Patents

Literature

30results about How to "Reduce the frequency of tool changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

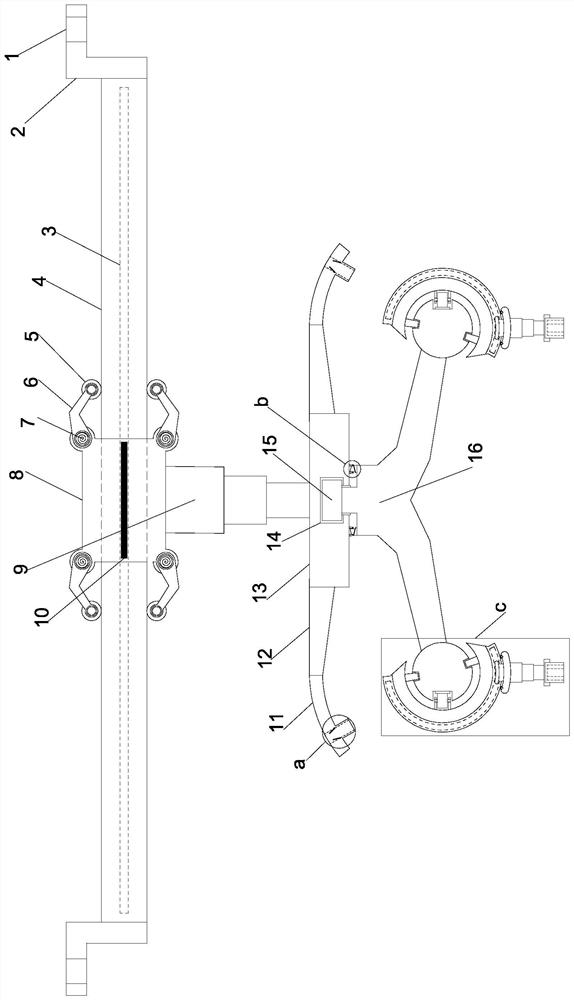

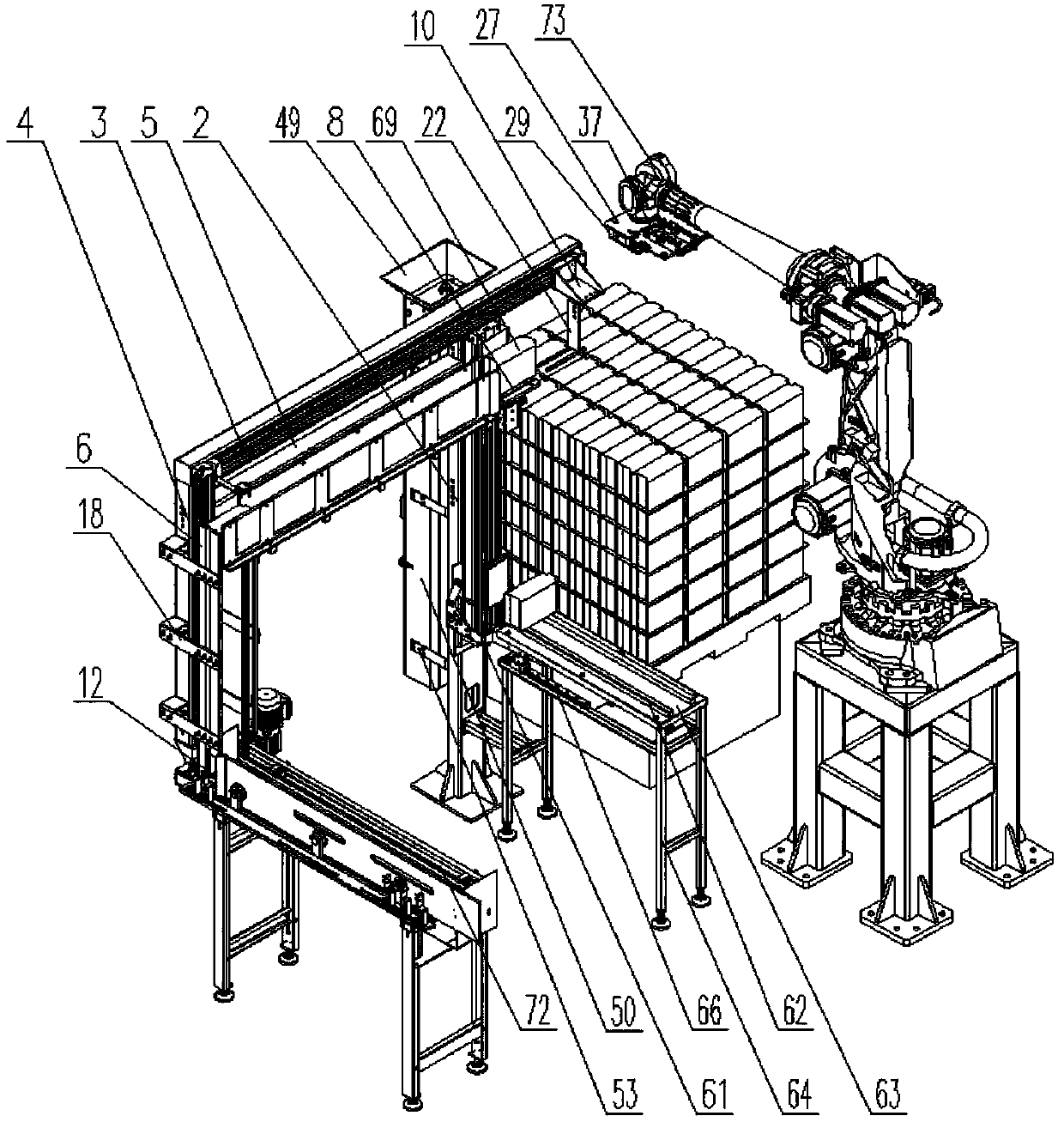

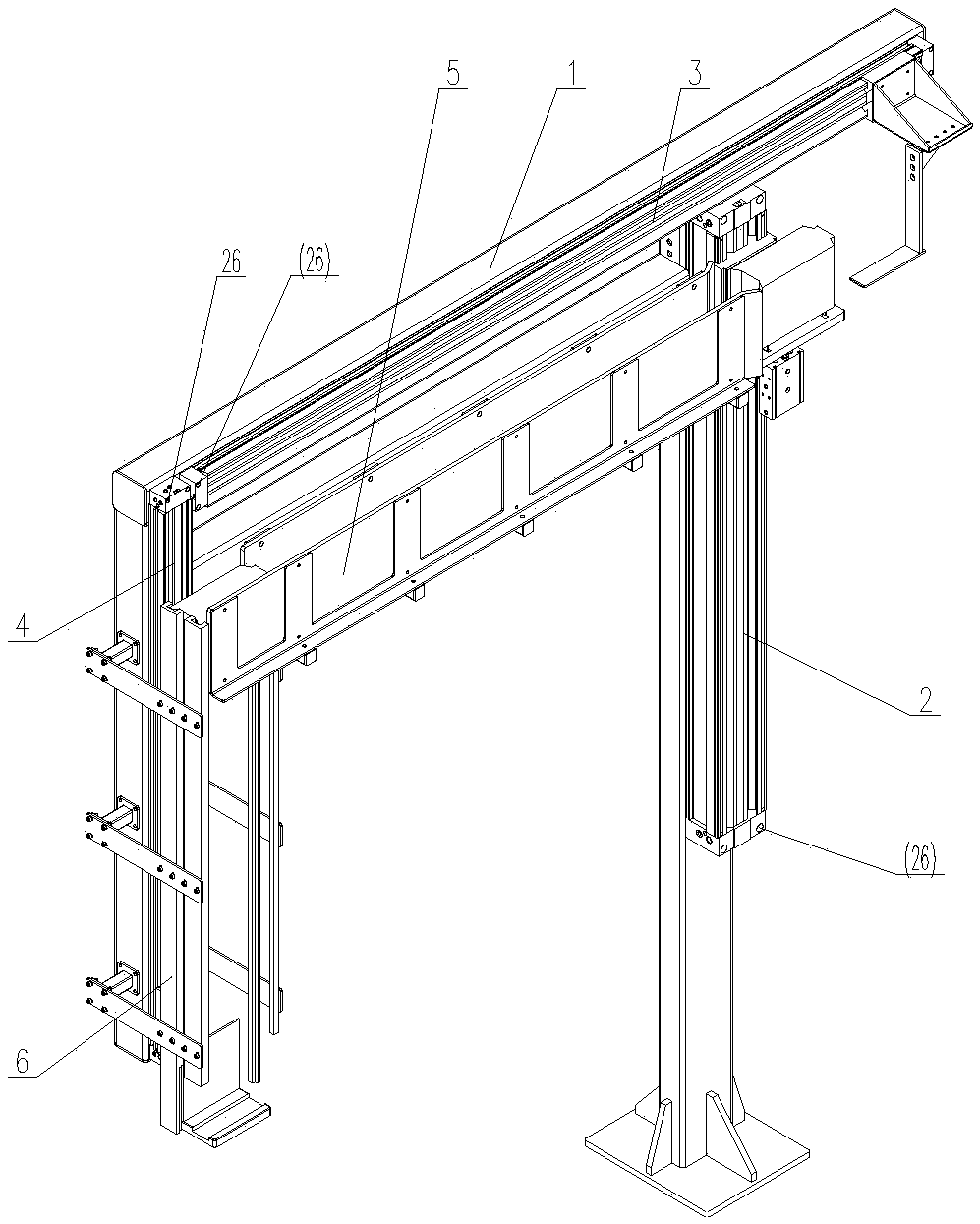

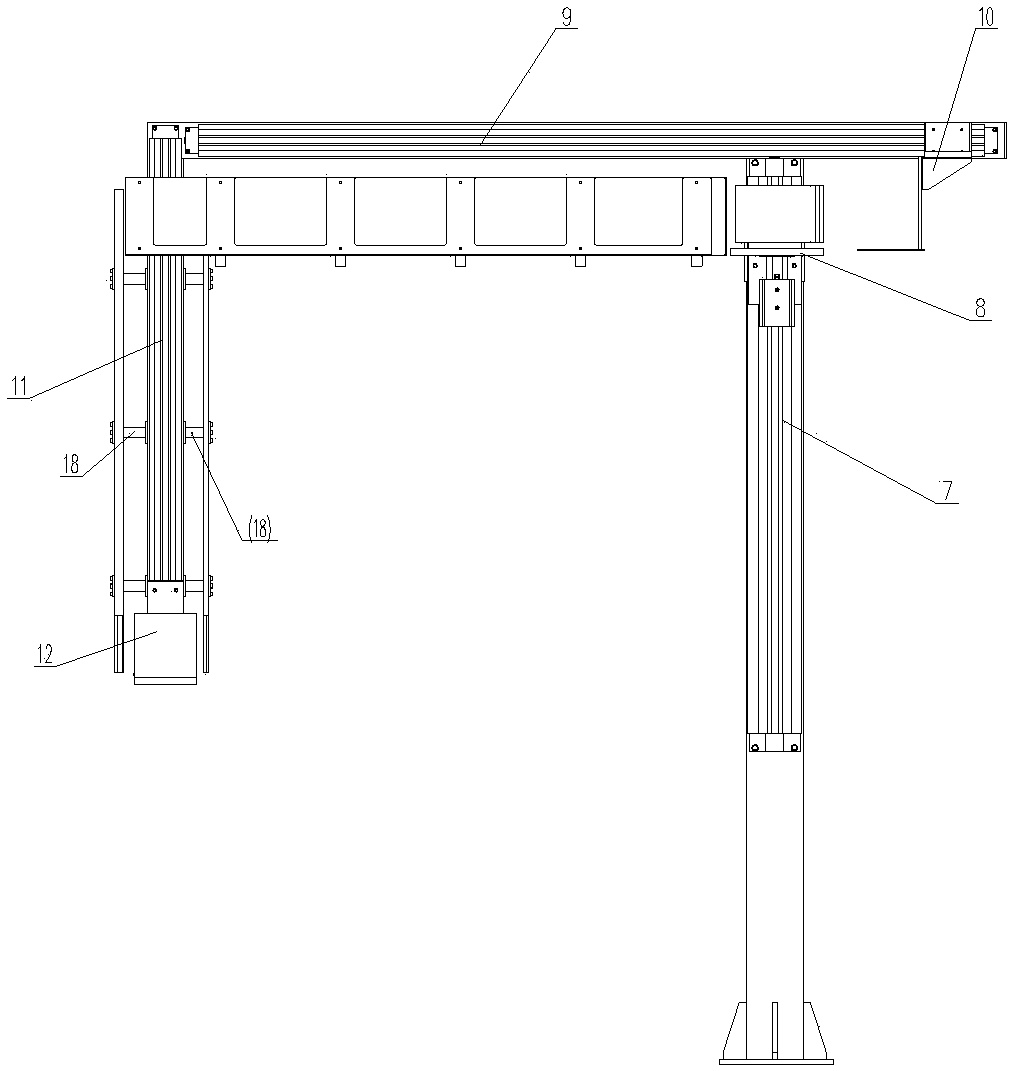

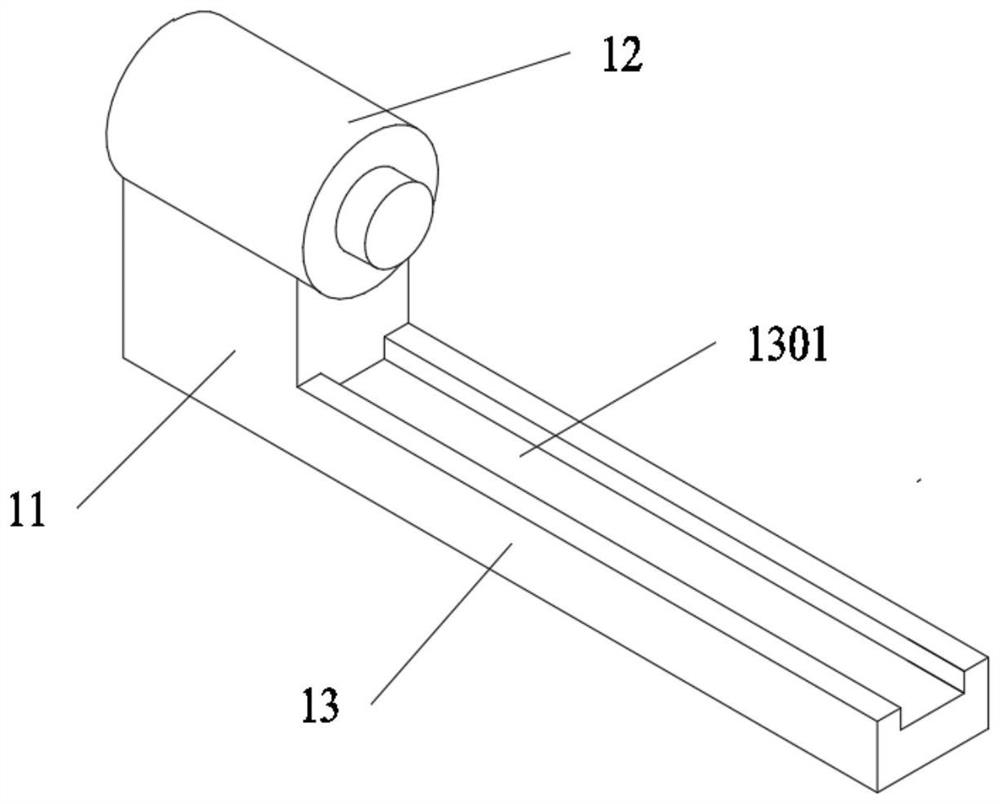

Robot-based automatic loading system for cigarette packaging square accessories

ActiveCN105883387ATimely detection of blockageIncrease falls intoConveyorsControl devices for conveyorsEngineeringAtmospheric pressure

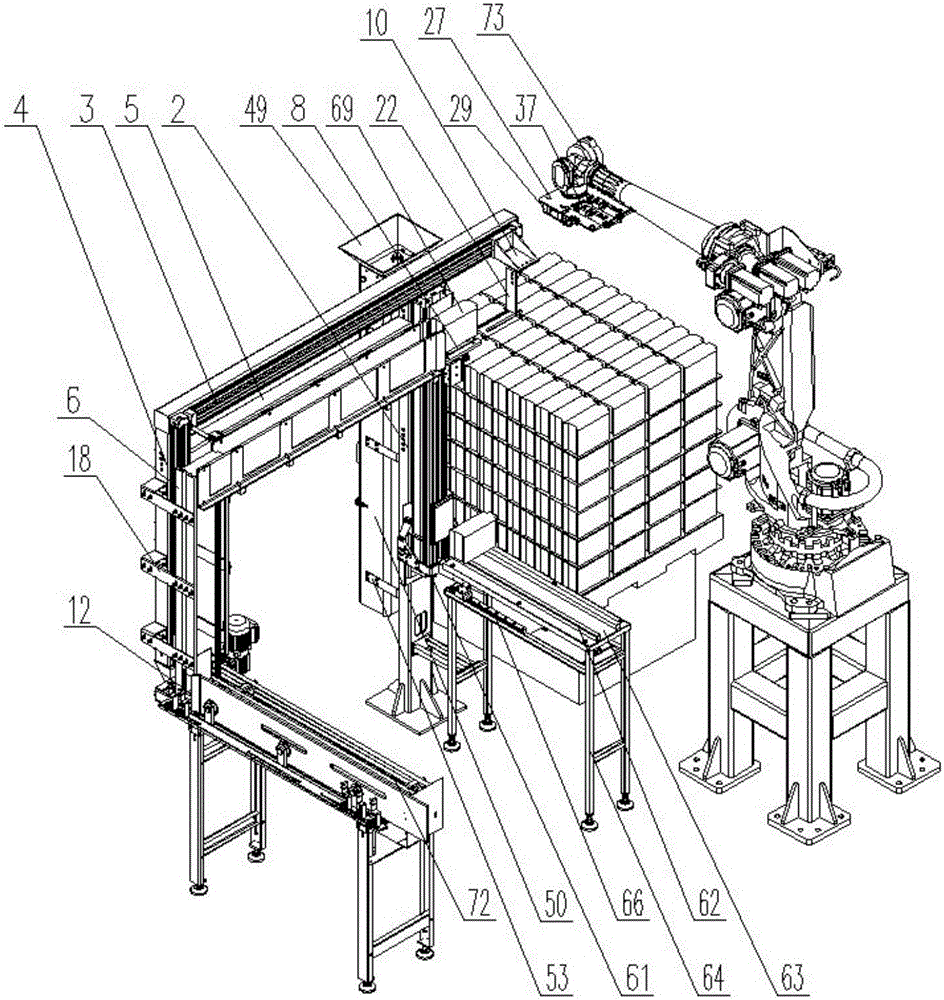

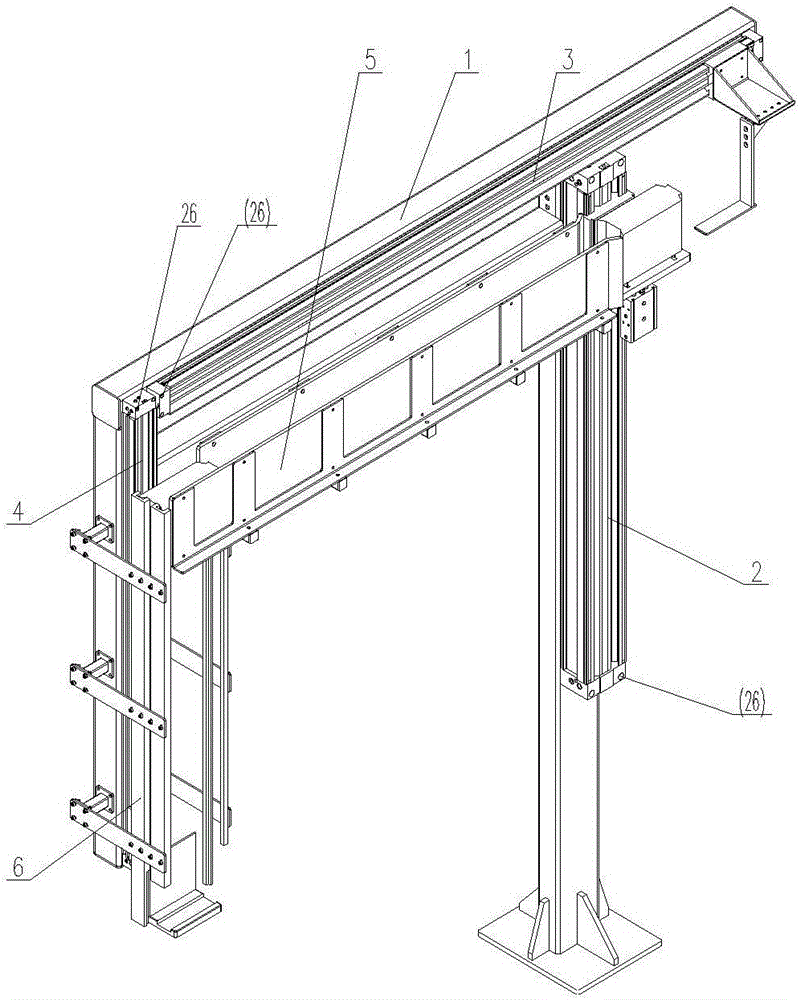

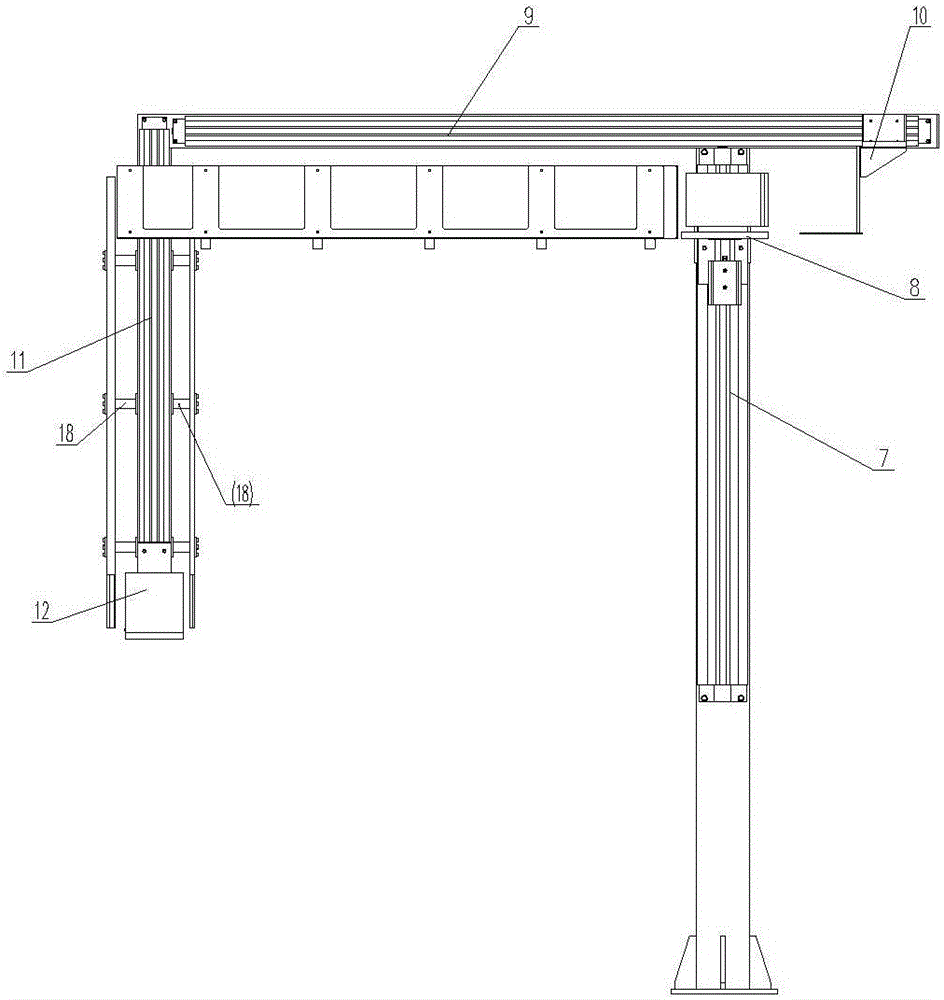

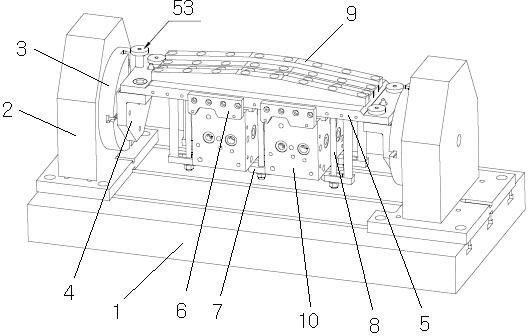

A robot-based automatic loading system for cigarette packaging square accessories is characterized by comprising a bulk accessory conveyor system arranged on a gantry-type main support, a robot fixture close to the right side of the gantry-type main support, a bulk accessory wrapper recycling device fixed at the front end of the right side of the gantry-type main support, an automatic bulk accessory waste recycling device fixed at the rear end of the right side of the gantry-type main support, a bulk accessory wrapper withdrawal assisting mechanism arranged on a bulk accessory conveying rack, a synchronous belt conveyor connected to the left side of the gantry-type main support, and a joint robot arranged on the robot fixture, as well as a pneumatic system for providing power for a material transporting system, a material conveying system and a tool cutting system. The robot-based automatic loading system has the following beneficial effects: the production cost is effectively lowered, and the production efficiency is greatly improved; and the robot-based automatic loading system is simple in structure, good in strength and rigidity and stable and reliable in operation, and is efficient and energy-saving.

