Ring cutter

A ring cutting and cutting tool technology, which is applied to cable installation devices, metal processing, electrical components, etc., can solve the problems of damaged cores, reduced production efficiency, and difficulty in determining the depth of cutting tools, so as to reduce the frequency of tool replacement and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

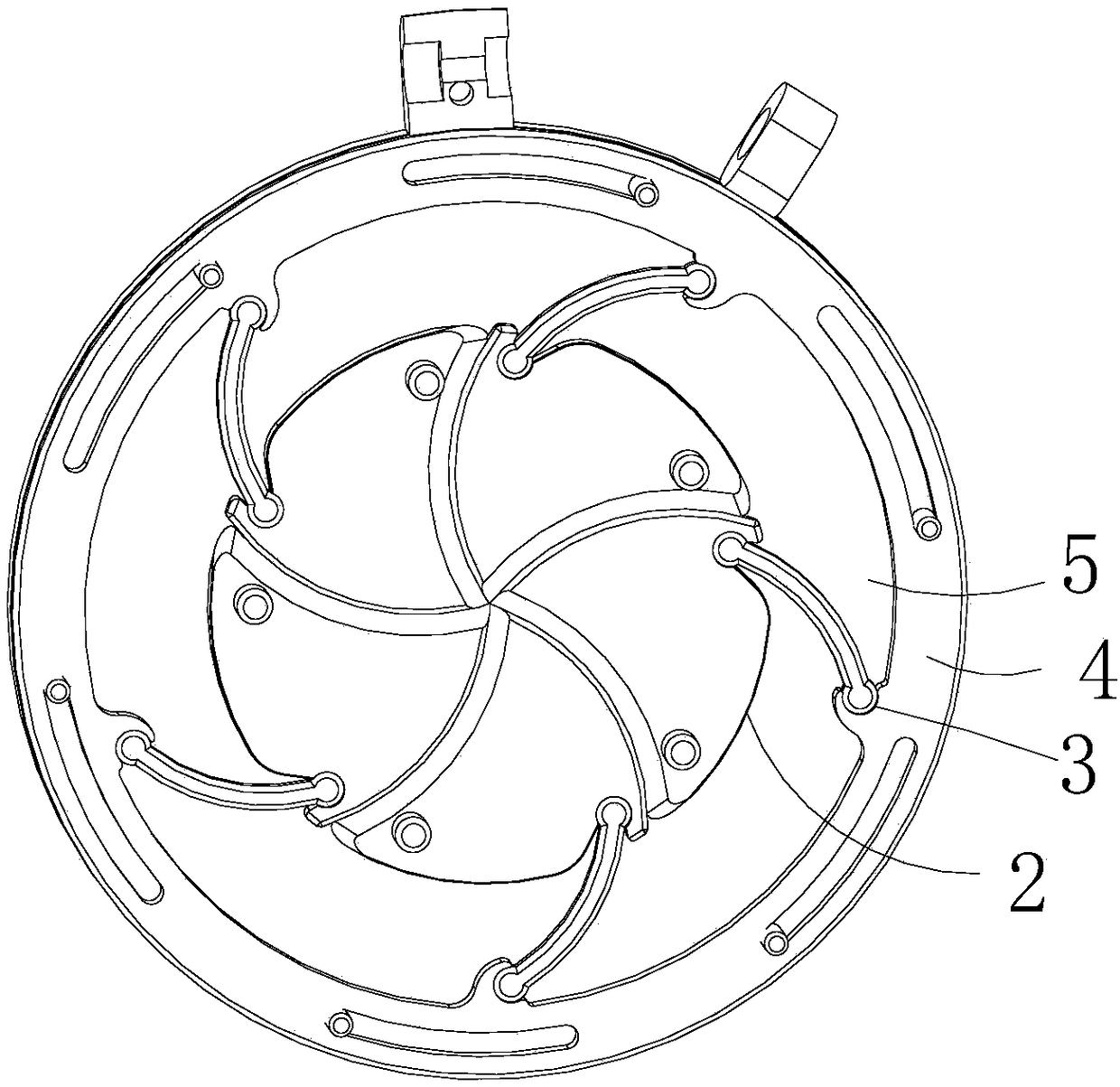

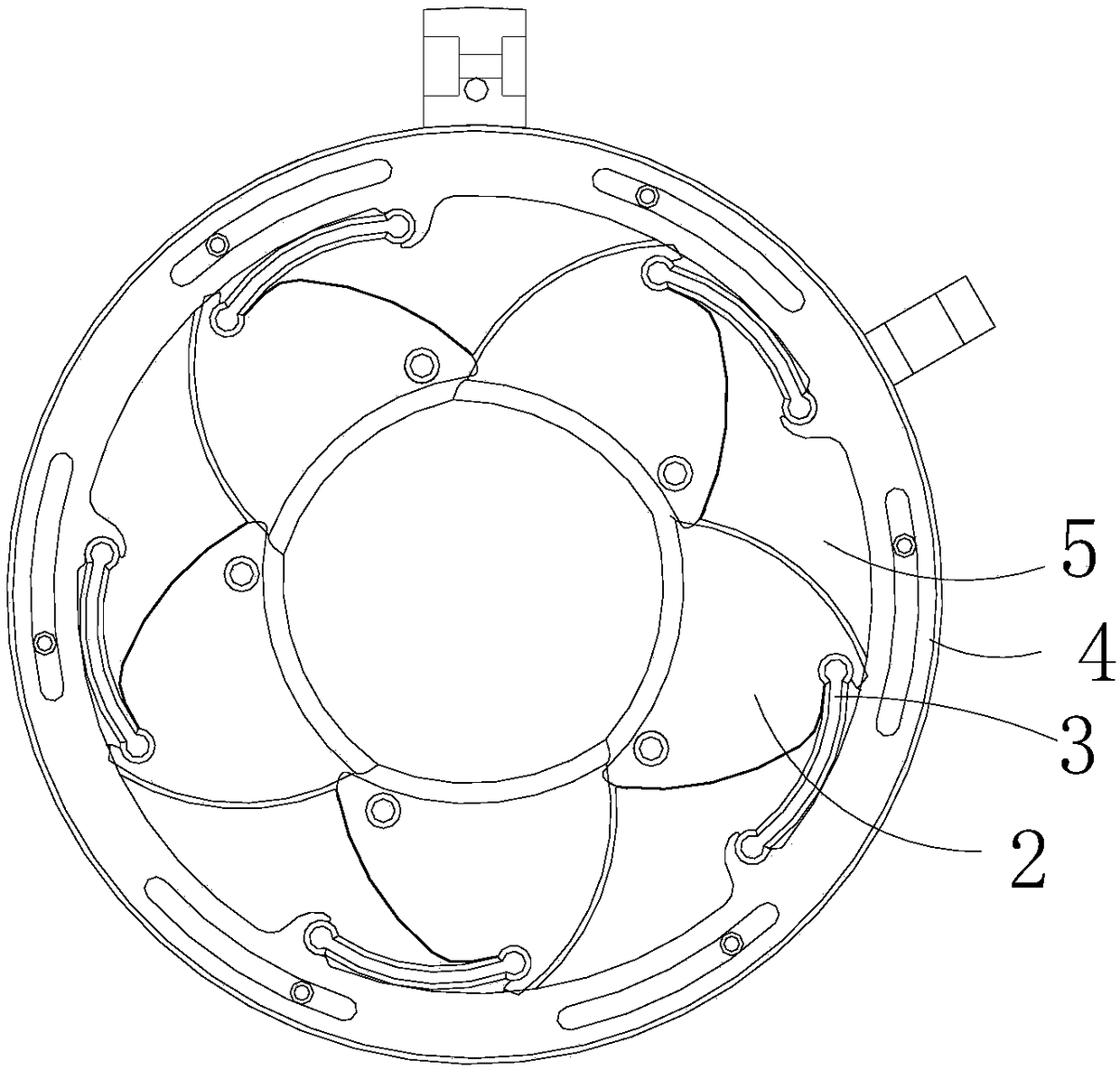

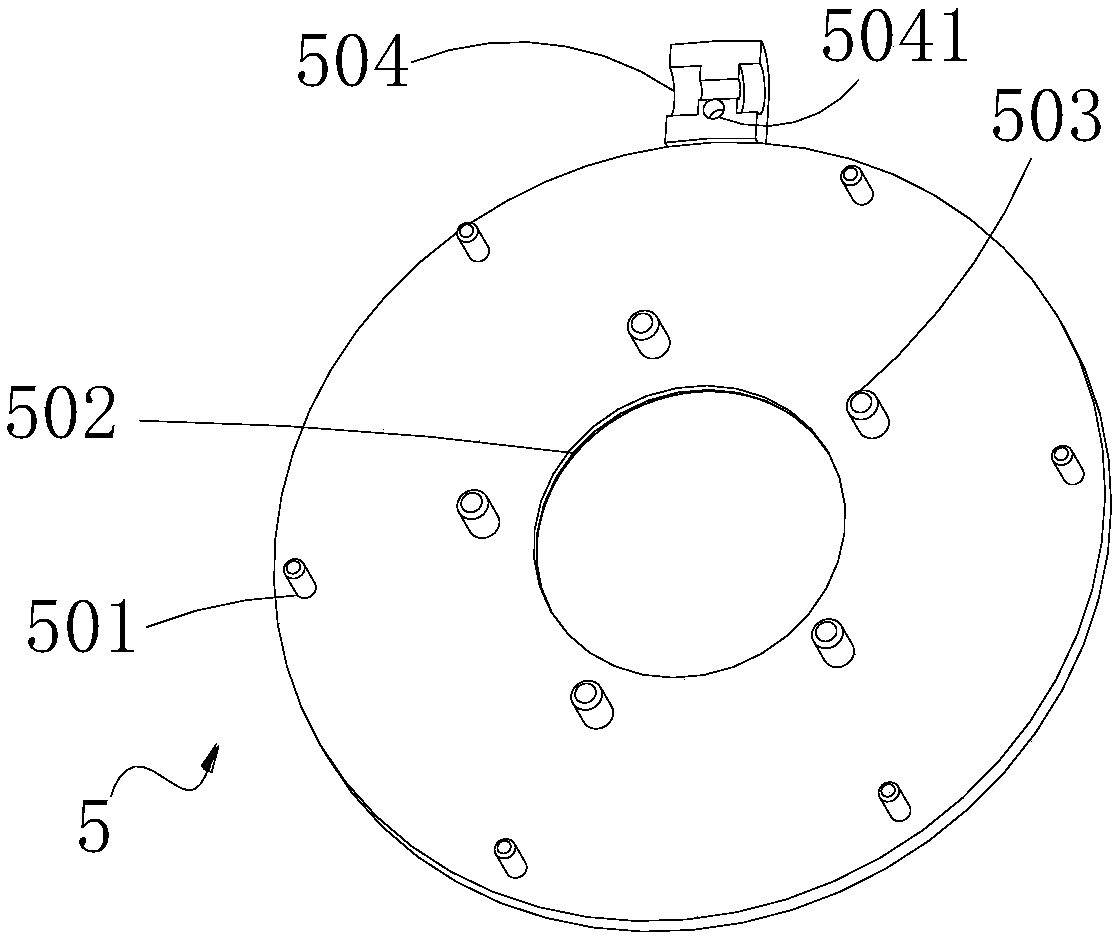

[0039] This embodiment relates to a circular cutting tool, which mainly includes a base, a rotating mounting part and a blade set. The rotating mounting part is rotatably arranged on the base, and a transparent housing cavity is formed in the middle of the rotating mounting part; the blade set is Housed in the containing cavity, it is