Machining technology for alloy-inlaid alloy internal and external chamfering push-pull cutter

A processing technology and a technology of pushing and pulling knives, which are applied in the field of machining technology of inner and outer chamfering push-pulling knives inlaid with alloys, can solve the problems of poor impact resistance of solid carbide, high cost of tool use, fractures or teeth, and save processing time. , the effect of improving quality and precision, and saving the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

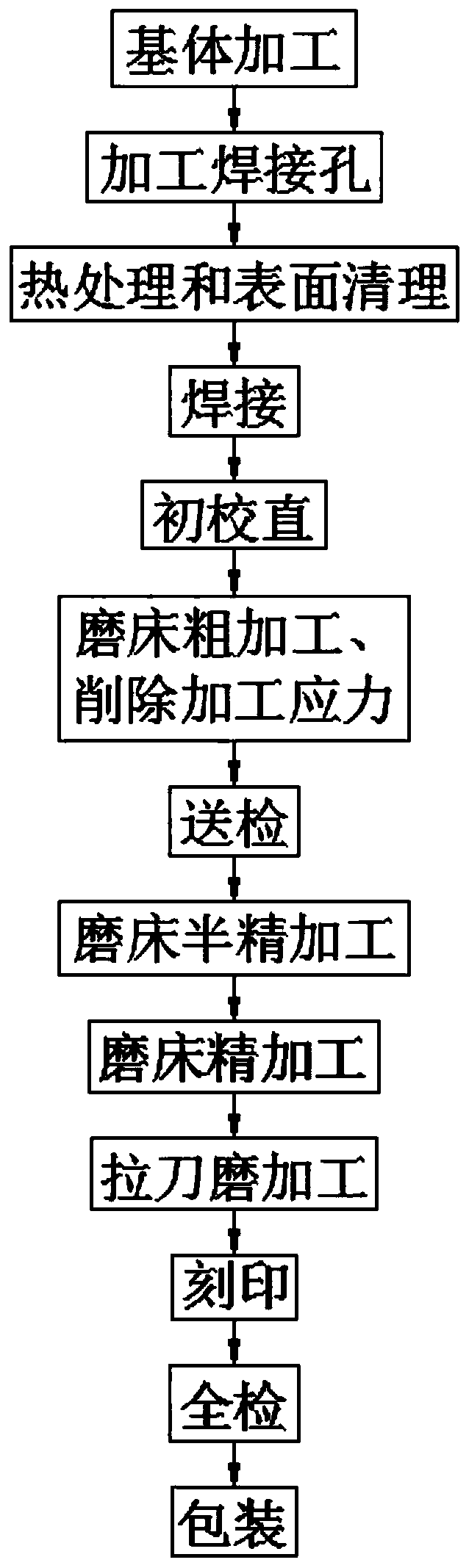

[0051] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0052] figure 1 It is a flow chart of an embodiment of the processing technology of a push-pull knife with inner and outer chamfering inlaid with alloy according to the present invention. Such as figure 1 As shown, the processing technology of the alloy-inlaid internal and external chamfering push-pull knife provided in this embodiment is used to process a push-pull knife inlaid with cemented carbide on a rigid substrate, including the following steps:

[0053] Step S1: substrate processing;

[0054] Use forgings or machine-pressed steel plates to make blanks, and then use milling machines or planers and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com