Tunnel boring machine cutterheads for complex hard rock geology

A technology for tunneling and hard rock, which is applied in the field of tunnel boring machine cutterheads, which can solve the problems of high maintenance and manufacturing costs, difficult welding of cutterheads, and high failure rate, and achieve the effects of reducing labor intensity, improving rock breaking efficiency, and small disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

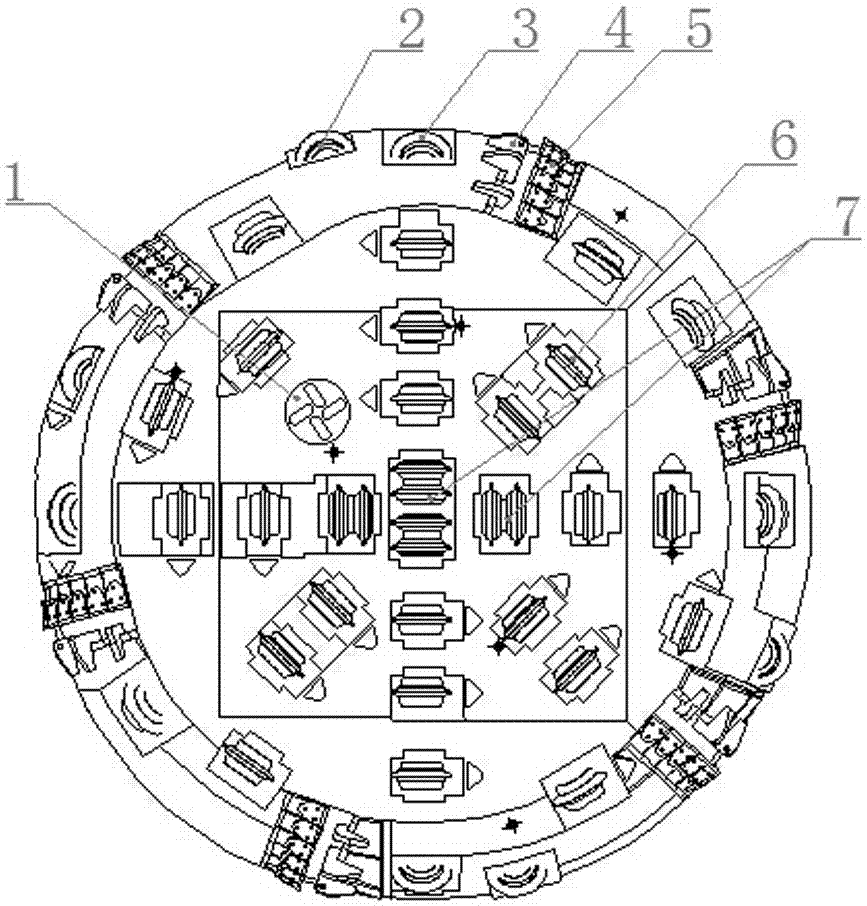

[0027] like figure 1 As shown, the center hob and the front hob of the TBM cutterhead are arranged in the same diameter structure, and are equipped with a center hob 7, a front hob 6, a side knife 3, a gage knife 2, a shovel knife 5, a manhole 1, and a water spray Mouth and so on.

