Rotary cutting tool with double cutting edge

A technology of rotating cutting tools and cutting edges, which is applied in the direction of milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problems of small contribution to cutting, reduce cutting feed, and high cost of use, so as to improve cutting efficiency and reduce replacement Knife frequency and the effect of improving application ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

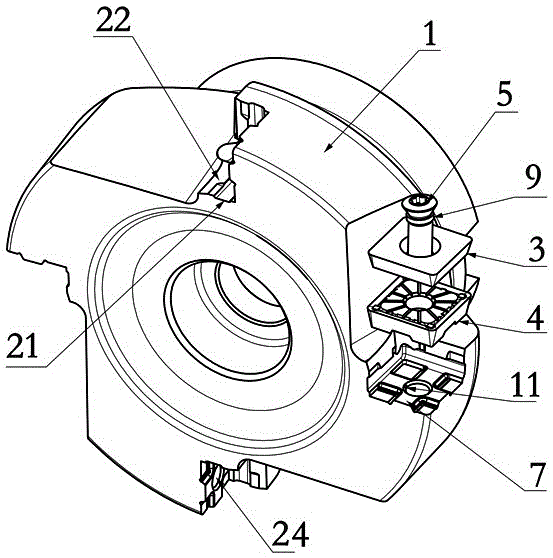

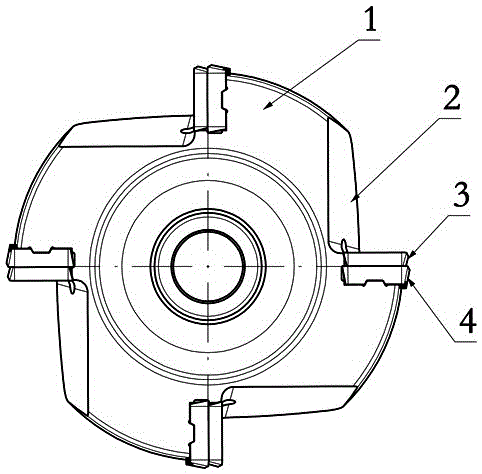

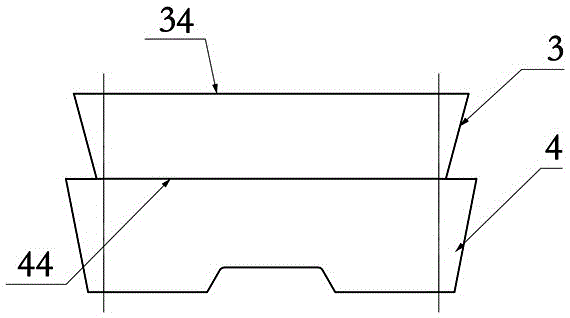

[0037] Figure 1 to Figure 7Shown is the first embodiment of the rotary cutting tool with double-layer cutting edge of the present invention, the rotary cutting tool includes a cutter body 1, at least one set of sipes 2 are arranged on the cutter body 1, and the slits 2 are fastened The part 5 is fixed with a cutting blade group consisting of a first cutting blade 3 and a second cutting blade 4, the first cutting blade 3 is pressed on the second cutting blade 4, and the second cutting blade 4 is pressed on the sipe 2, The second cutting blade 4 has a larger rotational cutting radius than the first cutting blade 3. During cutting, the cutting feed of the second cutting blade 4 is greater than or equal to the cutting feed of the first cutting blade 3. In a single sipe There are superposed first cutting blades 3 and second cutting blades 4, the two blades are independent of each other, and can be processed separately during processing, and the design restrictions on the respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com