High-frequency quenching clamp using marble as locating block

A technology of high-frequency quenching and positioning blocks, applied in the direction of quenching devices, manufacturing tools, heat treatment equipment, etc., can solve the problems of increasing tool cost, increasing tool change frequency, tool loss, etc., to prolong service life, reduce wear, and improve finished products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

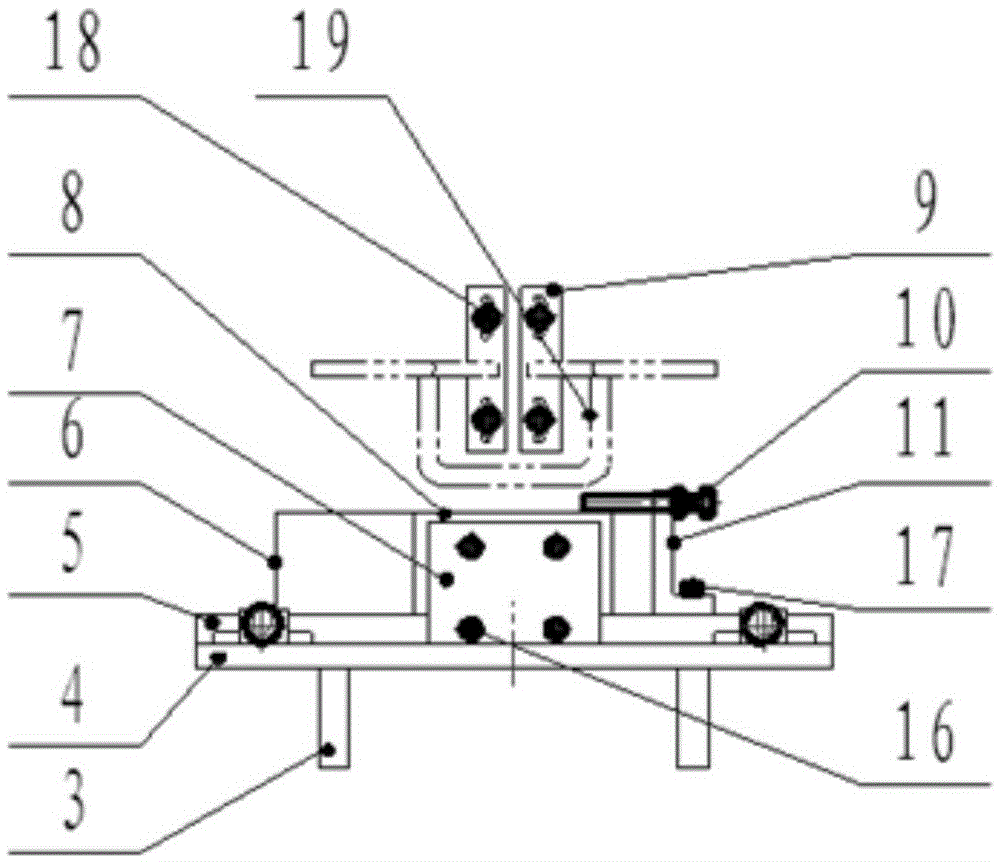

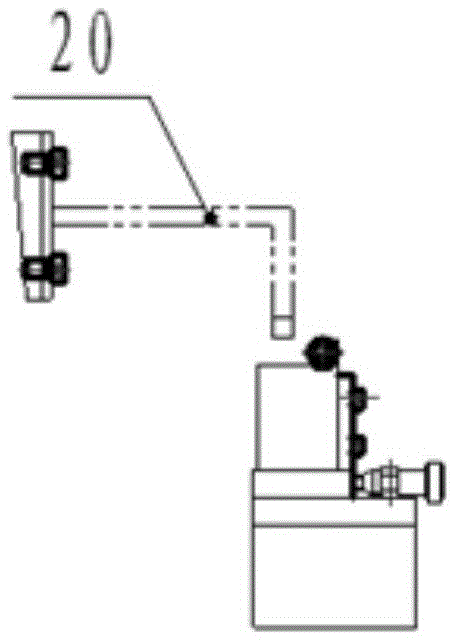

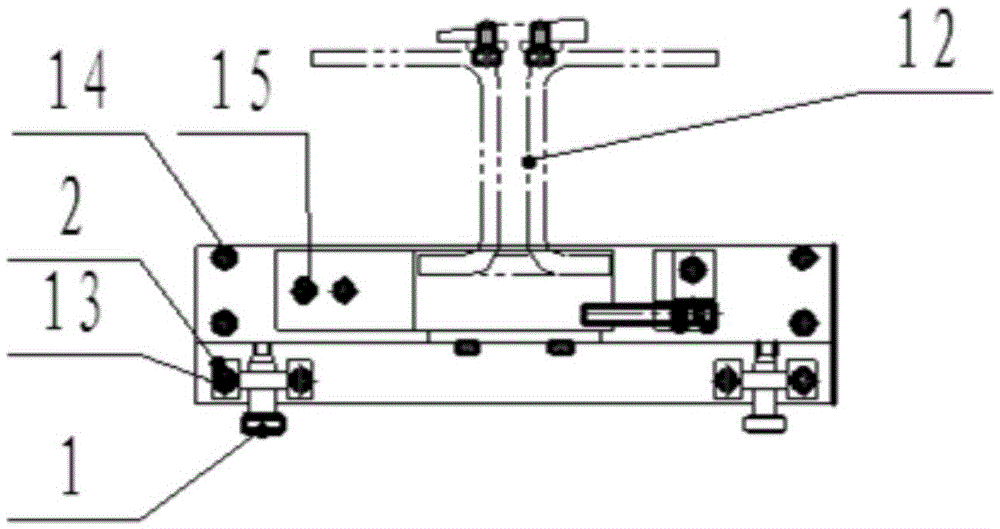

[0019] like figure 1 and figure 2 As shown, a high-frequency quenching fixture using marble as a positioning block includes a support foot 3, a clamping body 4, an adjustment plate 5, a guide seat 6, a side plate 7, a marble positioning block 8, a bracket 11 and a sensing conductor 12; The upper part of the support foot 3 is fixedly installed with the clamping body 4; one side of the upper part of the clamping body 4 is installed with the adjustment plate 5 through the screw B14, and the other side is installed with two adjustment supports 2 through the screw A13, and the two adjustment supports 2 are respectively located at Both ends; the adjustment supports 2 are horizontally installed with adjustment screws 1 that are perpendicular to the adjustment plate 5, the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com