Foamed plastic cutting machine

A technology of foam plastics and cutting machines, which is applied in the field of foam plastics, and can solve the problems of reduced cutting accuracy, excessive influence of processing time on the initial sharpness of the cutting position of the heating wire, and increased difficulty of processing operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

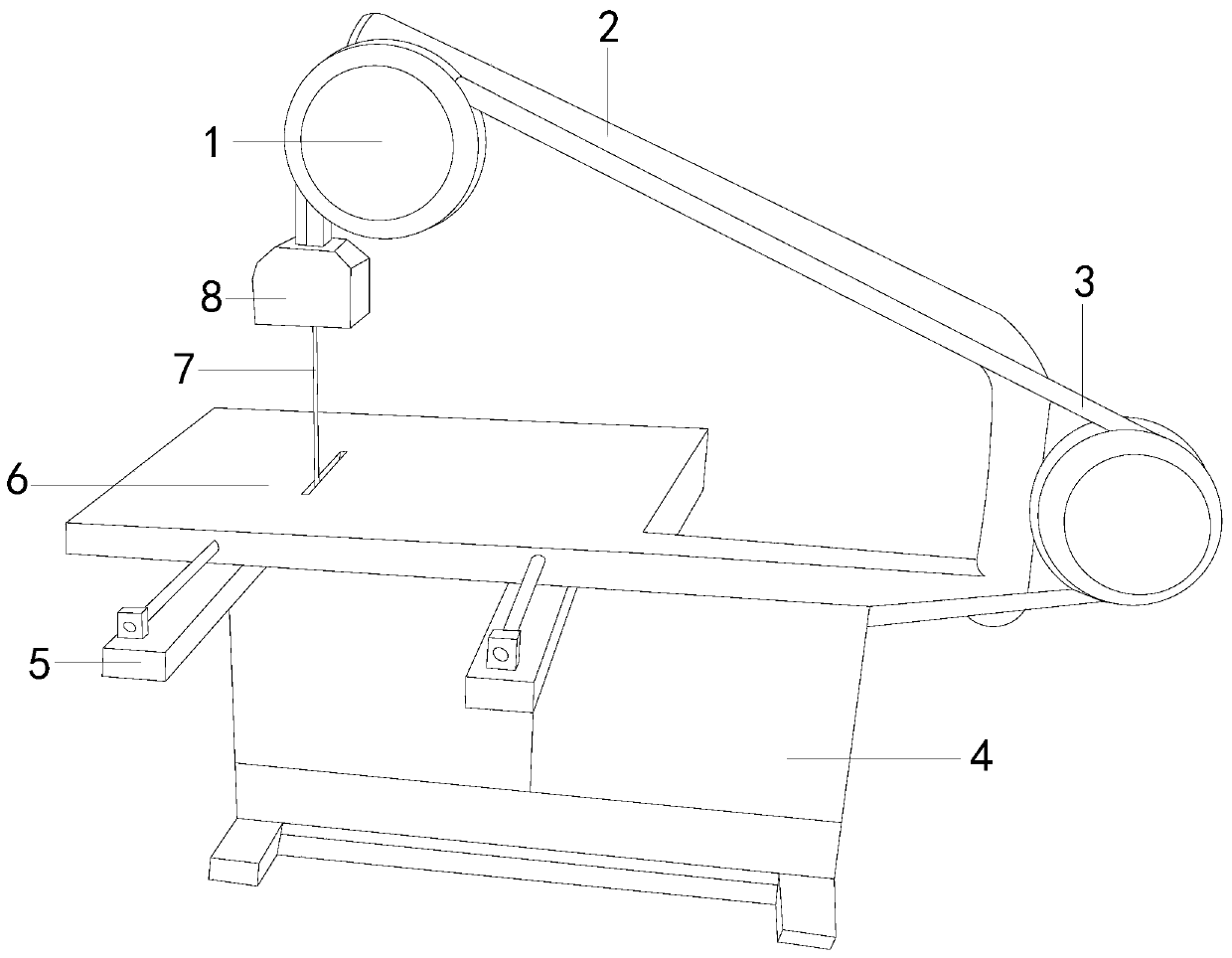

[0020] see figure 1, the present invention provides a cutting machine for foamed plastics, its structure includes: power shaft 1, bracket 2, transmission rod 3, body 4, adjustment seat 5, negative pressure plate 6, electric heating wire tube 7, self-cleaning cutter 8 , the power shaft 1 is located at both ends of the support 2 and connected to each other through the transmission rod 3, one end of the transmission rod 3 is connected to the fuselage 4, the side of the fuselage 4 is provided with an adjustment seat 5 and is located at the bottom of the negative pressure plate 6, the negative pressure The plate 6 runs through and connects the heating wire tube 7, and one end of the heating wire tube 7 is connected with the self-cleaning cutter 8, and the self-cleaning cutter 8 is connected with the power shaft 1. The interior is composed of rotating shaft parts, which mainly provide the source of power potential energy for other components of the equipment, and undertake the func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com