A high-efficiency heat dissipation type transformer device for thermal power generation

A transformer and heat-dissipating technology, applied in the field of high-efficiency heat-dissipating transformers for thermal power generation, can solve the problems of shortening the service life of the transformer, failing to work normally, causing accidents, etc., and achieving the effect of improving the heat-dissipating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

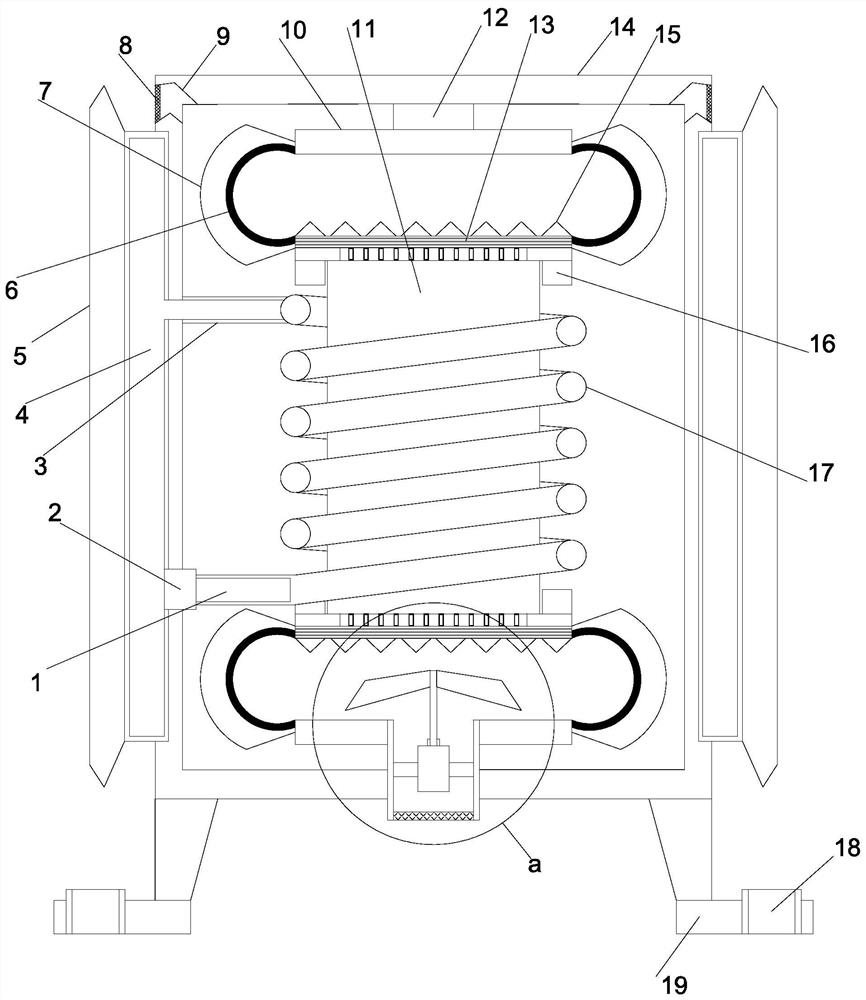

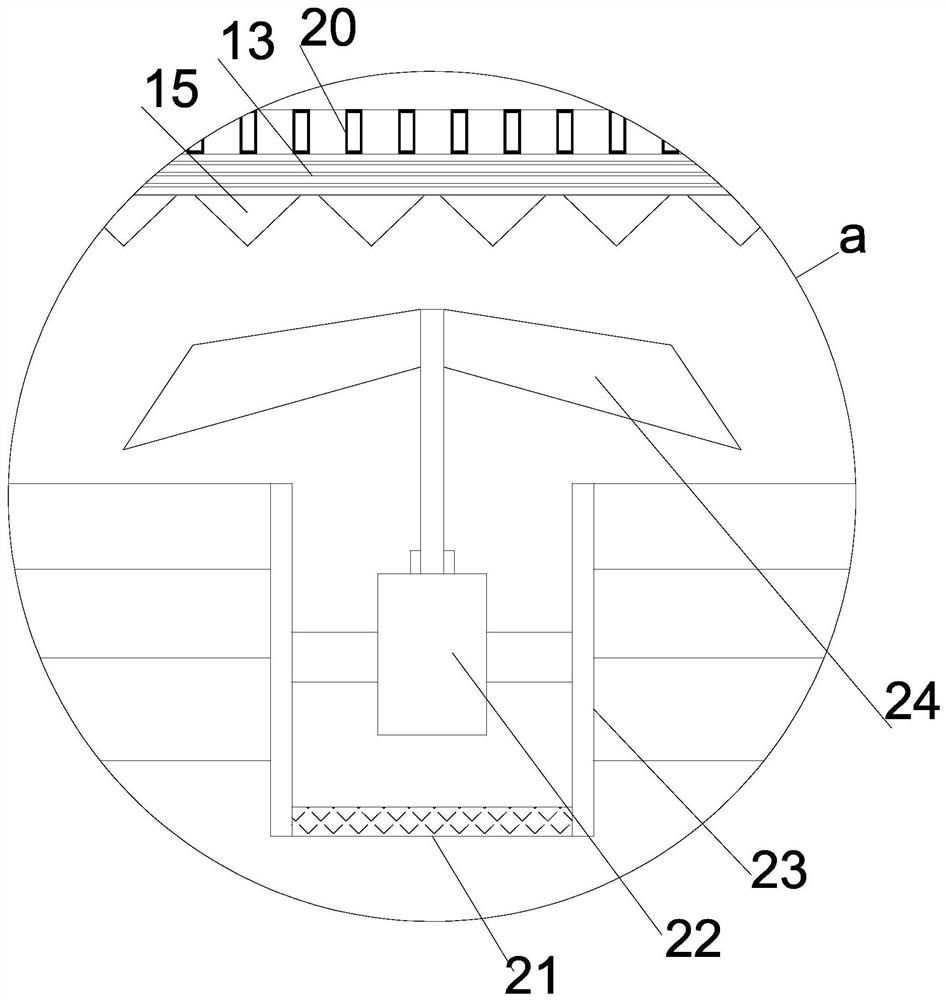

[0022] see Figure 1~4 , in an embodiment of the present invention, a high-efficiency heat-dissipating transformer device for thermal power generation, including a vertically arranged support installation cover 14, a transformer main body 11 is vertically arranged at the inner middle position of the support installation cover 14, and the support installation cover 14 The lower end is provided with a bending mounting plate 19 at equal angles, and fixed mounting holes 18 