Tooth profile finishing method of large modulus hard tooth surface rack

A technology with hard tooth surface and large modulus, which is applied in the field of tooth shape finishing, can solve the problems of not meeting the requirements of batch processing, taking a long time on the machine tool for processing, and low processing efficiency, so as to save the disassembly time and improve the processing efficiency. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

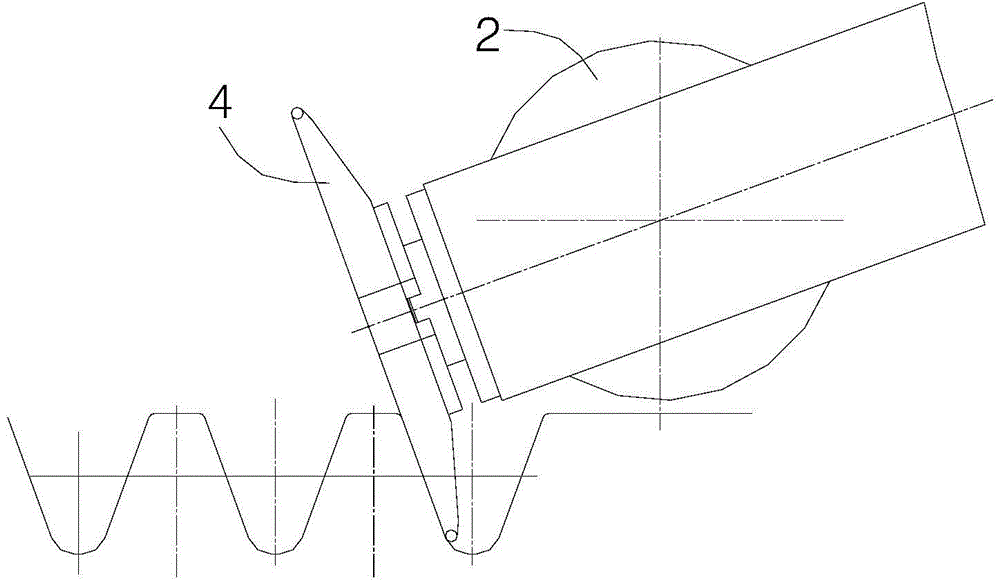

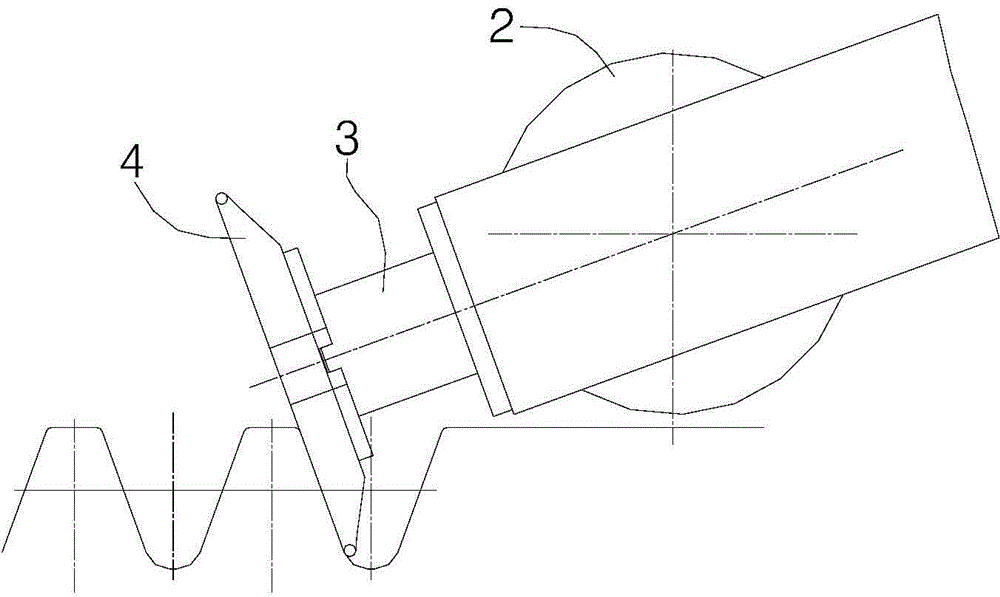

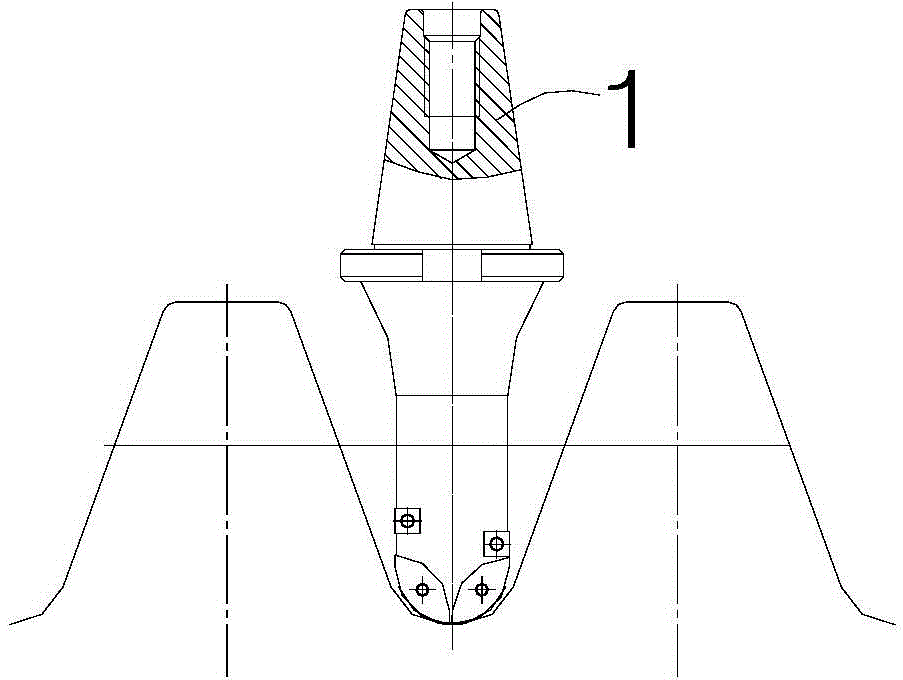

[0034] The tooth shape finishing method of the large modulus hardened tooth surface rack is installed on the worktable of the machine tool after surface quenching, and the left tooth slope 701 and the right tooth slope 702 are milled by the track method with the face milling cutter 4; Then the arc surface 801 of the left tooth bottom and the arc surface 802 of the right tooth bottom are milled by the forming method through the ball end milling cutter 1; On the one hand, the above method can effectively improve the processing efficiency, and on the other hand, it can ensure that the surface roughness meets the corresponding requirements. The above-mentioned ball-end milling cutter 1 is preferably a clip-type ball-end milling cutter of Hitachi Japan’s high-strength and high-hardness powerful milling machine, and the model of the cutter body is AB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com