Cutting tool with two cutting inserts in a single flute

A cutting insert and cutting tool technology, which is applied to tools for lathes, accessories of toolholders, turning equipment, etc., can solve the problems of complex cutting insert structure, poor chip breaking and chip tolerance, and difficulty in precision control. Simple structure, improving cutting efficiency and reducing cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

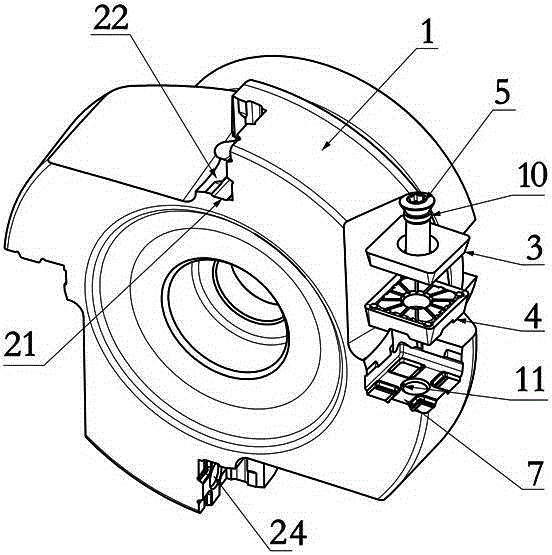

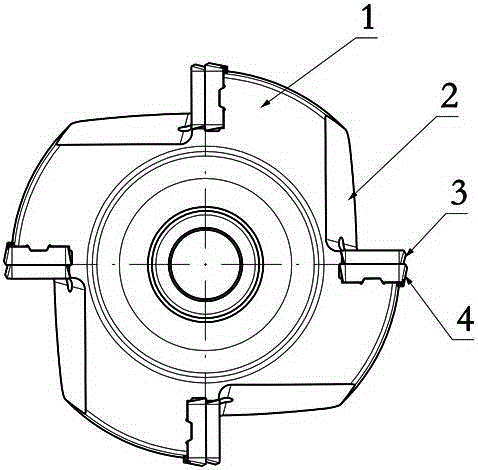

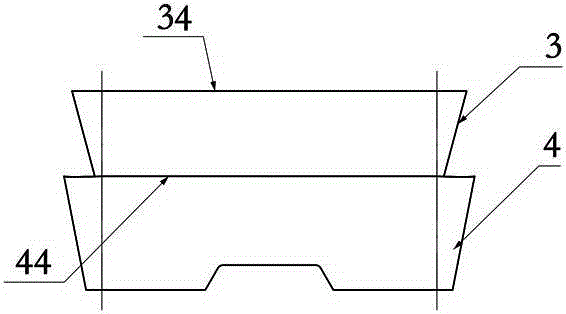

[0035] Figure 1 to Figure 7 It shows the first embodiment of the cutting tool with two cutting blades with a single sipe of the present invention, the cutting tool includes a cutter body 1, at least one set of sipe 2 is arranged on the cutter body 1, and the sipe 2 passes through a tight The firmware 5 is fixed with a cutting blade group consisting of a first cutting blade 3 and a second cutting blade 4, the first cutting blade 3 is pressed on the second cutting blade 4, and the second cutting blade 4 is pressed on the sipe 2 , during cutting, the first cutting blade 3 and the second cutting blade 4 complete the cutting independently successively, and an independent first cutting blade 3 and a second cutting blade 4 are arranged in a single sipe, and the two cutting blades can share a large The groove design space can greatly improve the chip removal performance, thereby improving the cutting efficiency of the cutting tool; at the same time, the damage of the cutting edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com