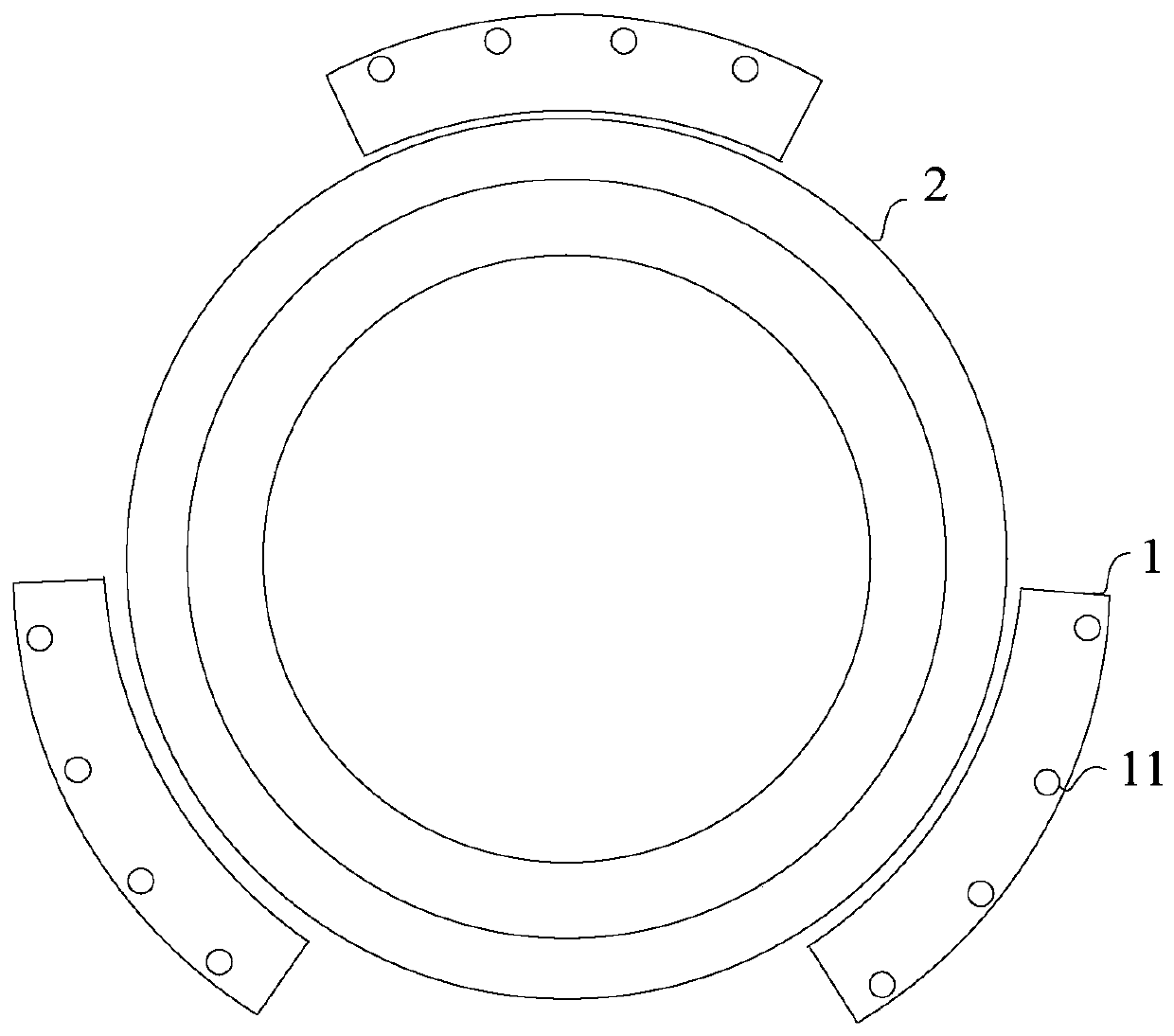

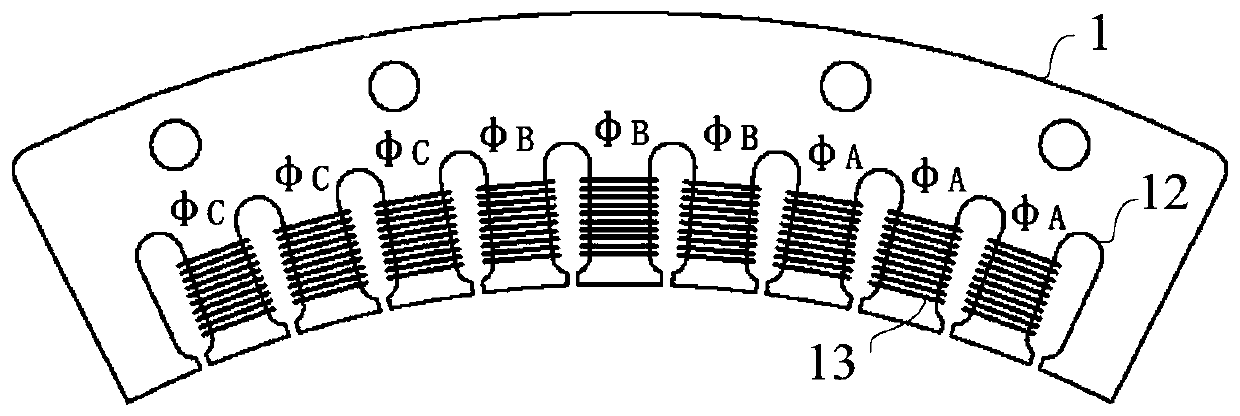

[0036] figure 1 For the structural diagram of an arc-shaped linear motor provided in the embodiment of the present application, refer to example 1, the motor is a three-phase AC permanent magnet synchronous motor, and the motor includes three stators 1 and one rotor 2 with the same structure; The stator 1 is connected with the stationary part of the tracking device; the rotor 2 is connected with the rotating part of the tracking device, and there is a gap between each of the three stators 1 and the rotor 2 .

[0037] In the embodiment of the present application, since the arc-shaped linear motor can include three stators 1 and one rotor 2, and the three stators 1 are connected to the stationary part of the tracking device, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com