Self-repairing transformer oil conservator respirator

A technology of transformer oil and self-repair, which is applied in the field of transformers and can solve problems such as easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

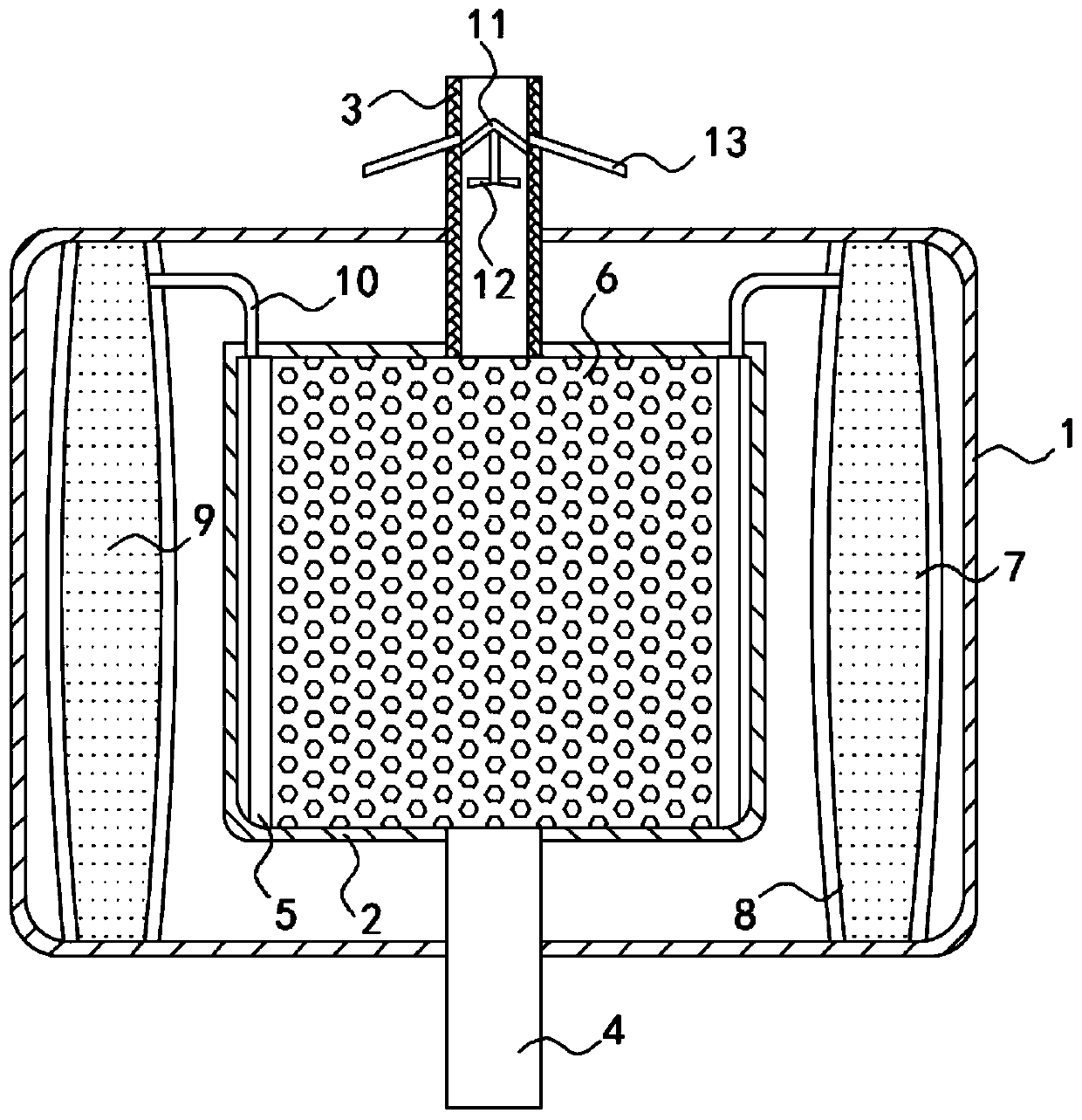

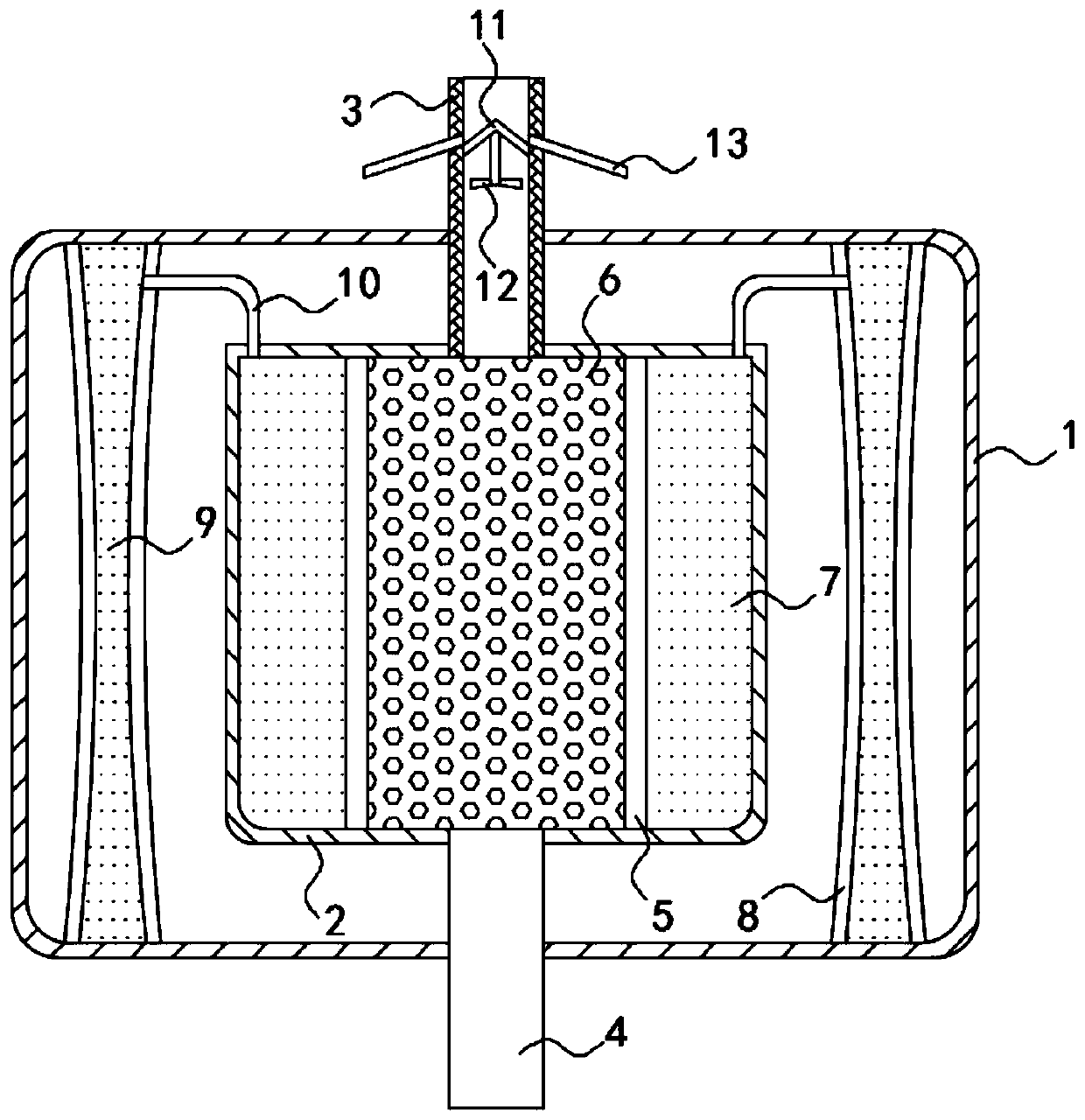

[0018] Such as Figure 1-2 As shown, a self-repairing transformer oil pillow respirator includes an outer shell 1 and an inner shell 2, the outer shell 1 and the inner shell 2 are made of light-transmitting materials, such as PVC materials, and the outer shell 1 is set on The inner shell 2 is fixedly connected with the inner shell 2, the upper end and the lower end of the inner shell 2 are fixedly connected with an upper air guide tube 3 and a lower air guide tube 4 respectively, the upper end of the upper air guide tube 3 communicates with the outside world, and the lower air guide tube 4 The lower end of the upper air duct 3 is connected with the transformer oil conservator, and the inner wall of the upper air duct 3 is rotatably connected with a dust filter 11, and the lower surface of the dust filter 11 is fixedly connected with a fan 12, and the fan 12 is coaxially arranged with the upper air duct 3, and the dust filter 11 is in the form of The center is arranged in an um...

