Multi-tool-position conversion device and multi-cutter hand-hold electric carving machine applying same

A conversion device and multi-knife position technology, which is applied in the fields of engraving and decorative arts, can solve the problems that operators cannot work freely, affect the quality of work, increase the cost of equipment, etc., and achieve rapid and convenient operation, improve efficiency, and occupy less space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

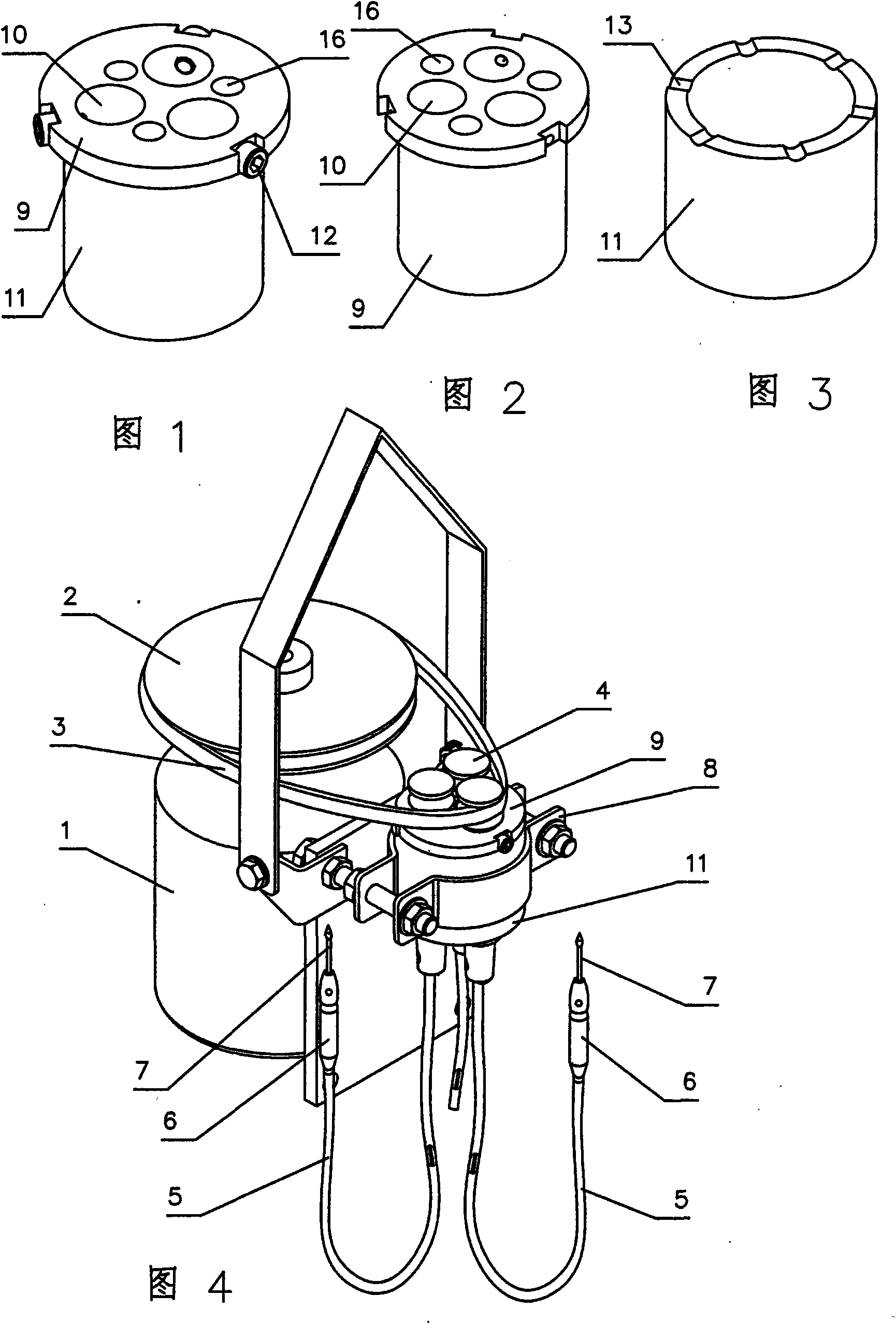

[0035] Embodiment 1: as Figure 1 to Figure 3 As shown, the turntable 9 is placed in the sleeve 11 fixed on the bracket 8 to rotate and cooperate. The turntable 9 is provided with several axial holes 10 around the center corresponding to the driven wheels 4 of the electric engraving machine. The sleeve 11 The upper end is provided with several positioning grooves 13, and the upper edge of the turntable 9 is provided with positioning pins 12 correspondingly matched with the positioning grooves 13 to form a positioning mechanism. In order to make the turntable 9 have a better heat dissipation effect, several heat dissipation holes 16 may also be provided on the turntable 9 in this embodiment.