Owner:云南昆船电子设备有限公司

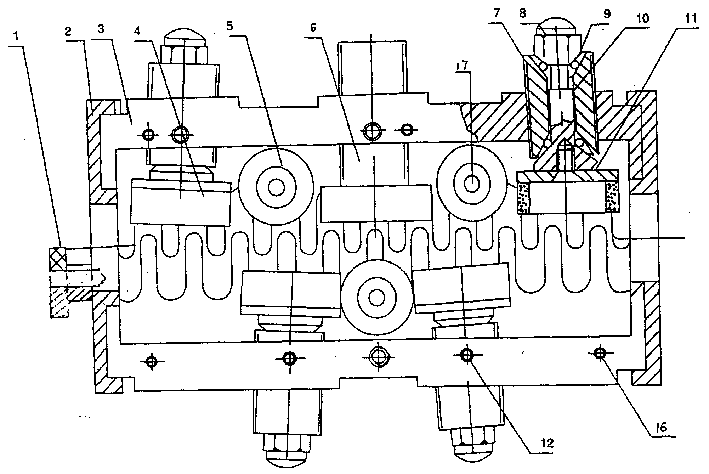

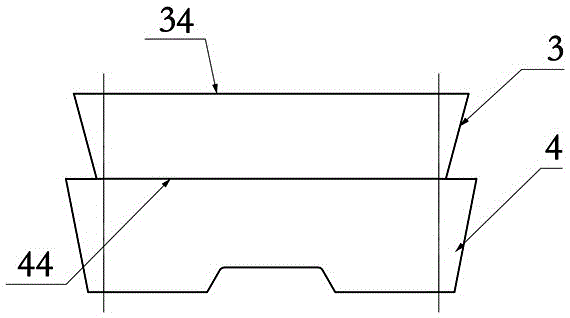

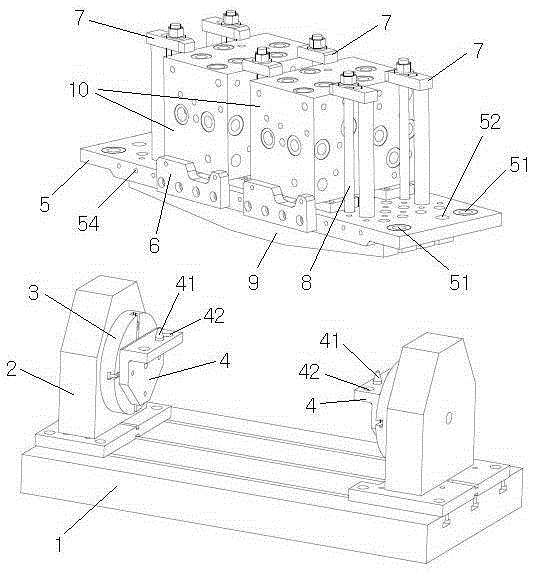

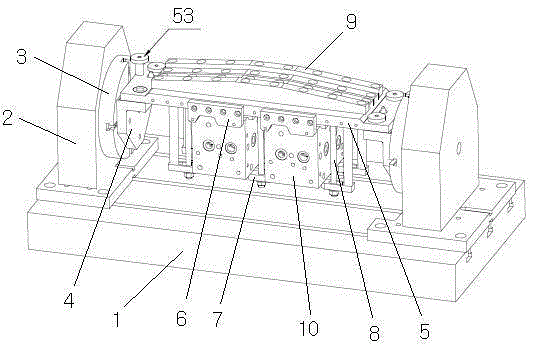

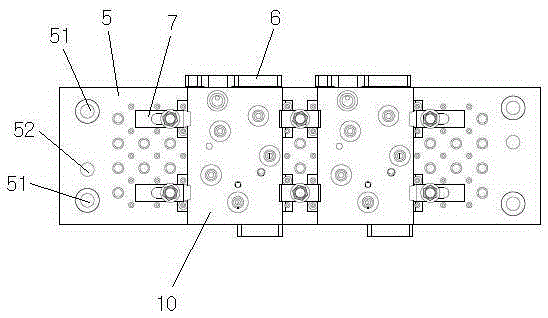

Workpiece clamp for numerical control machine tool

InactiveCN102350649AReduce the frequency of tool changesImprove processing efficiencyPositioning apparatusMetal-working holdersNumerical controlBatch processing

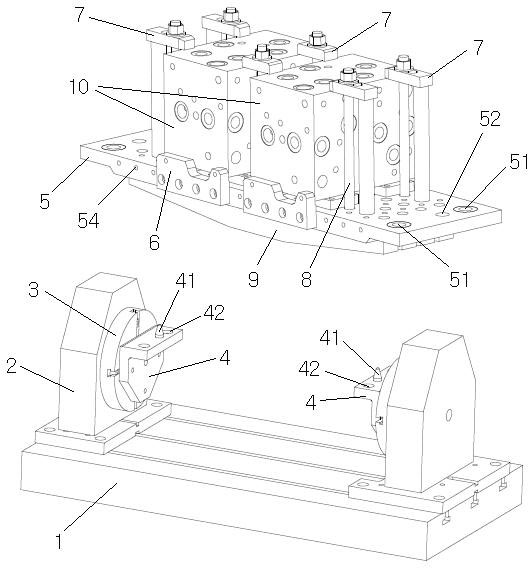

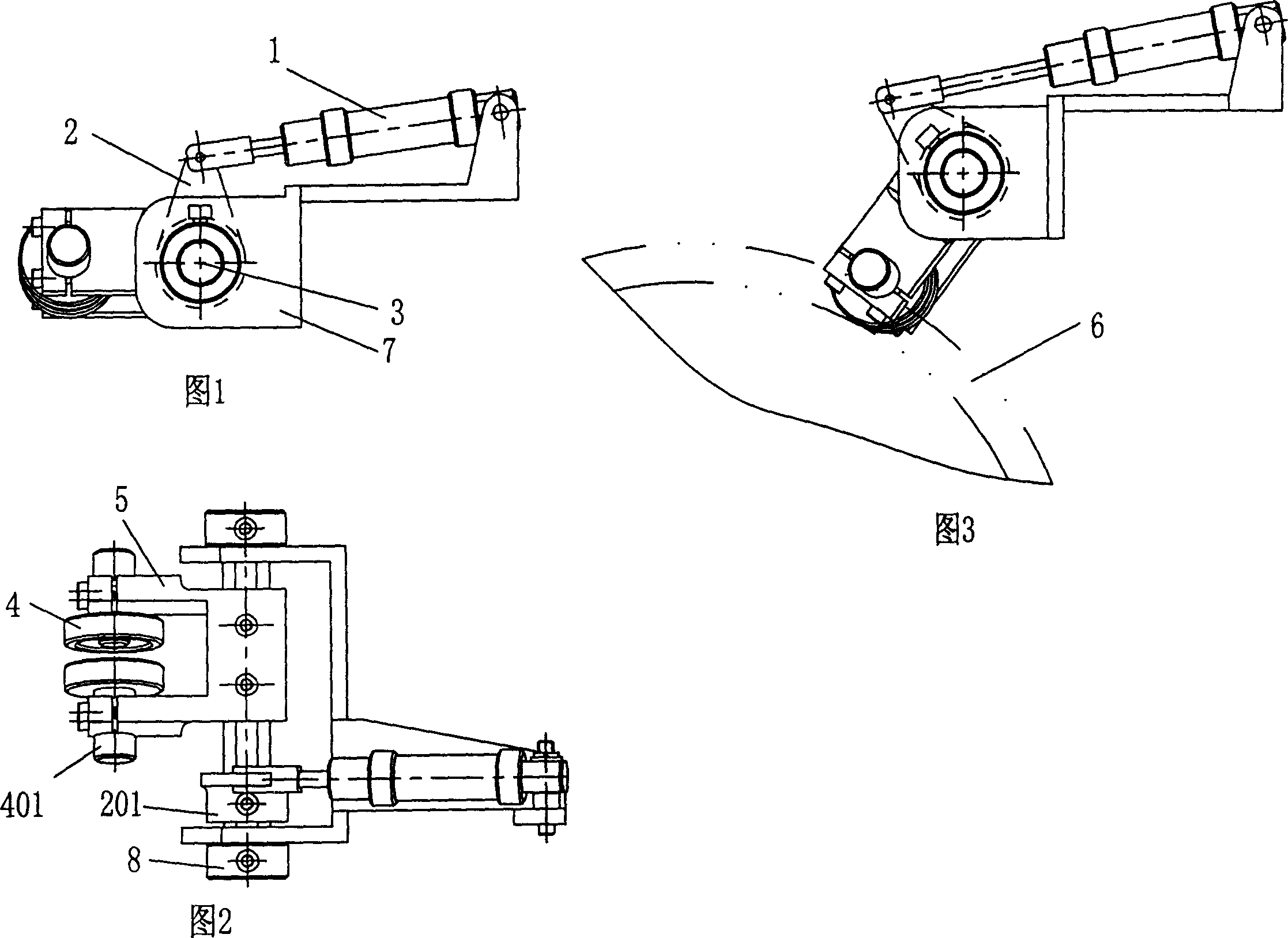

The invention discloses a workpiece clamp for a numerical control machine tool, which relates to the technical field of numerical control machine tools and aims at solving the technical problem of improving the batch processing efficiency. The clamp comprises two transfer plates, a bridge plate, a plurality of side screw bolts, a plurality of side pressing plates, a plurality of positioning screw rods, a plurality of positioning pressing plates and four ball lock shafts, wherein the two transfer plates are respectively arranged on two motive power heads of the numerical control machine tool, the upper part of each transfer plate is respectively bent in the direction towards the other transfer plate and is respectively provided with an initial positioning pin, the front part and the back part of each transfer plate are respectively provided with a transfer hole, a ball lock is arranged in each transfer hole, the bridge plate is a rectangular flat plate, screw hole arrays are arranged on the plate surface of the bridge plate, an initial positioning hole is respectively arranged at the left edge and the right edge of the plate surface of the bridge plate, four bridging holes are arranged at four corners of the plate surface of the bridge plate, a plurality of side screw holes are respectively arranged at the peripheral surface of each long edge of the bridge plate, the plate surface of each side pressing plate is provided with a plurality of side pressing holes, and positioning holes for the positioning screw rods to pass through are respectively arranged on each positioning pressing plate. The clamp provided by the invention can be used for mounting and clamping a plurality of workpieces in one step.

Owner:SHANGHAI HUIYI CONTROL SYST

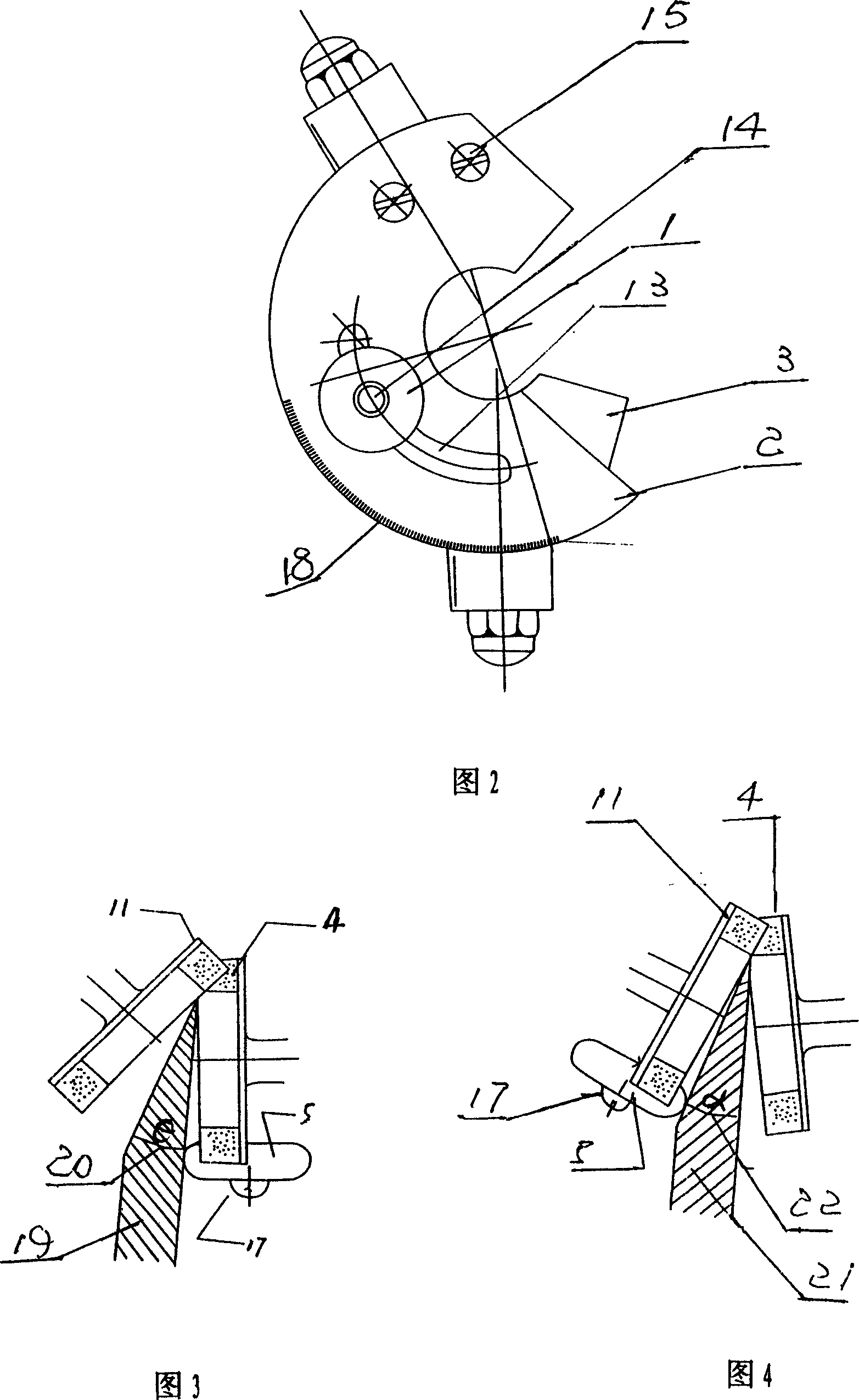

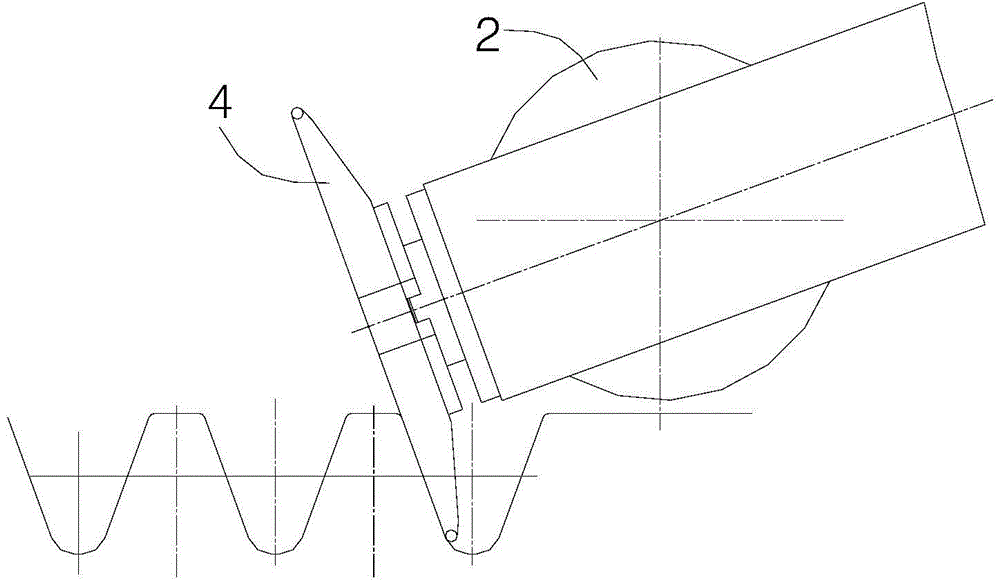

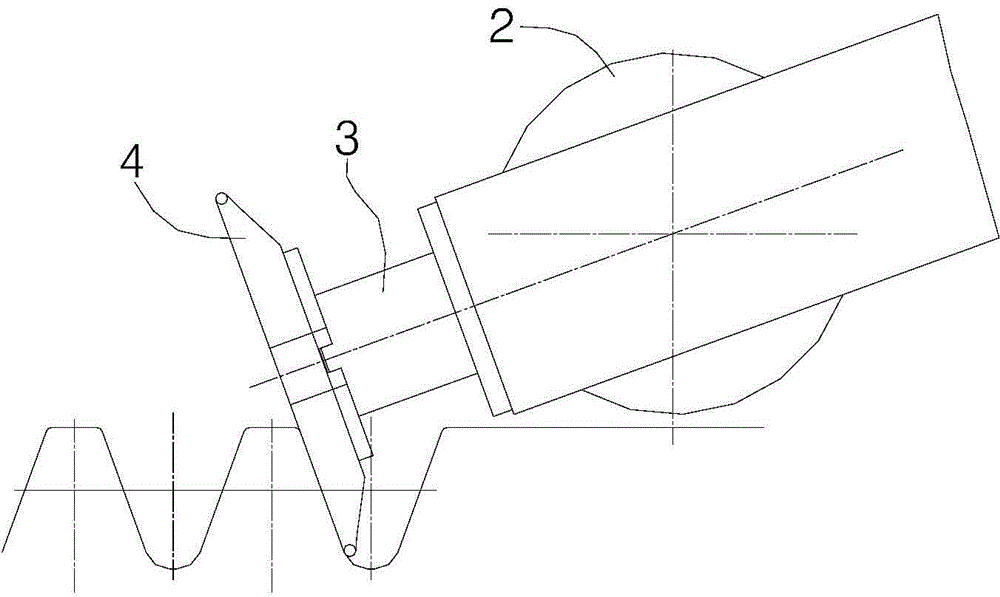

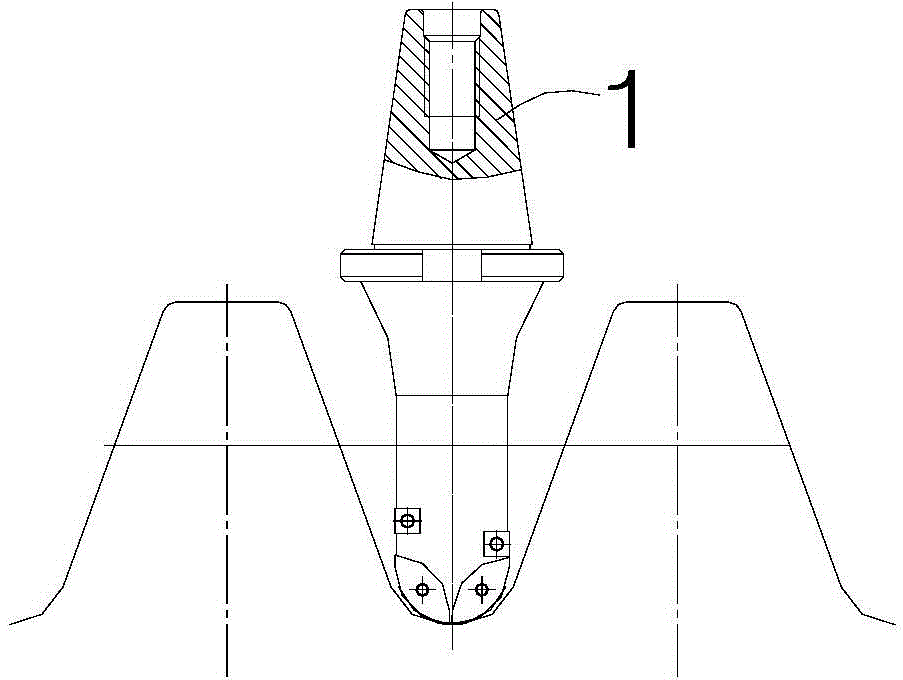

Automatic knife grinder for numerically controlled fabrics cutting machine

InactiveCN1963010AReduce laborSimple structureSevering textilesOther manufacturing equipments/toolsKnife sharpenerEngineering

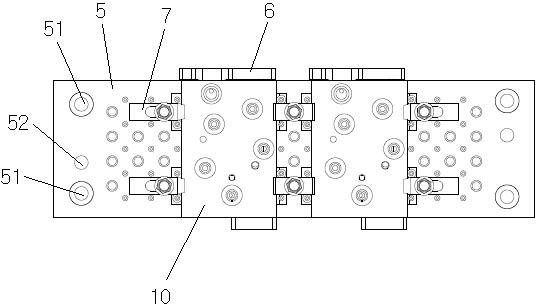

The invention provides automatic knife sharpener of digital control fabric cutting machine. It comprises of sharpening parts, swing components and fixed components. The swing components comprises cylinder, deflection plate and deflection axis; the sharpening parts comprises two abrasive disks equipped parallel, abrasive disk axis and the sharpening fixed parts, the deflection plate and the axle sleeve are one unit and are installed with the deflection axis firmly, the abrasive disk axis is installed with the sharpening fixed parts firmly, the sharpening fixed parts are fixed on the deflection axis obliquely, the cylinder and the deflection axis are fixed on the fixed plate, two ends of said deflection axis are equipped with fender blocks, the fixed plate is fixed on the frame. The invention is simple in structure, low cost and sharpening finely, it solves the automatically sharpening caused by the cut knife of the cutting machine become inactivating after used for a long time, it reduces the frequency of changing knife tools, reduces the amount of labor workers and improves the production efficiency greatly.

Owner:李德锵

Knife fine grinding apparatus

InactiveCN1517177AImprove sharpnessExtend your lifeOther manufacturing equipments/toolsEngineeringKnife blades

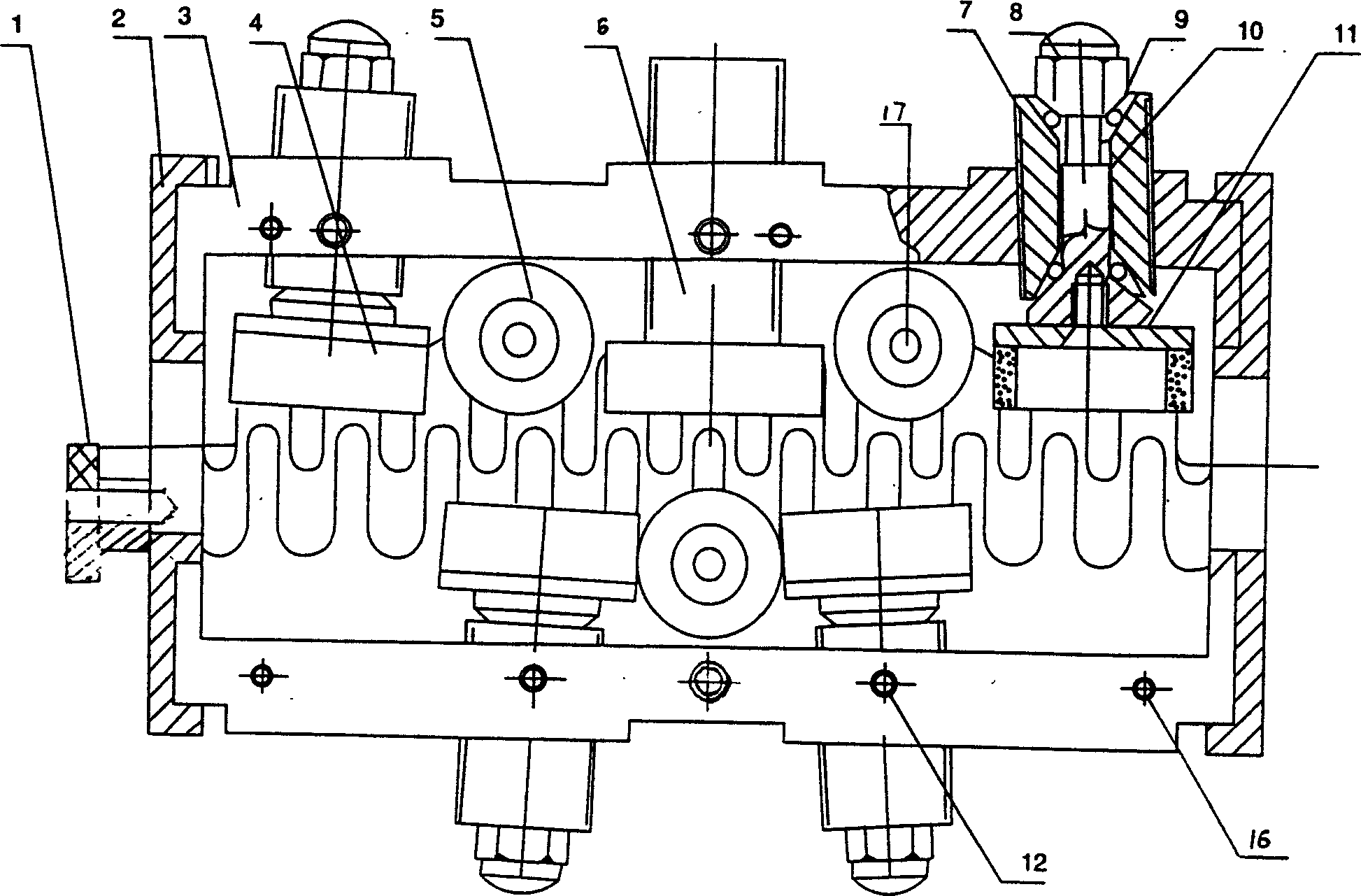

A fine grinder for blade is disclosed. A casing with V-shaped slot is composed of two semi-arc cases whose both ends are matched with rotary disks. 4 grinding wheels (two for each semi-arc half) are adhered to fixing plates and then installed to rotary shaft without axial toggles. The screw sleeve is used to regulate the axial position of rotary shaft. 3 guide rollers in the case can ensure the optimal contact between blade and grinding wheels. After a blade is fixed and the grinding wheels move together to form a V-shaped grinding notch, the cutting edge of said blade can be ground back and forth.

