Automatic knife grinder for numerically controlled fabrics cutting machine

An automatic knife sharpening and cutting machine technology, applied in the cutting of textile materials, other manufacturing equipment/tools, textiles and papermaking, etc., can solve the problems of heavy workload, passivation of cutting knives, etc., achieve low cost and reduce the replacement of knives The frequency, the effect of reducing the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

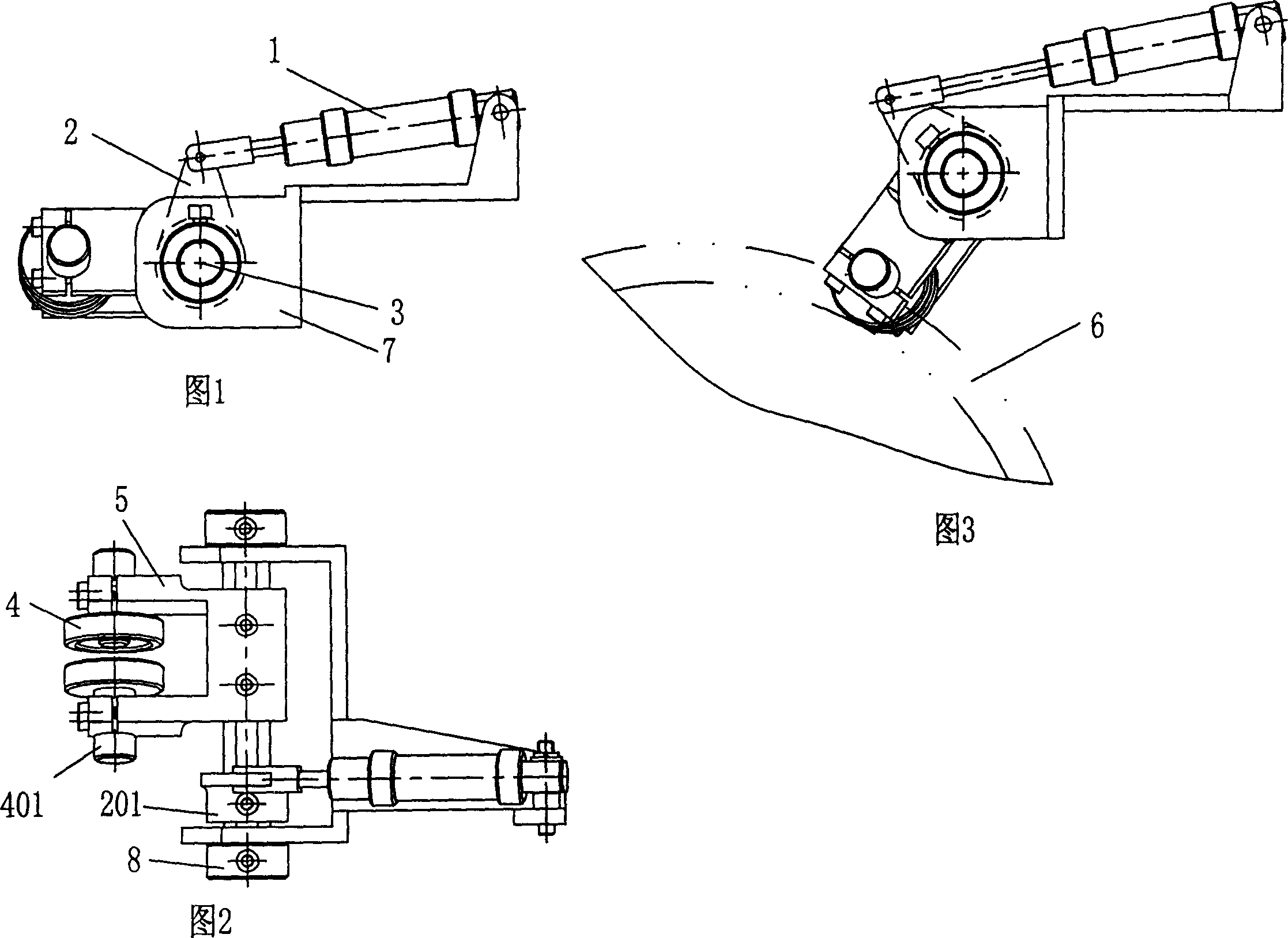

[0009] Referring to Figures 1 to 3, the automatic sharpening device of the CNC fabric cutting machine is composed of a sharpening part, a swinging part and a fixed part. The oscillating part includes a cylinder 1 , a deflection plate 2 and a deflection shaft 3 , and the deflection plate 2 and the shaft sleeve 201 are integrally connected with the deflection shaft 3 . The sharpening component includes two parallel emery wheels 4, a grinding wheel shaft 401, and a sharpening fixture 5, and the grinding wheel axle 401 is fixedly connected with the sharpening fixture 5. The sharpening fixture 5 is obliquely fixed on the deflection shaft 3 to ensure the misalignment of the grinding wheel 4 and the surface 6 to be sharpened. The cylinder 1 and the deflection shaft 3 are installed on the fixed plate 7, and the cylinder 1 and the fixed plate 7 are fixedly connected. The two ends of the deflection shaft 3 are provided with stop blocks 8, which prevent the deflection shaft 3 from fallin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com