Multi-functional fiber reinforced resin cutting grinding wheel and manufacture technology thereof

A fiber-reinforced resin and cutting grinding wheel technology, applied in the field of grinding wheels, can solve the problems of inability to cut different materials, single use of grinding wheels, and low versatility, and achieve the effects of reducing the frequency of tool replacement, improving operating efficiency, and reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

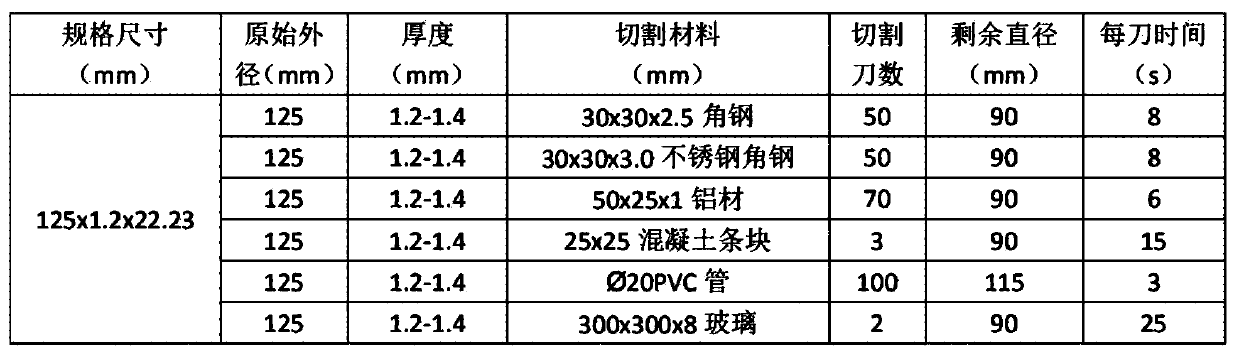

[0022] Multifunctional Fiber Reinforced Resin Cutting Wheel, Multifunctional Fiber Reinforced Resin Cutting Wheel, the percentage of mixed abrasive is as follows: Aluminum Oxide 25-35%, Special Abrasive 15-25%, Silicon Carbide 20-30%, Phenolic Resin 5-15%, Glass fiber 10-15%, filler 2-4%.

[0023] Preferably, 30% of aluminum oxide, 20% of special abrasive, 25% of silicon carbide, 10% of phenolic resin, 12% of glass fiber, and 3% of filler.

[0024] Preferably, the special abrasive is SG abrasive.

[0025] Preferably, the filler is one of tungsten carbide, silicon carbide, graphite, aluminum magnesium hydrotalcite-diamond mixture.

[0026] A manufacturing process for producing the above-mentioned multifunctional fiber-reinforced resin cutting whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com