Heat dissipation channel assembly piece, partition plate heat dissipation assembly and air conditioner

A technology of heat dissipation channels and assemblies, applied in air conditioning systems, heat exchanger shells, space heating and ventilation, etc., can solve problems affecting component life, aging PCB boards, temperature rise, etc., to ensure electrical safety, Improve the service life and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

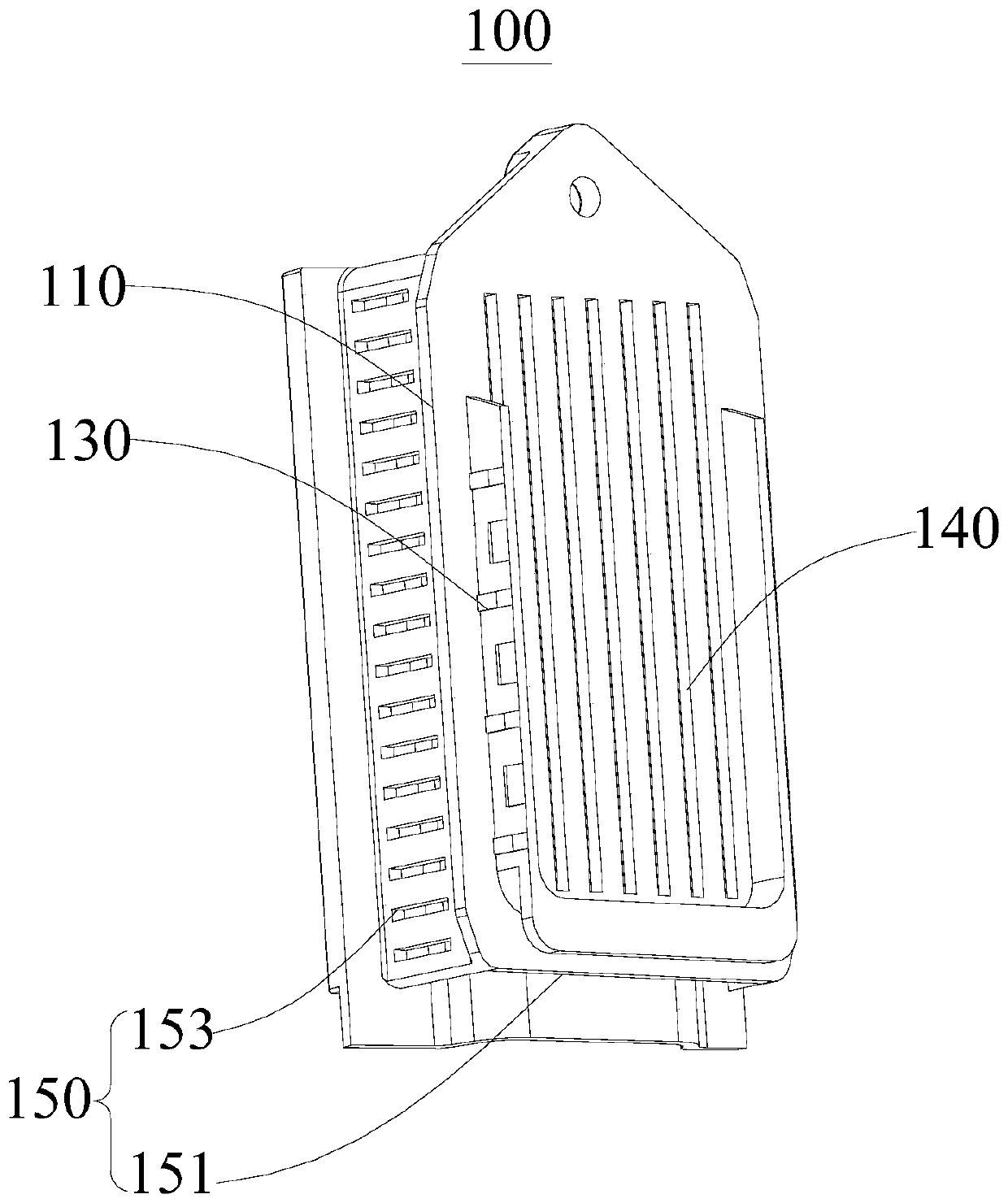

[0062] see in conjunction Figure 1 to Figure 3 , the present embodiment provides a heat dissipation channel assembly 100 for assembling on the wind-proof vertical plate 210. The heat dissipation channel assembly 100 has good heat dissipation and ventilation effects, and has good waterproof performance, which can effectively prevent the wind-proof vertical plate from The rainwater on the outside of the 210 splashes onto the components inside the wind-proof vertical plate 210 .

