A kind of chemical curing agent and its preparation method and application

A chemical curing and cross-linking agent technology, applied in chemical instruments and methods, applications, other chemical processes, etc., can solve the problems of thin skin damage, desertification control with little effect, peeling off, etc., achieve mild reaction conditions, improve wind erosion resistance and resistance The ability of water erosion, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

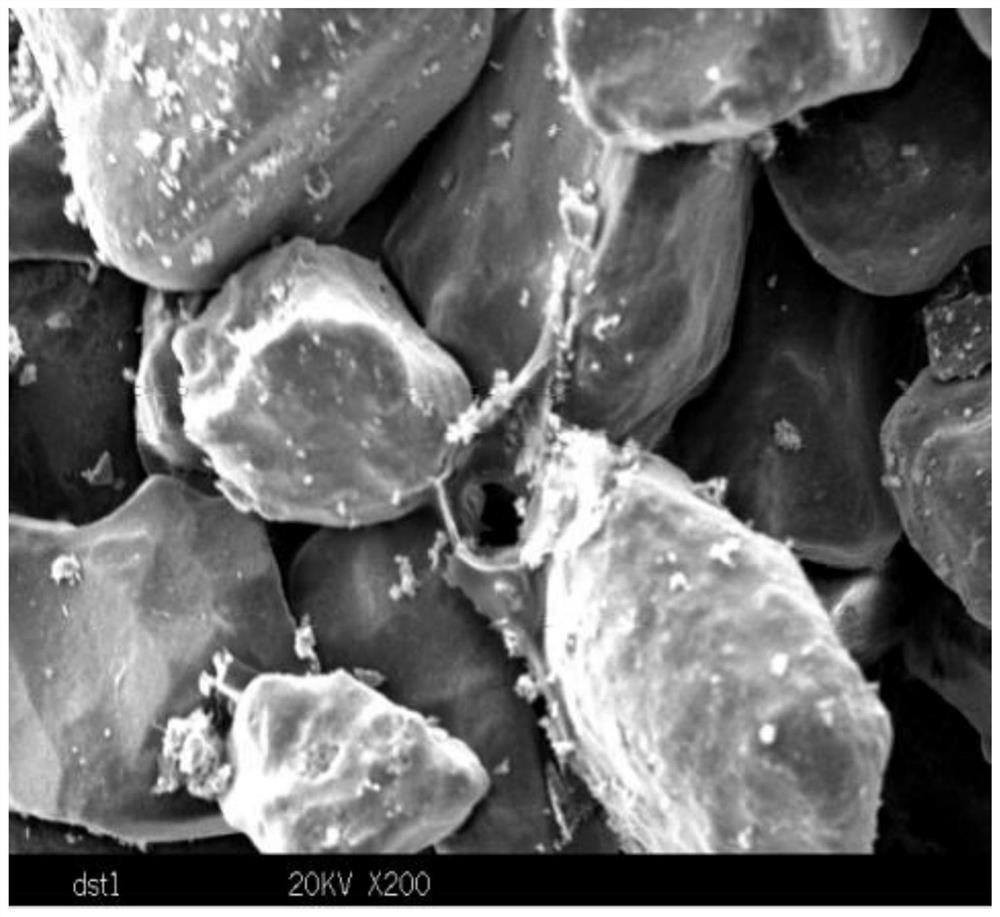

Image

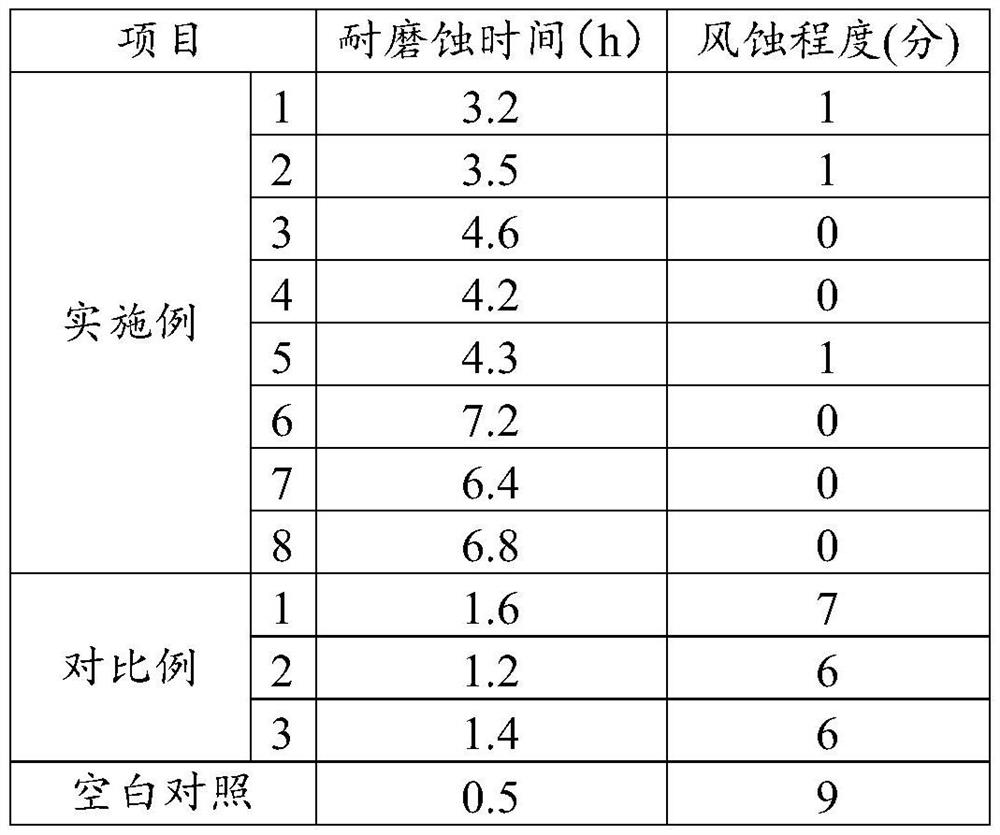

Examples

preparation example Construction

[0027] This embodiment also provides a method for preparing the above-mentioned chemical curing agent, which includes:

[0028] Mix 20-50 parts by weight of polyvinyl alcohol, 10-30 parts of polyacrylamide and 10-30 parts of acrylate with water, and heat reaction at 60-80°C for 30-120 minutes to obtain the first group Preferably, the heating reaction is a water bath heating reaction, that is, mixing each component in the raw material with water in parts by weight, and heating and reacting for 30 to 120 minutes at a water bath temperature of 60 to 80°C to obtain the first component . By heating in a water bath, the reaction temperature is effectively controlled, which is conducive to the stable progress of the reaction.

[0029] A sodium silicate solution with a concentration of 2-5% by mass is prepared to obtain the second component; preferably, the concentration of the sodium silicate solution is 3%.

[0030] Further, in a preferred embodiment of the present invention, the ...

Embodiment 1

[0036] This embodiment provides a chemical curing agent, which includes a first component and a second component. Among them, the first component is mainly prepared by mixing the following raw materials in parts by weight with water: 50 parts of polyvinyl alcohol, 10 parts of polyacrylamide and 30 parts of acrylate; the second component includes silicic acid in parts by weight Sodium 5 parts.

[0037] The preparation method of this chemical curing agent is:

[0038] Mix the raw material components of the first component with water, and heat and react at 60°C for 120 minutes to obtain the first component;

[0039] A sodium silicate solution with a mass percent concentration of 5% was prepared to obtain the second component.

[0040] The method of using this chemical curing agent: first spray the first component on the surface of the sand, and then spray the second component on the surface of the sand to obtain the purpose of sand fixation, wherein the first component and the ...

Embodiment 2

[0042] This embodiment provides a chemical curing agent, which includes a first component and a second component. Among them, the first component is mainly prepared by mixing the following raw materials in parts by weight with water: 40 parts of polyvinyl alcohol, 15 parts of polyacrylamide and 25 parts of acrylate; the second component includes silicic acid in parts by weight Sodium 3 parts.

[0043] The preparation method of this chemical curing agent is:

[0044] Mix the raw materials in the first component with water, and heat and react in a water bath at 80°C for 30 minutes to obtain the first component;

[0045] A sodium silicate solution with a mass percent concentration of 2% was prepared to obtain the second component.

[0046] The method of using this chemical curing agent: first spray the first component on the surface of the sand, and then spray the second component on the surface of the sand to obtain the purpose of sand fixation, wherein the first component and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com