Stuffing discharging machine capable of reducing extrusion damage

A technology for stuffing machines, stuffing bags, for use in coinless or similar appliances, coin-operated devices for dispensing discrete items, coin-operated devices for controlling the dispensing of fluid/granular materials from containers, etc., It can solve problems such as bump breakage and filling machine failure, and achieve the effect of reducing extrusion damage and not easy to break and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

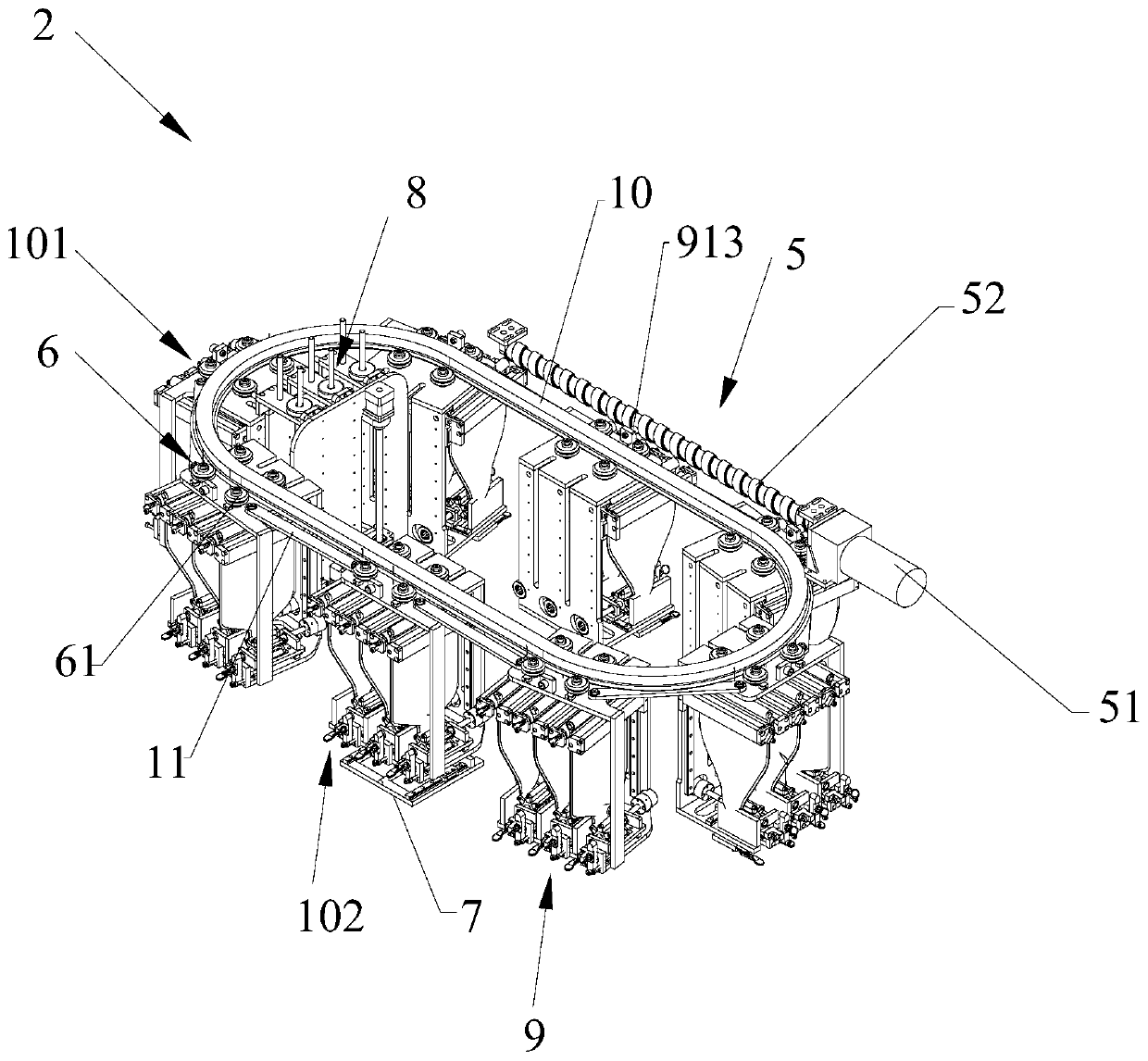

[0033] The present invention will be further elaborated below in combination with specific embodiments and accompanying drawings.