[0063] The heat dissipation channel assembly 100 provided in this embodiment includes a heat dissipation box body 110 and an assembly part 130, the assembly part 130 is arranged on one side of the heat dissipation box body 110, and is used to be assembled in the installation through hole 211 of the windshield riser 210, so as to Make the heat dissipation box body 110 block the installation through hole 211, the side of the heat dissipation box body 110 close to the assembly part 130 is provided with a ...

no. 2 example

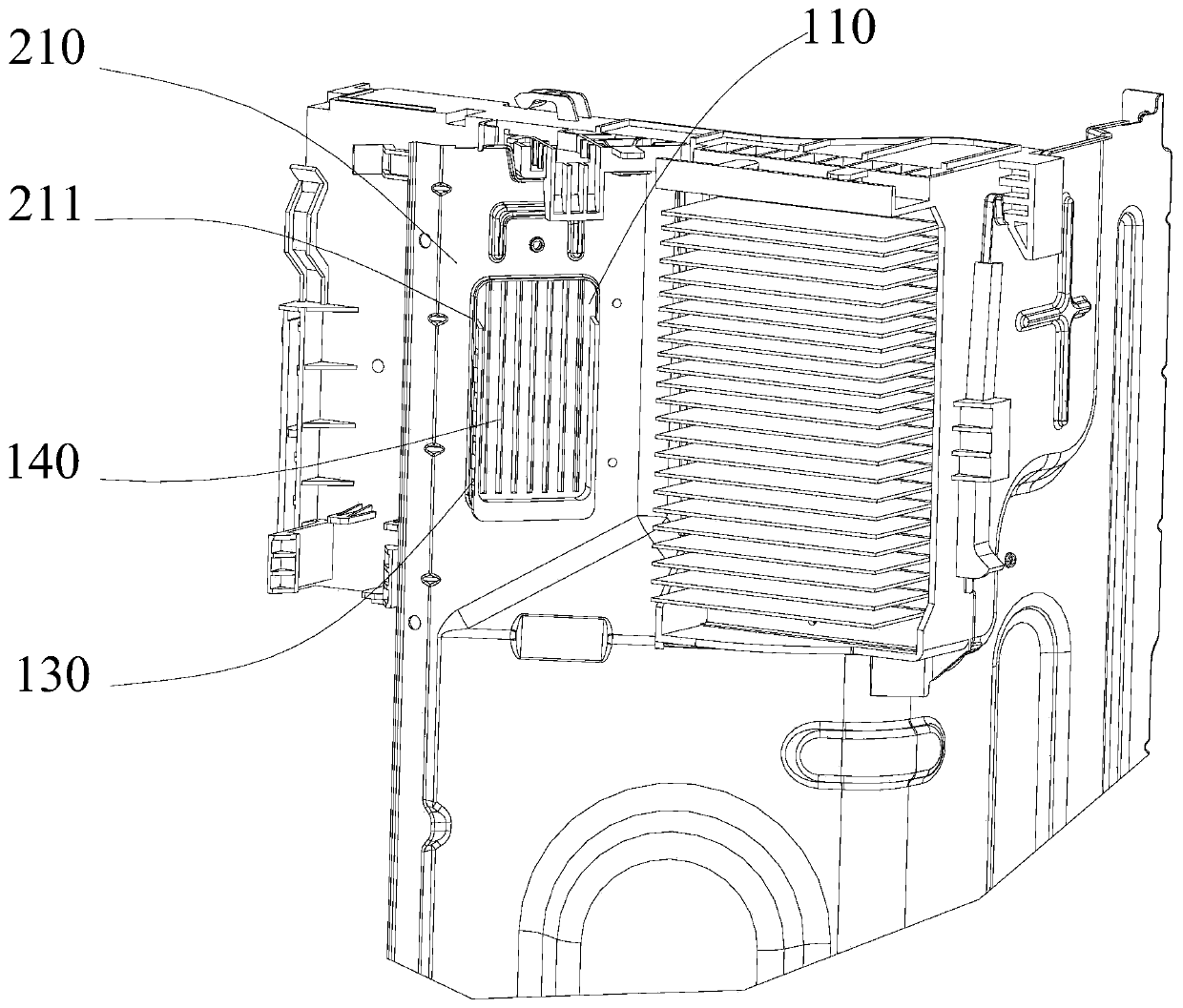

[0093] see in conjunction Figure 8 and Figure 9 , this embodiment provides a partition heat dissipation assembly 200, the partition heat dissipation assembly 200 includes a windshield vertical plate 210 and a heat dissipation channel assembly 100, wherein the basic structure and principle of the heat dissipation channel assembly 100 and the technical effects produced and the first The first embodiment is the same, and for brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0094]An installation through-hole 211 is provided on the wind-proof vertical plate 210 , and the heat dissipation channel assembly 100 includes a heat-dissipating box body 110 and an assembly part 130 . Install in the through hole 211, so that the heat dissipation box body 110 blocks the installation through hole 211, the side of the heat dissipation box body 110 close to the assembly part 130 is provided with a firs...

