A Positioning and Tool Changing CNC Tool Post Based on Reliability Comprehensive Design

A tool holder and tool type technology, which is applied in the field of CNC tool holder for positioning tool change based on comprehensive design of reliability, can solve the problems of accurate positioning tool change tool quantity defect and low reliability in the working range, and achieves the improvement of the working range. , The tool change process is continuous and stable, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

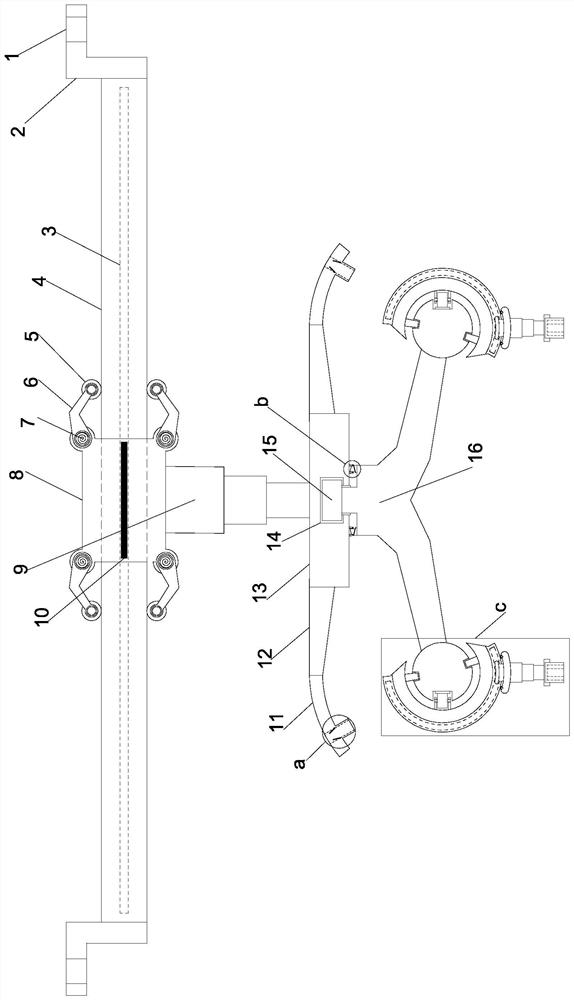

[0023] see Figure 1~5 , in an embodiment of the present invention, a positioning tool change type numerical control tool holder, including a support guide column 4 arranged horizontally, two ends of the support guide column 4 are symmetrically provided with a fixed mounting frame 2, and the upper ends of the fixed mounting frame 2 are provided with The fixed installation hole 1 is equipped with a sliding installation cylinder 8 horizontally in conjunction with the supporting guide column 4, and a lifting installation plate 13 is horizontally arranged directly below the sliding installation cylinder 8, and the lifting installation plate 13 and the sliding installation cylinder 8 are connected by an electronically controlled lifting column 9 Connection, the front and rear sides of the support guide column 4 are all horizontally provided with limit guide grooves 3, and the inner side of the sliding installation cylinder 8 is matched with the limit guide groove 3. All are symmetr...