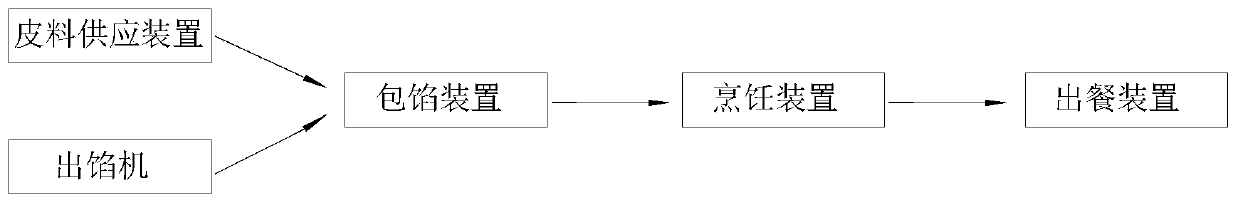

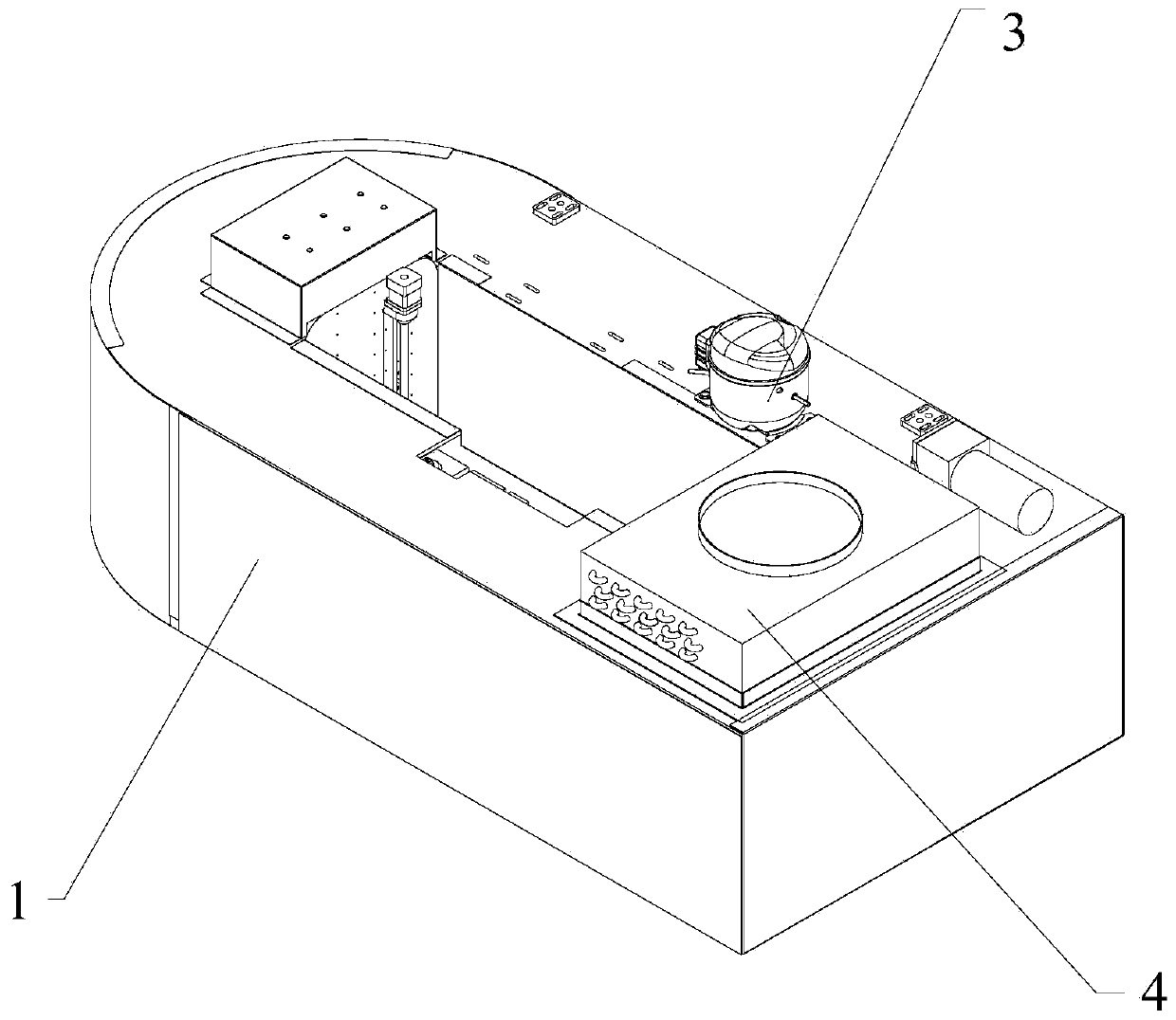

[0034] Such as figure 1 The equipment for automatic production and sales of stuffed food includes a leather material supply device, a stuffing machine, a stuffing device, a cooking device and a meal delivery device. It is sequentially connected with the meal-out device, wherein the skin material supply device is used to provide skin materials, for example: the skin material supply device provides dumpling wrappers in the dumpling automatic making vending machine, and the skin material supply device provides wonton skins in the wonton automatic making vending machine. The leather material supply device can only supply the finished leather material to the stuffing device, or it can be the device for making leather material inside the vending equipment, for example: in the dumpling vending machine, it includes a dough mixing device, a dough kneading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com