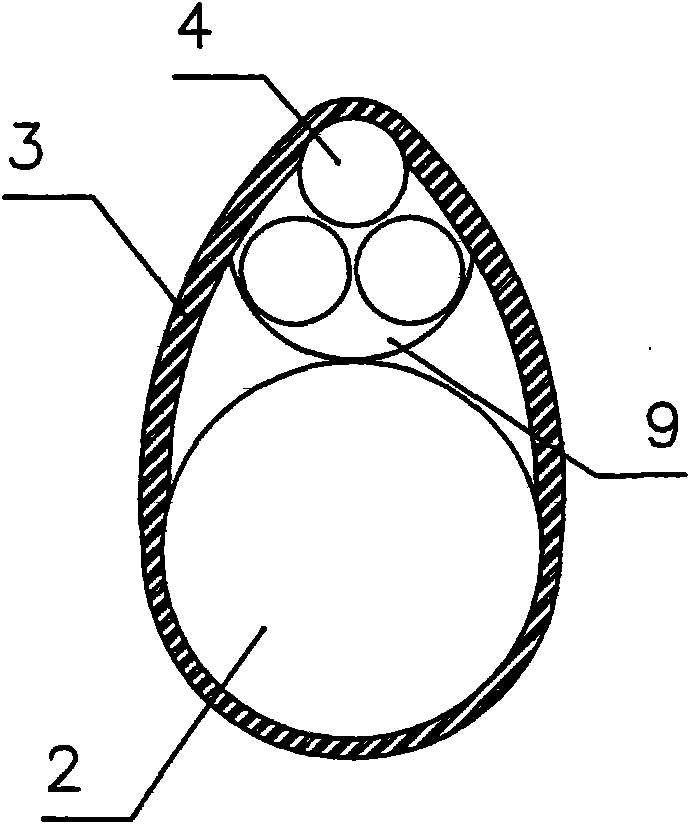

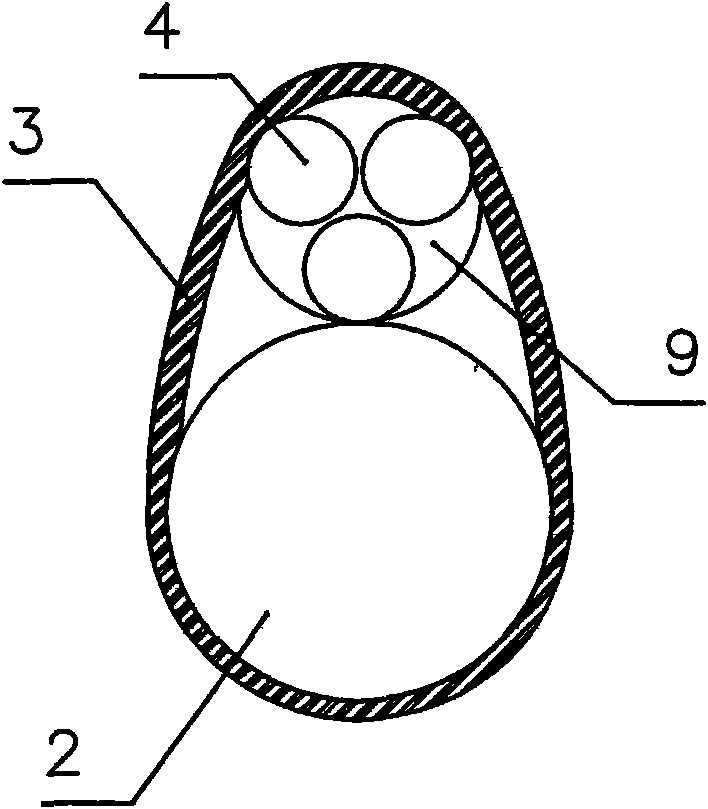

[0036] Set the above-mentioned multi-knife conversion device on the engraving machine to form a multi-knife hand-held electric engraving machine, such as Figure 4 and Figure 5 As shown, the driving wheel 2 is connected to the motor shaft of the motor 1, and there are three driven whee...

Embodiment 2

[0042] Embodiment 2: as Figure 10 As shown, the turntable 9 of the multi-tool conversion device in this embodiment is connected to the support 8 through the rotation of the central axis, and the side wall of the turntable 9 is provided with several lugs 14, and the lugs 14 and the movable stop located at the fixed place The sheets 15 are correspondingly matched to form a positioning mechanism. The undescribed parts of the engraving machine using the above-mentioned multi-knife position conversion device are the same as in Embodiment 1. When switching between different engraving knives 7, pull the movable stopper 15 so that it does not stop, and turn the turntable 9 to the required position. Utilize the lug 14 and the reset movable stopper 15 to cooperate and locate correspondingly, also can realize non-stop tool change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com