Buckle type keel assembly and wall with same

A snap-on, keel technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of affecting the strength of the wall, the connection is not tight, and the gypsum board drilling is large, so as to improve the stability of the connection structure and avoid long The effect of the application of self-tapping screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

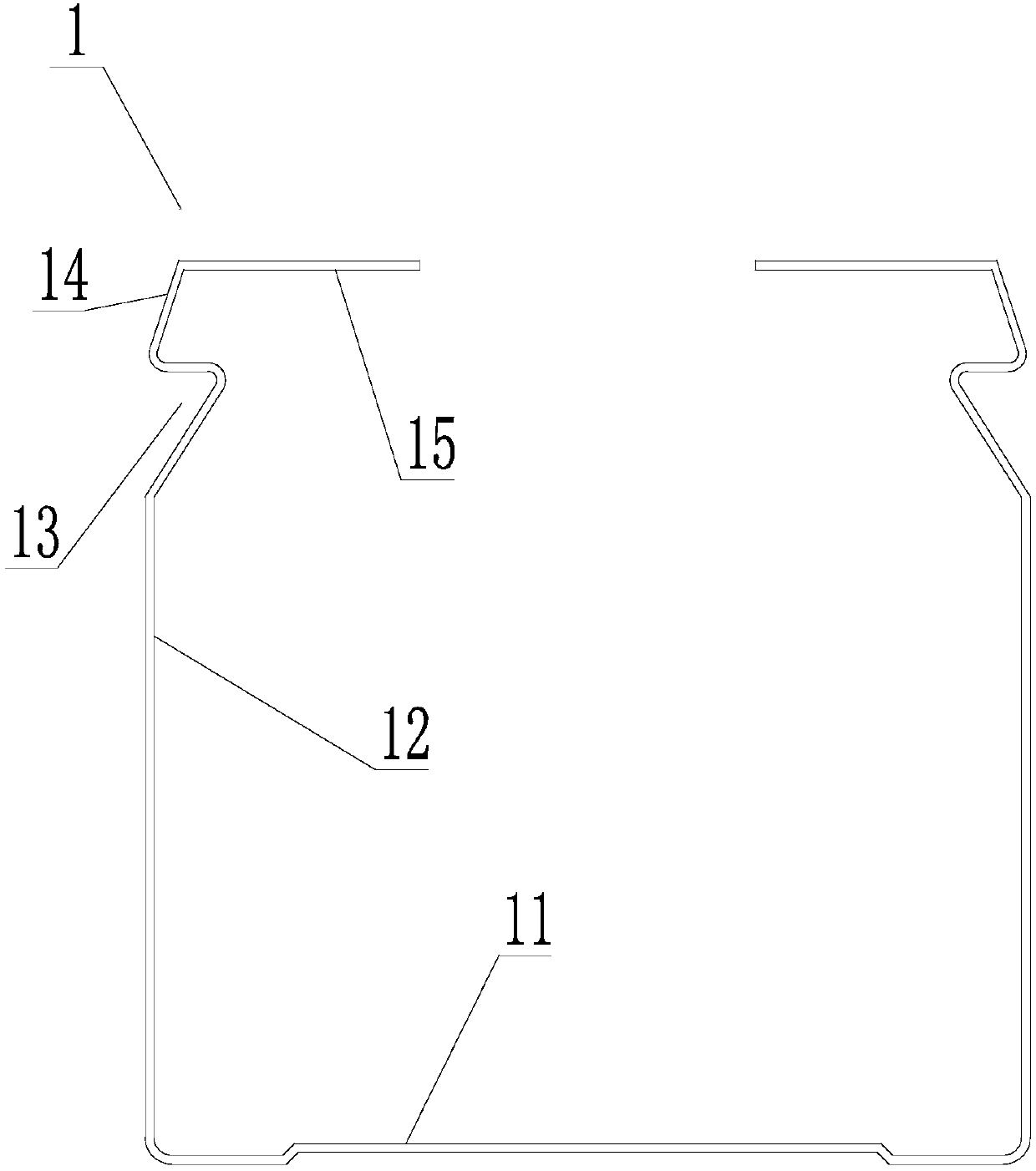

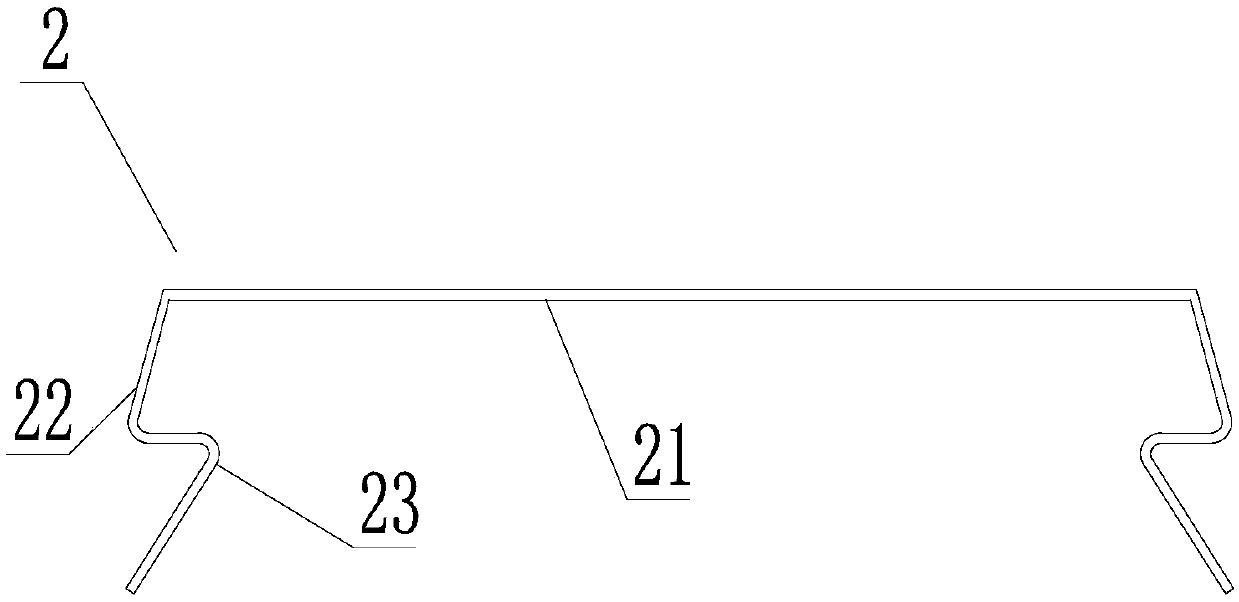

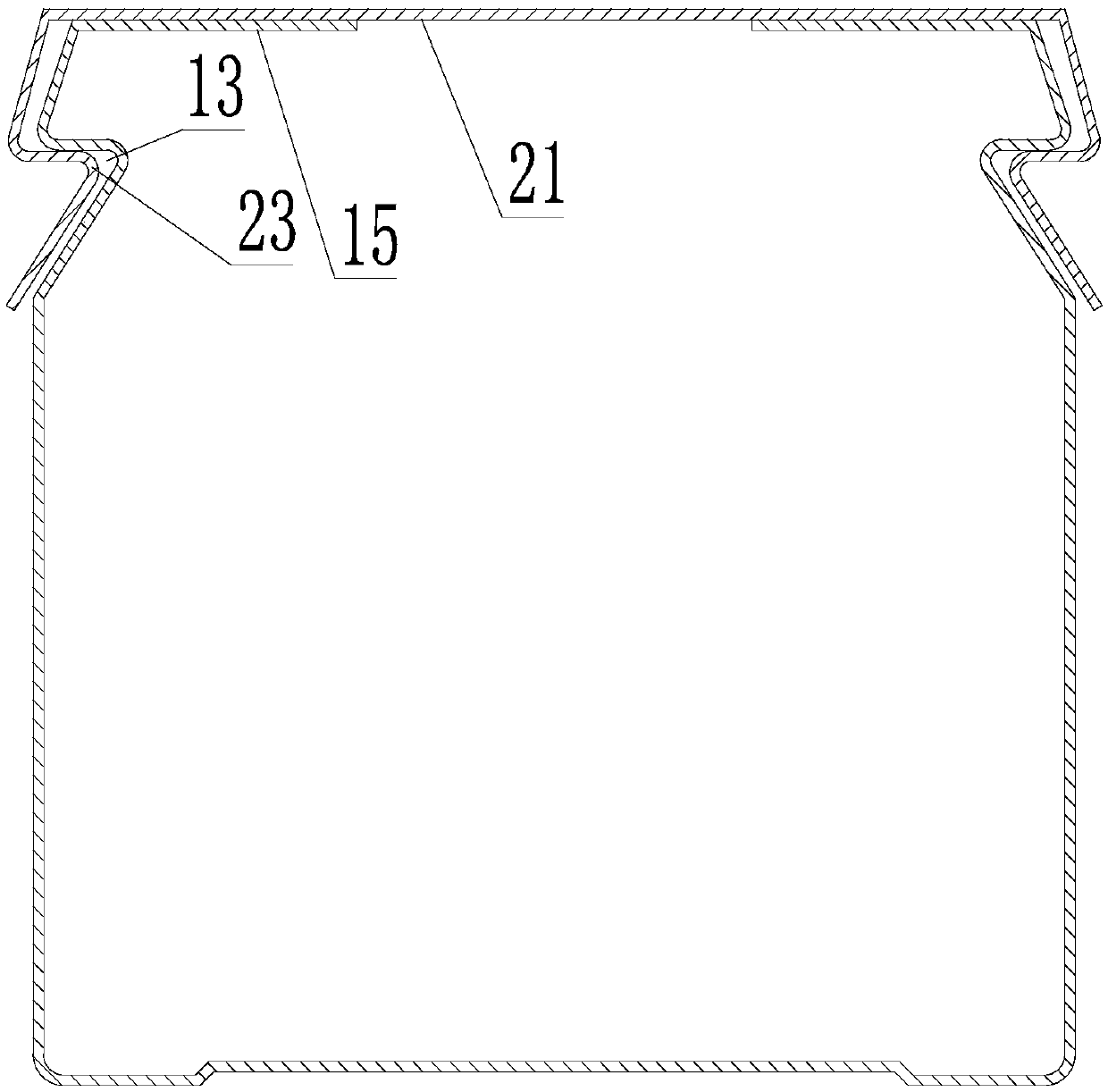

[0063] to combine Figure 1 ~ Figure 3 As shown, Embodiment 1 of the present invention provides a buckle-type keel assembly, including a first keel 1 and a second keel 2 that are snap-connected; the first keel 1 includes a first bottom edge 11 and is arranged on the first bottom edge 11 The first sides 12 on both sides, the