Wear-resistant gauge protection tearing cutter

A wear-resistant, tearing knife technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of increased thrust, high frequency of start and stop of shield machine, high frequency of tool change, etc., and achieve the speed of delaying wear , Improve the excavation efficiency and reduce the frequency of tool change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

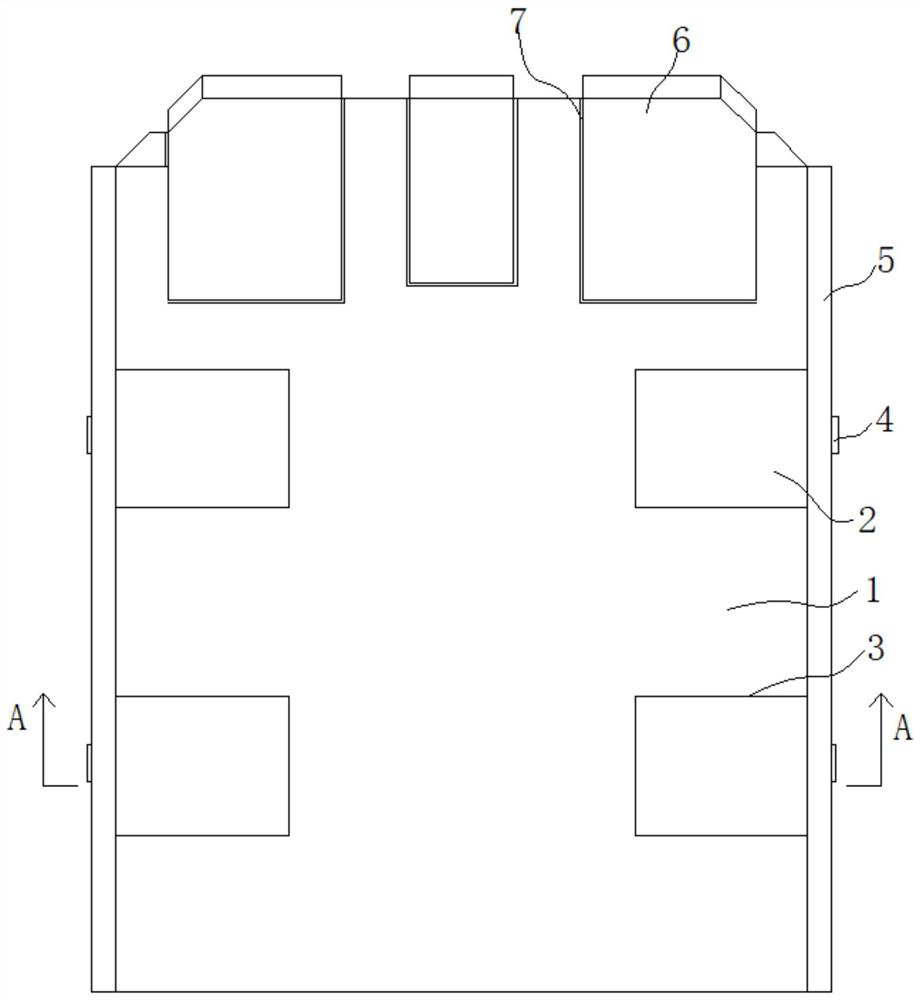

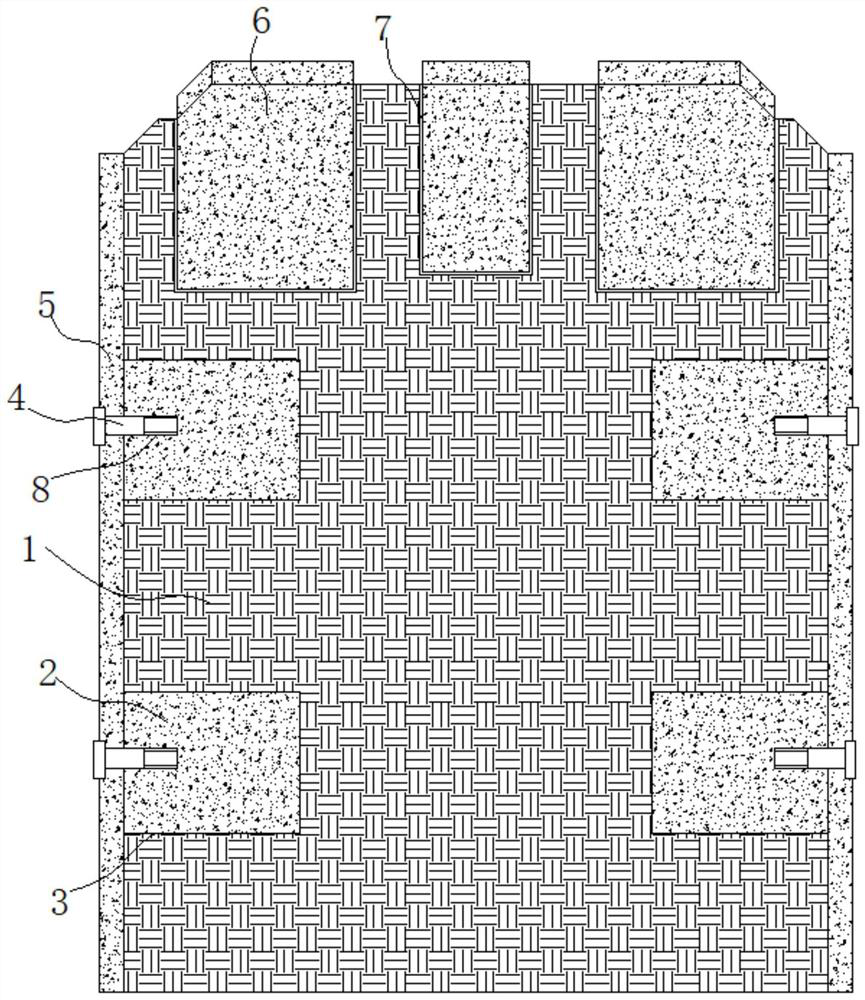

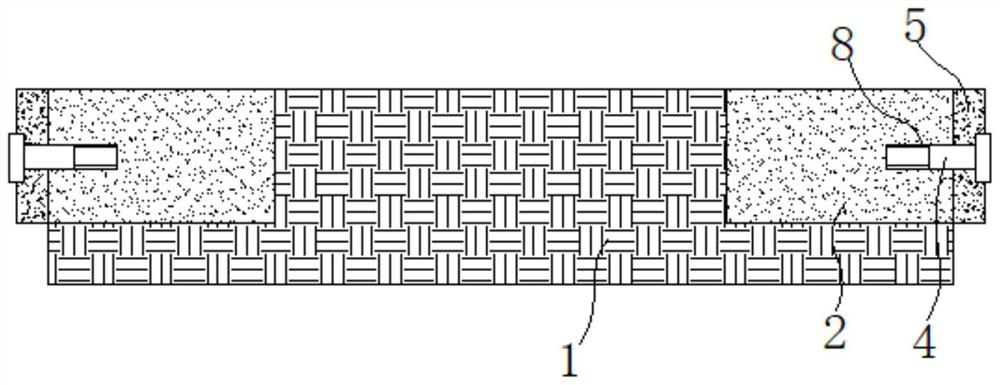

[0041] Such as figure 1 As shown, a wear-resistant gauge tearing knife includes a blade body 1 and an alloy blade 6 fixed on the head of the blade body 1;

[0042] Two grooves 3 are respectively opened on the upper surface of the blade 1 and at positions close to both sides of the blade 1, and the two grooves 3 on the same side are respectively distributed at the front and rear of the side, and the grooves 3 are adjacent to the corresponding side walls of the blade 1. An alloy block 2 is fixed in the groove 3, and the upper surface of the alloy block 2 is flush with the upper surface of the blade 1;

[0043] Both sides of the blade 1 are respectively provided with alloy plates 5 detachably connected to the corresponding alloy blocks 2. The length direction of the alloy plate 5 extends along the length direction of the side wall of the blade 1, and is close to the corresponding side wall of the blade 1. The upper edge of the plate 5 is flush with the upper surface of the blade 1 and...

Embodiment 2

[0051] The difference from Example 1 is:

[0052] Such as Figure 4 with Image 6 As shown, the upper edge of the alloy plate 5 is integrally formed with an alloy wing plate 9 that extends horizontally to the blade 1, and the lower surface of the alloy wing plate 9 abuts against the upper surface of the blade 1.

[0053] Specific, such as Figure 5 with Figure 7 As shown, the lower surface of the alloy wing plate 9 is integrally formed with a plurality of alloy positioning posts 10, the upper surface of the blade 1 is provided with positioning grooves corresponding to the alloy positioning posts 10, and the alloy positioning posts 10 are inserted into the corresponding positioning grooves, and The inner wall of the positioning groove is used for clearance fit.

[0054] Preferably, the alloy positioning column 10 has a square column structure, and the positioning groove has a square groove 3 structure matching the shape and size of the alloy positioning column 10.

[0055] Preferably...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com