Robot-based automatic feeding system for square auxiliary materials in cigarette packs

An automatic feeding and robotic technology, applied in packaging, transportation and packaging, conveyor control devices, etc., can solve the problems of high price, long maintenance time, complicated imported equipment technology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

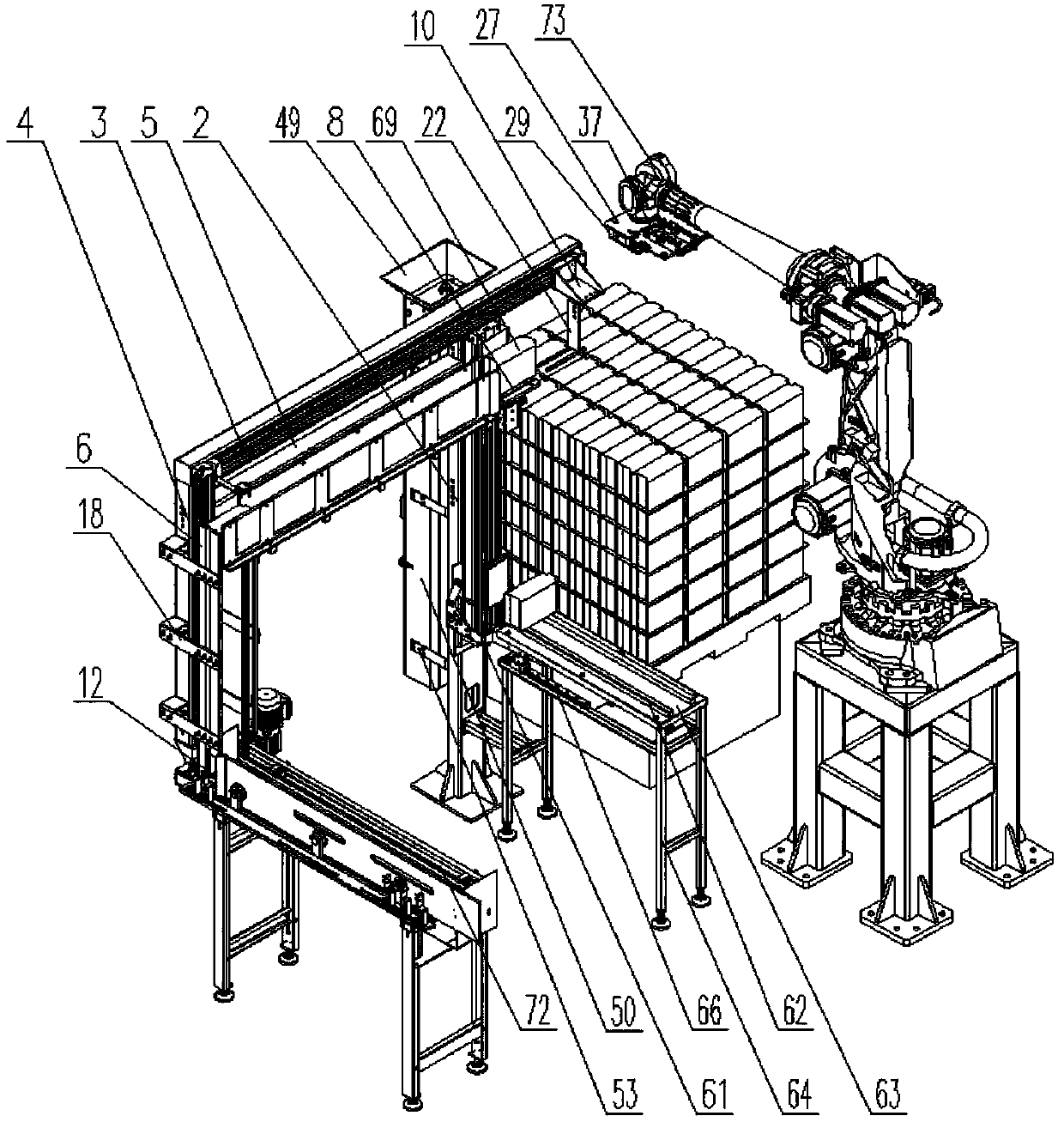

[0107] Such as figure 1 As shown, the robot-based automatic feeding system for square auxiliary materials for cigarette pack packaging of the present invention includes a bulk auxiliary material conveying frame, a robot clamp, a bulk auxiliary material wrapping paper recovery device, a bulk auxiliary material waste automatic recovery device, and a bulk auxiliary material. Wrap take-off aids, timing belt conveyors, articulated robots and pneumatic systems.

