Elastic sealing element for reciprocating moving equipment

A technology of elastic sealing and moving equipment, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as poor airtightness, and achieve the effect of improving stability and service life, stable sealing effect, and optimized structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

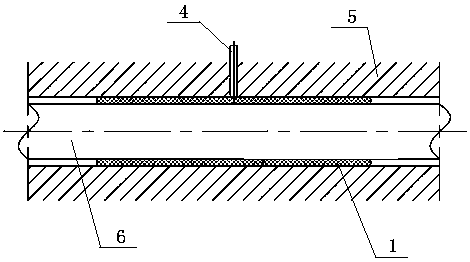

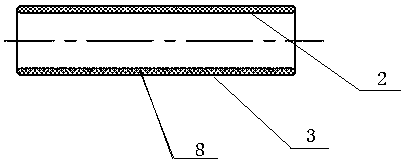

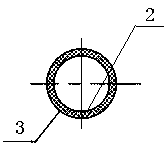

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

[0021] combine figure 1 , figure 2 , image 3 As shown, the elastic sealing element for reciprocating dynamic equipment has an annular cavity 1, the annular cavity 1 is placed in the outer cylinder 3 by the inner cylinder 2, and the two ends of the inner cylinder 2 and the outer cylinder 3 are respectively closed Formed, the outer cylinder 3 is provided with an injection pipe 4, and a one-way valve is arranged in the injection pipe 4, and the inner cylinder 2 and the outer cylinder 3 are made of elastic materials; the ring-shaped cavity 1 is placed outside the internal equipment that needs to be sealed. , the external equipment that needs to be sealed is surrounded by the annular cavity 1, and the internal equipment that needs to be sealed and the external equipment that needs to be sealed are reciprocating relative to each other, resulting in a relatively moving sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com