first bottom 11 is used to fix the gypsum board in the wall unit on one side, the first side 12 has a first buckle structure; the second keel 2 includes a second bottom 21 And the second side 22 arranged on both sides of the second bottom 21, the second bottom 21 is used to fix the gypsum board in the wall unit on the other side, and the second side 22 has a structure for matching the first buckle The second buckle structure; the cooperation of the first buckle structure and the second buckle structure constitutes a buckle connection structure.

[0064] In the specific operation, the above-mentioned buckle connection structure between the first keel 1 and ...

Embodiment 2

[0075] to combine Figure 4 ~ Figure 23 As shown, Embodiment 2 of the present invention provides a snap-fit assembled wall, which includes two opposite wall units; the wall unit includes gypsum board 4, filling cotton 5 and vertical joists, and the gypsum board 4 is fixed On the bottom edge of the vertical keel, the filling cotton 5 is fixed between the gypsum board 4 and the vertical keel, and the vertical keel is snap-connected with the vertical keel in another wall unit arranged oppositely.

[0076] In the specific operation, the buckle connection structure between the above two vertical keels can be used to effectively avoid the connection method of two wall units in the prior art through self-tapping screws, and can effectively avoid the problem caused by the use of longer self-tapping screws. A series of disadvantages brought about can effectively ensure the integrity of the gypsum board 4 board surface, and can also effectively ensure the connection stability between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com