Dedicated grounding wire clamp for power cable wiring terminal

A technology of terminal blocks and grounding clamps, which is applied in the direction of electrical connection seats and connection contact materials, etc., can solve problems such as safety accidents, loss of grounding protection of cable heads, etc., and achieve the effects of preventing injuries, ensuring safety, and being easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

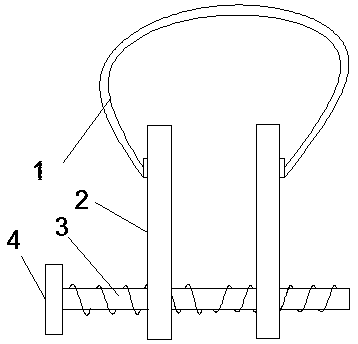

[0031] refer to figure 1 , this embodiment provides a special grounding clamp for power cable terminals, including a clamping mechanism and a connecting mechanism arranged on the clamping mechanism; the clamping mechanism includes two splints 2 and Connect the fixed module; the connection mechanism includes a wire 1 connecting two splints 2, and the splint 2 is connected to a grounding wire. The fixing module includes a lead screw 3 connected to the two splints 2, a through hole with an internal thread is provided on the splint 2, and a positive hole matching the internal thread is provided at one end of the lead screw 3. external thread, the other end of the screw 3 is provided with a reverse external thread matching the internal thread. A handle 4 is provided at the end of the lead screw 3 .

[0032] In this embodiment, the splint 2 is a copper plate with a cuboid structure, and the wire 1 is a copper wire with an insulating layer, which is fixed on the copper plate by bol...

Embodiment 2

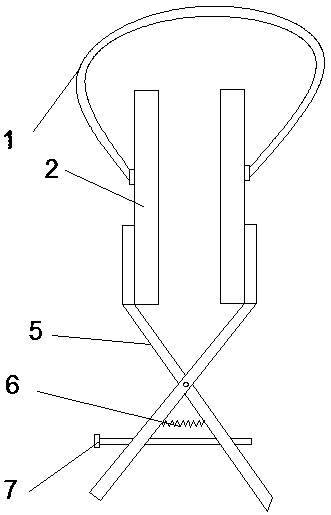

[0037] refer to figure 2 , this embodiment provides a special grounding clamp for power cable terminals, which is an improvement on the basis of Embodiment 1: the fixing module includes a connecting rod 5 connected to the splint 2, and two connecting rods 5 The rods 5 are cross-connected, and a connecting piece is arranged between the two connecting rods 5 . The connecting piece can be a spring 6 or a bolt 7, and of course, the spring 6 and the bolt 7 can also be provided at the same time. The connecting rod 5 is welded on the splint 2 . The two connecting rods 2 are cross-connected, and the connecting piece is fixed at the lower part of the crossing part, which is similar to scissors. Of course, it can also be designed that the ends of the two connecting rods 2 are connected together, like tweezers, and the connecting piece is arranged between the two connecting rods 2 . Through the elastic force of the spring 6 and the tightness of the bolt 7, the adjustment of the dista...

Embodiment 3

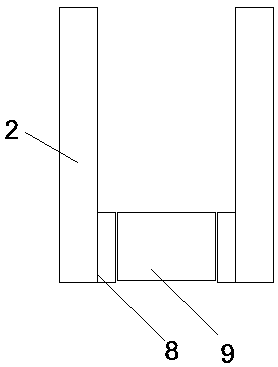

[0039] refer to image 3 , This embodiment provides a special grounding clamp for power cable terminals, which is an improvement on the basis of Embodiment 1 or 2: the lower part of the inner side of the clamping plate 2 is provided with a limiting structure. The limiting structure is a limiting block 8 welded on the lower part of the splint 2 . The thickness of the limiting block 8 matches the thickness of the head of the connecting terminal 9 . Since the terminal is usually fixed on the fixture, the advantage of this design is that the splint 2 can just clamp the terminal 9 through the limit block 2 instead of clamping the fixture. When the terminal is disassembled, it can always be grounded. Ensure the personal safety of operators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com