Low-cost modular drop hammer type impact fixture with non-single impact position point

A technology of impact position and modularization, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of poor practicability, maintaining the same boundary conditions, and high overall cost of fixtures, and achieve the effect of good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

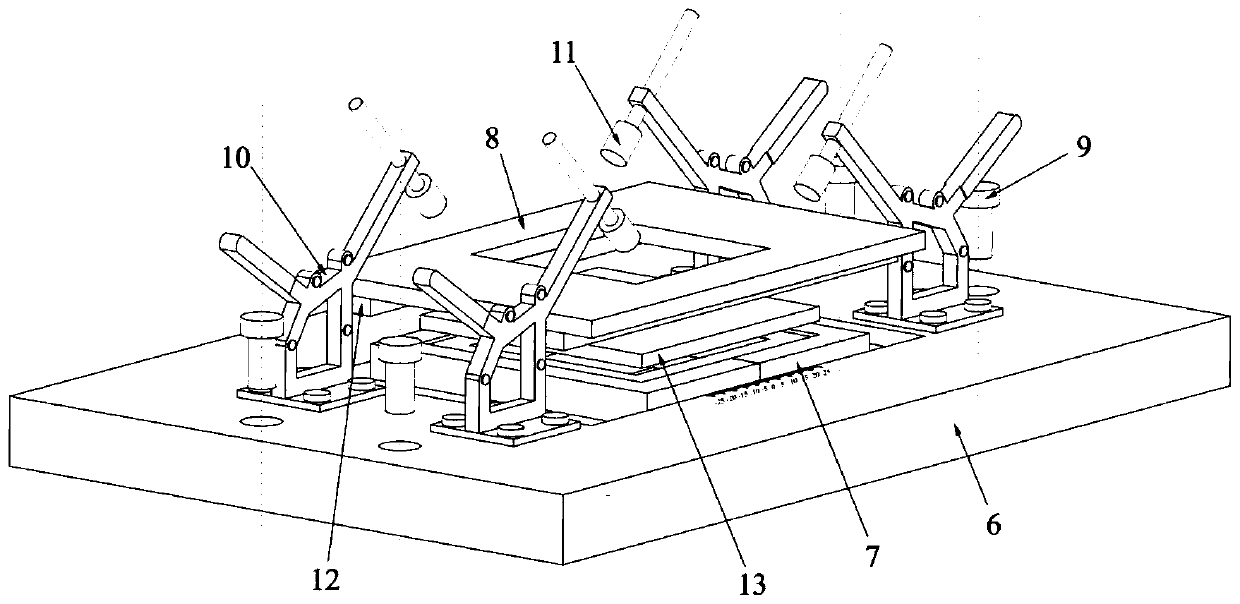

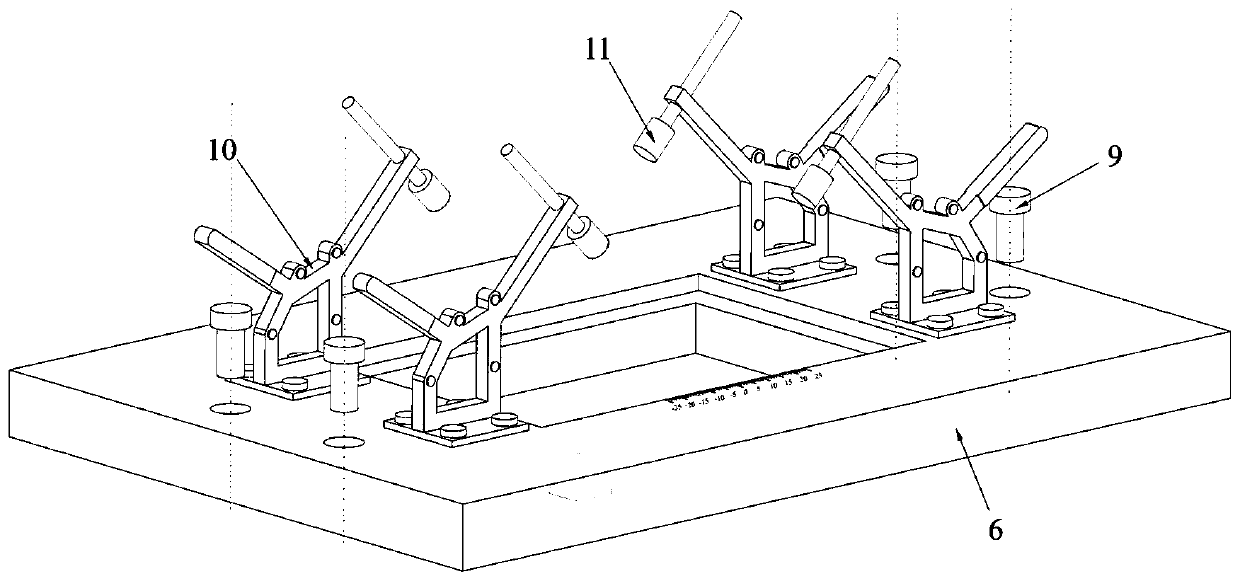

[0019] The following examples refer to Figure 1~5 .

[0020] The low-cost, modular, and non-single impact drop impact clamp of the present invention includes a standard clamp 6 , a support plate 7 , a cover plate 8 , a bolt 9 , a hinge clamp 10 , a rubber indenter 11 and a rubber pad 12 . The standard fixture 