Owner:陈瑞生

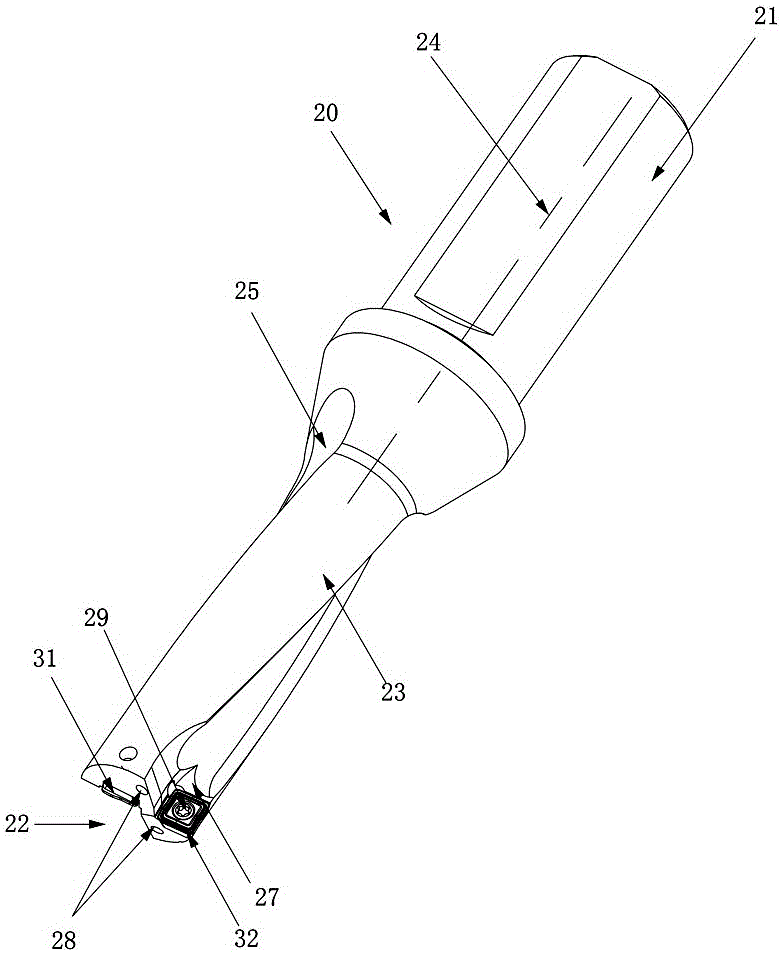

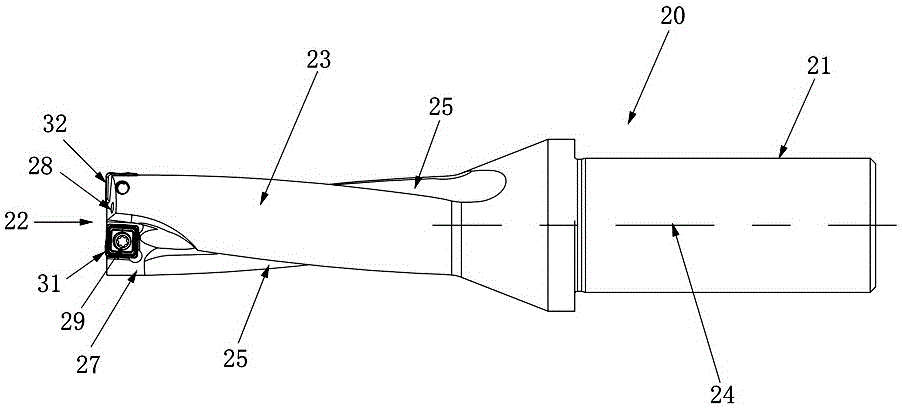

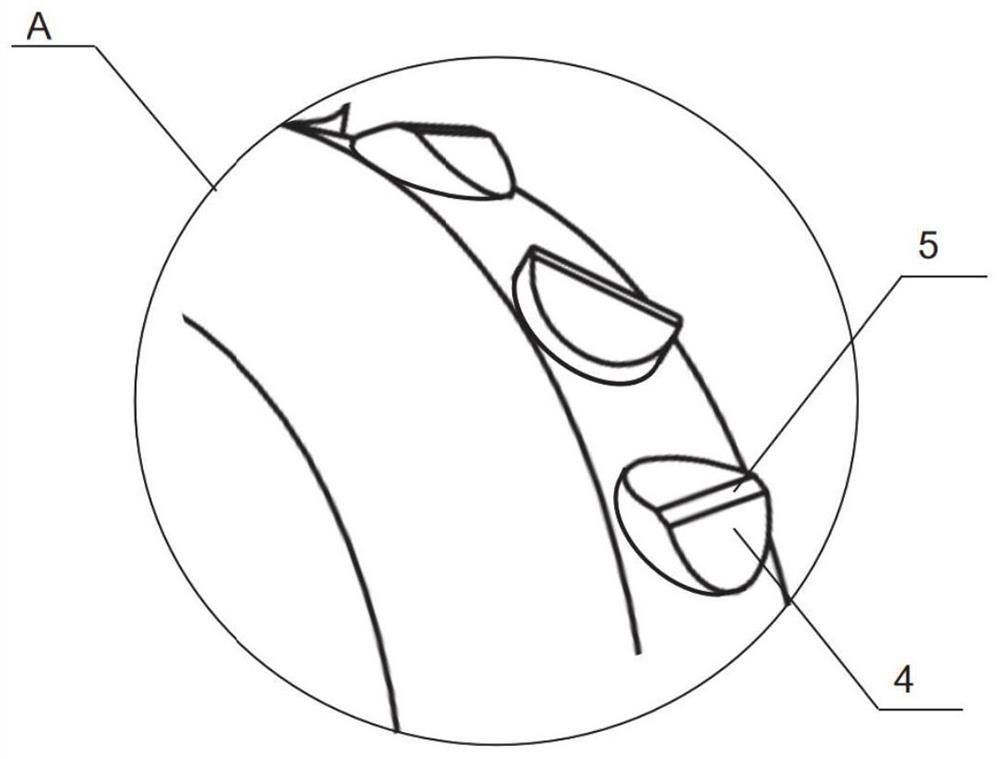

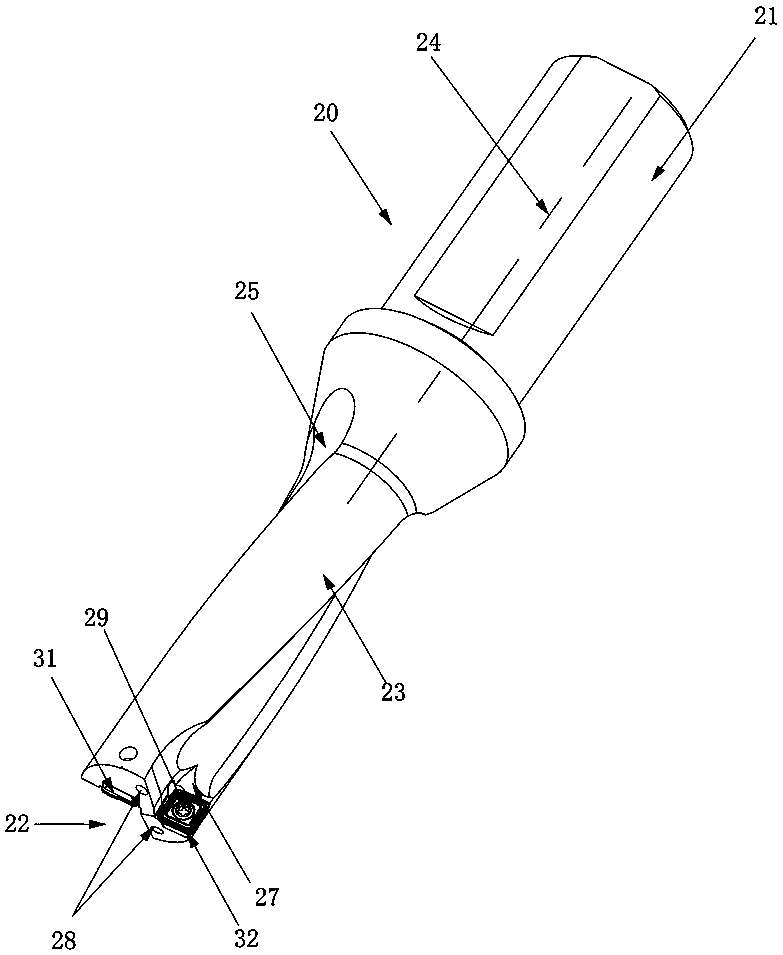

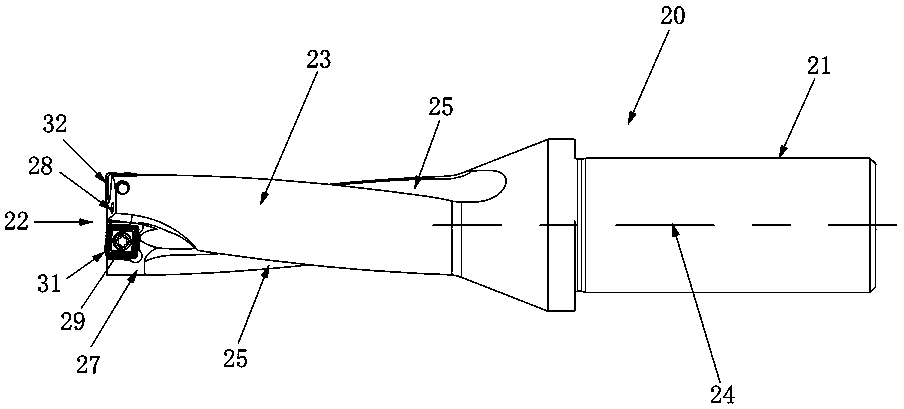

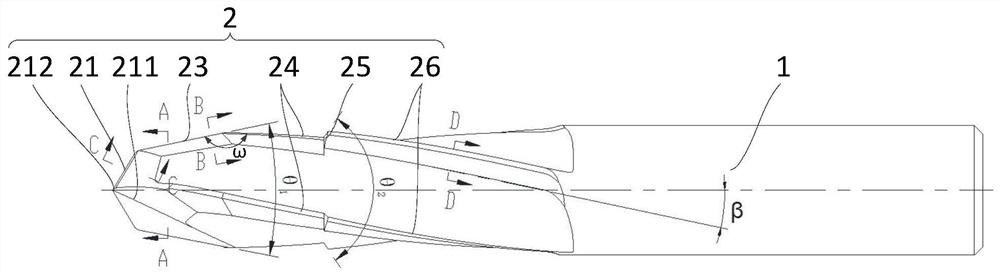

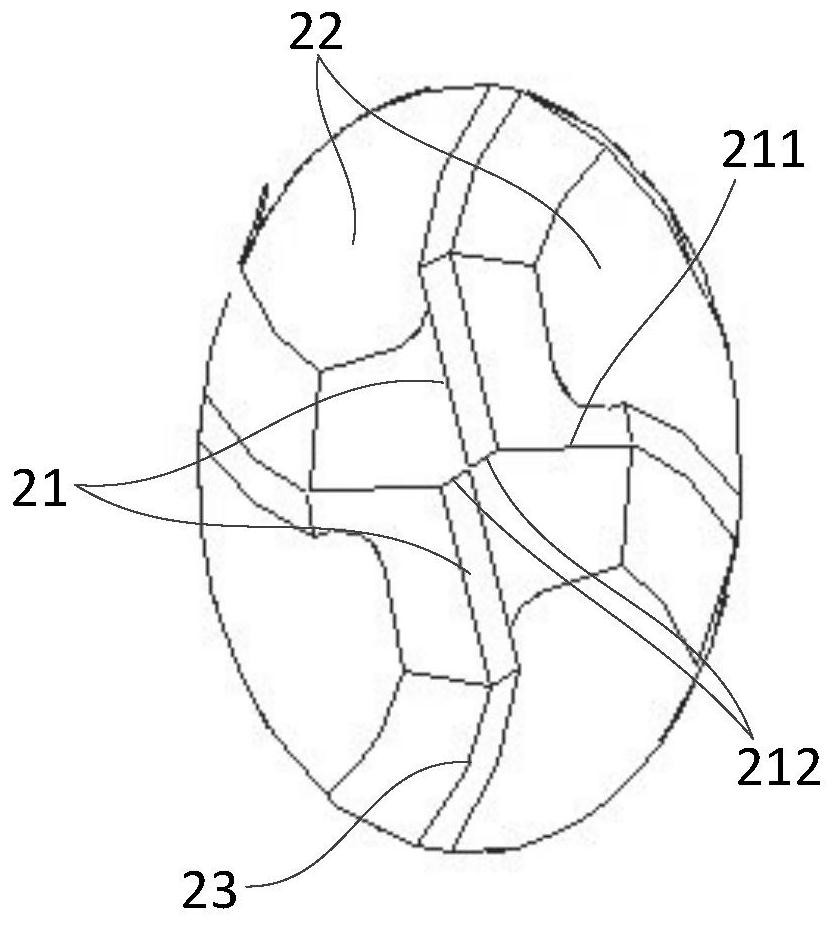

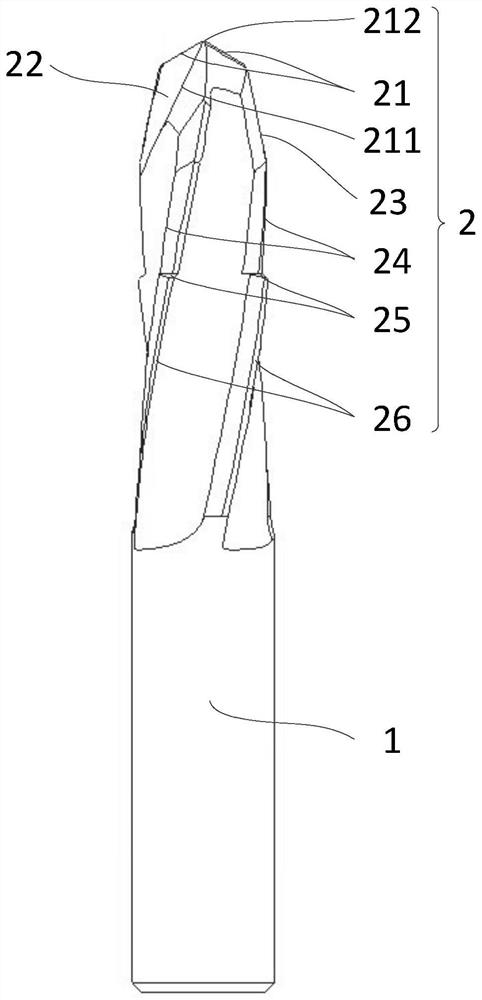

Drilling tool

ActiveCN106694962AReduce manufacturing difficultyReduce crashTransportation and packagingTrepanning drillsEngineeringMachining

The invention discloses a drilling tool. The drilling tool comprises a tool body; the tool body comprises a handle part, a cutting end part and a peripheral surface located between the handle part and the cutting end part; the handle part and the peripheral surface are symmetric about a rotation central axis of the tool body; a central groove and a circumferential groove which both communicate with a spiral groove in the circumferential surface are formed in the cutting end part, wherein the center groove is arranged adjacent to the rotation central axis, and the circumferential groove is arranged adjacent to the peripheral surface; cutting blades are arranged in the central groove and the circumferential groove, wherein the cutting blade arranged in the central groove is an inner blade, the cutting blade arranged in the circumferential grooves is an outer blade, and the inner blade and the outer blade are the same cutting blades; each cutting blade comprises a short cutting edge and a long cutting edge which are adjacent; the edge shape of each short cutting edge is different from the edge shape of the corresponding long cutting edge; the long cutting edge of the inner blade and the short cutting edge of the outer blade are combined to form a complete main cutting edge used for drilling a hole, the inner blade completes machining of a center area of the hole, and the outer blade completes machining of an outer ring area of the hole. The drilling tool has the advantages of being small in cutting vibration, high in machining precision, stable, reliable and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

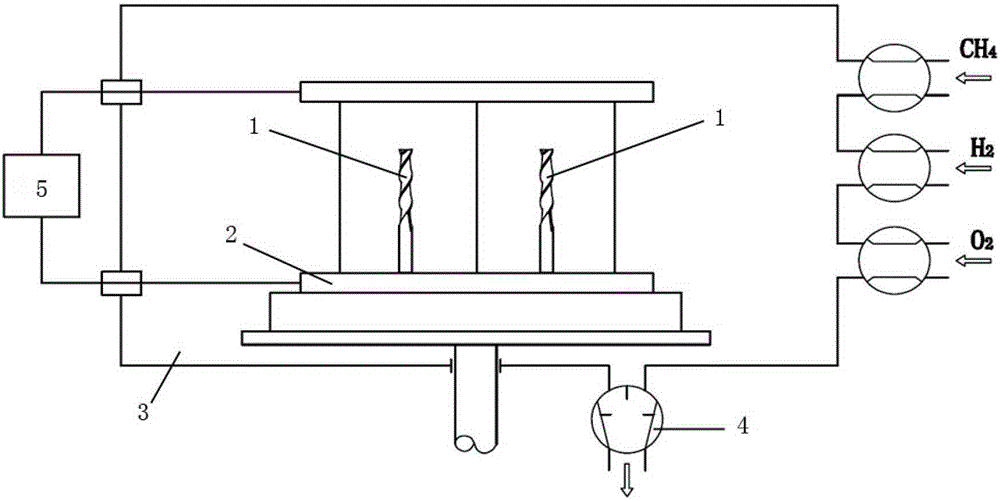

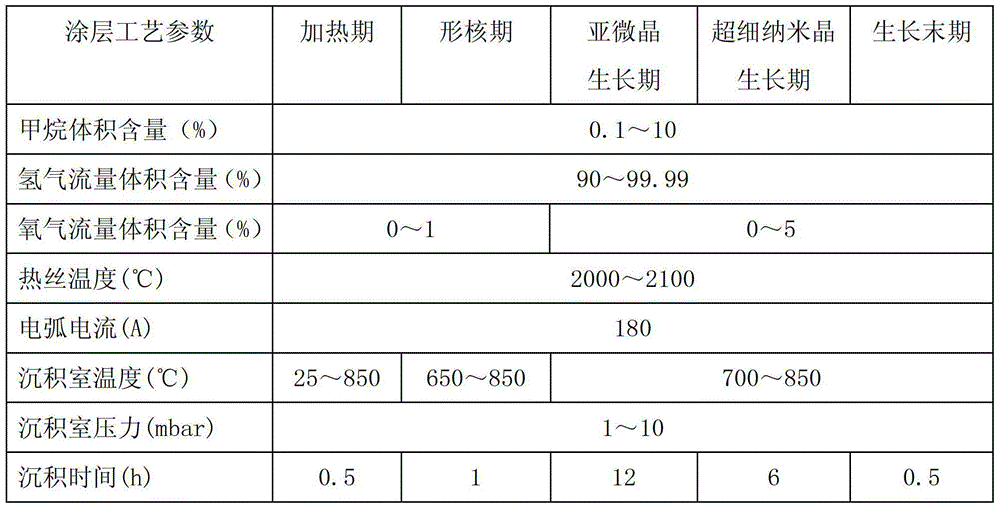

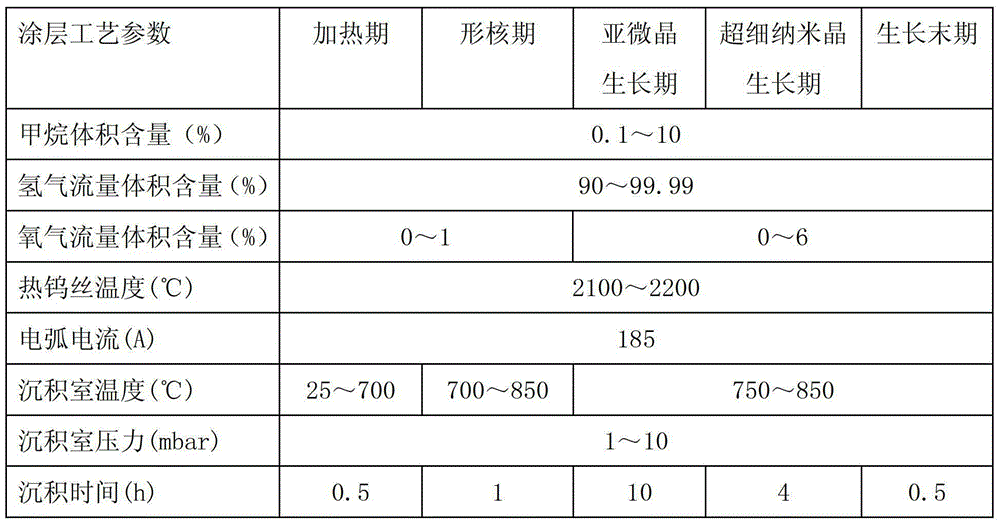

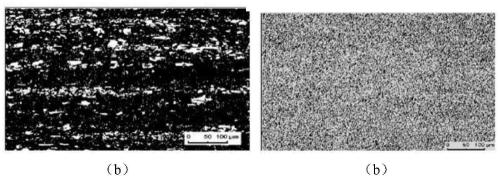

A preparation method of diamond composite coating for micro milling cutter

ActiveCN103436855BImprove display finishImprove wear resistanceChemical vapor deposition coatingGas phaseMilling cutter

The invention discloses a preparation method of a diamond composite coating of a micro milling cutter, and relates to the micro milling cutter. The preparation method comprises the following steps of: placing a PCB (Printed Circuit Board) micro milling cutter into a tool and then placing into a deposition reaction chamber; evacuating the deposition reaction chamber, and introducing methane (CH4), hydrogen gas and oxygen gas into the deposition reaction chamber; applying direct-current electric arc to a heating wire which is installed in the deposition reaction chamber, wherein a deposition process in the deposition reaction chamber is divided into five stages including a heating stage, a nucleation stage, a submicrocrystal growth stage, a superfine nanocrystalline growth stage and a final growth stage, different gas-phase deposition conditions are adopted in the five stages, the submicrocrystal growth stage and the superfine nanocrystalline growth stage can be generated in a circulating manner to form a diamond submicrocrystal and superfine nanocrystalline composite coating, and the circulating generation number is N (N is not less than 1). The prepared diamond composite coating of the micro milling cutter can be used for keeping the cutting edge to be sharp for a longer time, obviously improving the machining effect, prolonging the service life of the cutter, reducing the cutter changing frequency, improving the machining efficiency and lowering the machining cost.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

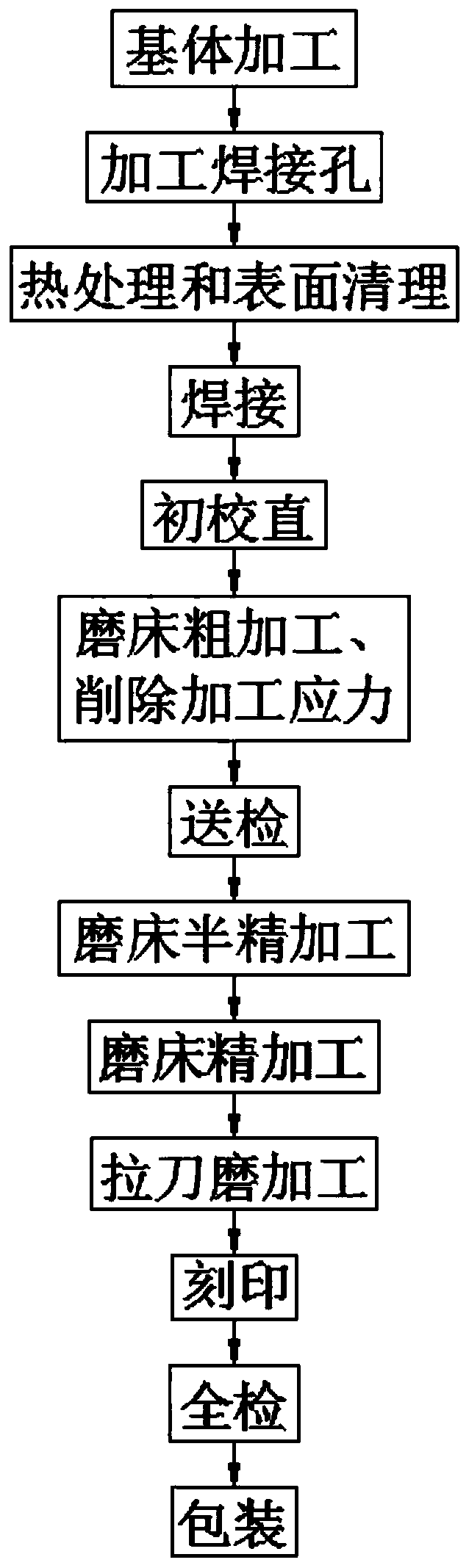

Machining technology for alloy-inlaid alloy internal and external chamfering push-pull cutter

The invention provides a machining technology for an alloy-inlaid alloy internal and external chamfering push-pull cutter and belongs to the technical field of tool manufacturing. The machining technology for the alloy-inlaid alloy internal and external chamfering push-pull cutter comprises the step one of base body machining; the step two of welding hole machining; the step three of heat treatment and surface clearing; the step four of welding; the step five of initial straightening; the step six of grinder rough machining and machining stress eliminating; the step seven of inspecting; the step eight of grinder semi-finishing; the step nine of grinder finish machining; the step ten of cutter milling; the step eleven of engraving and printing; the step twelve of full inspection; and the step thirteen of package. According to the machining technology, the purpose of inlaying a hard alloy to a steel base body and manufacturing the hard alloy into the push-pull cutter is achieved, the push-pull cutter can ensure good toughness, meanwhile, the service life can be prolonged, the manufacturing and using cost is reduced, the cutter replacing frequency is reduced, time and labor are saved,the production efficiency is improved, the use amount of national rare metal is reduced, and sustained use of resources is benefitted.