Embodiment 2

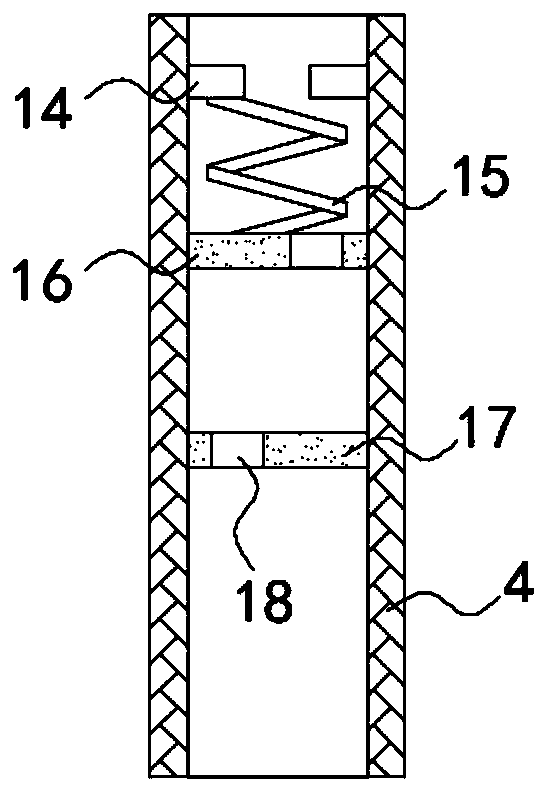

[0025] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the inner side wall of the lower air duct 4 is fixedly connected with a limit ring 14, and the lower end of the limit ring 14 is fixedly connected with an upper sealing plate 16 through a memory spring 15, and the upper end of the limit ring 14 is fixedly connected with an upper sealing plate 16. The bottom of the sealing plate 16 is provided with a lower sealing plate 17, the lower sealing plate 17 is fixedly connected with the inner side wall of the lower air guide tube 4, and the upper sealing plate 16 and the lower sealing plate 17 are all provided with vent holes 18, and the two vent holes 18 are staggered. set up.

[0026] In this embodiment, when the lens gathers light, the temperature in the inner casing 2 rises, and the memory spring 15 stretches to make the two sealing plates contact each other, and then the lower air duct 4 is closed to make the moisture evaporated in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com