6 is fixed with the base of the drop weight tester by bolts 9, the support plate 7 is embedded in the groove of the standard fixture 6, the test piece 13 is placed in the groove of the support plate 7, and the cover plate 8 is placed in the test piece. 13 above.

[0021] The center of the standard fixture 6 includes a groove with a plane size of length×width=150mm×100mm, and the center of the groove contains a square through hole; A rubber pressing head 11 is installed on the top of each hinge clamp 10 , and the hinge clamp 10 and the rubber pressing head 11 can lock the whole set of clamps.

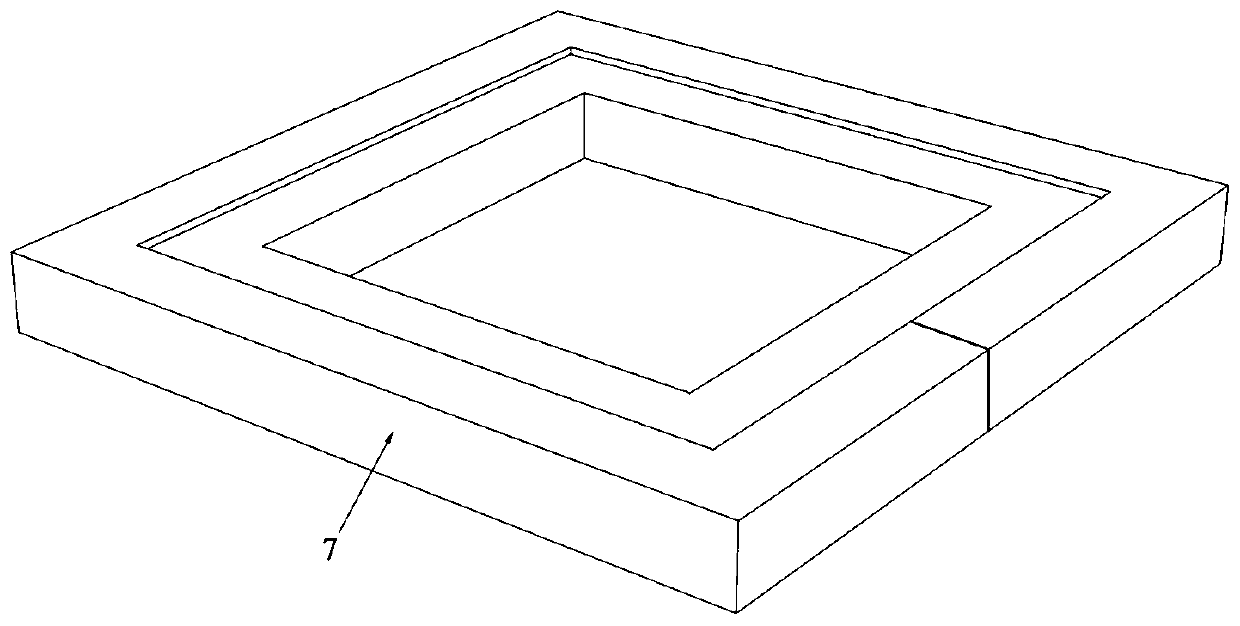

[0022] The plane of the support plate 7 is a rectangle, the width of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com