Owner:SHANGHAI YONGHUA ALLOY TOOL CO LTD

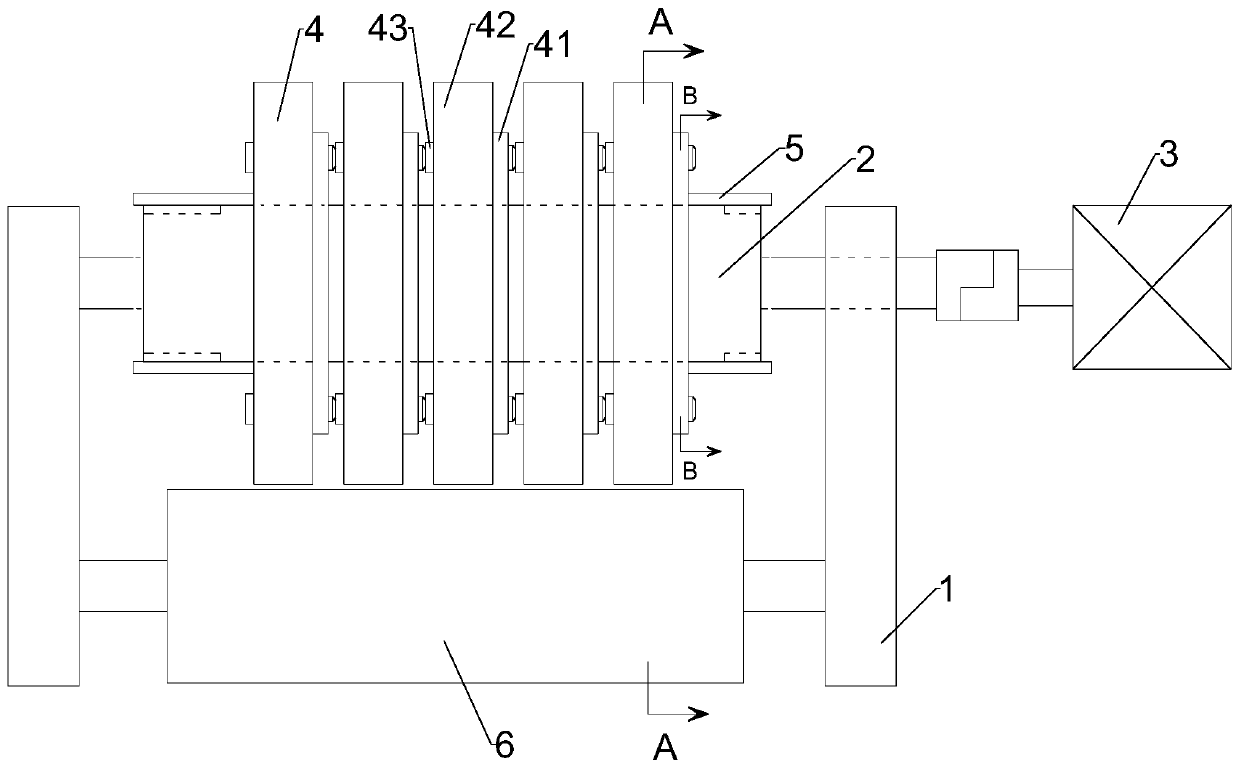

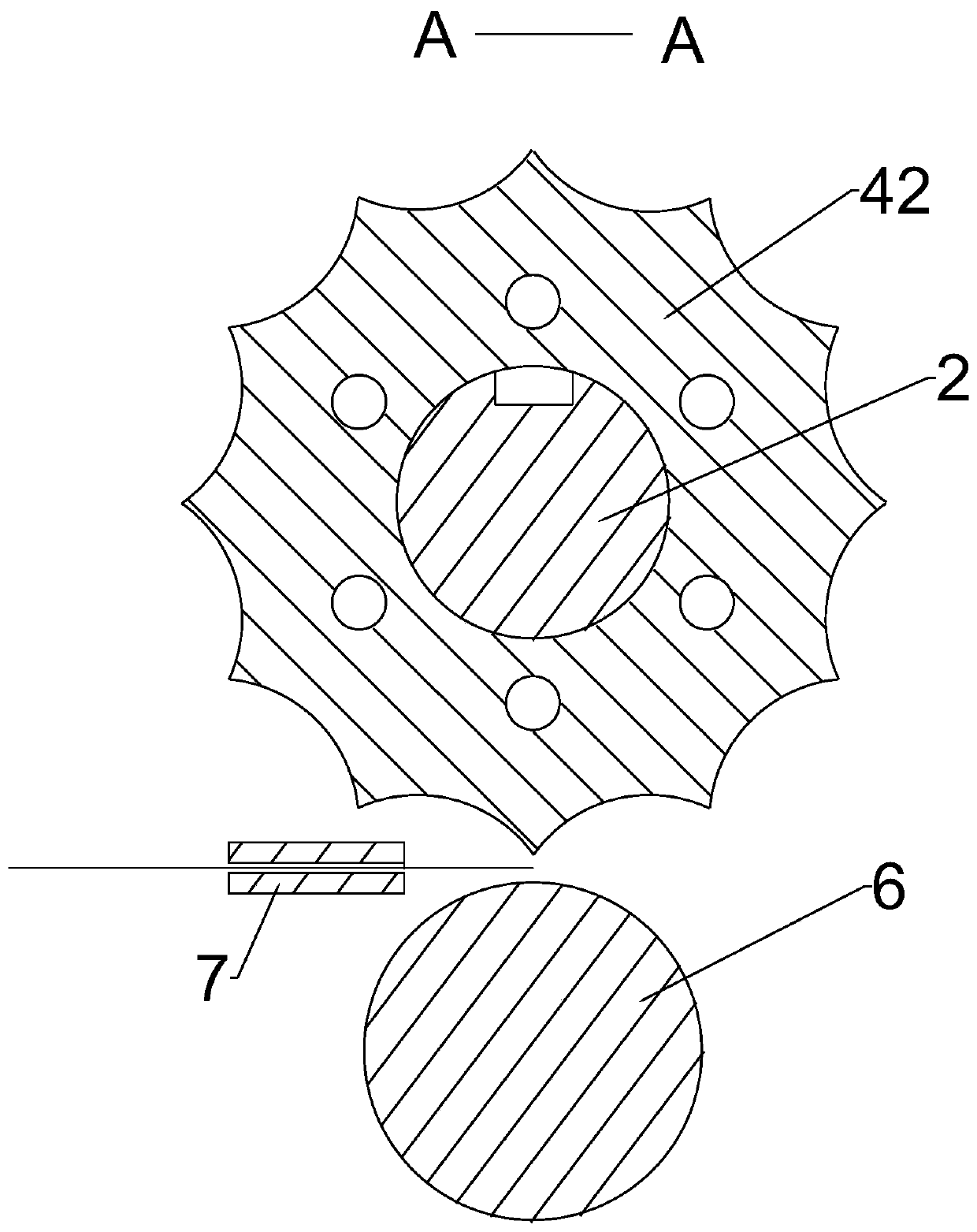

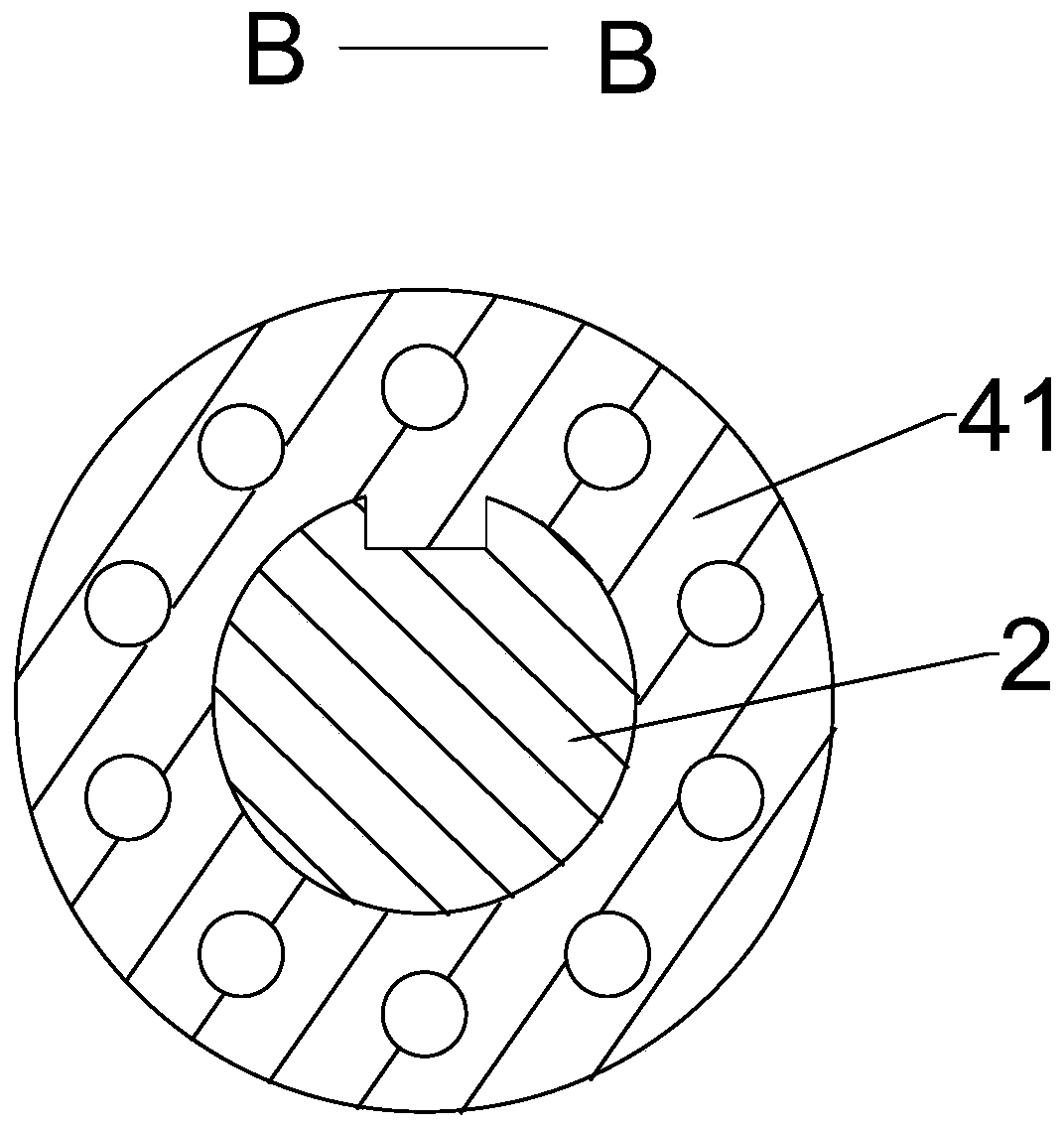

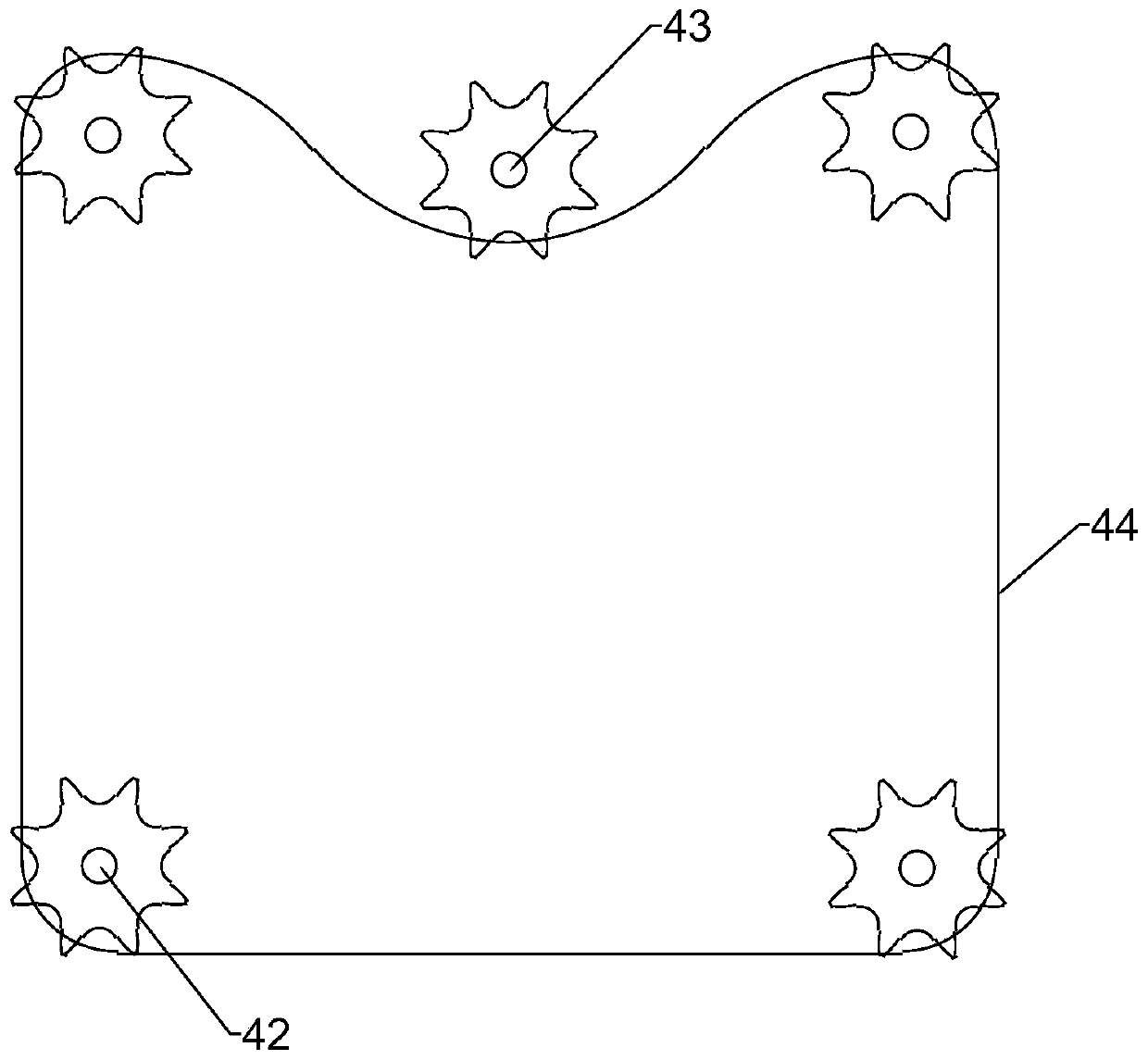

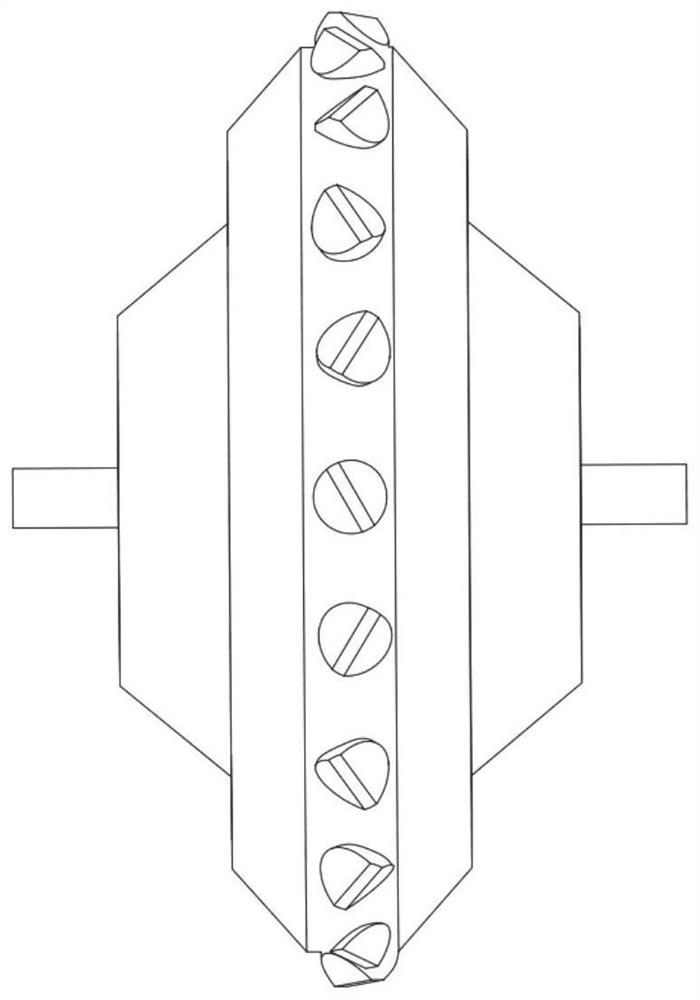

Cutting roller group of steel cut wire shot equipment

The invention relates to the field of metal abrasive processing, in particular to a cutting roller group of steel cut wire shot equipment. The cutting roller group includes a supporting frame, a rotating shaft, a motor, a plurality of cutting device, threaded sleeves, a pressure-bearing roller and an orientation column; the rotating shaft is arranged on the upper part of the supporting frame, oneend of the rotating shaft penetrates through a through hole of the supporting frame and is connected to the motor, the pressure-bearing roller is arranged on the lower part of the supporting frame, the cutting devices are arranged in a linear shape, each cutting device rotates on the self-axis at a certain angle relative to the previous cutting device to be installed on the rotating shaft, the threaded sleeves are arranged on threads at the two ends of the rotating shaft, and the orientation column is arranged on the front of the supporting frame. The cutting devices are arranged on the same rotating shaft, the centralized one-time cutting of a steel wire is turned into single scattered cutting, the time for cutting the steel wire is divided, the use efficiency of the motor is improved, and meanwhile, the impact of a cutting tool cutting the steel wire is reduced and uniform, so that the failure rate of the cutting devices is reduced.

