Knife fine grinding apparatus

A fine grinding, blade technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as unevenness, low efficiency, and the left blade is not sharp enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

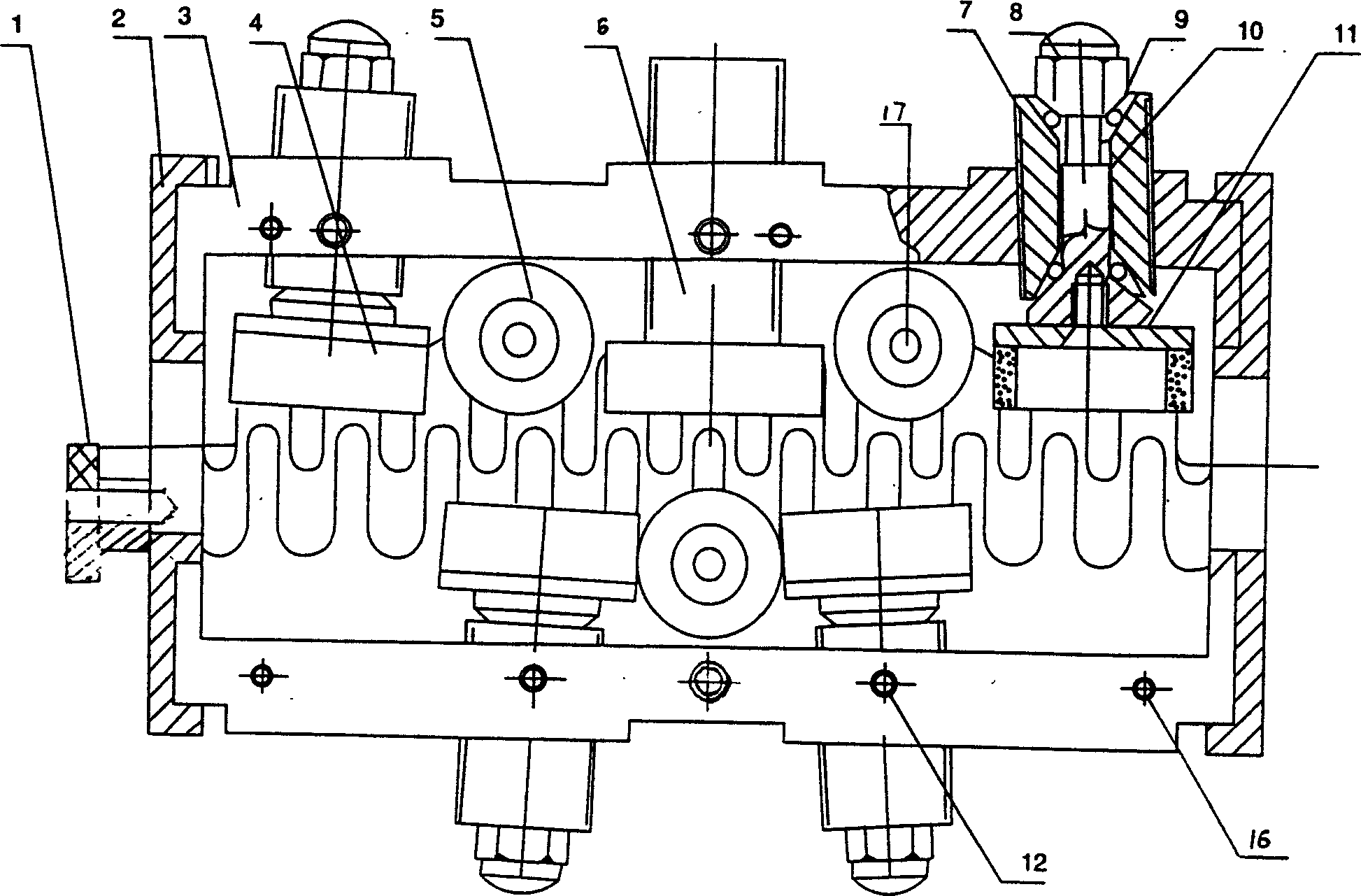

Embodiment Construction

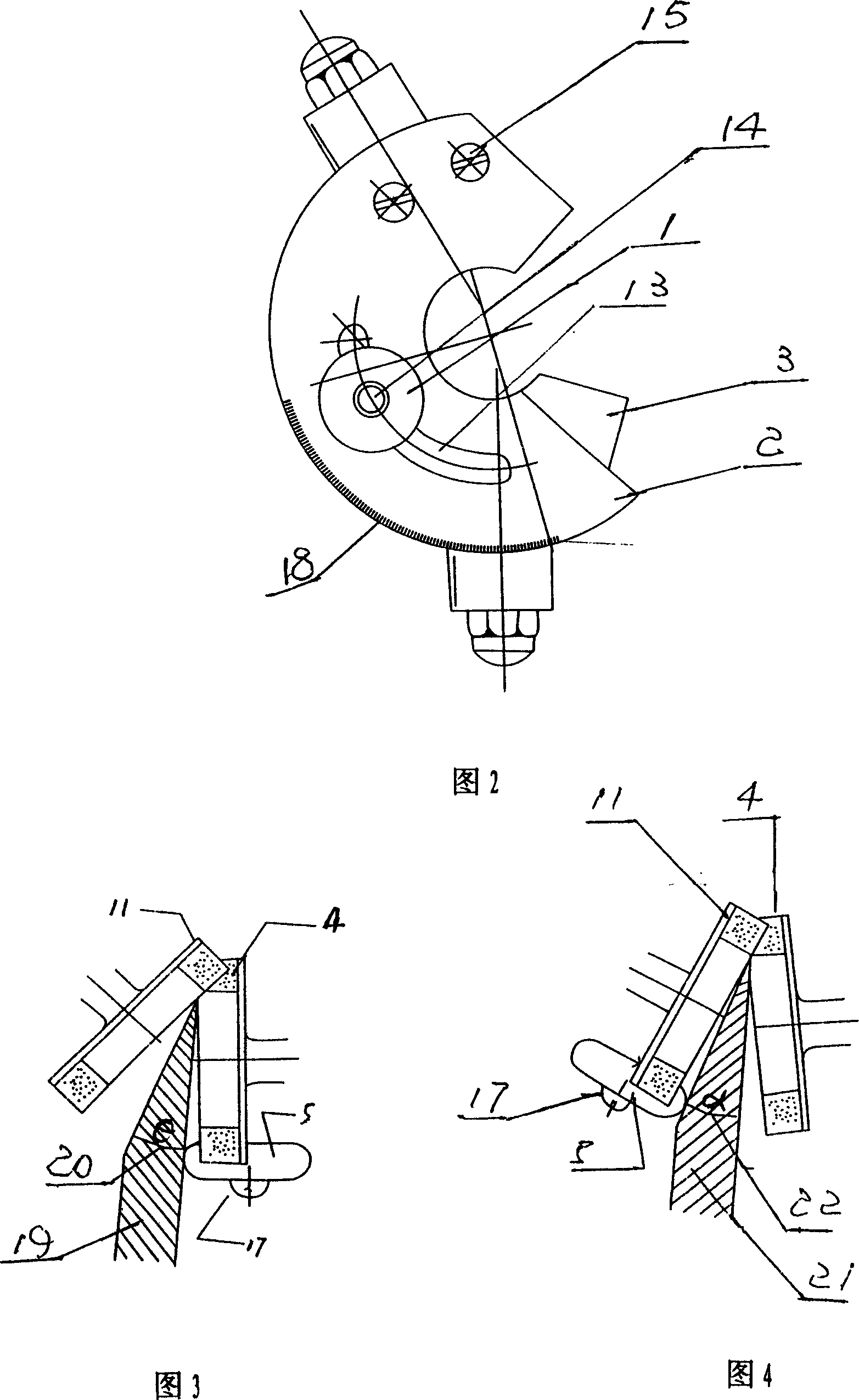

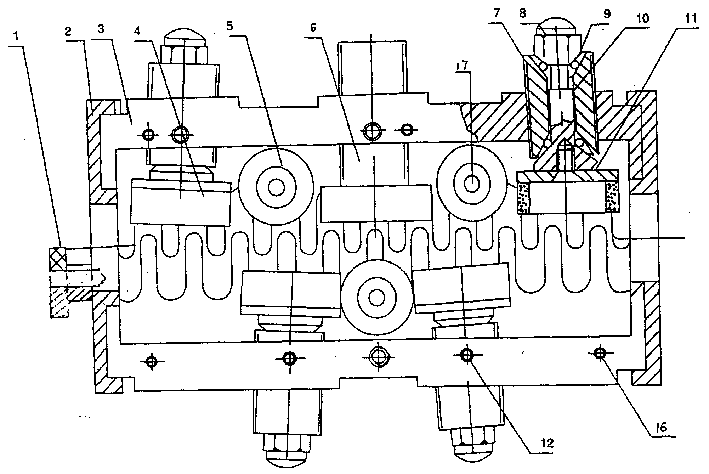

[0014] The material of grinding wheel (4) is a quartzite agate grinding wheel, natural oil stone grinding wheel, cubic boron nitride grinding wheel, white corundum, rice-pudding corundum grinding wheel, and housing (3) is an aluminum casting. When in use, adjust its degree along the arc groove (13) of the rotating disc (2), so that the end faces of the grinding wheels on both sides fit together to form a V-shaped grinding mouth. The V-shaped grinding mouth is aligned with the blade, and the blade can be finely ground by pushing it back and forth by hand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com