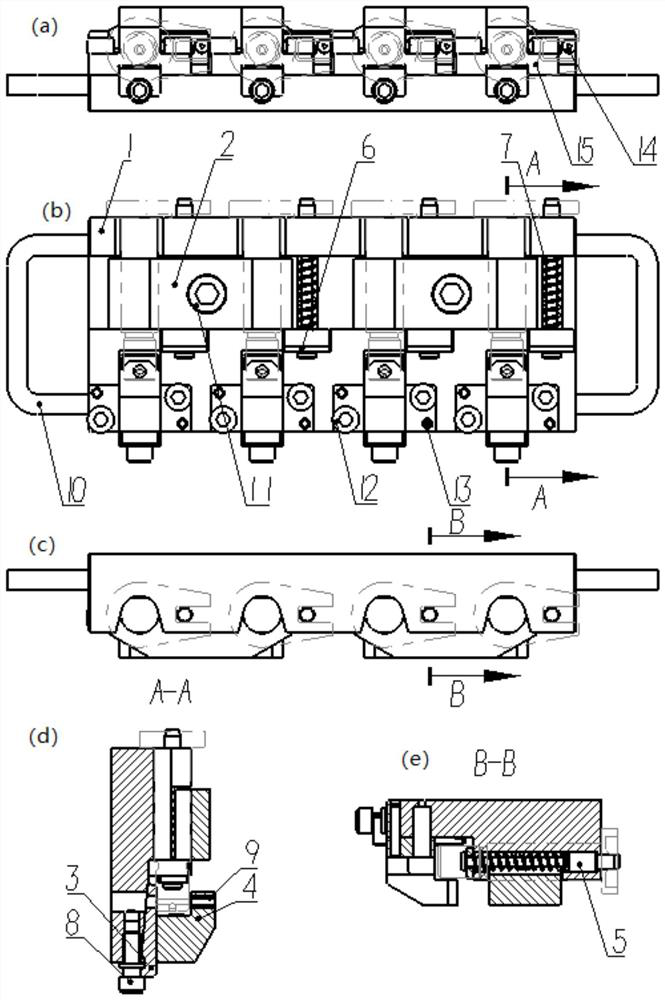

Shaft type one-jig multi-piece fuse hole machining drill jig

A multi-piece, fuse technology, which is applied in the direction of drilling molds for workpieces, can solve the problems of increased auxiliary time for frequent loading and unloading of workpieces, long moving strokes of machine tools, and low production efficiency, so as to reduce tool change frequency and improve processing. Efficiency, support and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below. Drilling molds for machining fuse holes in one mold with multiple parts for shafts mainly integrate three innovative points: clamping with multiple pieces in one mold, fixed angle with spring pins, and stable support with wedges. This drilling mold has the function of clamping 4 products at one time, and can continue to expand the processing of multiple products according to the actual needs and the stroke of the machine table. The basic support 1 is used as an integral support for the entire drilling jig, and is used for positioning the outer cylindrical surface and the bottom surface of the product 15, and is also used for matching and connecting other components to achieve specific functions. The angular positioning pin 5 is used to locate the angular direction of the product, and cooperate with the positioning of the base support on the outer cylindrical surface and bottom surface of the product to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com