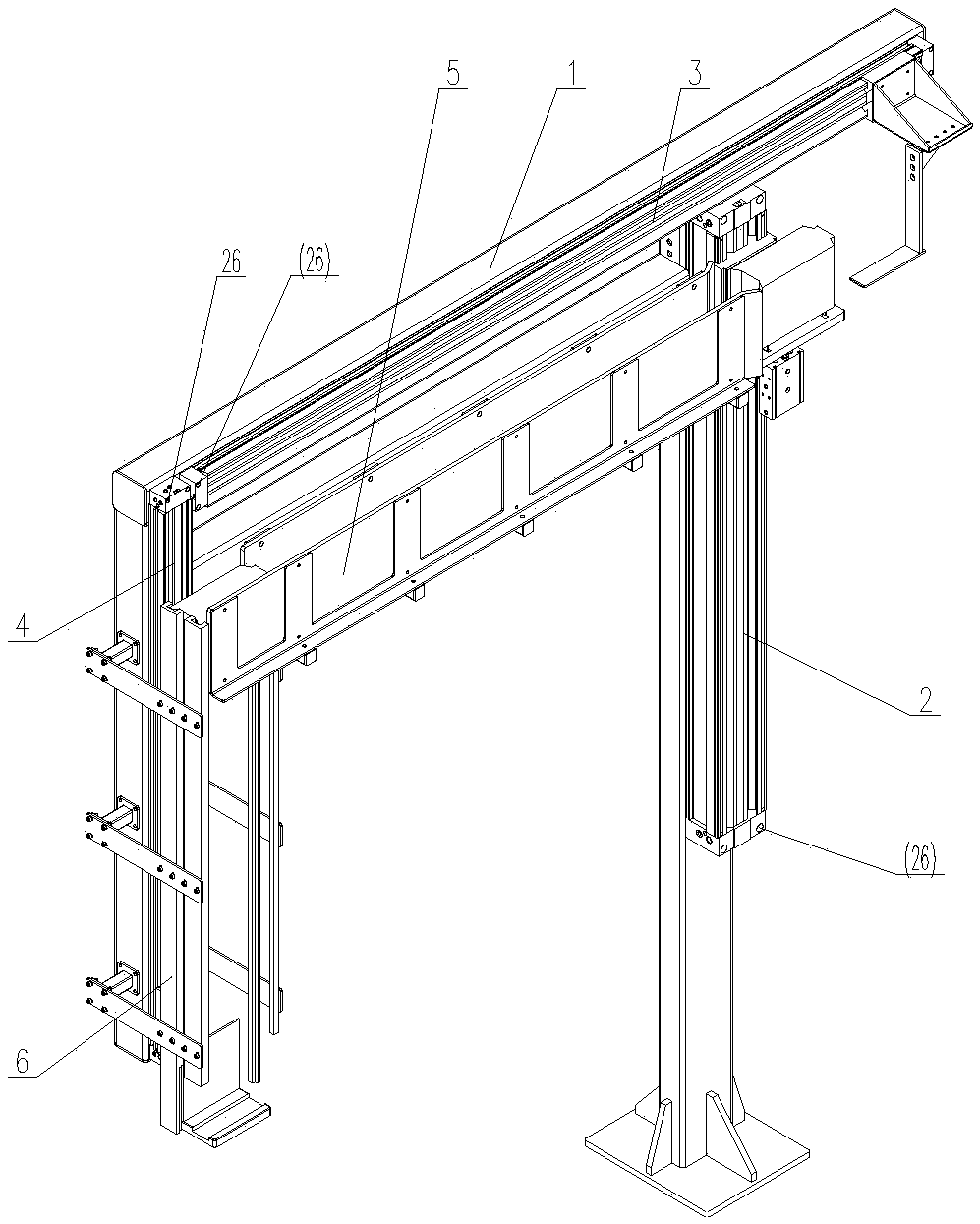

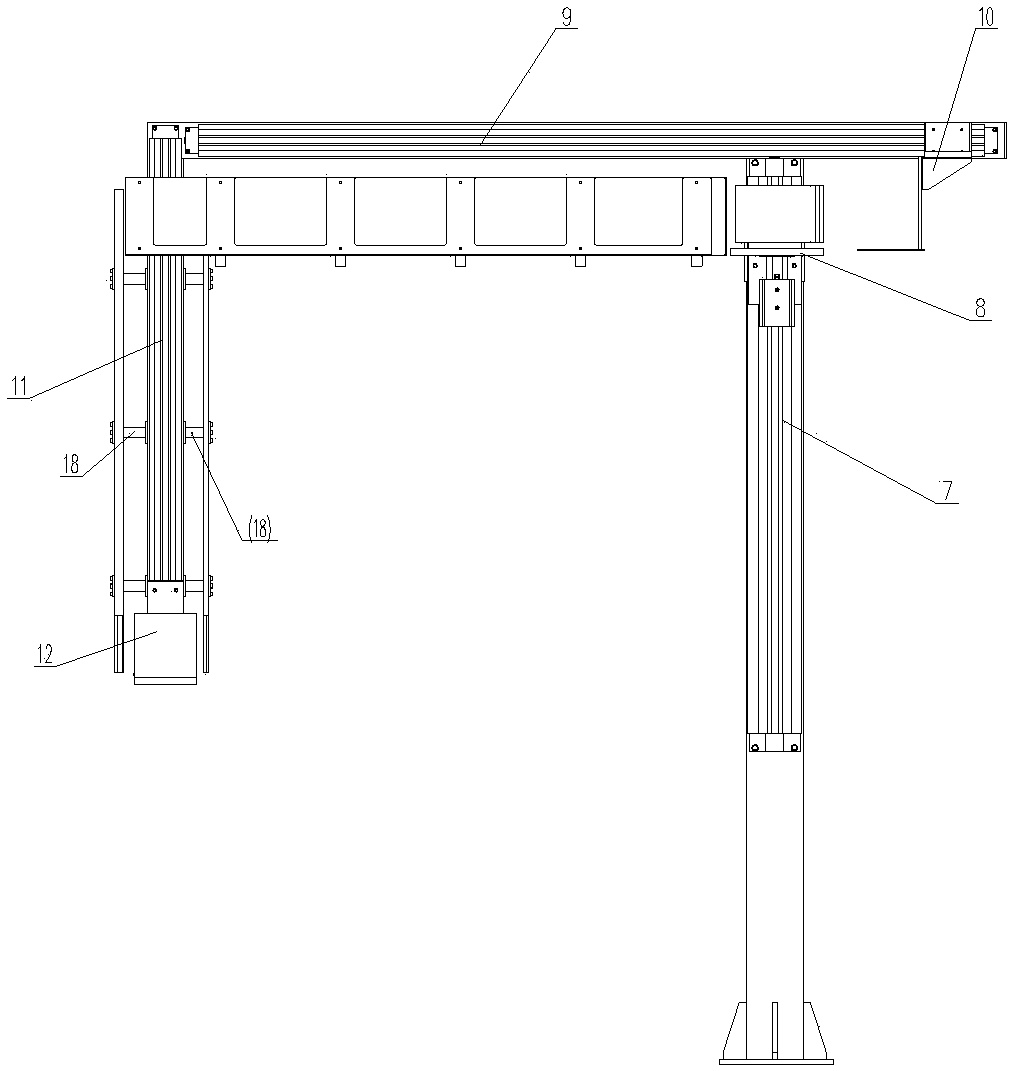

[0108] Such as figure 2 As shown, a gantry frame frame for auxiliary material conveying is characterized in that it consists of a gantry-type main frame 1, a right conveying device 2, a horizontal conveying device 3, a left conveying device 4, a horizontal channel 5 and a shaping mechanism 6. The right conveying device 2 is fixed on the right side of the gantry-type main support 1 through the connecting shaft 26; the horizontal conveying device 3 is fixed on the upper middle of the gantry-type main support 1 through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com