are arranged on the bending mounting plate 19. The upper and lower ends of the transformer main body 11 are provided with a limit mounting cylinder 16, facing the support cover of the limit mounting cylinder 16. A fixed installation plate 10 is arranged horizontally inside, and a heat conduction plate 13 is arranged horizontally on the side of the limit installation cylinder 16 facing the fixed installation plate 10, and a number of arc-shaped heat conduction plates are arranged at equal angles between the heat c...

Embodiment 2

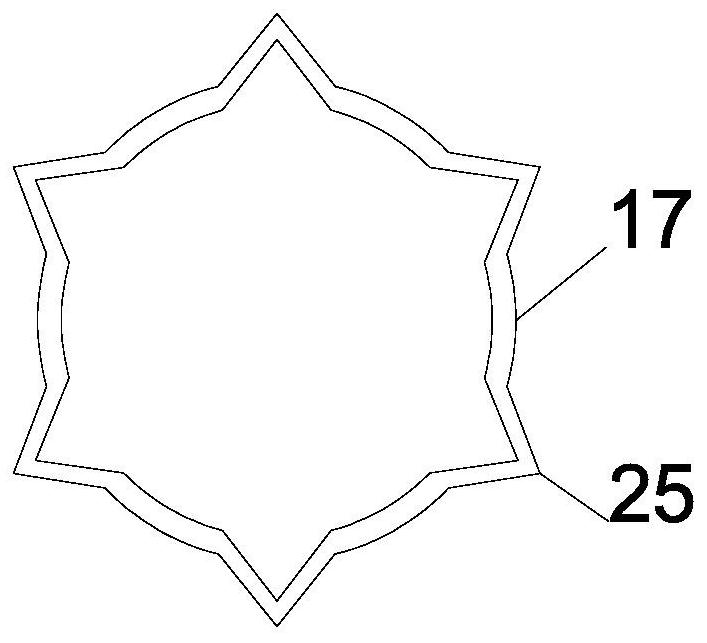

[0025] On the basis of Embodiment 1, since multiple sets of heat pipes 20 point contact for heat conduction, the speed of heat conduction is significantly improved, and the heat conduction protrusions 25 on the heat conduction pipe 17 will significantly increase the heat conduction area, and the sub-cooling process cooperates with liquid cooling to dissipate heat , so that the thermal effect is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com