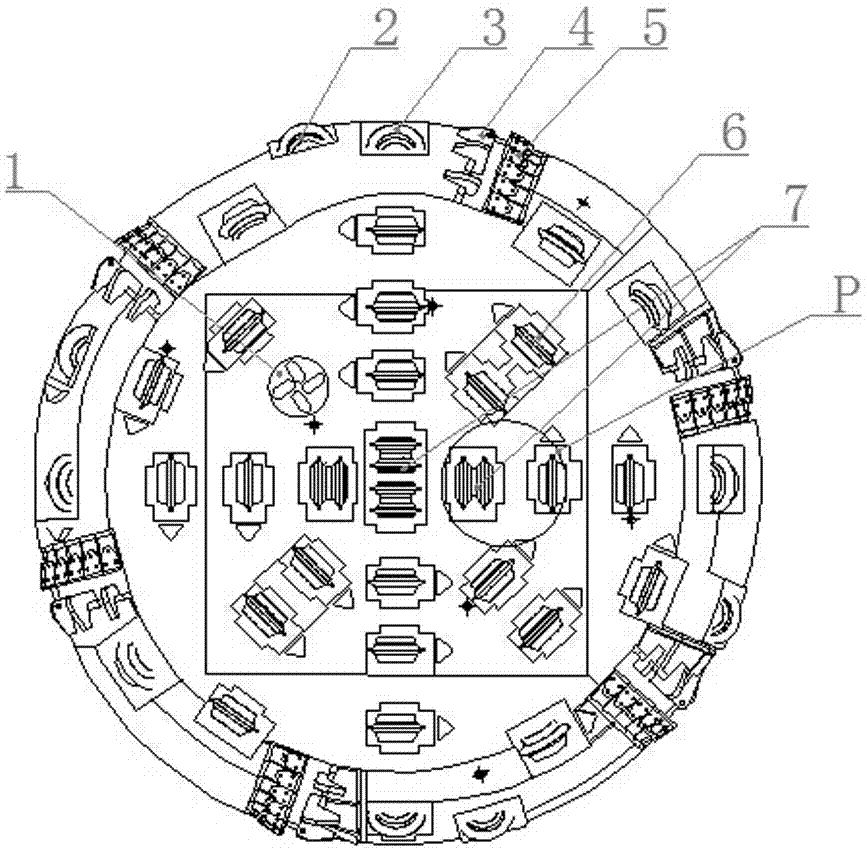

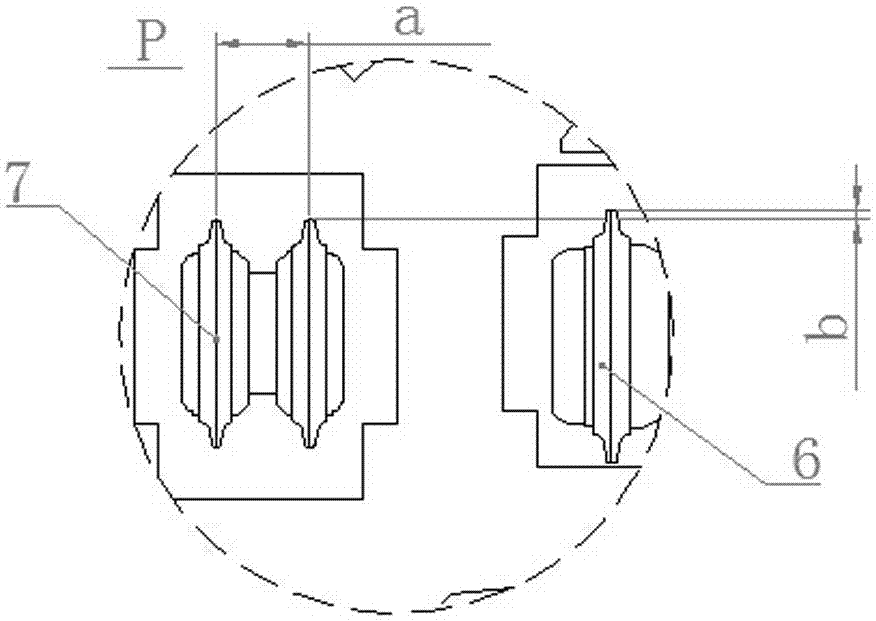

[0028] like figure 2 As shown, the center hob box 70 (including double-edged hobs and four-edged hobs) of the new cutter head of the present invention is redesigned and improved to one to two smaller cutter numbers, and the number of smaller grades depends on the specific situation. Depending on geological conditions; Gauge cutter box 9 can be designed with a larger cutter number. If the diameter of the center hob 7 of the original cutter head design is consistent with other cutters, the center hob 7 is limited by the bearing capacity and the double-connected quadruple structure of the center cutter, so the distance between the bearings cannot be reduced, and the distance between the cutters ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com