Visual sensor working state test method

A visual sensor and working state technology, applied in the field of sensor testing, can solve problems such as easy misjudgment, closed-loop testing, and high risk of leaving the factory, and achieve the effects of eliminating judgment errors, improving testing efficiency, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0052] A kind of visual sensor working condition testing method, the measuring part of visual sensor comprises: camera and part 1, comprises the following steps:

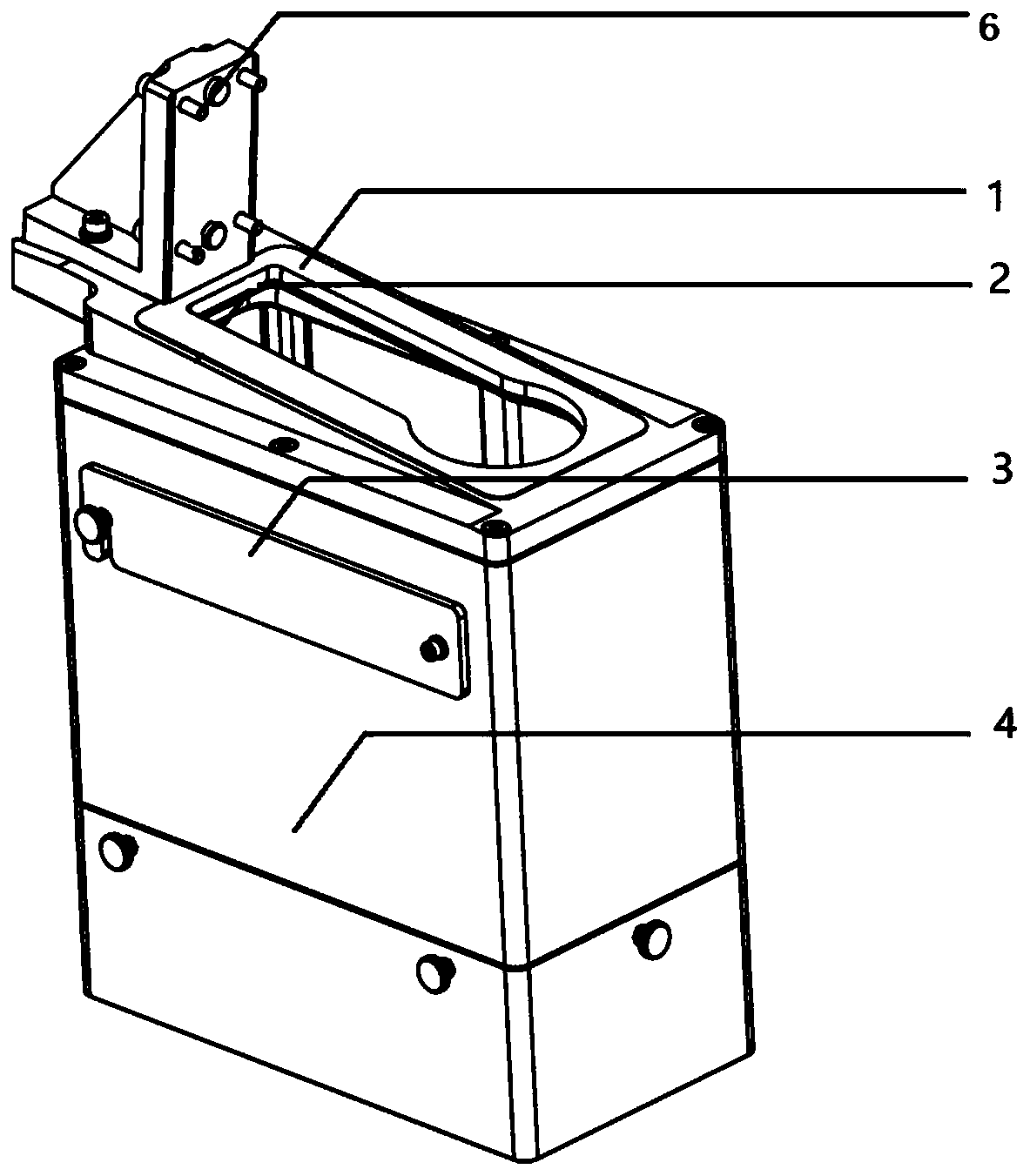

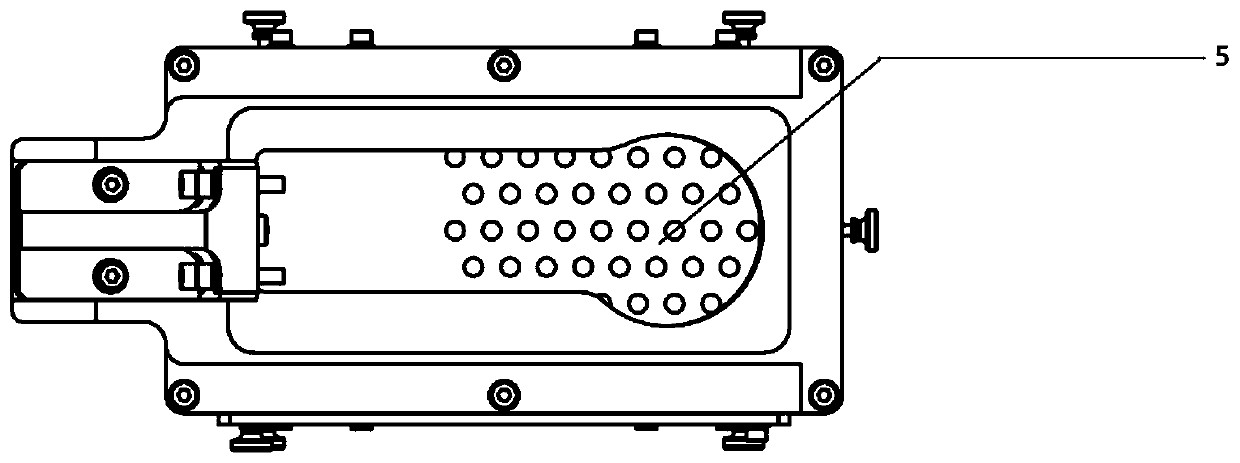

[0053] 1) Fix the vision sensor to be tested on the test device, such as figure 1 As shown, the visual sensor can be fixed on the positioning bracket 6 by screws, covering the opening 1 of the test device, and the inner cavity 2 of the test device forms a closed dark room; in the test device, a target 5 ( Such as figure 2 shown);

[0054] The visual sensor to be tested is fixed on the test device, and when the working state is manually determined to be normal, the image of the target under the open or closed state of the acquisition part 1 is respectively collected, stored, and used as a standard image under different states; then according to step 2) Carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com