High-efficiency anti-glare led directional light based on positive and negative two-way Fresnel lens

A Fresnel lens and high light efficiency technology, which is applied to light sources, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problem of difficult control of illuminance uniformity in secondary light distribution design, and low light of medium-power chip modules. It can improve the optical efficiency, increase the central light intensity, and reduce the light loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

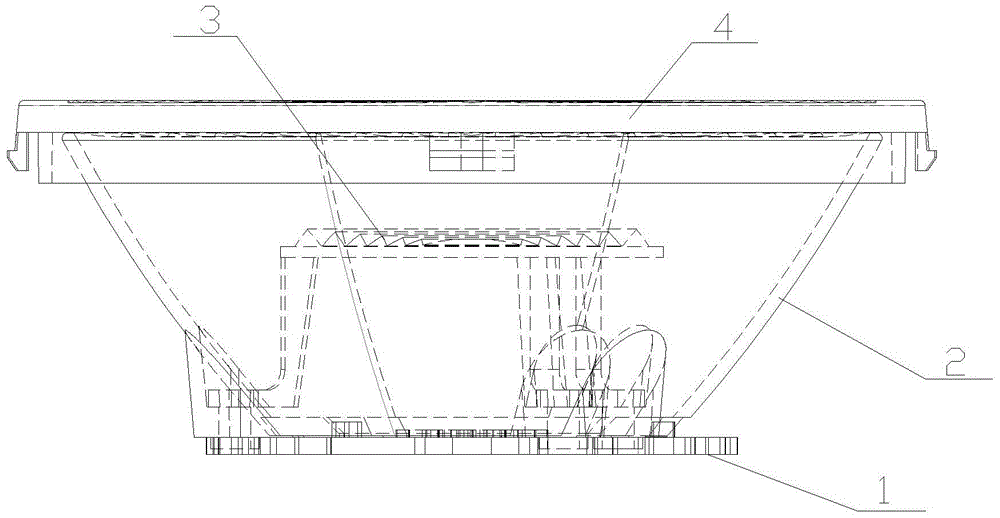

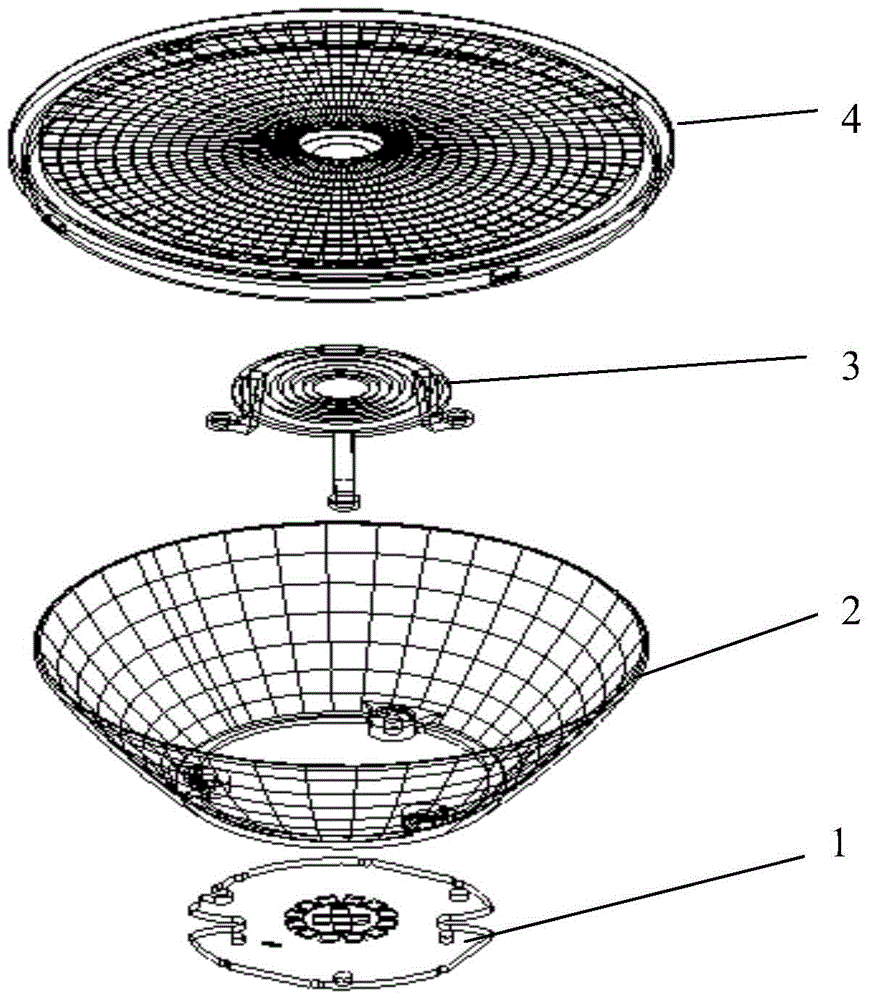

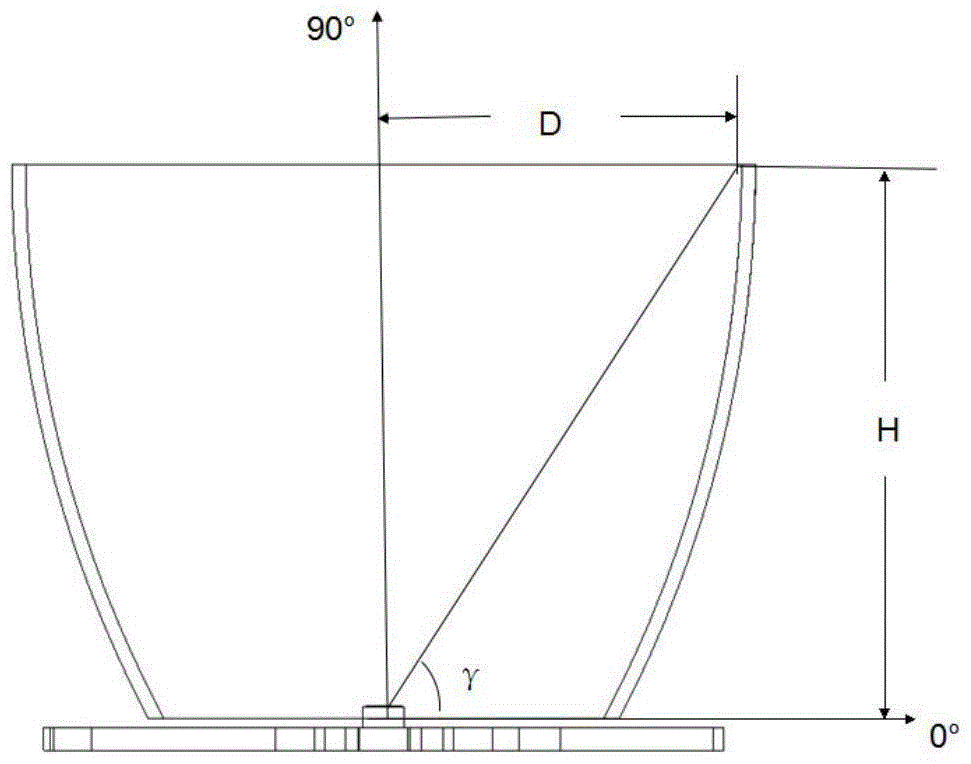

[0034] Such as figure 1 , figure 2 As shown, this embodiment is based on the high-efficiency anti-glare LED directional light of the positive and negative two-way Fresnel lens, including the LED substrate 1, the reflector 2, the forward Fresnel lens 3 and the reverse Fresnel lens 4, the described The reflector 2 is arranged on the LED substrate 1, the forward Fresnel lens 3 is arranged in the cavity of the reflector 2, the forward Fresnel lens 3 is suspended on the bottom of the reflector, and the reverse Fresnel lens The lens 4 is set on the top of the reflector 2; the geometric center of the medium power module is used as the reference point, and the chip light-emitting angle is divided into two ring parts of 0°-γ° and γ°-90°, and the optics of the two parts are independently designed .

[0035] In order to achieve a better light output effect, in this embodiment, the LED substrate 1 is provided with a plurality of LED light-emitting diodes, and the plurality of LED light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com