Degradable desert sand fixing agent

A sand-fixing agent and desert technology, applied in the field of degradable desert sand-fixing agent, can solve the problems of desert sand-fixing agent such as poor wind erosion resistance and not easy to degrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

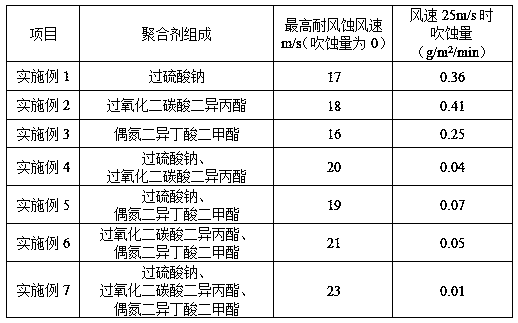

Embodiment 1

[0054] 1. Preparation of superabsorbent

[0055] Add 10 g of cornstarch into a three-necked flask of 100 ml of deionized water, stir at a speed of 300 r / min, control the temperature at 70° C., gelatinize for 1 hour and then cool to room temperature. Add 50g of acrylic acid into the beaker, then add 50g of 20% sodium hydroxide solution, and transfer it to a three-necked flask after neutralization. Then add 1.0 g of sodium persulfate and 0.3 g of N,N-methylenebisacrylamide to replace the air in the system with nitrogen, adjust the temperature to 70°C, and react for 2 hours to obtain a transparent gel block. Dry in an oven at 80° C. for 5 hours to obtain a superabsorbent precursor. Then pulverize it and pass through a mesh sieve to obtain a colorless and transparent granular superabsorbent.

[0056] 2. Superabsorbent mixed with other raw materials

[0057] Add 50g of biological organic matter, 50g of bentonite, 50g of nutrient element mixture, 50g of organic fertilizer and 50g...

Embodiment 2

[0062] 1. Preparation of superabsorbent

[0063] Add 10 g of cornstarch into a three-necked flask of 100 ml of deionized water, stir at a speed of 300 r / min, control the temperature at 70° C., gelatinize for 1 hour and then cool to room temperature. Add 50g of acrylic acid into the beaker, then add 50g of 20% sodium hydroxide solution, and transfer it to a three-necked flask after neutralization. Then add 1.0 g of diisopropyl peroxydicarbonate and 0.3 g of N,N-methylenebisacrylamide, replace the air in the system with nitrogen, adjust the temperature to 70°C, and react for 2 hours to obtain a transparent gel block. Dry in an oven at 80° C. for 5 hours to obtain a superabsorbent precursor. Then pulverize it and pass through a mesh sieve to obtain a colorless and transparent granular superabsorbent.

[0064] 2. Superabsorbent mixed with other raw materials

[0065] Add 50g of biological organic matter, 50g of bentonite, 50g of nutrient element mixture, 50g of organic fertiliz...

Embodiment 3

[0070] 1. Preparation of superabsorbent

[0071] Add 10 g of cornstarch into a three-necked flask of 100 ml of deionized water, stir at a speed of 300 r / min, control the temperature at 70° C., gelatinize for 1 hour and then cool to room temperature. Add 50g of acrylic acid into the beaker, then add 50g of 20% sodium hydroxide solution, and transfer it to a three-necked flask after neutralization. Add 1.0g dimethyl azobisisobutyrate and 0.3g N,N-methylenebisacrylamide respectively, replace the air in the system with nitrogen, adjust the temperature to 70°C, and obtain a transparent gel block after 2 hours of reaction . Dry in an oven at 80° C. for 5 hours to obtain a superabsorbent precursor. Then pulverize it and pass through a mesh sieve to obtain a colorless and transparent granular superabsorbent.

[0072] 2. Superabsorbent mixed with other raw materials

[0073] Add 50g of biological organic matter, 50g of bentonite, 50g of nutrient element mixture, 50g of organic fert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com