C-PVC power cable protection pipe

A technology for power cables and protection tubes, applied in the field of C-PVC power cable protection tubes, can solve the problems of weak protection of power cables, no adjustment function, and low fire performance, so as to improve protection ability, enhance stability, The effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

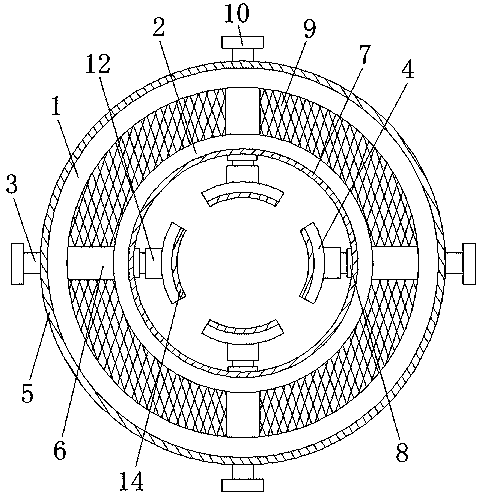

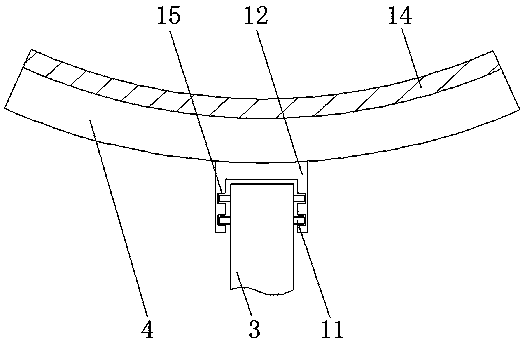

[0020] as attached Figure 1-3 As shown, a C-PVC power cable protection tube includes an outer ring 1, an inner ring 2, an adjusting screw 3 and a fastening block 4, and it is characterized in that: the outer ring 1 is provided with a connecting screw barrel 6, so The inner ring 2 described above is arranged in the outer ring 1, the outer wall of the inner ring 2 is connected with the connecting screw barrel 6, and the inner wall of the inner ring 2 is provided with a fixing nut 8 communicating with the connecting screw barrel 6, and the outer ring 1 is connected with the connecting screw barrel 6. The screw barrel 6, the inner ring 2 and the connecting screw barrel 6 are connected by welding to enhance the connection strength between the outer ring 1 and the connecting screw barrel 6 and the inner ring 2 and the connecting screw barrel 6, and improve the structural strength of the power cable protection tube , enhance the protection of the power cable protection tube to the p...

Embodiment 2

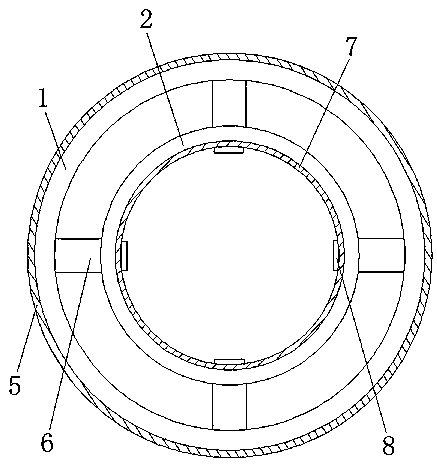

[0028] as attached Figure 4 As shown, a C-PVC power cable protection tube includes an outer ring 1, an inner ring 2, an adjusting screw 3 and a fastening block 4, and it is characterized in that: the outer ring 1 is provided with a connecting screw barrel 6, so The inner ring 2 described above is arranged in the outer ring 1, the outer wall of the inner ring 2 is connected with the connecting screw barrel 6, and the inner wall of the inner ring 2 is provided with a fixing nut 8 communicating with the connecting screw barrel 6, and the outer ring 1 is connected with the connecting screw barrel 6. The screw barrel 6, the inner ring 2 and the connecting screw barrel 6 are connected by welding to enhance the connection strength between the outer ring 1 and the connecting screw barrel 6 and the inner ring 2 and the connecting screw barrel 6, and improve the structural strength of the power cable protection tube , enhance the protection of the power cable protection tube to the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com