A temperature control system and control method for steam turbine exhaust cylinder

A temperature control system and exhaust cylinder technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of affecting the unit, aggravating the last stage blades, poor controllability, etc., achieving high returns and reducing temperature , Improve the effect of deep peak shaving capability and operational safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

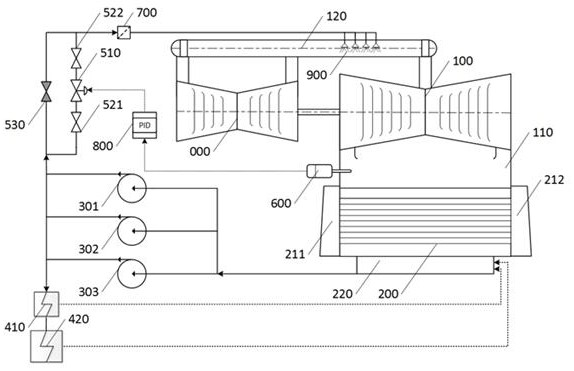

[0024] A temperature control system for the exhaust cylinder of a steam turbine, which includes a medium pressure cylinder 000, a low pressure cylinder 100, a low pressure exhaust cylinder 110, a condenser, a condenser heat trap 220, a condensate pump group, a heater group, and a temperature-reducing water injection regulating valve Group, exhaust steam temperature detection device 600, main controller 800 for water spray temperature reduction, temperature reduction water spray device and low pressure cylinder inlet flow passage 120; the low pressure cylinder 100, low pressure exhaust cylinder 110, condenser and condenser heat The traps 220 are arranged from top to bottom. The exhaust steam temperature detection device 600 is located on the cylinder wall of the low-pressure exhaust cylinder 110. The condenser is connected to a condensate pump group through a pipe. The condensate pump group includes a condensate pump A301, Condensate pump B302 and condensate pump C303 are connect...

Embodiment 2

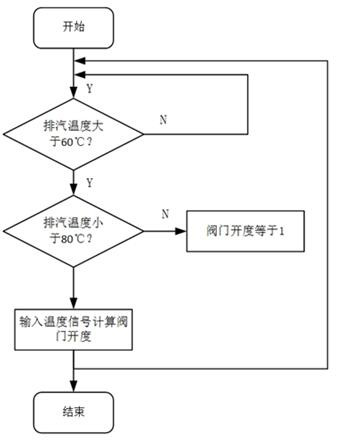

[0026] A control method for the temperature control system of the exhaust cylinder of a steam turbine, such as figure 2 The pattern shown is carried out. When the low-pressure cylinder is running at ultra-low load, the steam enters the main condensation zone of the condenser through the low-pressure exhaust cylinder. The circulating cooling water enters the water chamber, and the circulating cooling water exits the water chamber. The steam becomes condensed after condensation. The water is boosted by the condensate pump group as the spray water source for the temperature-reducing water spray device to achieve cooling of the low-pressure exhaust cylinder. The exhaust steam temperature detection device detects the temperature of the low-pressure cylinder in real time, and the temperature-reducing spray is controlled by the main controller of spray water temperature reduction. The opening degree of the water main regulating valve realizes the size of the water volume of the temper...

Embodiment 3

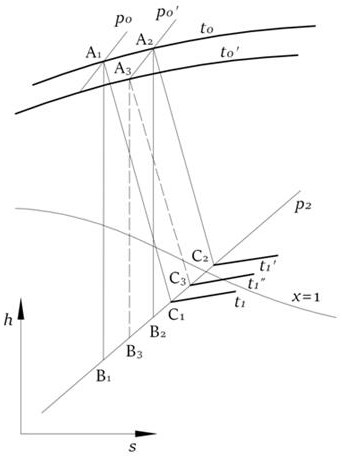

[0028] A working principle diagram of a temperature control system for the exhaust cylinder of a steam turbine, such as image 3 Shown, including inlet isobars of low pressure cylinder under rated conditions p 0 , Ultra-low load low pressure cylinder inlet isobar p 0 ' , Low pressure cylinder exhaust steam isobar p 2 , The inlet isotherm of the low pressure cylinder before spraying water temperature reduction t 0 , Low-pressure cylinder exhaust steam isotherm before water spray desuperheating under rated conditions t 1 , The inlet isotherm of the low pressure cylinder after spraying the temperature t 0 ' , Exhaust steam isotherm of low-pressure cylinder before ultra-low-load water injection to reduce temperature t 1 ' , The ideal expansion line A of the low pressure cylinder before the water spray at the rated working condition 1 B 1 , The actual expansion line A of the low-pressure cylinder before the water spray at the rated working condition 1 C 1 , The ideal expansion line A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com