Clothes drying method and clothes processing device using the method

A clothing processing device and clothing technology, applied in the field of clothing processing, can solve the problems of high surface temperature of fabrics, poor drying uniformity, and obvious fluffing, etc., to control surface temperature, improve drying uniformity, and reduce friction and wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

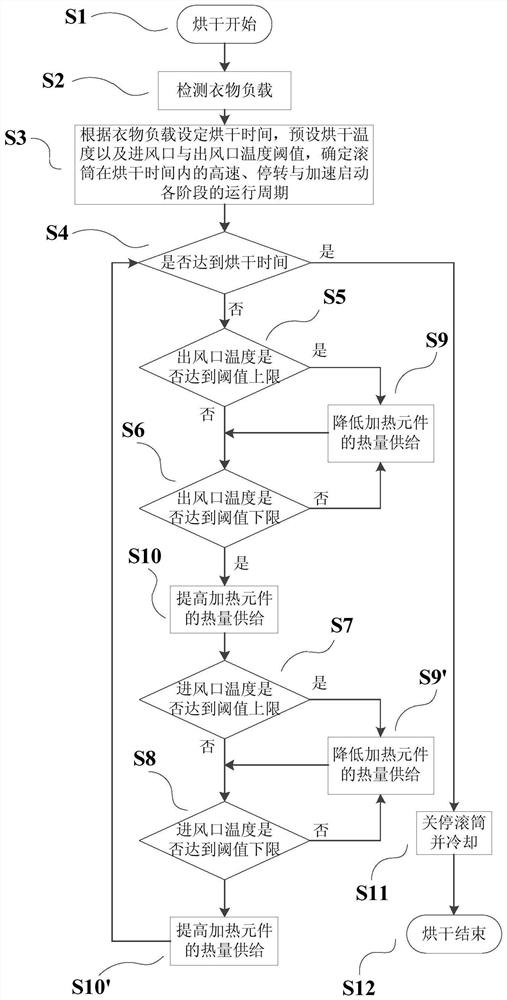

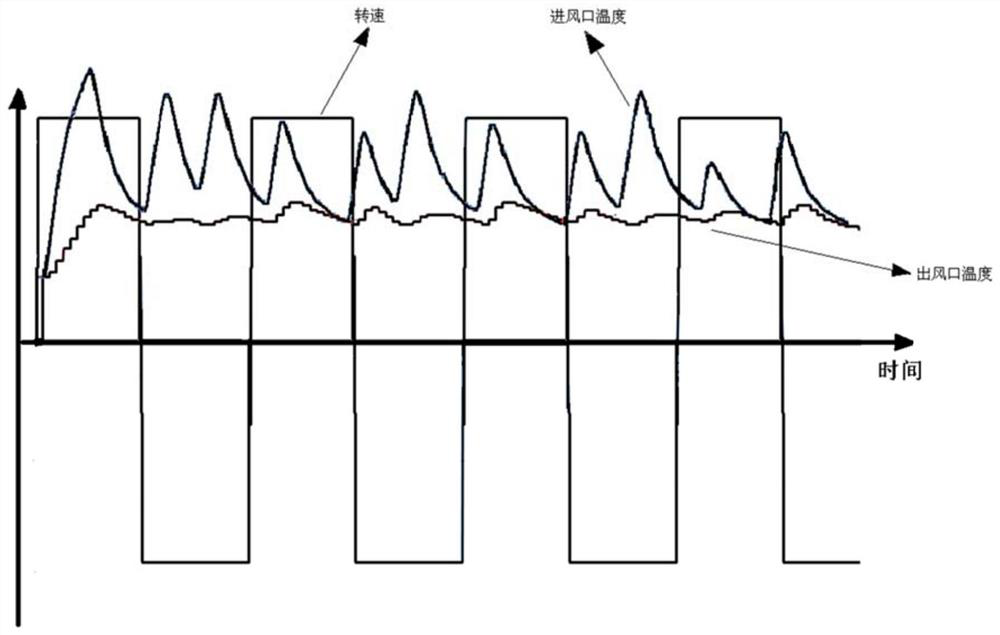

[0055] In this example, if Figure 1~2 As shown, a method for drying clothes is provided, including: the clothes processing device controls the drum to stop intermittently during the drying time and accelerates the startup according to the load of the clothes, so that the clothes are evenly distributed on the inner wall of the drum; The heat supply of the circulating air is controlled by the temperature of the air outlet, so that the surface temperature of the clothes is equal to the preset drying temperature.

[0056] In this embodiment, the rotation speed and rotation period of the drum are adjusted according to the load of the clothes, in order to reduce the friction between the fabrics and the friction between the fabric and the drum wall. There is no relative friction between the drums, and at the same time, the woolen fabric is in a stretched state, which is more conducive to drying; while the temperature of the air outlet detected in real time is closest to the drying t...

Embodiment 2

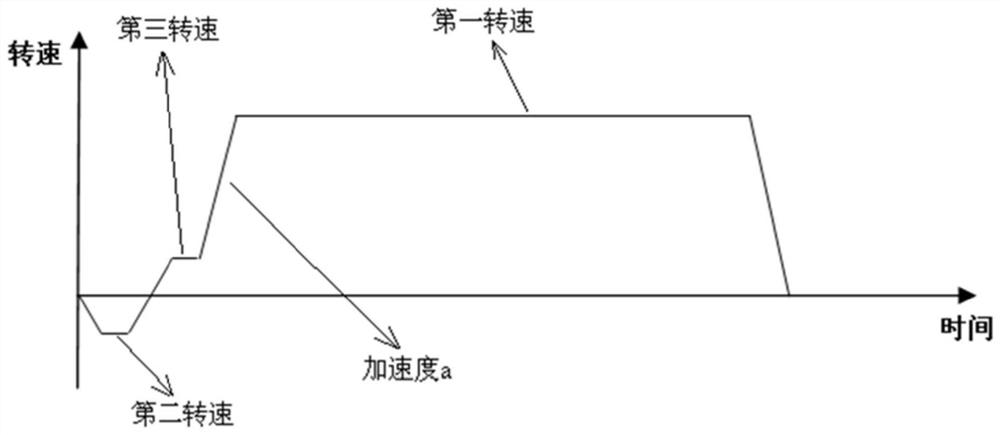

[0083] This example Figure 4 Shown, the difference with embodiment 1 is:

[0084] In this example, if Figure 5 As shown, the rotation direction of the drum at the first rotation speed is the same as that at the second rotation speed, and the rotation direction of the drum at the first rotation speed and the third rotation speed are the same.

[0085] In this embodiment, adjusting the rotation direction of the drum at the first, second, and third rotational speeds can further improve the effects of shaking and uniform distribution.

[0086] In this embodiment, the clothes processing device acquires the preset drying temperature and the temperature thresholds of the air inlet and the air outlet according to the load of the clothes, and when the temperature of the air inlet and / or the air outlet exceeds the threshold range, the heating element is adjusted to increase or decrease the temperature in the drum. For the heat supply of circulating air, the upper limit of the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com