Owner:王认认

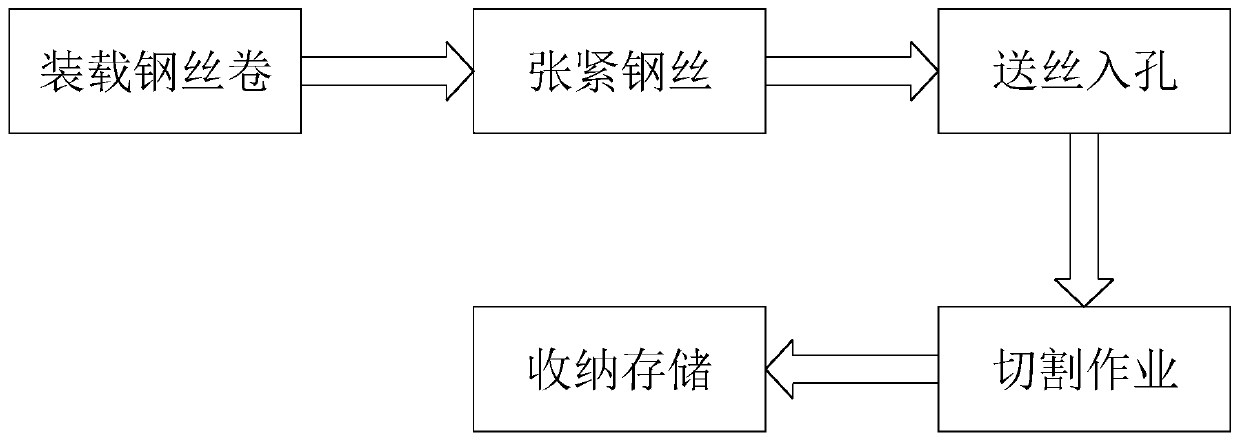

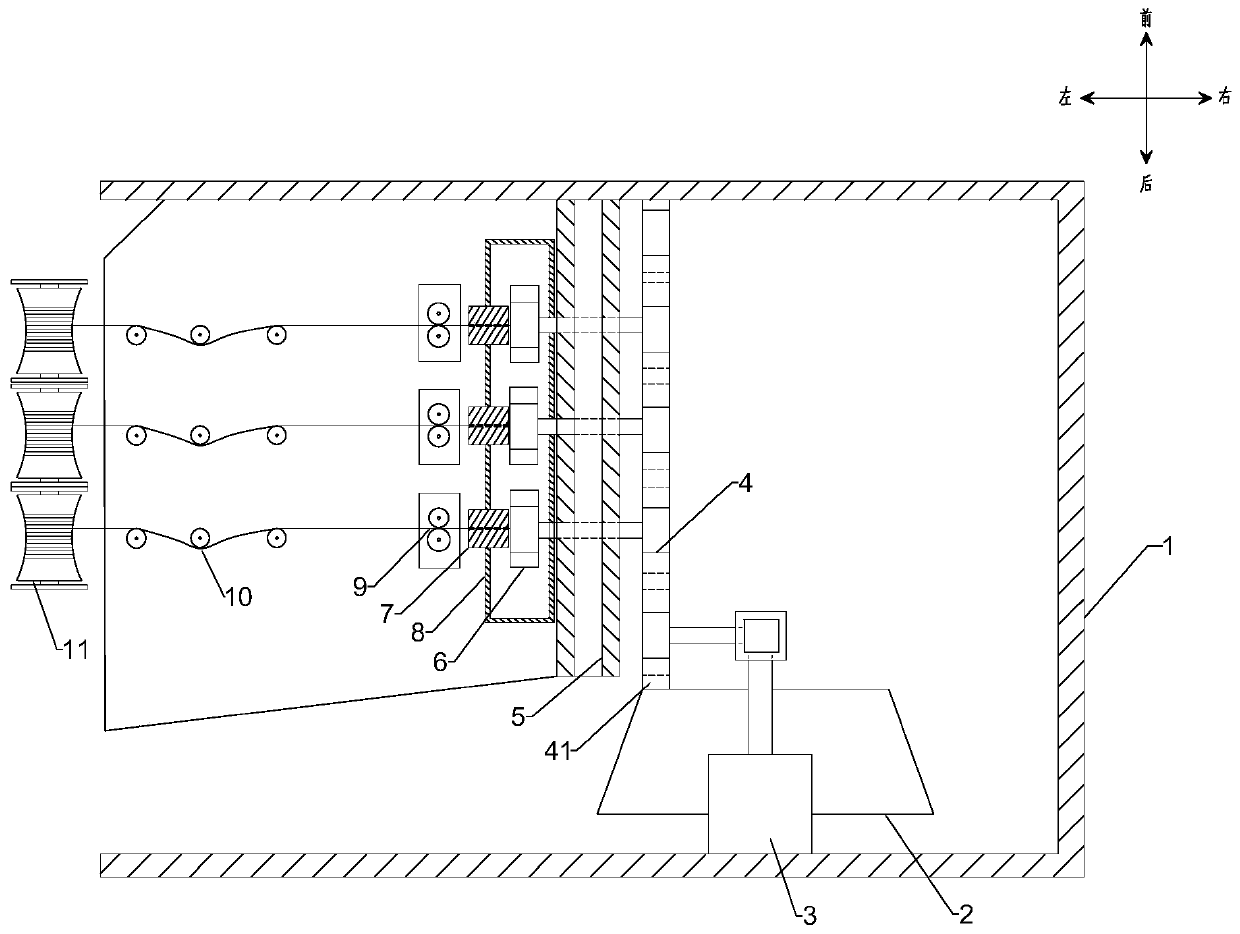

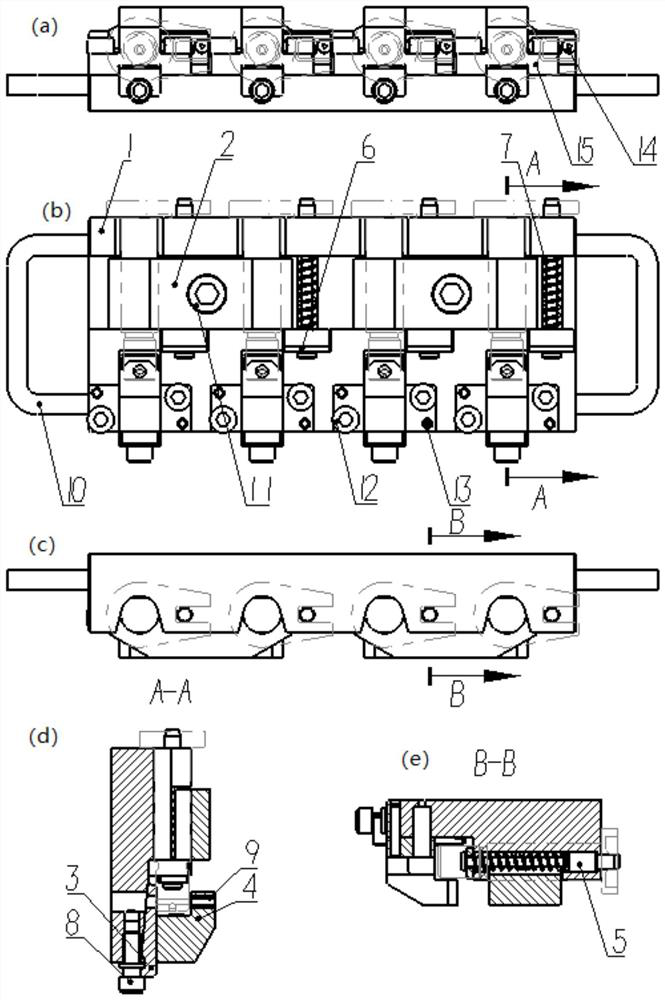

Metal abrasive processing technology

The invention relates to the processing field of metal abrasive, in particular to a metal abrasive processing technology. A device for realizing the metal abrasive processing technology comprises a housing, a base, an electric motor, a transmitting device, a supporting plate, rotary cutters, cutting platforms, a pill loading box, wire transporting devices, tensioning wheels and wire supporting wheels, wherein the base is arranged in the housing; the electric motor is mounted on the base; the transmitting device is arranged on the base; each rotary cutter penetrates through a corresponding through hole in the supporting plate to be linked to a corresponding chain wheel of the transmitting device; and a steel wire on each wire supplying wheel sequentially penetrates through the correspondingtensioning wheel, the corresponding wire transporting device and the corresponding cutting platform. According to the metal abrasive processing technology disclosed by the invention, the rotary cutters are arranged, so that integrated one-time cutting of steel wires is replaced by single repeated dispersing cutting, so that time for cutting the steel wires by the rotary cutters is dispersed, thepower of the electric motor is effectively used, impact vibration to the cutters is small, the structural stability of the movable connecting parts of the cutters is improved, and the failure rate isreduced.

Owner:王认认

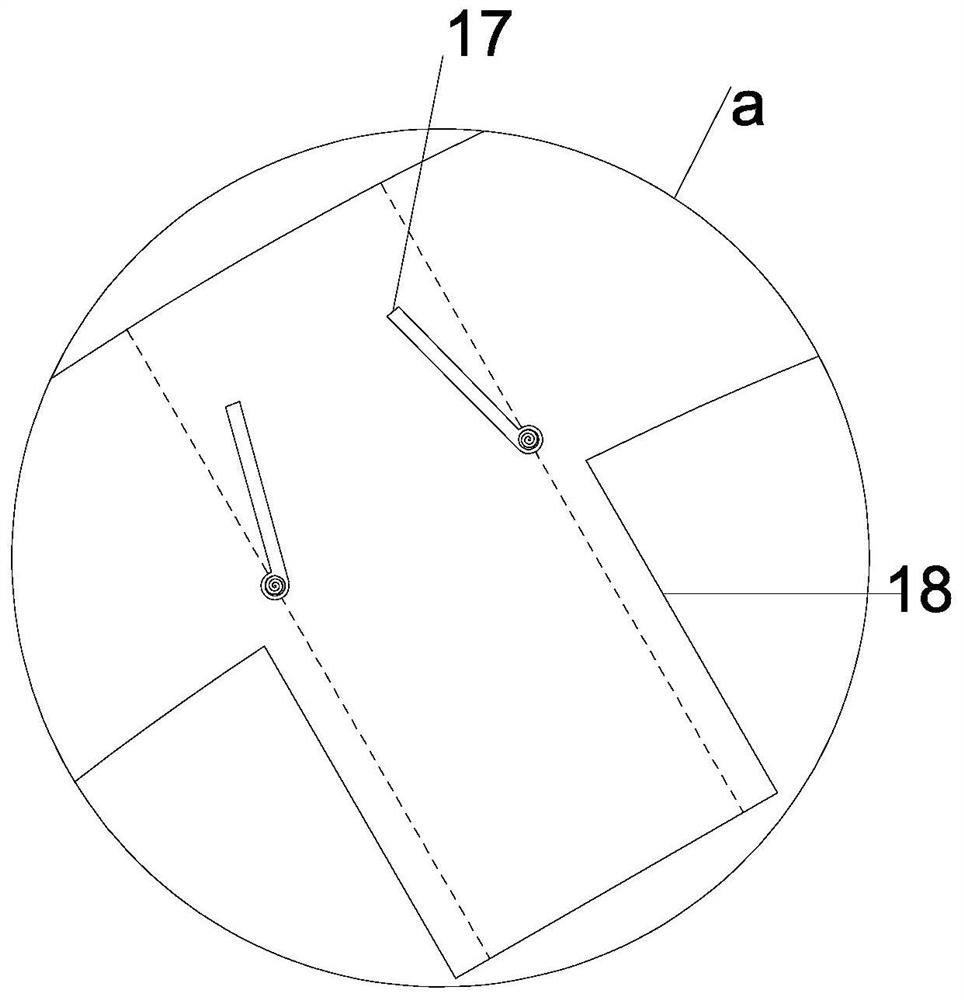

Shaft type one-jig multi-piece fuse hole machining drill jig

PendingCN113477988APrecise positioningStable supportDrill jigsStructural engineeringMachining process

The invention belongs to the field of aviation machining process equipment, and discloses a shaft type one-jig multi-piece fuse hole machining drill jig. The drill jig mainly comprises a foundation support, an angular positioning pin, a wedge block and the like. The front end of the angular positioning pin is manufactured into a conical surface structure to be matched with a product notch; and an elastic structure is made to eliminate over-positioning. The wedge block moves forwards in a wedge groove and meanwhile generates Z-direction displacement so as to make contact with products to play a supporting role, and it is guaranteed that the products do not vibrate during drilling. The foundation support serves as an integral support of the whole drill jig, is used for positioning the outer cylindrical surfaces and the bottom surfaces of the products and is matched and connected with other elements to achieve specific functions. One-jig multi-piece clamping, elastic pin angle direction fixing and wedge block stable supporting of shaft products needing to be provided with small-size fuse holes are achieved. The purposes of accurate positioning, reliable supporting, reduction of tool changing frequency and improvement of machining efficiency are achieved.

Owner:SHENYANG AIRCRAFT CORP

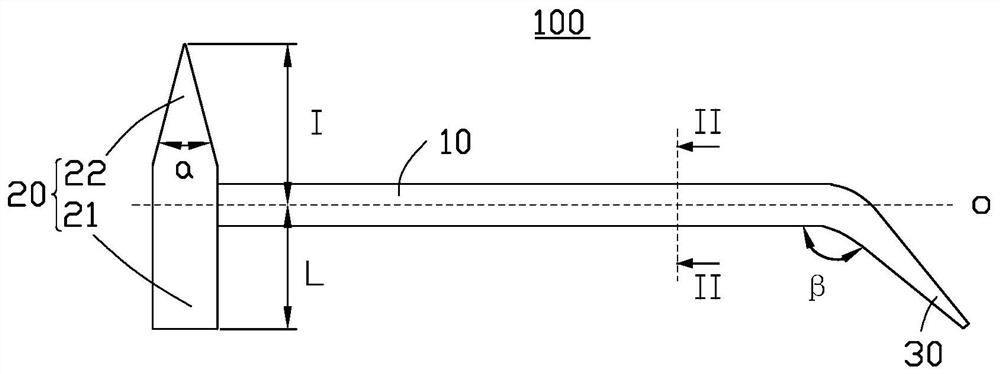

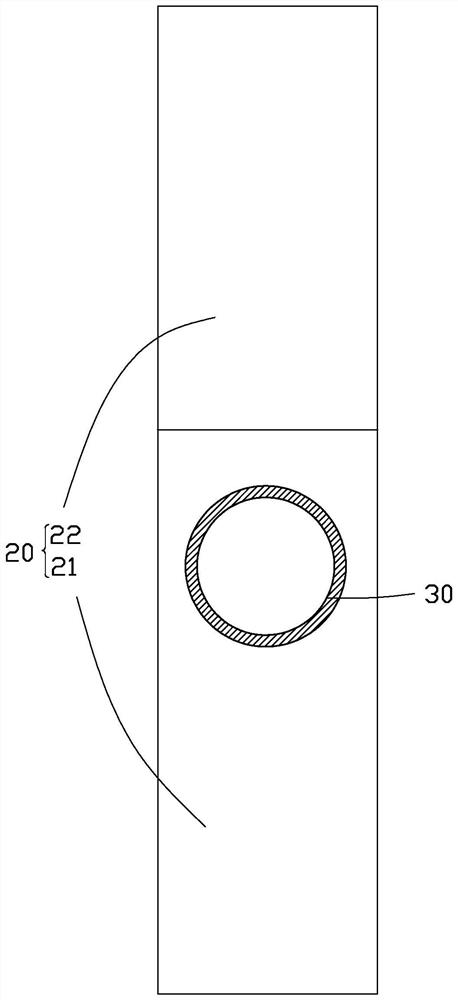

Formwork dismounting tool

PendingCN113356590AReduce typesReduce the frequency of tool changesForm treatmentArchitectural engineeringBuilding construction

The invention relates to the field of building construction tools, in particular to a formwork dismounting tool. The formwork dismounting tool is used for mounting and dismounting formworks and comprises a rod body, a hammer head and a prying head, and the hammer head is located at one end of the rod body; and the prying head is positioned at the other end of the rod body. The hammer head and the prying head are located at the two ends of the rod body correspondingly, the hammer head is used for knocking a pin piece so that the pin piece and a pin can be fixed or separated, the prying head is used for prying concrete on the formwork away from the formwork, and the hammer head and the prying head are combined to the rod body, so that the types of tools needed when the formwork is disassembled can be reduced, the frequency of replacing the tools is reduced, the time for searching corresponding types of tools is saved, and the construction efficiency is improved.

Owner:SNTO TECH GRP

Rotary cutting tool with double cutting edge

The invention discloses a rotary cutting tool with a double-layered cutting edge. The rotary cutting tool comprises a tool body, the tool body is provided with at least one set of tool grooves, a cutting tip set consisting of a first cutting tip and a second cutting tip is fixed on each tool groove by a fastener, the first cutting tip is pressed on the second cutting tip, the second cutting tip is pressed on the tool groove, and in the process of cutting processing, the cutting feed of the second cutting tip is larger than or equal to that of the first cutting tip. The rotary cutting tool with a double-layered cutting edge disclosed by the invention has the advantages of high cutting efficiency, easy manufacturing, cost reduction and smooth chip removal.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

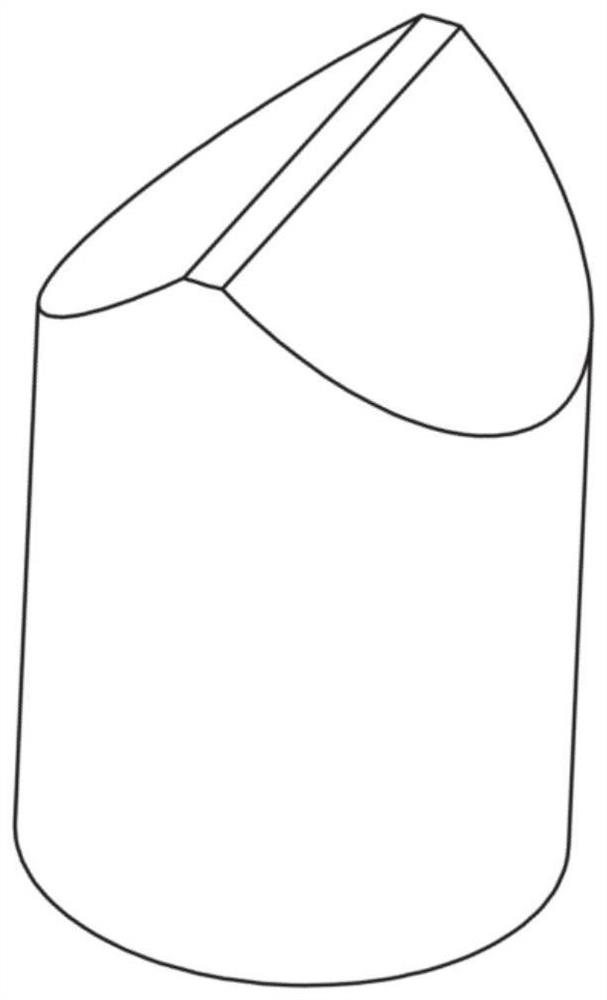

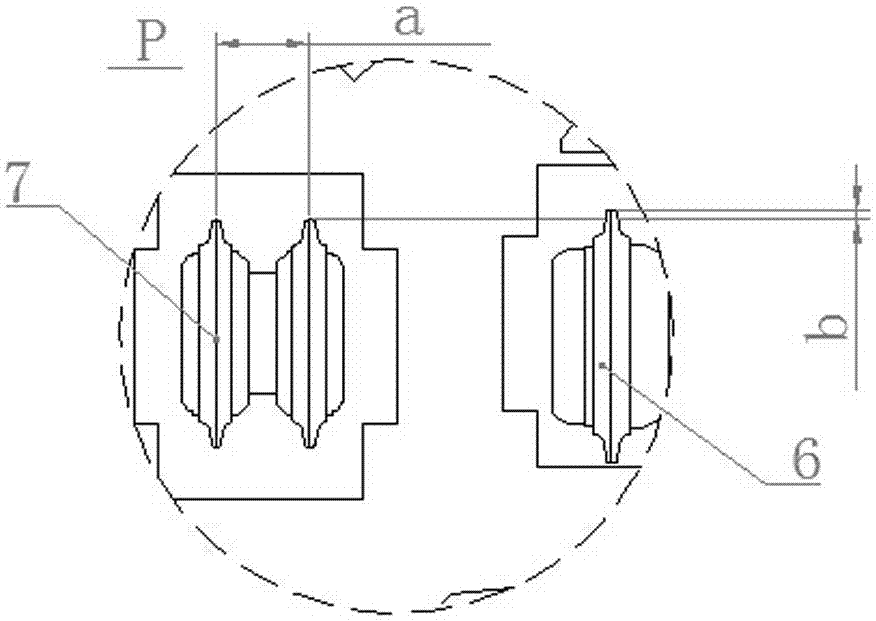

Tunnel boring machine hob ring, hob and boring machine comprising hob

PendingCN113338982AReduce the frequency of tool changesImprove work efficiencyTunnelsTunnel boring machineManufacturing engineering

The invention provides a tunnel boring machine hob ring, a hob and a boring machine comprising the hob. The hob ring is installed on the tunnel boring machine hob, cylindrical hard alloy hob teeth are installed on the hob ring on the outermost circumferential surface of the tunnel boring machine hob, and the cylindrical hard alloy hob teeth are installed on an installation groove formed in the hob ring and fixed through welding; the cylindrical hard alloy hob teeth installed in the installation groove are higher than the surface of the hob ring; and the cylindrical hard alloy hob teeth are distributed on the hob ring in the circumferential direction of the hob, the top ends of the cylindrical hard alloy hob teeth are rectangular edge strips, and the hard alloy hob teeth with the left-leaning rectangular edge strips and the hard alloy hob teeth with the right-leaning rectangular edge strips are alternately distributed.

Owner:SHANDONG UNIV

Tooth profile finishing method of large modulus hard tooth surface rack

ActiveCN103480919BGood effectImprove processing efficiencyMilling cuttersGear teethMilling cutterEngineering

The invention discloses method for finish machining of tooth profile of a large-modulus hard-tooth-face rack. The method is high in production efficiency and suitable for batch part production. The method comprises the steps of installing the rack subjected to surface hardening on a working table of a machine tool; firstly using face milling cutter to perform milling to a left tooth oblique plane and a right tooth oblique plane by means of a track method; using a ball end mill to perform milling to the left tooth bottom circular-arc surface and the right tooth bottom circular-arc surface by means of a forming method; using the ball end mill to perform milling to the tooth bottom face by means of the track method. In addition, cutter structures, cutter and machine tool selection, cutter using modes and cutter installing modes are further optimized. Compared with the prior art, the machining efficiency is remarkably improved, and the tooth face roughness meets the requirement.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

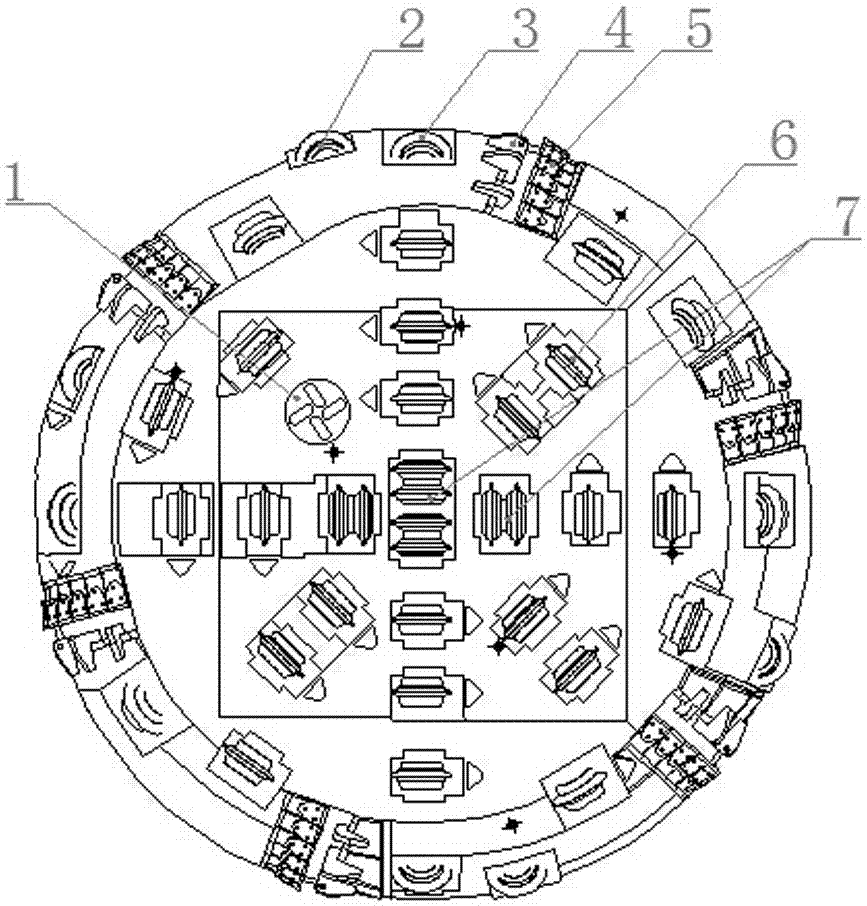

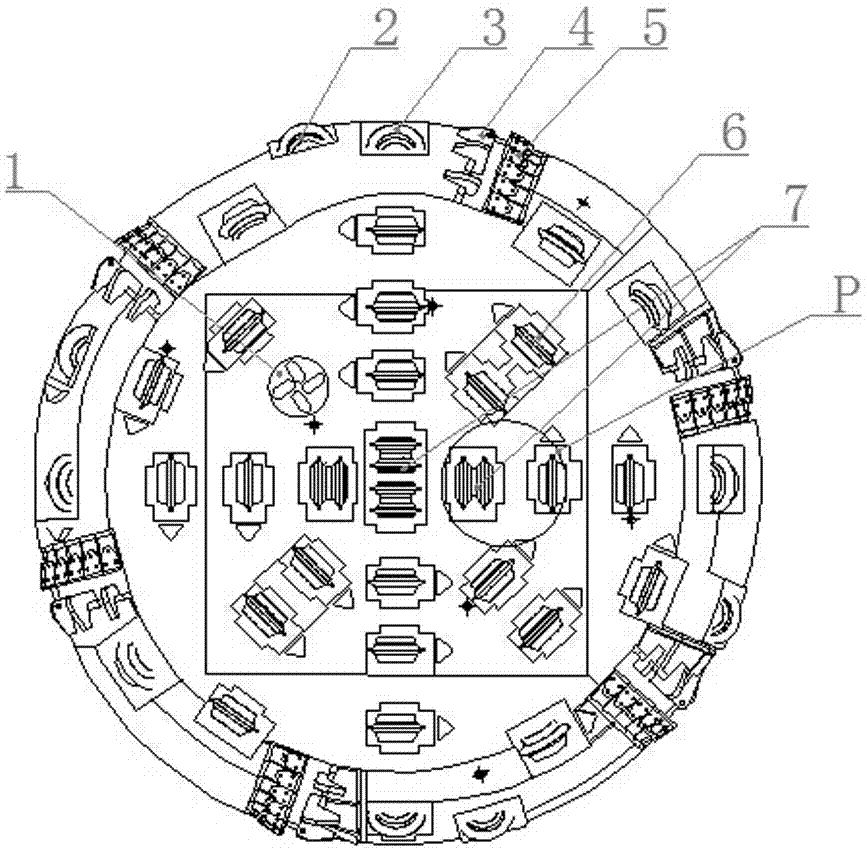

Tunnel boring machine cutterheads for complex hard rock geology

ActiveCN105350976BImprove rock breaking efficiencyReduce disturbanceTunnelsHobbingArray data structure

A tunnel boring machine cutter head suitable for complex hard rock geology, including manholes, gauge cutters, side cutters, scrapers, shovel blades, positive hob, center hob and water spray nozzles, and an array is arranged in the center of the cutter head The center hob is provided with an array of positive hob on the periphery of the center hob, and an array of gauge knives, edge knives, scrapers and shovels uniformly distributed along the outer periphery of the cutter head on the periphery of the positive hob; There are also manholes on the periphery, and several water nozzles are arranged around the cutter head. The center hob adopts a small-spacing cutter; the diameter-keeping cutter adopts a cutter box structure in which large and small knives are interchanged; and the side cutter raises its cutter shaft when excavating. The advantages of the invention are that the center cutter of the cutter head can realize the spacing between small cutters, improve the rock breaking efficiency of the center cutter, reduce the labor intensity of construction personnel, speed up the construction progress and save the construction cost.