Embodiment 2

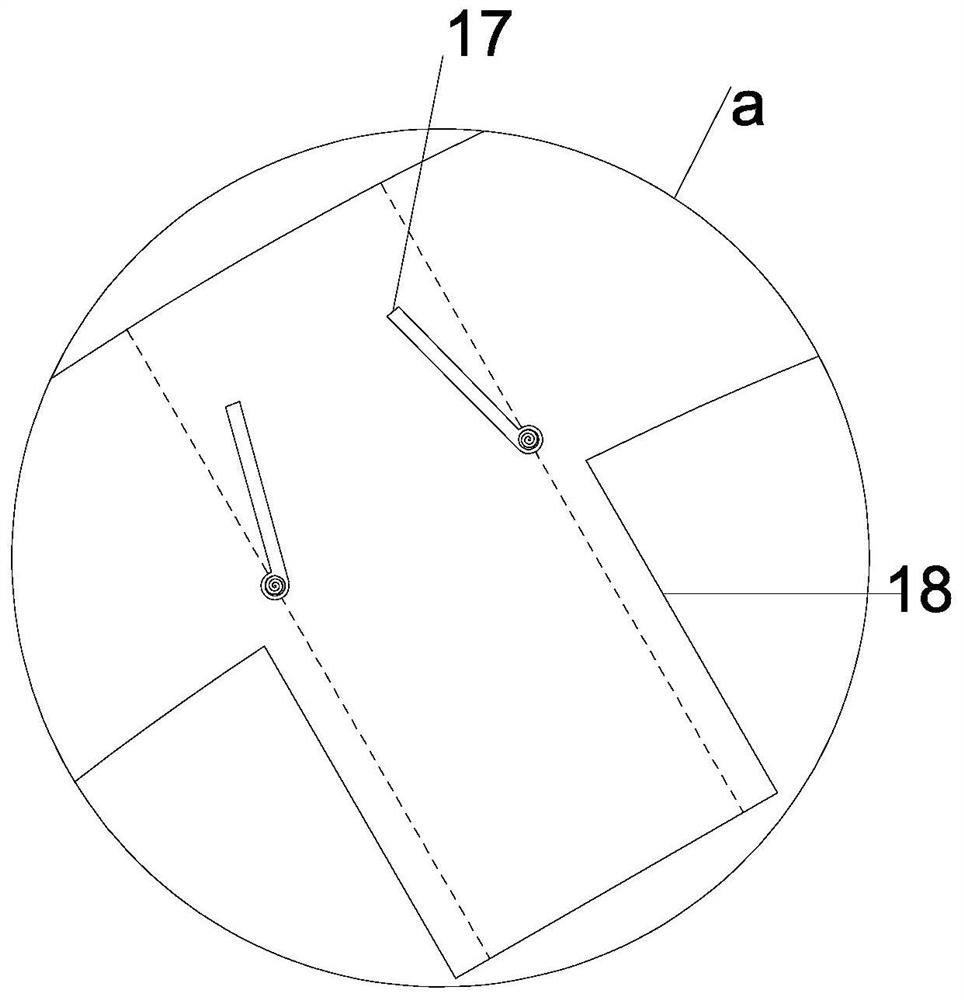

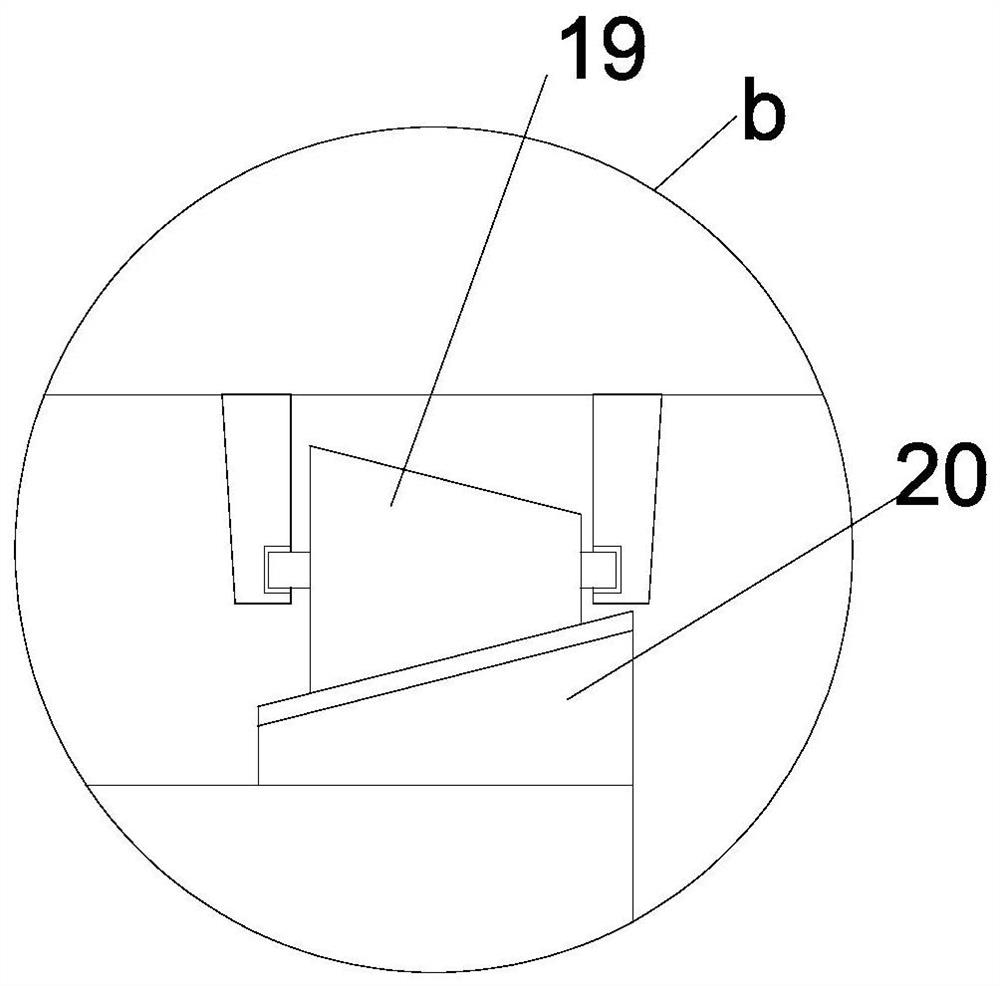

[0026]On the basis of Embodiment 1, through the meshing transmission of the driving helical gear 19 and the rotating helical gear ring 20, the rotating mounting plate 16 is roughly rotated and displaced with low precision, and then matched with the meshing of the driving gear and the steering gear ring 26 transmission to achieve precise positioning and tool change, and at the same time, the tool can be inserted into the tool mounting cylinder 18 from bottom to top. Under the action of the reset shaft, the reset clamping plate 17 squeezes and fixes the tool. can be pulled out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com