no. 3 example

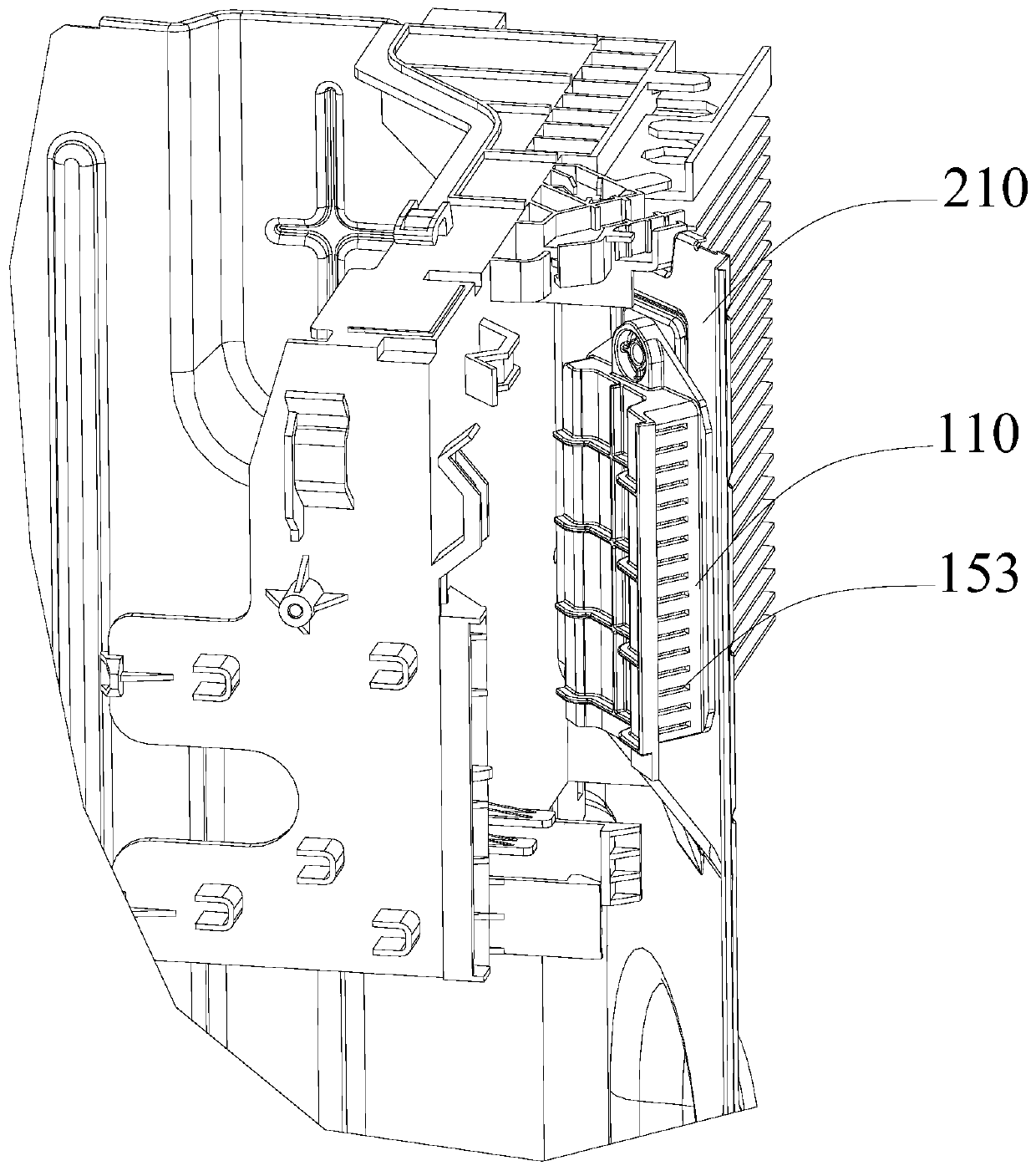

[0098] see Figure 10 , this embodiment provides an air conditioner 10, including a partition heat dissipation assembly 200, wherein the basic structure and principle of the partition heat dissipation assembly 200 and the technical effects produced are the same as those of the first embodiment. For a brief description, this embodiment part For those not mentioned, reference may be made to the corresponding content in the second embodiment.

[0099] The partition heat dissipation assembly 200 includes a wind-shielding vertical plate 210 and a heat dissipation channel assembly 100. The wind-shielding vertical plate 210 is provided with an installation through hole 211. The heat dissipation channel assembly 100 includes a heat dissipation box body 110 and an assembly part 130. The assembly part 130 is provided with On one side of the heat dissipation box body 110, it is used to be assembled in the installation through hole 211 of the windshield vertical plate 210, so that the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com