Owner:中船(青岛)轨道交通装备有限公司

A Positioning and Tool Changing CNC Tool Post Based on Reliability Comprehensive Design

ActiveCN112171349BImprove efficiencyHigh tool change accuracyPositioning apparatusMetal-working holdersNumerical controlGear wheel

The invention relates to the field of numerical control machining, in particular to a positioning tool change type numerical control tool holder based on reliability comprehensive design, which includes horizontally arranged support and guide columns, fixed mounting frames are symmetrically arranged at both ends of the support and guide columns, and the fixed mounting frame The upper ends are provided with fixed installation holes, and a sliding installation cylinder is arranged horizontally in conjunction with the supporting guide column, and a lifting installation plate is horizontally arranged directly below the sliding installation cylinder, and the lifting installation plate and the sliding installation cylinder are connected by an electronically controlled lifting column. The middle position of the lifting installation plate is vertically equipped with a limited rotation sleeve, through horizontal guide displacement adjustment, lifting height adjustment, and rotation displacement adjustment, the working range of the device is significantly improved, and the helical gear coarse adjustment and gear fine adjustment are used to realize positioning. Tool change operation, and the device can preset multiple sets of tools at the same time, the tool change process is continuous and stable, so that the device can greatly improve the efficiency of CNC operations, reduce the frequency of tool change, and at the same time have high tool change accuracy.

Owner:JILIN UNIV

Cutting tool with two cutting inserts in a single flute

The invention discloses a cutting cutter of which a single cutter groove provided with two cutting blades. The cutting cutter comprises a cutter body which is provided with at least one cutter groove group. A cutting blade group composed of the first cutting blade and the second cutting blade is fixed in the cutter groove through fasteners. The first cutting blade is pressed on the second cutting blade and the second cutting blade is pressed on the cutter groove. In the time of cutting, the first cutting blade and the second cutting blade perform cutting independently in sequence. The cutting cutter of which the single cutter groove provided with the two cutting blades has the advantages of being simple in structure, convenient to manufacture, smooth in chip discharging, high in cutting efficiency and capable of saving cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Cutting cutter of which single cutter groove provided with two cutting blades

The invention discloses a cutting cutter of which a single cutter groove provided with two cutting blades. The cutting cutter comprises a cutter body which is provided with at least one cutter groove group. A cutting blade group composed of the first cutting blade and the second cutting blade is fixed in the cutter groove through fasteners. The first cutting blade is pressed on the second cutting blade and the second cutting blade is pressed on the cutter groove. In the time of cutting, the first cutting blade and the second cutting blade perform cutting independently in sequence. The cutting cutter of which the single cutter groove provided with the two cutting blades has the advantages of being simple in structure, convenient to manufacture, smooth in chip discharging, high in cutting efficiency and capable of saving cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Multi-tool-position conversion device and multi-cutter hand-hold electric carving machine applying same

The invention relates to a multi-tool-position conversion device and a multi-cutter hand-hold electric carving machine applying same; a plurality of axial holes are arranged around the center of a rotating platform of the conversion device, and the rotating platform is provided with a locating mechanism. The electric carving machine comprises a motor and a driving wheel, the rotating platform is connected on a bracket, driven wheels are correspondingly arranged inside the axial holes and correspond to a flexible shaft, a handle and a carver, and any or two adjacent driven wheels can be switched and located, so as to be contacted and matched with a belt in a transmission way. The multi-tool-position conversion device has reasonable and simple structure, and can be matched with the existingcarver for use. The electric carving machine is provided with a plurality of different carvers which are debugged, so as to realize carver replacement without stopping the machine, thus reducing the frequency of carver replacement and the equipment loss, being rapid and convenient in operation, and greatly improving the working efficiency of carving work; in addition, one carving machine can be used for operating a plurality of carvers, so that the cost is reduced, the occupying space is small, the operation station is proper, and the work quality can be improved.

Owner:许金钰

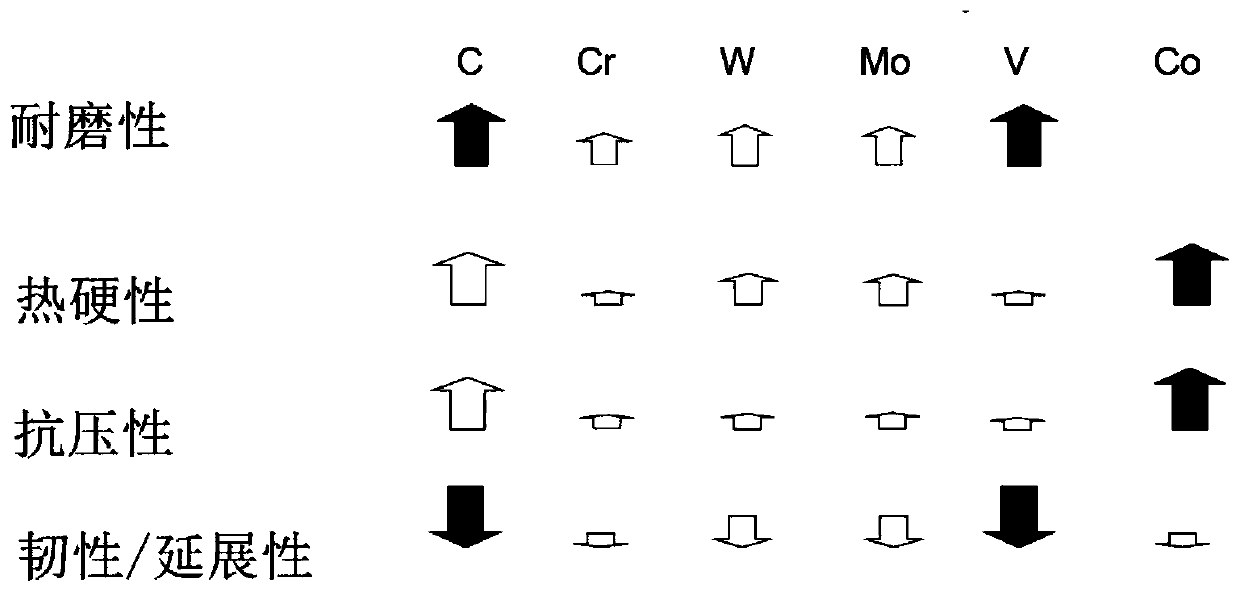

Broaching tool and preparation method thereof

InactiveCN111041420AReduce contentIncrease contentVacuum evaporation coatingSputtering coatingIon bombardmentTitanium nitride

The invention relates to a broaching tool, which comprises a tool base body and an aluminum-titanium-silicon coating, wherein the surface of the tool base body is coated with the aluminum-titanium-silicon coating. The tool base body is made of alloy and comprises the following components in percentage by weight: 1.3%-2% of C, 4%-5% of Cr, 1.5%-3% of Mo, 4%-6% of V, 8%-12% of W, 7%-9% of Co and thebalance of Fe. The weight percentage of aluminum in the aluminum-titanium-silicon coating is 50%-70%, the weight percentage of titanium is 20%-40%, and the weight percentage of silicon is 5%-15%. Thepreparation method comprises the steps of A, pretreating the tool base body; b, conducting coating deposition, specifically, mounting the pretreated tool base body in a vacuum coating machine, heating to a temperature of 450 DEG C, and adjusting to the vacuum degree to be 5-6*10<-3>Pa; opening an argon flow valve, adjusting the vacuum degree to be 0.1-10Pa, adjusting the ion bombardment voltage to be 200V-1kV negative high voltage, wherein the ion bombardment time is 5-30min, and plasma cleaning is conducted on the surface of the tool base body; then opening a pure titanium target and an N2 flow valve, and depositing a titanium nitride base coat for 15-20 minutes; and then opening an aluminum-titanium-silicon target, adjusting the vacuum degree to be 3-5Pa, adjusting the current to be 150-200A, and depositing the aluminum-titanium-silicon nano composite layer for 20-30 minutes.

Owner:采埃孚汽车科技(张家港)有限公司

Robot-based automatic feeding system for square auxiliary materials in cigarette packs

ActiveCN105883387BRealize handlingRemove obstaclesConveyorsControl devices for conveyorsEngineeringAtmospheric pressure

A robot-based automatic loading system for cigarette packaging square accessories is characterized by comprising a bulk accessory conveyor system arranged on a gantry-type main support, a robot fixture close to the right side of the gantry-type main support, a bulk accessory wrapper recycling device fixed at the front end of the right side of the gantry-type main support, an automatic bulk accessory waste recycling device fixed at the rear end of the right side of the gantry-type main support, a bulk accessory wrapper withdrawal assisting mechanism arranged on a bulk accessory conveying rack, a synchronous belt conveyor connected to the left side of the gantry-type main support, and a joint robot arranged on the robot fixture, as well as a pneumatic system for providing power for a material transporting system, a material conveying system and a tool cutting system. The robot-based automatic loading system has the following beneficial effects: the production cost is effectively lowered, and the production efficiency is greatly improved; and the robot-based automatic loading system is simple in structure, good in strength and rigidity and stable and reliable in operation, and is efficient and energy-saving.