composed of a plurality of blades with blades; each blade is distributed in the circumferential direction of the containing cavity, and forms a relative pivot connection with the base, and each blade is hinged on the rotating mounting part through the connecting part; In the middle of the accommodating cavity, the area of the circular cutting space formed by the blades of the blades dynamically changes due to the rotation of the rotary mounting portion relative to the base.

[0040] When removing cables or pipes, the ring cutting tool of this embodiment drives multiple blades into the surface of the cable or pipe through the rotation of the rotary ...

Embodiment 2

[0049] This embodiment relates to a circular cutting tool, such as Figure 9 to Figure 11 As shown, it has substantially the same structure as the ring cutting tool described in the first embodiment, and the main difference lies in the drive connection pair. In this embodiment, the drive connection pair is configured as a gear pair that meshes with the rotating mounting part 4, Specifically, a plurality of gear teeth are formed in the circumferential direction of the rotation mounting portion 4 to cooperate with the driving rod 7 to drive the rotation mounting portion 4 to rotate relative to the base.

[0050] The structure of the driving rod 7 in this embodiment is as Picture 12 As shown, in order to ensure the smooth rotation of the rotating mounting part 4, a driving gear 701, an auxiliary driving gear 702, and a driving gear 701 located between the driving gear 701 and the auxiliary driving gear 702 are arranged at intervals on the central shaft 704 of the driving rod 7. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com