Owner:云南昆船电子设备有限公司

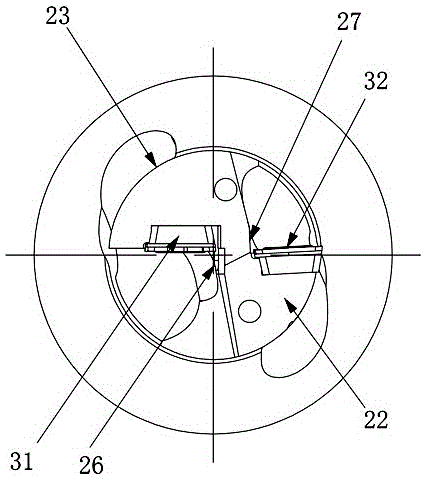

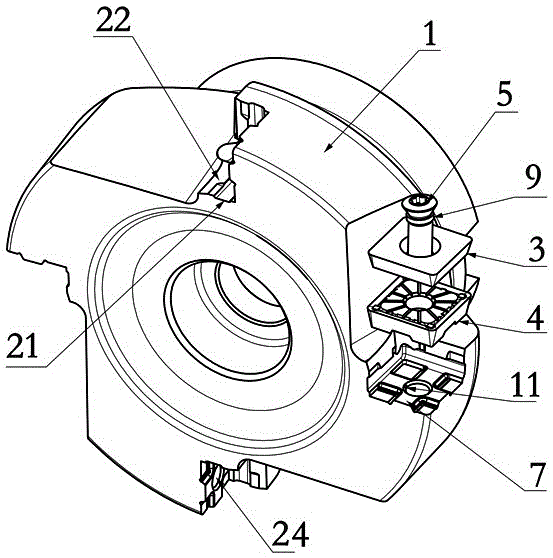

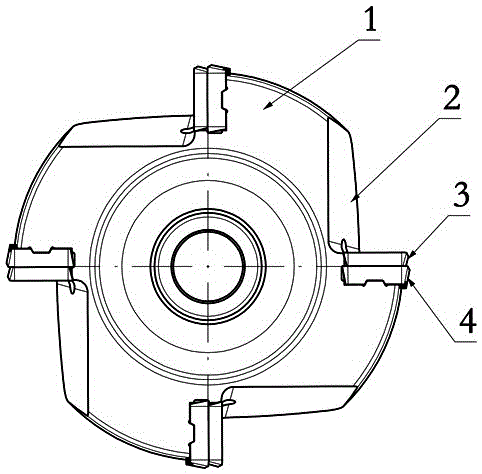

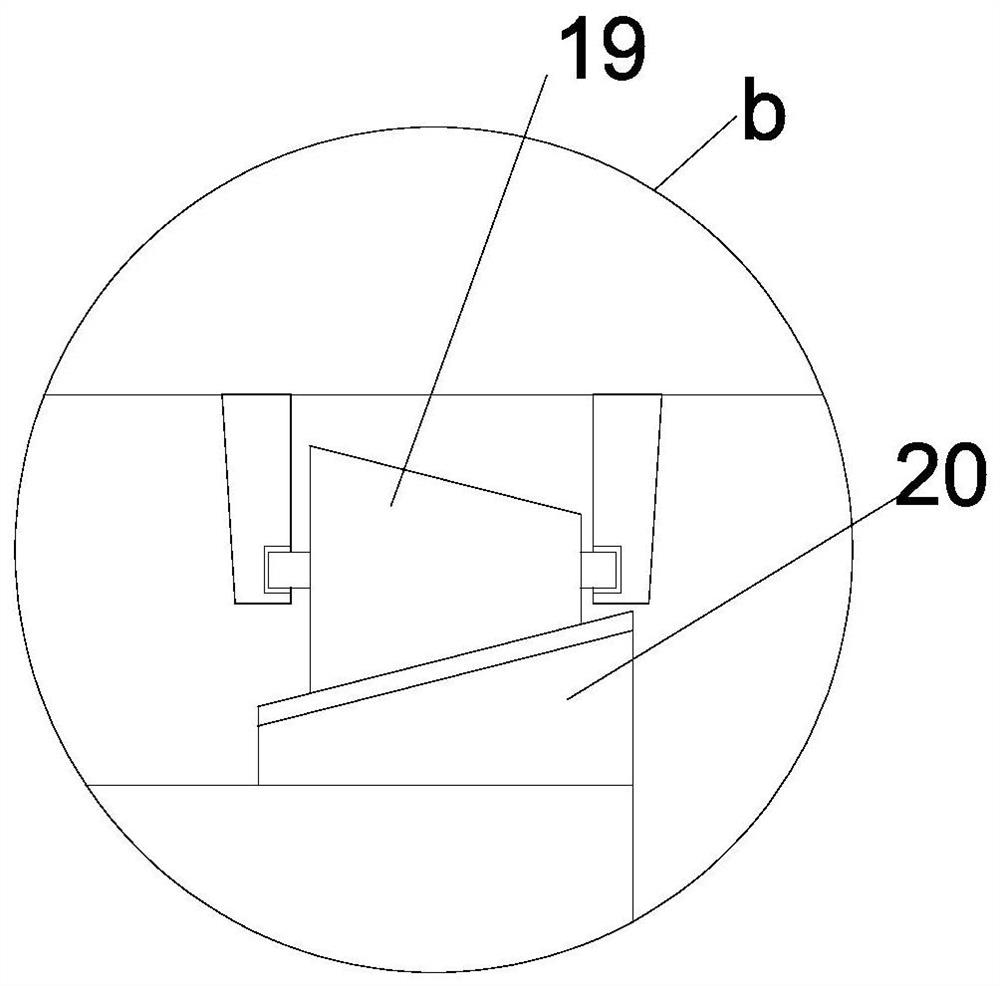

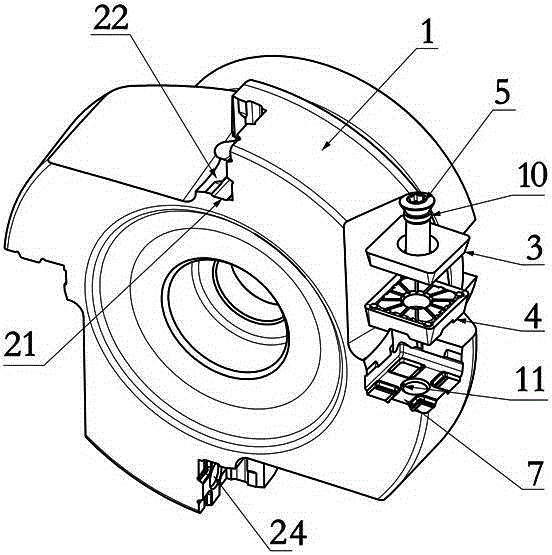

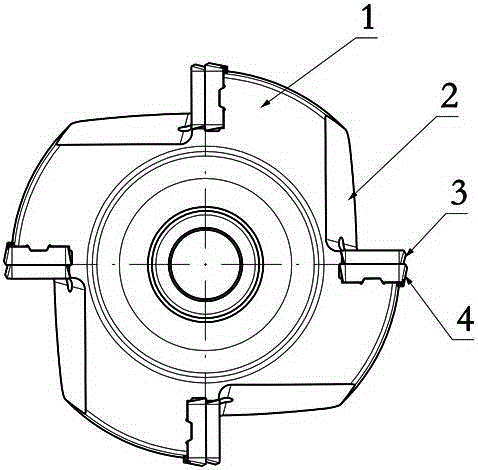

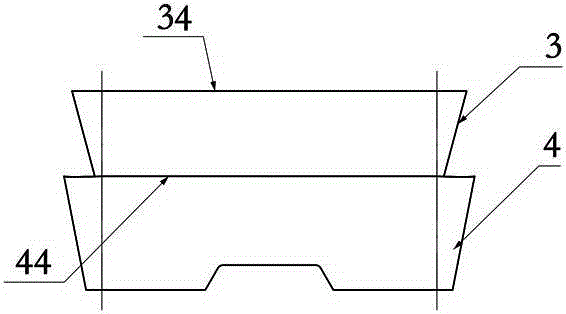

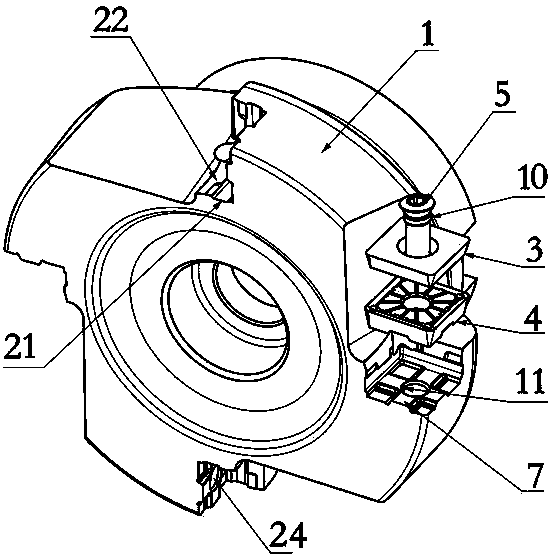

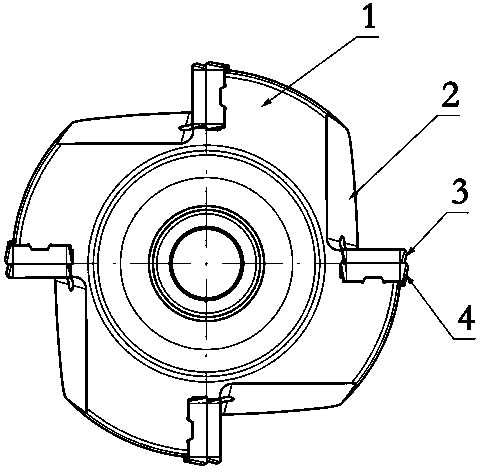

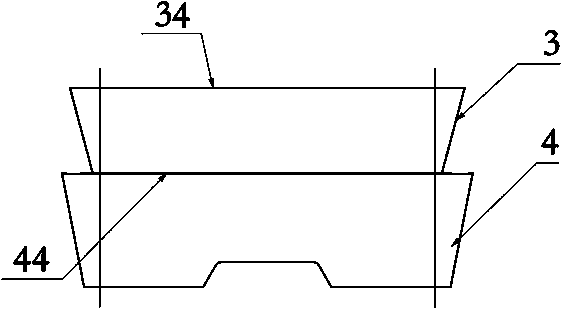

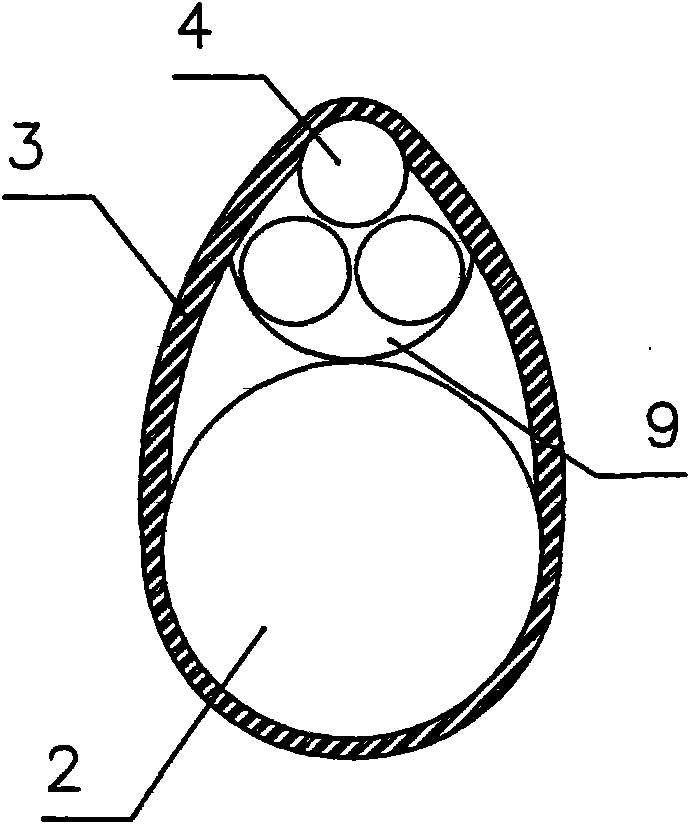

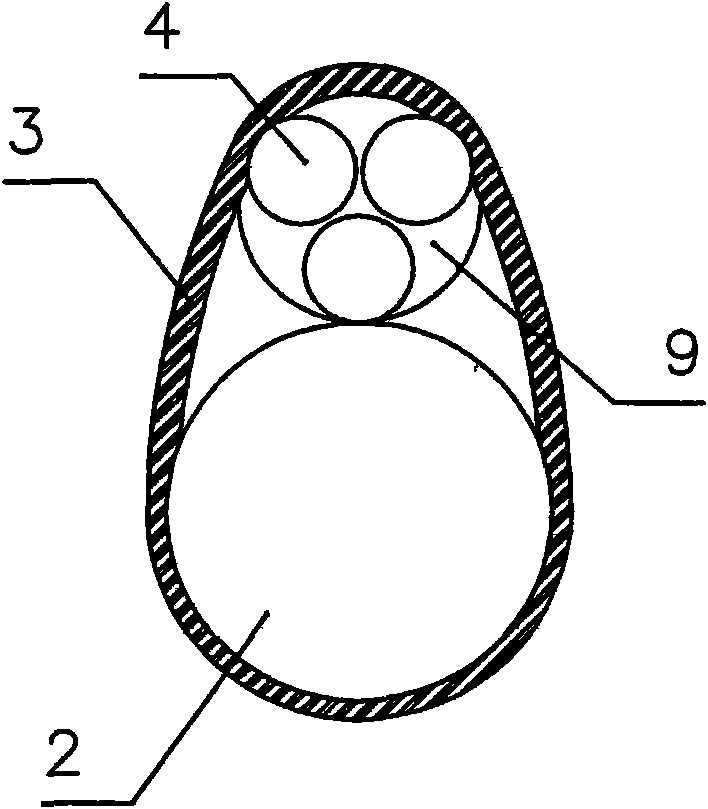

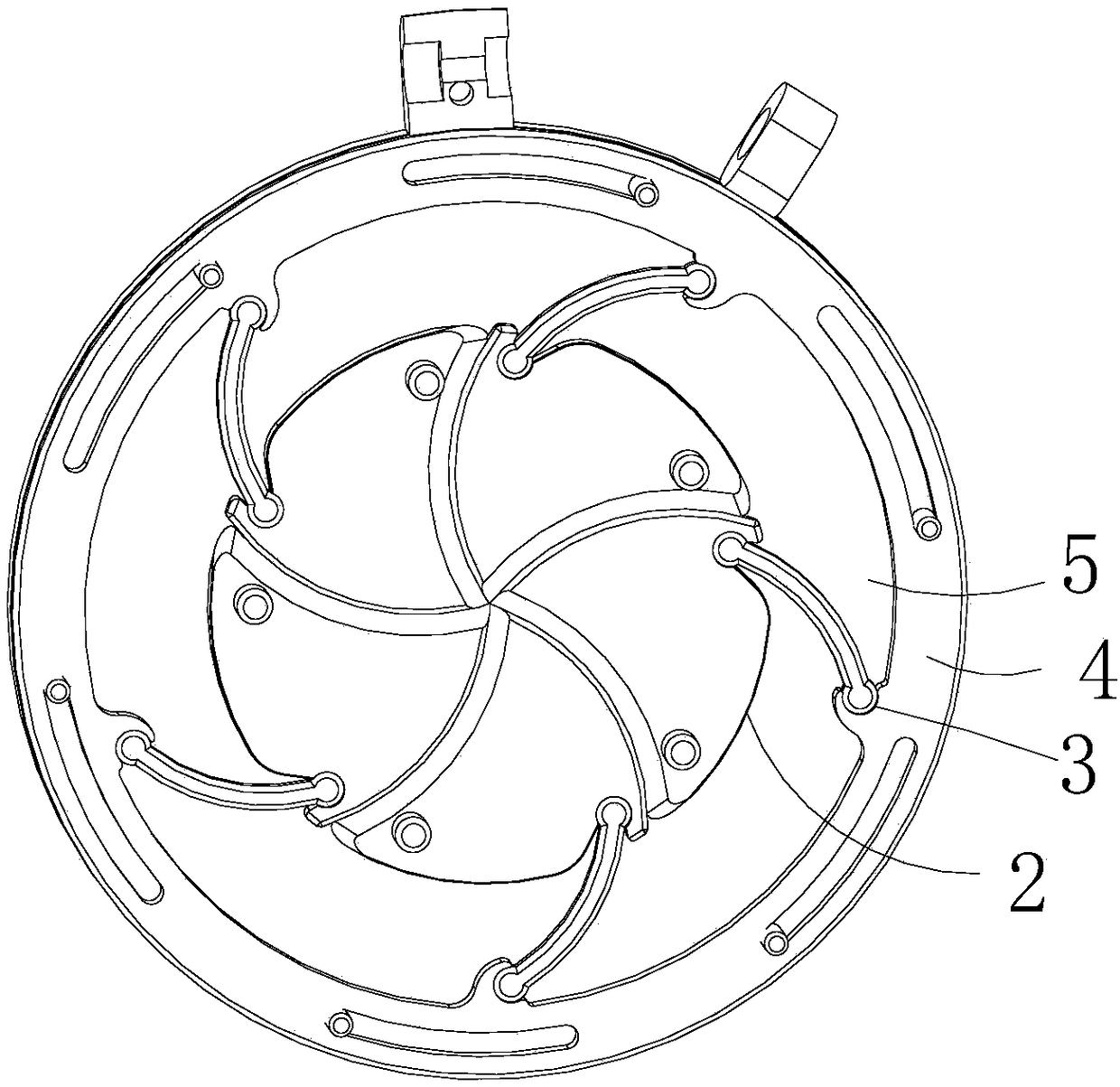

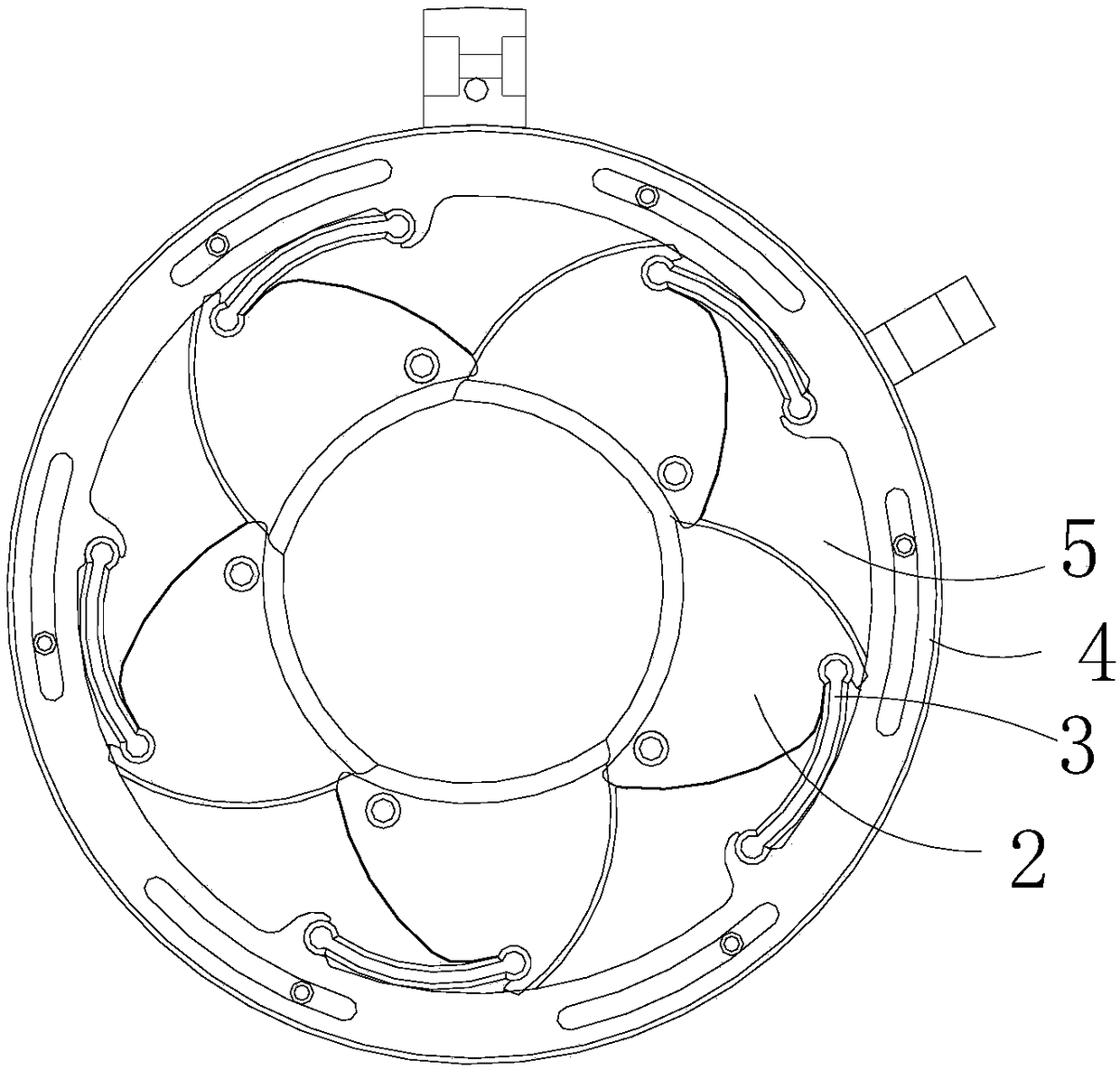

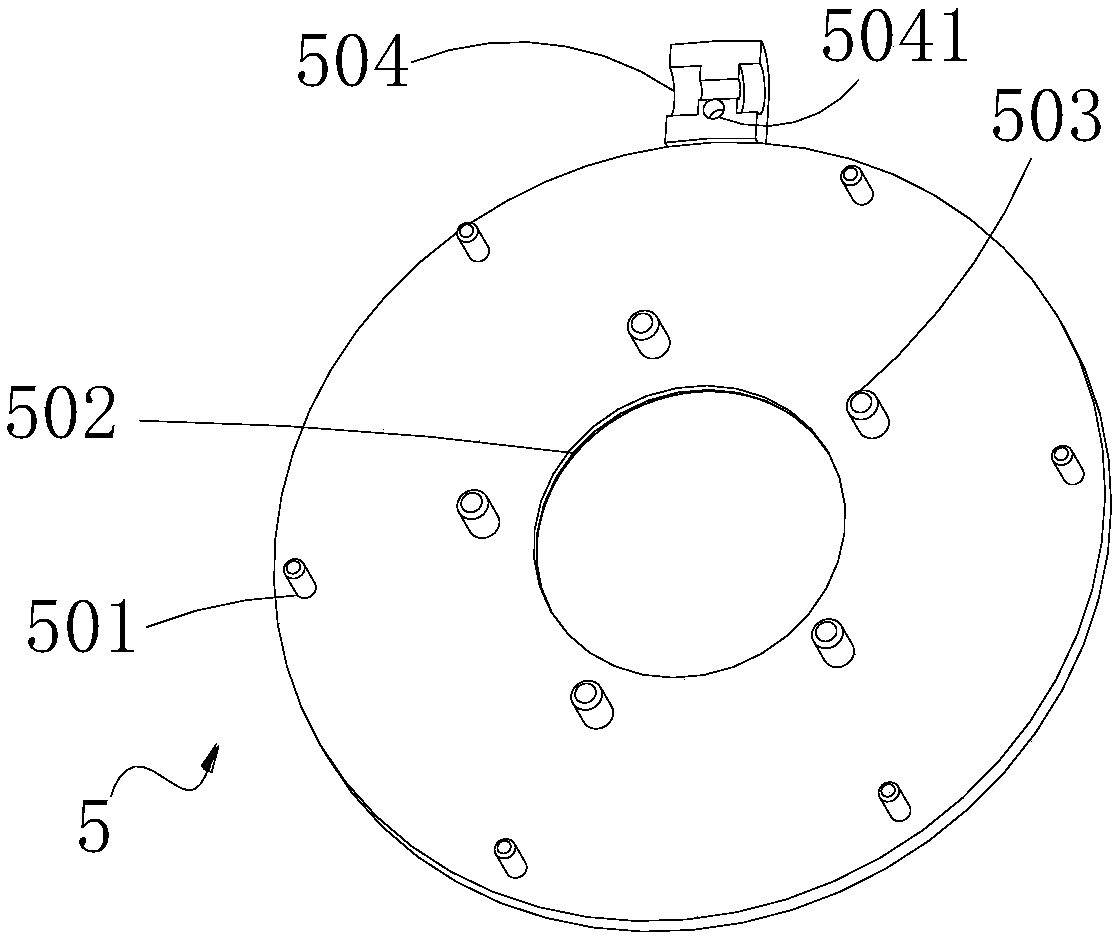

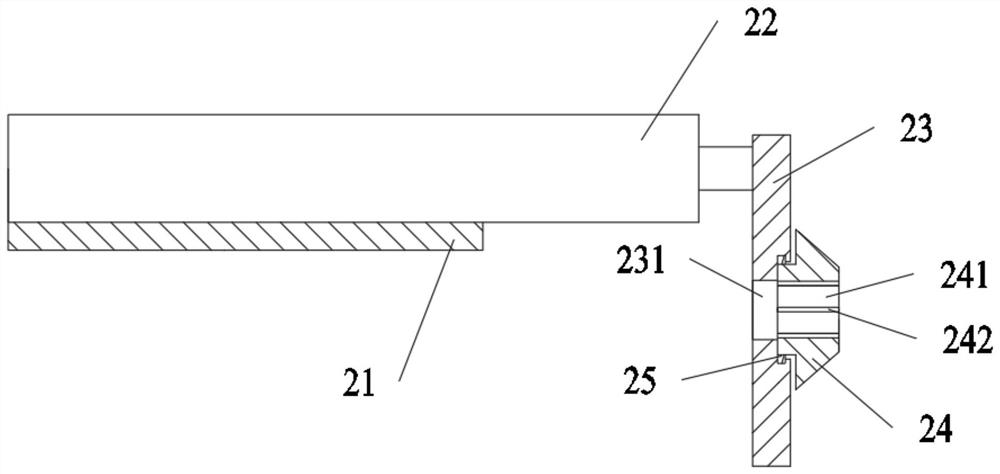

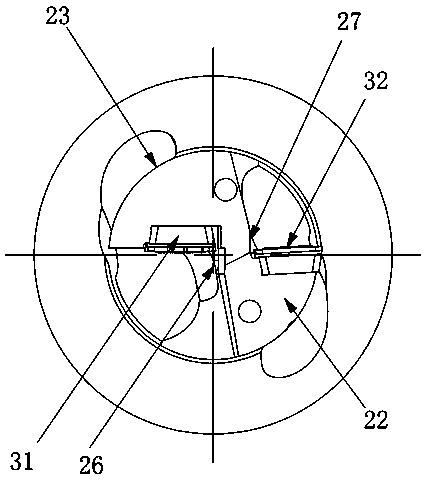

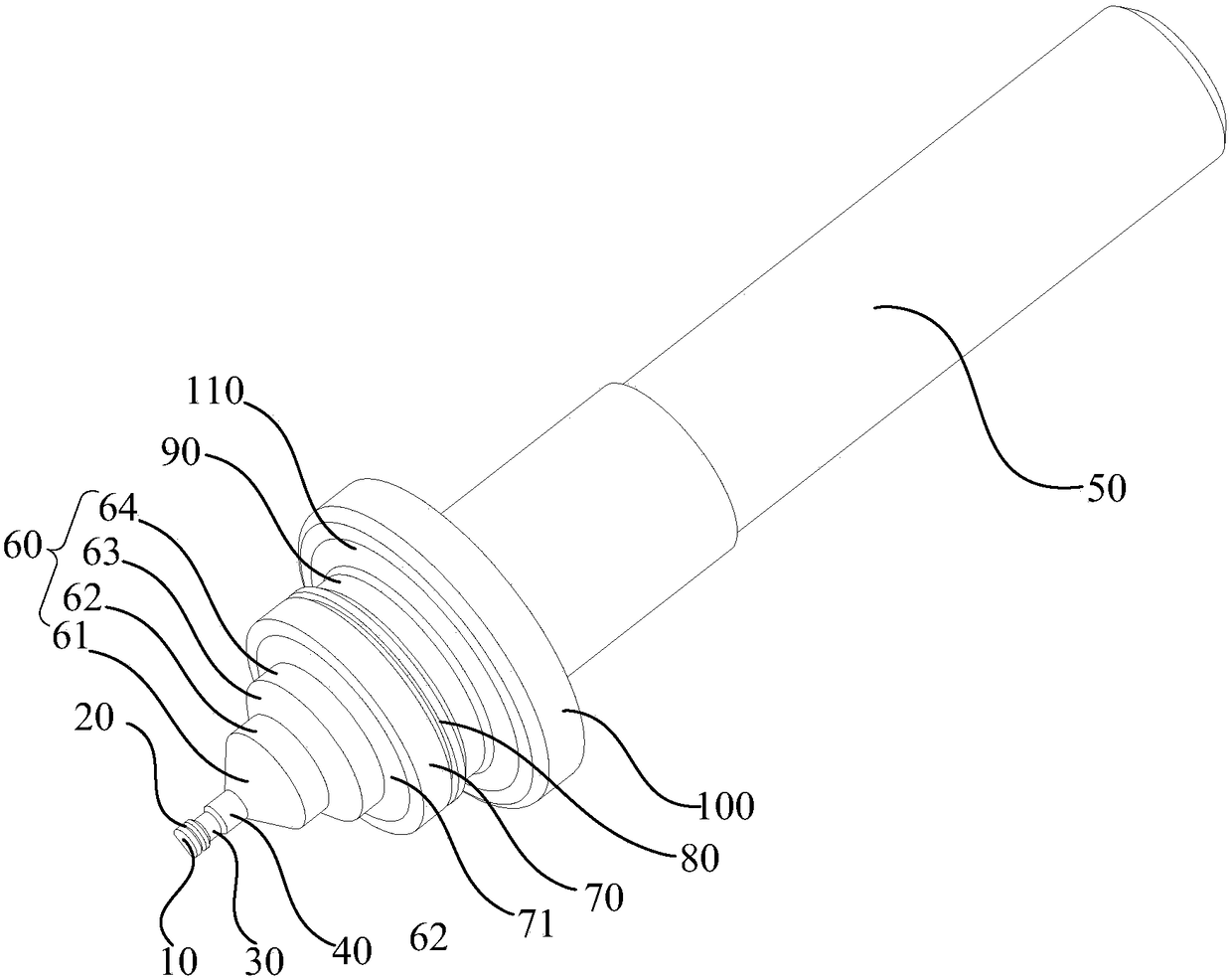

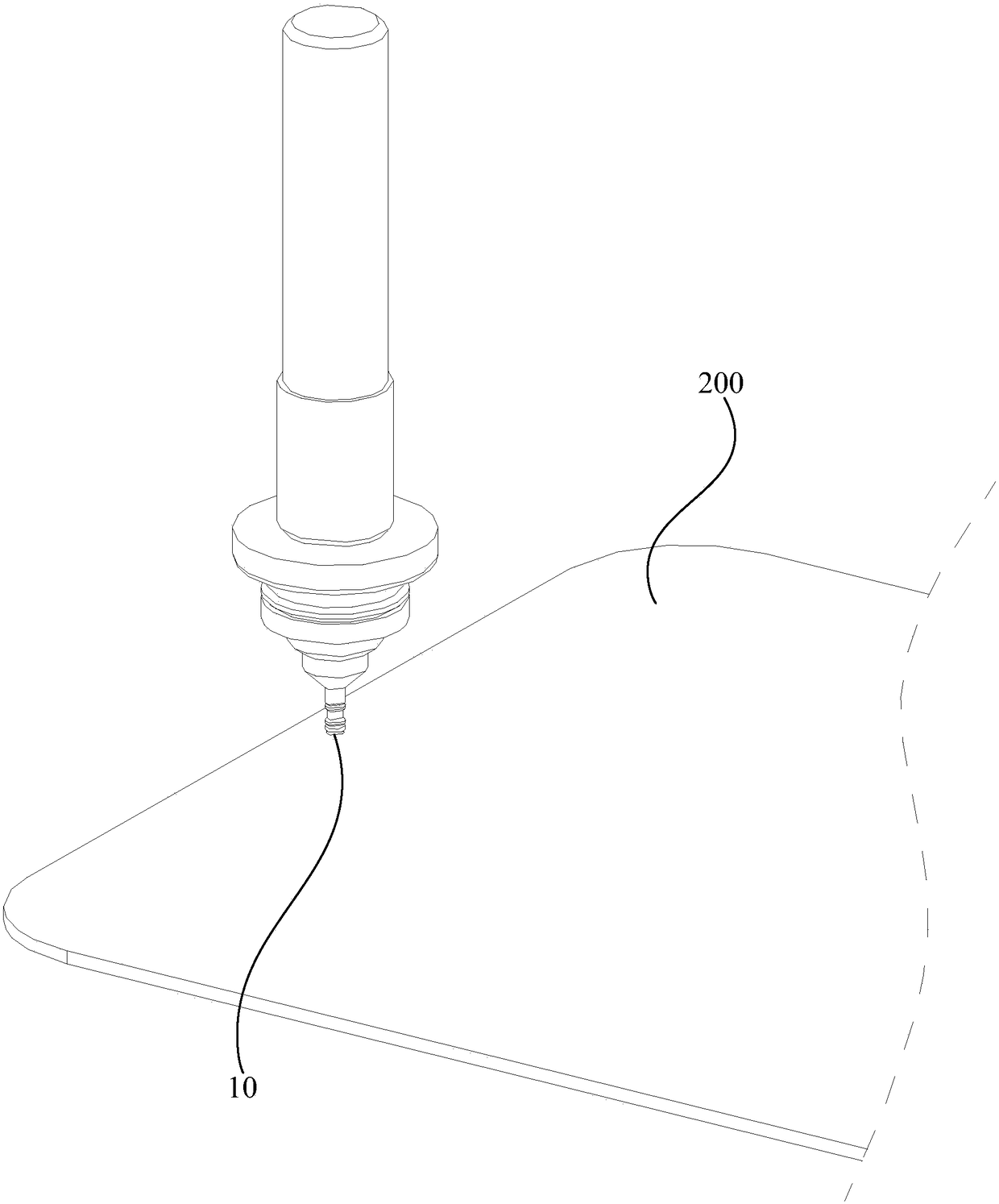

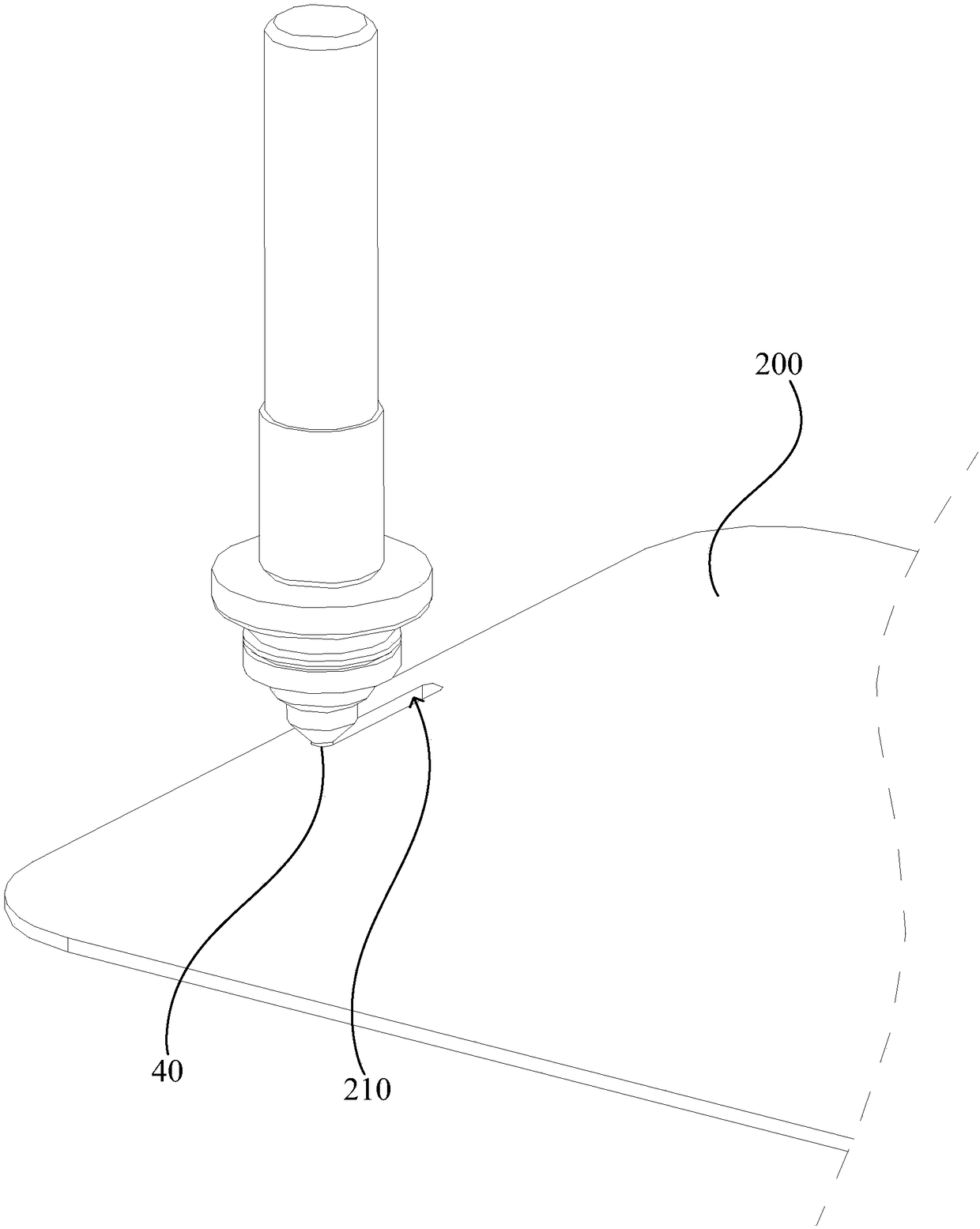

Ring cutter

ActiveCN106607953BEasy to cut and stripEasy to cut intoMetal working apparatusApparatus for removing/armouring cablesSurface layerEngineering

The invention provides a ring cutting tool. The ring cutting tool comprises a base body and a rotary installation portion rotationally arranged on the base body. A through containing cavity is formed in the middle of the rotary installation portion. A blade group is contained in the containing cavity and composed of multiple blades provided with cutting edge portions. All the blades are distributed in the circumferential direction of the containing cavity, and the blades are connected with the base body and can pivot relative to the base body. Each blade is hinged to the rotary installation portion through a connecting portion. The area of a ring cutting space which is defined by the cutting edge portions of all the blades in the middle of the containing cavity is driven to change dynamically because of rotation, relative to the base body, of the rotary installation portion. According to the ring cutting tool, the multiple blades are driven through rotation of the rotary installation portion to penetrate into a surface layer of a cable or pipe, the blades can easily enter the surface layer for cutting, and the cutting and stripping operation can be conducted on the surface layers, of different hardness degrees, of cables and pipes; and besides, the ring cutting space can change dynamically, so that the ring cutting tool is suitable for removing the surface layers of the cables or pipes of different diameters, the frequency of changing tools can be lowered during layer stripping, and the production efficiency is improved.

Owner:MIND ELECTRONICS APPLIANCE CO LTD

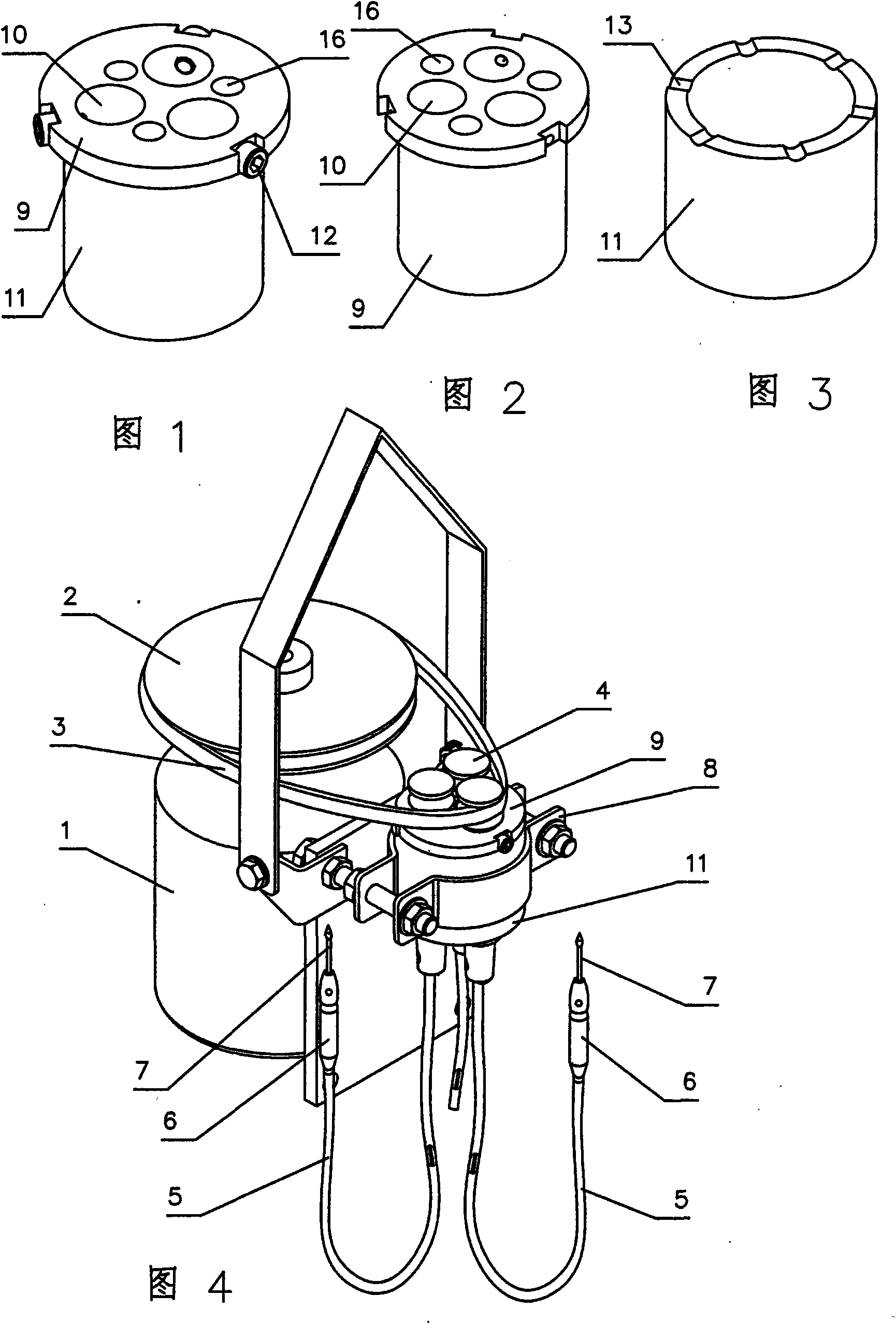

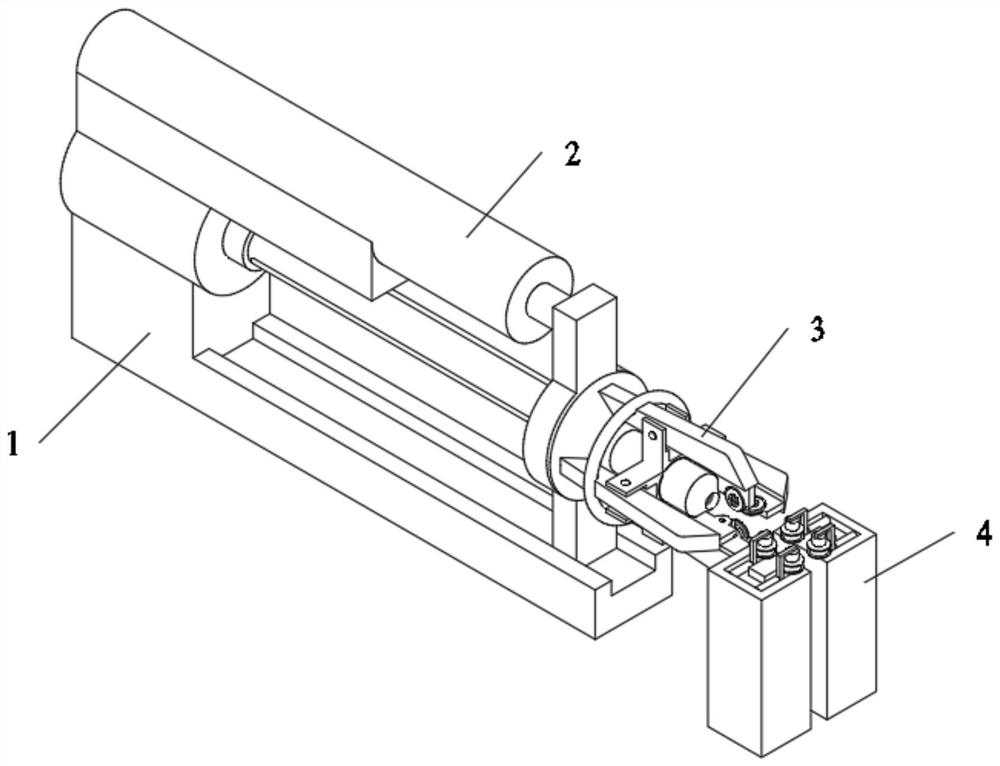

Automatic enamelled leather stripping device for starter armature assembly enamelled round wire

PendingCN113644524ASolve wear and tearReduce the frequency of tool changesLine/current collector detailsElectronic waste recyclingStructural engineeringAnnular array

The invention discloses an automatic enamelled leather stripping device for a starter armature assembly enamelled round wire. The device comprises a driving assembly, an adjusting assembly and a cutting assembly. One end of the adjusting assembly is fixedly mounted on the driving assembly; the cutting assembly comprises a rotating rod, a clamping part, knife rests, a fixing frame and second springs. The clamping part is in transmission connection with one end of an output shaft of the driving assembly through the rotating rod; the fixing frame is fixedly mounted at the joint of the clamping part and the rotating rod; the four groups of knife rests are annularly arrayed on the fixed frame by taking the central axis of the rotating rod as the center, and are hinged to the fixing frame; one end of an output shaft of the adjusting assembly is in transmission connection with the end faces of the ends, close to the adjusting assembly, of the knife rests. The second springs are sequentially connected with the four sets of knife rests in a clamped mode, and the second springs are connected end to end. Through the arrangement, the knife changing frequency is reduced, and the production efficiency is improved.

Owner:DONGFENG AUTOMOBILE ELECTRONICS

a drilling tool

ActiveCN106694962BReduce manufacturing difficultyReduce crashTransportation and packagingTrepanning drillsCentre of rotationMachining

The invention discloses a drilling tool. The drilling tool comprises a tool body; the tool body comprises a handle part, a cutting end part and a peripheral surface located between the handle part and the cutting end part; the handle part and the peripheral surface are symmetric about a rotation central axis of the tool body; a central groove and a circumferential groove which both communicate with a spiral groove in the circumferential surface are formed in the cutting end part, wherein the center groove is arranged adjacent to the rotation central axis, and the circumferential groove is arranged adjacent to the peripheral surface; cutting blades are arranged in the central groove and the circumferential groove, wherein the cutting blade arranged in the central groove is an inner blade, the cutting blade arranged in the circumferential grooves is an outer blade, and the inner blade and the outer blade are the same cutting blades; each cutting blade comprises a short cutting edge and a long cutting edge which are adjacent; the edge shape of each short cutting edge is different from the edge shape of the corresponding long cutting edge; the long cutting edge of the inner blade and the short cutting edge of the outer blade are combined to form a complete main cutting edge used for drilling a hole, the inner blade completes machining of a center area of the hole, and the outer blade completes machining of an outer ring area of the hole. The drilling tool has the advantages of being small in cutting vibration, high in machining precision, stable, reliable and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

A workpiece fixture of a CNC machine tool

InactiveCN102350649BReduce the frequency of tool changesImprove processing efficiencyPositioning apparatusMetal-working holdersNumerical controlBatch processing

Owner:SHANGHAI HUIYI CONTROL SYST

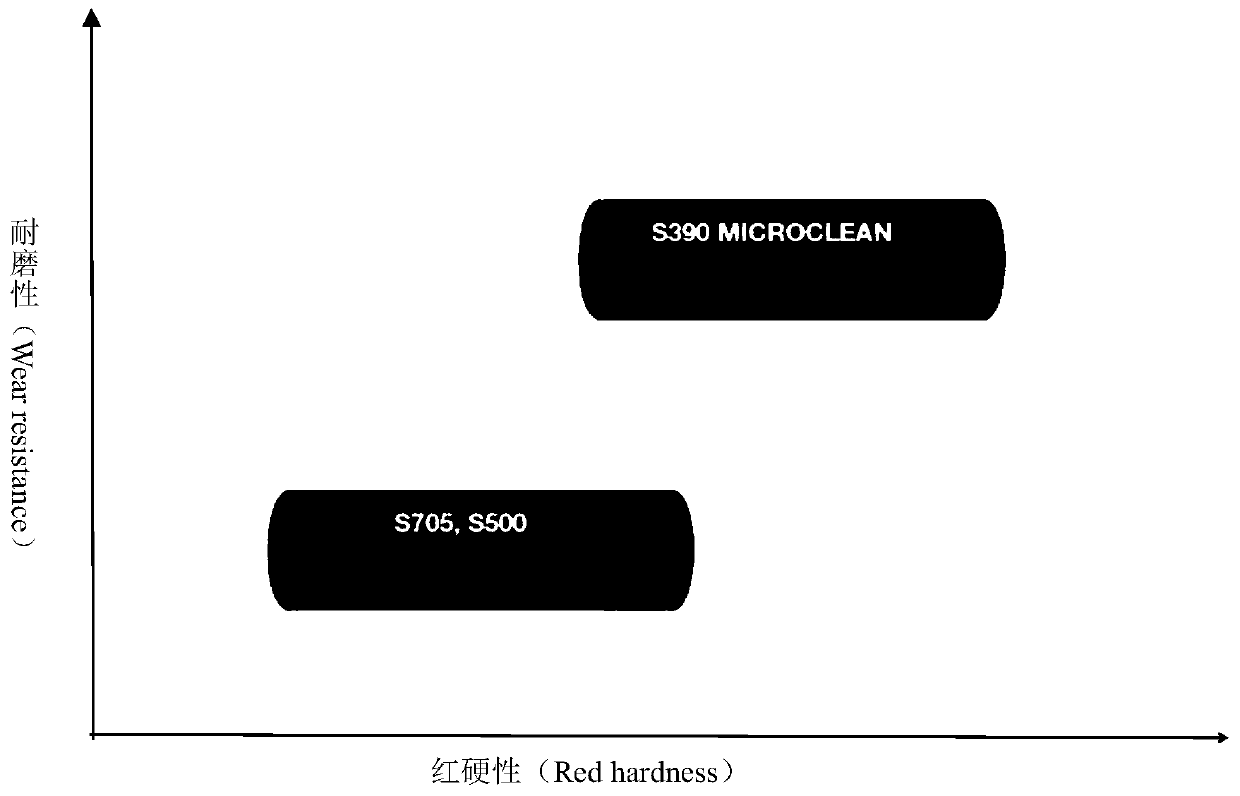

A high-performance hob cutter ring material and its preparation method

The invention discloses a high-performance cutter ring material and a preparation method thereof. The preparation method comprises steps of smelting, casting, electroslag remelting, uniform annealing,forging, spheroidizing annealing, quenching, tempering and the like, and the high-performance cutter ring material is prepared through following chemical elements in percentage: 0.55-0.70% of C, lessthan or equal to 0.40% of Si, less than or equal to 0.50% of Mn, 5.30-6.75% of Cr, 2.0-3.0% of Mo, 0.60-0.95% of V, less than or equal to 0.025% of S and P and the balance of iron. A high-performancecutter ring made of the material has the characteristics of being good in toughness, high in hardness, and the like, and compared with a cutter ring made of a conventional material, the cutter ring is remarkably good in wearing resistance, high in construction efficiency, long in service life and short in construction period.

Owner:中铁工程装备集团隧道设备制造有限公司

Compound cutter for non-metal composite material

PendingCN113020666ALarge apertureImprove machining accuracyTransportation and packagingMilling cuttersTool bitMilling cutter

The invention discloses a compound cutter for a non-metal composite material. A drilling edge firstly contacts with a workpiece, and a cutter head is fed in the axial direction, so that a broaching edge contacts with a drill hole, the pore diameter is further increased, and the inner hole of the drill hole is cut by using a reaming edge; if the larger pore diameter needs to be drilled, feeding is performed further in the axial direction, so that cutting is carried out by a milling cutter; a primary shape is formed firstly by adopting fine machining of the drilling edge, the cutting of the broaching edge gradually goes through cutting of the reaming edge, fine machining is carried out by using the milling edge, and the thickness required to be cut is very small in a transitional machining process from the drilling edge to the reaming edge, so that the higher machining accuracy is realized; similarly, the thickness required to be cut is also smaller in a transitional machining process from the broaching edge to the milling edge; and compared with a conventional drill bit, the accuracy of the drill bit is higher. According to the broaching edge and the milling edge, two different pore diameters can be drilled and machined, and the cutter can be used as a milling cutter, milling machining is carried out; and the compound cutter simultaneously has the functions of machining two pore diameters and performing milling and cutting operations, so that the cutter replacement frequency is reduced, and the machining efficiency is improved.

Owner:海南中智康弘精工技术有限公司

Grinding tool for protective lens

PendingCN108356644AExtended service lifeLarge processing stressOptical surface grinding machinesEngineeringMachining

The invention relates to a grinding tool for a protective lens. The grinding tool comprises a drilling portion, a first sand isolation segment, a fine trimming face grinding segment, a rough ore facegrinding segment and a main driving shaft. The drilling portion, the first sand isolation segment, the fine trimming face grinding segment, the rough ore face grinding segment and the main driving shaft are sequentially connected and coaxially arranged. The fine trimming face grinding segment and the rough ore face grinding segment are each columnar. The outer diameter of the fine trimming face grinding segment is less than that of the rough ore face grinding segment. By means of the grinding tool for the protective lens, when rough grinding machining is conducted on the inner side wall of a through hole in the rough ore face grinding segment, the fine trimming face grinding segment cannot be subjected to large machining stress, and therefore, the rupture or deformation phenomenon of the fine trimming face grinding segment can be avoided; thus, the service life of the grinding tool for the protective lens can be prolonged, and cost can be lowered; in addition, the tool replacement frequency can be reduced in the production process, and the problem that product quality is lowered due to tool replacement is avoided; and production efficiency is improved.

Owner:VITALNK IND SHENZHEN +1

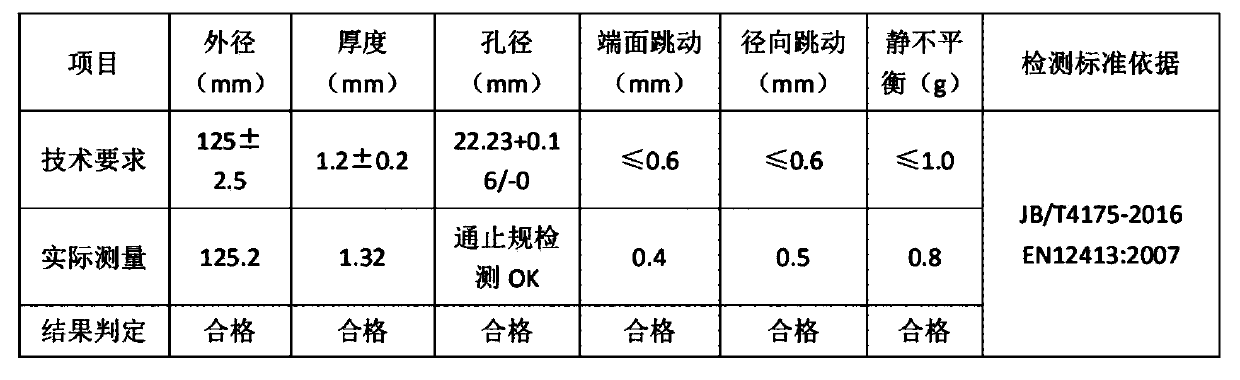

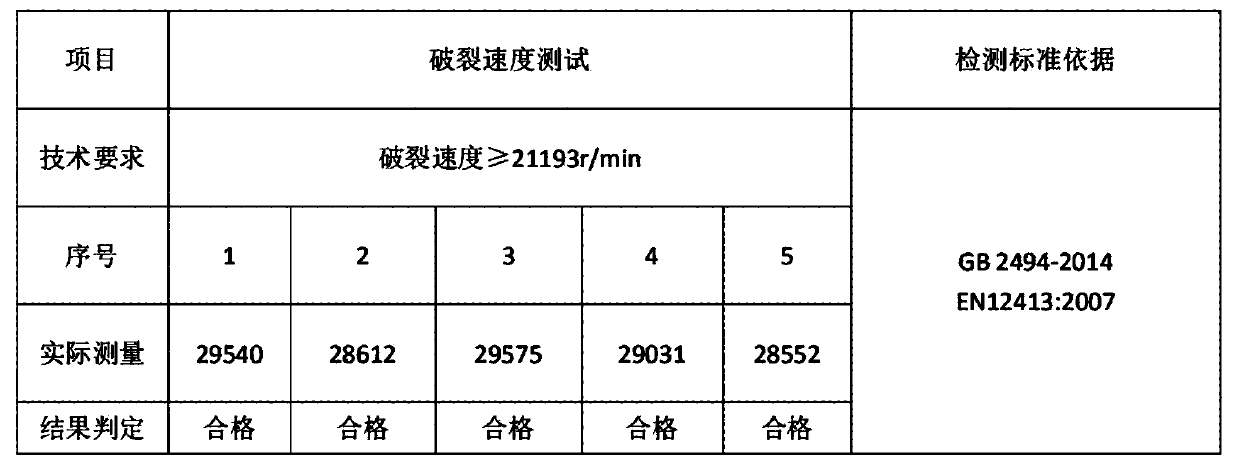

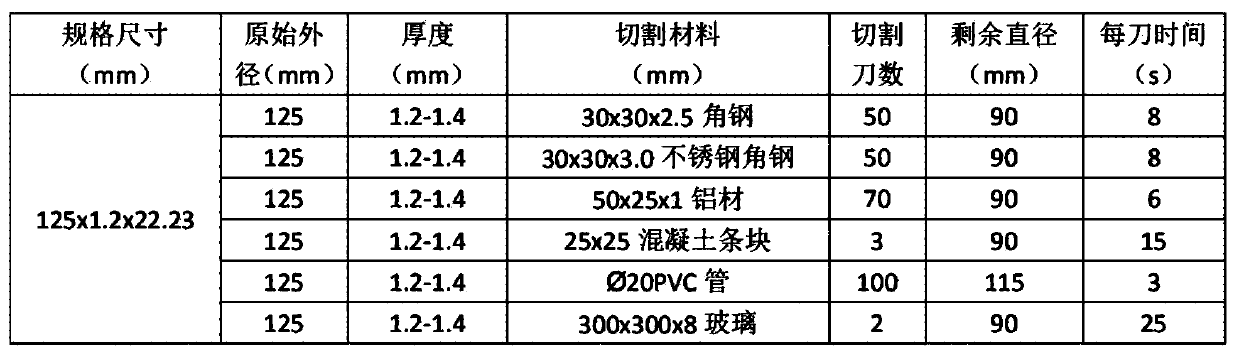

Multi-functional fiber reinforced resin cutting grinding wheel and manufacture technology thereof

InactiveCN110000717AReduce tool change frequencyImprove work efficiencyAbrasion apparatusGrinding devicesMultiple functionCaking

The invention relates to a grinding wheel and discloses a multi-functional fiber reinforced resin cutting grinding wheel and a manufacture technology thereof. Mixed abrasives comprise 30% of aluminumoxide, 20% of special abrasives, 25% of silicon carbide, 10% of phenolic resin, 12% of glass fibers and 3% of filler. The manufacture technology comprises mixing, pressing and heating to carry out solidification, wherein mixing is carried out at specific humidity and temperature to avoid caking. The multi-functional fiber reinforced resin cutting grinding wheel provided by the invention is appliedto various workpiece materials, so that the tool changing frequency is reduced, the operation efficiency is increased, and users are facilitated. The elasticity is great, and the sensitivity to oscillation, impact and pressure test is low.

Owner:浙江亚孙砂轮有限公司

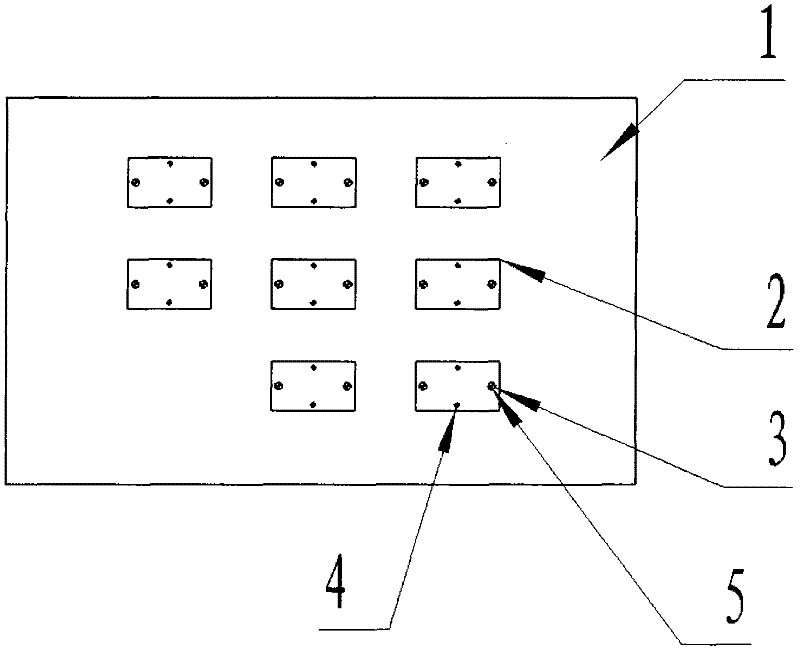

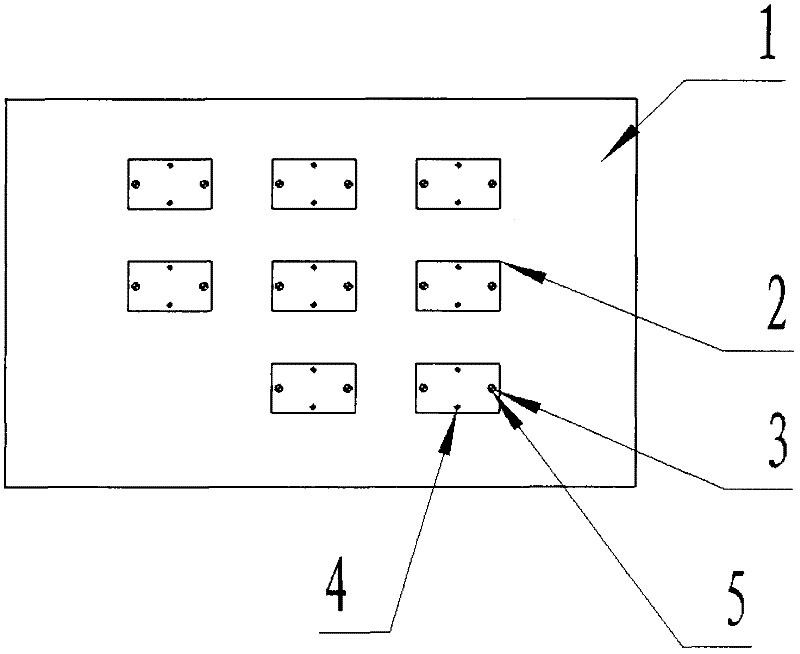

Sculpturing method of sculpturing machine frock

InactiveCN102328544AReduce the frequency of tool changesShorten the timeModel makingEngravingMechanical engineeringEngineering

The invention relates to a sculpturing method of a sculpturing machine frock, in particular to a sculpturing method of a sculpturing machine frock, capable of sculpturing multiple material trays at the same time. The method comprises the following steps of: fixing 16 pins on a base plate; making pin holes in the material trays; inserting the pins in the pin holes for fixing the material trays; and finally fixing the pins with screws. The sculpturing method has the advantages that cutters do not need to be replaced, cutter replace frequency is reduced, time is saved and working efficiency is improved.

Owner:YANTAI LIKAI ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com